White corundum stands as a pivotal material in multiple high-value industries, from abrasives and refractories to advanced ceramics and electronics. Its exceptional hardness, chemical stability, and purity make it indispensable for businesses seeking durable, high-performance solutions. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe—including dynamic markets such as Indonesia and Spain—understanding the nuances of sourcing white corundum is essential to maintaining competitive advantage and ensuring supply chain resilience.

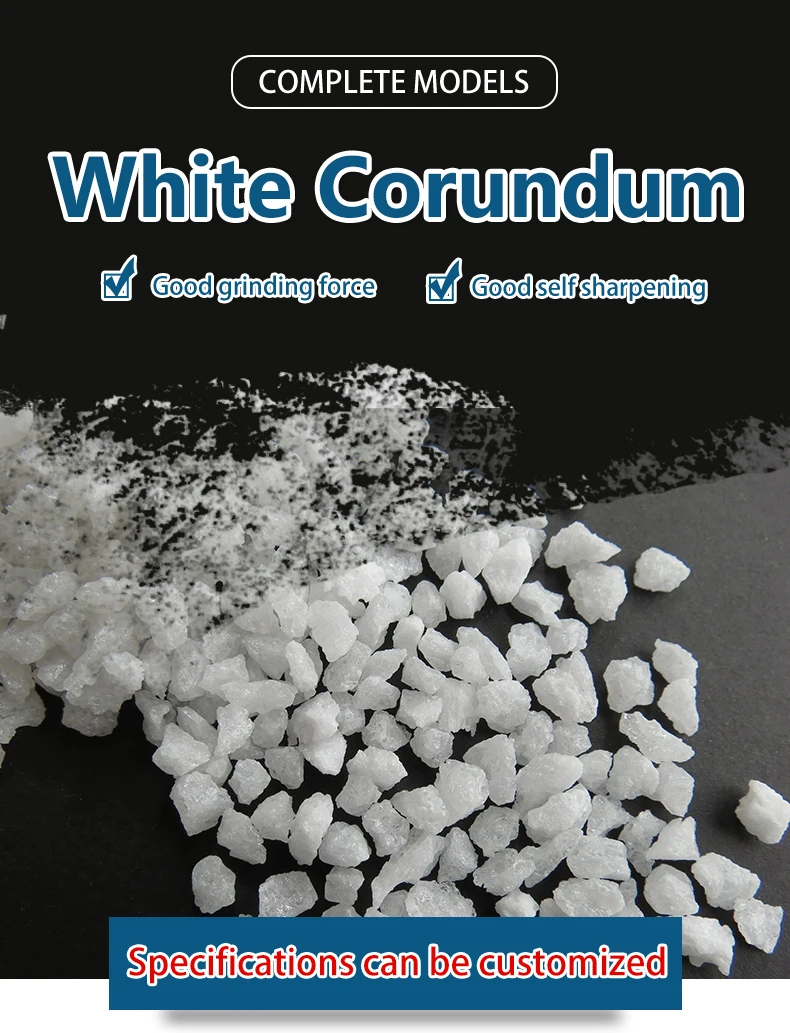

Illustrative Image (Source: Google Search)

This comprehensive guide offers an authoritative roadmap to the global white corundum market. It delves into the various types and grades of white corundum, clarifying how material characteristics impact application suitability. You will gain insights into manufacturing processes and rigorous quality control standards that distinguish reliable suppliers. The guide further explores pricing structures and market dynamics, equipping buyers to negotiate effectively and optimize procurement strategies.

Key features include:

By leveraging this knowledge, B2B buyers can make informed decisions that reduce risk, improve product quality, and foster long-term supplier partnerships. Whether you are expanding into new markets or refining your current procurement approach, this guide empowers you to navigate the complexities of the white corundum supply chain with confidence and precision.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused White Corundum | Manufactured via high-temperature fusion; consistent purity and hardness | Abrasives, grinding wheels, cutting tools | Pros: Uniform quality, high hardness; Cons: Higher cost, energy-intensive production |

| White Aluminum Oxide | Naturally occurring with minimal impurities; granular texture | Polishing agents, blasting media | Pros: Cost-effective, versatile; Cons: Variability in grain size and purity |

| Synthetic White Corundum | Lab-grown with controlled crystal structure; high transparency | Optical components, precision machining | Pros: High precision, customizable; Cons: Limited supply scale, higher price point |

| White Corundum Grit | Crushed and graded particles; variable grain size | Surface preparation, sandblasting | Pros: Effective for cleaning and surface prep; Cons: Dust generation, inconsistent particle shape |

| High-Purity White Corundum | Ultra-pure with minimal defects; enhanced mechanical strength | High-end abrasives, electronic substrates | Pros: Superior performance, reliability; Cons: Premium pricing, niche availability |

Fused White Corundum is produced by melting high-purity alumina at extremely high temperatures, resulting in a product with uniform hardness and consistent chemical composition. This makes it ideal for abrasive applications requiring durability and precision, such as grinding wheels and cutting tools. Buyers should consider its higher cost and energy-intensive manufacturing process, which is justified by its performance in demanding industrial environments.

White Aluminum Oxide is a naturally occurring variant characterized by its granular texture and moderate purity. It is widely used as a polishing agent and blasting media due to its cost-effectiveness and versatility. However, B2B buyers must account for potential variability in grain size and impurities, which can affect consistency in large-scale production.

Synthetic White Corundum is lab-grown to achieve controlled crystal structures and high optical clarity, making it suitable for precision machining and optical components. This type offers customization options for specific industrial needs but comes with limited supply scalability and a higher price point, factors critical for procurement planning.

White Corundum Grit consists of crushed and graded particles with varying grain sizes, primarily utilized in surface preparation and sandblasting. Its effectiveness in cleaning and preparing surfaces is balanced against challenges such as dust generation and irregular particle shapes, which may require additional handling considerations for buyers.

High-Purity White Corundum is distinguished by its ultra-pure composition and minimal defects, delivering enhanced mechanical strength and reliability. It finds application in high-end abrasives and electronic substrates where performance is paramount. This type commands premium pricing and is typically available in niche markets, necessitating strategic sourcing for international buyers.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of white corundum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives Manufacturing | Production of grinding wheels, sandpapers, and polishing tools | High hardness and purity improve cutting efficiency and surface finish | Consistent grain size, chemical purity, and supply reliability are critical |

| Electronics & Semiconductors | Substrate and polishing media for wafer fabrication | Enables ultra-smooth surfaces and precise material removal | Ultra-fine particle size and contamination-free material essential |

| Automotive Industry | Surface finishing and cleaning of engine components | Enhances durability and performance by removing micro-impurities | Bulk supply with uniform quality and tailored grit sizes for specific tasks |

| Construction & Ceramics | Abrasive blasting and ceramic tile polishing | Improves durability and aesthetic quality of end products | High abrasion resistance and minimal dust generation preferred |

| Metalworking & Tooling | Sharpening and finishing cutting tools and molds | Prolongs tool life and ensures precision in metal fabrication | Sourcing from suppliers with stringent quality control and traceability |

White corundum is widely utilized in abrasives manufacturing, where its exceptional hardness and purity make it ideal for producing grinding wheels, sandpapers, and polishing tools. For B2B buyers from regions like Africa and South America, ensuring consistent grain size and chemical purity is essential to maintain efficiency and product quality. Reliable supply chains are vital to avoid production delays, especially for large-scale manufacturers.

In the electronics and semiconductor industry, white corundum serves as a critical polishing medium for wafer fabrication. Its ultra-fine particle size and contaminant-free nature enable the creation of ultra-smooth surfaces required for high-performance electronic components. Buyers from Europe and the Middle East should prioritize suppliers who can guarantee stringent quality standards and batch consistency to meet precise industry demands.

The automotive sector benefits from white corundum in surface finishing and cleaning of engine parts. Its abrasive properties help remove micro-impurities, enhancing component durability and performance. International buyers, particularly in markets like Indonesia and Spain, need to source white corundum that offers uniform grit sizes and bulk availability, supporting high-volume production without compromising quality.

In construction and ceramics, white corundum is used for abrasive blasting and polishing ceramic tiles, contributing to product durability and aesthetic appeal. For B2B buyers in these sectors, selecting white corundum with high abrasion resistance and low dust generation is crucial to optimize operational efficiency and maintain workplace safety.

Finally, the metalworking and tooling industry relies on white corundum for sharpening and finishing cutting tools and molds. This application extends tool life and ensures precision in metal fabrication processes. Buyers should focus on suppliers with robust quality control systems and traceability to guarantee consistent material performance, which is particularly important for clients in diverse international markets.

Related Video: Uses and Gratifications Theory

Key Properties:

Fused white corundum is produced by melting and rapidly cooling high-purity alumina, resulting in a dense, crystalline structure with excellent hardness (Mohs 9), high melting point (~2050°C), and outstanding chemical inertness. It exhibits superior resistance to abrasion, high temperatures, and corrosion.

Pros & Cons:

- Pros: Exceptional durability and wear resistance make it ideal for abrasive blasting, grinding, and polishing applications. Its chemical stability ensures longevity in corrosive environments.

- Cons: The manufacturing process is energy-intensive, leading to higher costs. Its brittleness can pose challenges in impact-heavy applications.

Impact on Application:

Fused white corundum is highly compatible with aggressive media such as acids and alkalis, making it suitable for chemical processing industries. Its high hardness ensures efficient material removal in surface finishing.

International B2B Considerations:

Buyers in Europe and the Middle East often require compliance with ASTM C799 and DIN EN 14178 standards for abrasive materials, ensuring quality and safety. African and South American markets may prioritize cost-effectiveness but still demand consistent quality, often verified through ISO certifications. Indonesian buyers should consider local import regulations and certifications aligned with JIS standards for abrasives.

Key Properties:

This material is mechanically crushed and graded white corundum with slightly lower density than fused variants. It retains high hardness and excellent chemical resistance but may have more irregular particle shapes.

Pros & Cons:

- Pros: Generally more affordable than fused corundum, easier to source in bulk, and suitable for a wide range of abrasive applications.

- Cons: Less uniformity in particle size and shape can affect consistency in high-precision applications. Slightly lower resistance to thermal shock compared to fused corundum.

Impact on Application:

Ideal for sandblasting, grinding wheels, and non-critical polishing where cost-efficiency is prioritized. Its compatibility with various media remains strong but less optimal for extremely corrosive environments.

International B2B Considerations:

Buyers in Africa and South America often favor this material due to its lower cost and availability. Compliance with ASTM C709 or equivalent regional standards is common. European buyers may require tighter quality control and certification, while Middle Eastern companies often look for materials with proven durability under high-temperature conditions.

Key Properties:

Manufactured by sintering white corundum powders into dense ceramic forms, these tiles offer excellent abrasion resistance, high compressive strength, and chemical inertness. They withstand temperatures up to 1600°C and resist corrosion from most acids and alkalis.

Pros & Cons:

- Pros: Ideal for protective linings in chutes, hoppers, and pipelines due to their wear resistance and ease of installation. They provide long service life and reduce maintenance costs.

- Cons: Higher initial investment and potential brittleness under mechanical shock or impact loading. Requires skilled installation to avoid cracking.

Impact on Application:

Widely used in mining, cement, and chemical industries where equipment faces abrasive slurries or powders. Their chemical resistance suits applications involving acidic or alkaline media.

International B2B Considerations:

European and Middle Eastern buyers typically expect compliance with DIN EN 1094 and ASTM C633 standards for ceramic materials. African and South American markets may focus on cost-to-performance balance, favoring suppliers who provide technical support for installation. Indonesian buyers should verify compatibility with local environmental regulations.

Key Properties:

Micronized white corundum powder is finely ground alumina with particle sizes typically below 10 microns. It exhibits high purity, chemical inertness, and excellent hardness, making it suitable for precision polishing and surface finishing.

Pros & Cons:

- Pros: Enables ultra-fine polishing and finishing of metals, glass, and ceramics. Its fine particle size allows for smooth surface results and reduced material waste.

- Cons: Higher processing costs due to fine grinding and classification. Less suitable for heavy abrasion or blasting applications.

Impact on Application:

Commonly used in electronics, optics, and precision engineering industries where surface quality is critical. It is compatible with a wide range of chemical media, including solvents and acids.

International B2B Considerations:

Buyers in Europe and the Middle East often require adherence to ISO 9001 quality management systems and particle size distribution standards. African and South American companies may prioritize suppliers offering competitive pricing without compromising purity. Indonesian buyers should ensure compliance with JIS standards and verify supplier certifications.

| Material | Typical Use Case for white corundum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused White Corundum | Abrasive blasting, grinding, chemical processing | Exceptional hardness and chemical stability | High cost and brittleness | High |

| White Aluminum Oxide (Crushed) | Sandblasting, grinding wheels, general abrasives | Cost-effective and widely available | Less uniformity and lower thermal shock resistance | Low |

| White Corundum Ceramic Tiles | Protective linings in mining, cement, chemical | Excellent wear resistance and easy installation | Higher initial cost and brittleness | Medium |

| White Corundum Powder (Micronized) | Precision polishing in electronics, optics | Ultra-fine particle size for smooth finishes | High processing cost, unsuitable for heavy abrasion | High |

The production of white corundum, a highly durable and abrasive material primarily composed of aluminum oxide (Al₂O₃), involves several critical stages designed to ensure optimal purity, consistency, and performance. Understanding these stages allows B2B buyers to assess supplier capabilities and align expectations with application requirements.

1. Raw Material Preparation

White corundum manufacturing begins with sourcing high-purity bauxite or synthetic alumina powders. The raw materials undergo rigorous refining to remove impurities such as iron oxides, which can affect the color and hardness. Advanced purification techniques like chemical leaching or flotation may be employed to achieve the desired whiteness and chemical stability. For B2B buyers, verifying supplier raw material origin and purity certificates is essential to ensure consistency in end-product quality.

2. Forming and Shaping

Once purified, the alumina powders are formed into specific shapes and sizes depending on application demands. Common techniques include:

This stage is crucial for achieving uniform hardness and grain structure, impacting abrasive efficiency and wear resistance.

3. Assembly and Blending

For composite abrasive products or blends, white corundum grains may be mixed with other abrasives or binders to tailor performance characteristics. The blending process must maintain homogeneity to prevent weak spots or inconsistent abrasion rates. Buyers should inquire about mixing technologies and quality controls during this phase.

4. Finishing and Packaging

Final finishing may include sieving for precise size classification, surface treatments to enhance bonding properties, and drying to remove residual moisture. Packaging is designed to protect the product from contamination and humidity, often in moisture-proof bags or sealed containers.

Quality assurance (QA) and quality control (QC) are pillars for suppliers aiming to meet international standards and satisfy the stringent requirements of global B2B markets. For buyers, understanding the QC framework helps in selecting reliable partners and mitigating supply risks.

Key International Standards and Certifications

- ISO 9001: The global benchmark for quality management systems, ensuring consistent processes and continuous improvement. Suppliers certified under ISO 9001 demonstrate commitment to quality control, documentation, and traceability.

- CE Marking: While not directly applicable to raw white corundum, CE certification may be relevant for finished abrasive tools or machinery incorporating white corundum in Europe, confirming compliance with EU safety and environmental directives.

- API (American Petroleum Institute) Standards: For applications in oil and gas, such as abrasive blasting, suppliers may adhere to API standards to ensure material suitability under harsh conditions.

- REACH and RoHS Compliance: Particularly important for European buyers, these regulations control the presence of hazardous substances, ensuring white corundum products meet environmental and health safety criteria.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw material purity, chemical composition, and particle size distribution before production begins. IQC often involves spectrometric analysis and microscopy to detect impurities or inconsistencies.

- In-Process Quality Control (IPQC): Continuous monitoring during sintering, crushing, and blending phases. Techniques include temperature control, density measurements, and particle size sampling to maintain manufacturing consistency.

- Final Quality Control (FQC): Comprehensive testing of finished products covering granulometry, hardness (Mohs scale), whiteness index, and abrasion resistance tests. Packaging integrity and moisture content are also verified at this stage.

Common Testing Methods

- X-Ray Fluorescence (XRF): For elemental composition analysis ensuring purity and absence of contaminants.

- Laser Diffraction Particle Size Analysis: Provides precise grain size distribution critical for abrasive performance.

- Mohs Hardness Testing: Confirms the abrasive hardness level, essential for industrial applications.

- Colorimetry: Assesses whiteness and color consistency, a key quality parameter for white corundum.

- Moisture Content Testing: Ensures product stability and prevents degradation during storage and transport.

B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should adopt a proactive approach to verify supplier QC processes, ensuring product reliability and compliance with regional regulations.

1. Conducting Supplier Audits

- Request on-site or virtual audits to review manufacturing processes, QC laboratories, and documentation systems.

- Evaluate supplier adherence to ISO 9001 and other certifications.

- Inspect traceability records from raw material sourcing to finished goods.

2. Reviewing Quality Reports and Certificates

- Ask for detailed QC reports for each batch, including chemical composition, particle size distribution, and hardness tests.

- Verify authenticity of certifications through recognized bodies or online registries.

- Request third-party inspection or testing reports, especially if dealing with new or unverified suppliers.

3. Engaging Third-Party Inspection Services

- Utilize independent inspection agencies for pre-shipment product verification, reducing risks of non-compliance or quality deviations.

- Third-party labs can perform additional testing aligned with buyer-specific standards or regulatory requirements.

4. Understanding Regional QC and Certification Nuances

- Africa & South America: Emphasize supplier certifications recognized by local import authorities and compliance with environmental standards to facilitate customs clearance.

- Middle East: Focus on API and other oil industry standards if white corundum is intended for abrasive blasting or industrial applications. Regional regulatory bodies may require additional documentation.

- Europe (e.g., Spain): Prioritize REACH, RoHS, and CE compliance for finished products. Demand detailed technical data sheets and safety data sheets (SDS) due to stringent EU regulations.

- Indonesia & Southeast Asia: Check for adherence to both international standards and local quality regulations, as some countries may have specific import controls or certification requirements.

By integrating these insights into supplier evaluation and procurement strategies, international B2B buyers can secure high-quality white corundum supplies that meet technical specifications and regulatory demands, fostering long-term partnerships and operational success.

When sourcing white corundum, understanding the cost structure is essential to optimize procurement and negotiate effectively. The primary cost components include:

Several factors influence the final pricing that B2B buyers encounter:

For buyers from Africa, South America, the Middle East, and Europe, navigating the pricing landscape requires strategic insight:

The pricing of white corundum is highly dynamic and influenced by global market conditions, raw material availability, and geopolitical factors. The indicative prices provided by suppliers should be treated as starting points for negotiation rather than fixed figures. Buyers are encouraged to request detailed quotations and validate all cost components to ensure comprehensive budgeting.

By thoroughly understanding these cost components and pricing influencers, international B2B buyers can make informed decisions, optimize sourcing strategies, and secure competitive, reliable supplies of white corundum tailored to their market needs.

Understanding the technical properties and trade terminology related to white corundum is crucial for international B2B buyers seeking to optimize procurement and ensure product quality. Below is a detailed overview designed to empower decision-makers in Africa, South America, the Middle East, and Europe with actionable insights.

1. Material Grade

White corundum is classified into various grades based on purity and hardness, typically ranging from industrial grade to high-purity optical grade. Industrial grade is suitable for abrasive applications, while higher grades are used in precision manufacturing. For buyers, selecting the appropriate grade ensures compatibility with intended use, affecting performance and cost-efficiency.

2. Mohs Hardness

White corundum has a Mohs hardness of 9, making it one of the hardest minerals after diamond. This property is essential for applications requiring abrasion resistance, such as grinding wheels and cutting tools. Understanding hardness helps buyers assess durability and lifespan relative to competing abrasives.

3. Particle Size Distribution

The size and uniformity of white corundum particles influence surface finish and efficiency in polishing or blasting processes. Particle size is often specified in microns or mesh size. Buyers must specify size ranges to meet process requirements, as variations can impact product quality and operational consistency.

4. Chemical Purity

High chemical purity (typically above 99% Al₂O₃) is vital for applications in refractory materials and electronics. Impurities can affect thermal stability and electrical properties. Buyers targeting high-tech industries should prioritize suppliers that provide detailed purity analyses.

5. Bulk Density

Bulk density affects packaging, shipping costs, and material handling. It also influences the volume-to-weight ratio, which is important for storage planning and cost calculations. Knowing the bulk density helps buyers optimize logistics and inventory management.

6. Tolerance Levels

Tolerance refers to the allowable deviation in particle size, shape, or chemical composition. Tight tolerance levels ensure consistent product performance, especially in precision applications. Buyers should clearly communicate tolerance requirements to suppliers to avoid quality issues.

OEM (Original Equipment Manufacturer)

Refers to companies that produce components or materials that are used in another company’s end products. For white corundum buyers, OEM partnerships can mean access to customized grades or formulations tailored for specific machinery or production lines.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. Understanding MOQ is critical for budgeting and inventory decisions, especially for businesses in emerging markets where capital and storage space may be limited. Negotiating MOQs can lead to more flexible purchasing arrangements.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, delivery, and specification details. Crafting a clear RFQ with detailed technical requirements helps buyers receive accurate quotes and facilitates comparison across multiple suppliers.

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, EXW) that define responsibilities for shipping, insurance, and customs clearance between buyers and sellers. Familiarity with Incoterms enables buyers to control costs, manage risks, and clarify logistics responsibilities in international transactions.

Certification and Compliance Terms

Terms like ISO 9001 (quality management) or REACH (chemical safety in Europe) indicate supplier adherence to standards. Buyers should verify certifications to ensure regulatory compliance and product reliability, particularly for export markets with strict import regulations.

Lead Time

The period between order placement and delivery. Understanding lead time is essential for production planning and supply chain management. Buyers should discuss lead times upfront to avoid delays that can disrupt manufacturing schedules.

By mastering these technical properties and trade terms, international buyers can make informed purchasing decisions, negotiate better contracts, and establish reliable supply chains for white corundum. This knowledge is especially valuable when navigating diverse market conditions across Africa, South America, the Middle East, and Europe.

White corundum, prized for its exceptional hardness and purity, remains a critical industrial mineral in global B2B markets. Its primary applications span abrasive manufacturing, refractory materials, and advanced ceramics, catering to sectors such as automotive, electronics, and construction. The global demand is driven by rapid industrialization in emerging economies, particularly in Africa and South America, where infrastructure development fuels the need for durable materials. Meanwhile, established markets in Europe and the Middle East prioritize high-quality, consistent supply to support precision manufacturing and high-tech applications.

Key sourcing trends emphasize supply chain diversification and technological integration. Buyers from regions like Indonesia and Spain are increasingly leveraging digital platforms to connect directly with producers, enabling greater transparency and cost efficiencies. Additionally, the adoption of AI-powered analytics in procurement processes helps predict price fluctuations and optimize inventory management. The rise of customized grain sizes and purity levels reflects a growing demand for tailored solutions, particularly for specialized industrial uses.

Market dynamics reveal a competitive landscape influenced by geopolitical factors and raw material availability. African nations rich in corundum reserves are emerging as strategic suppliers, while regulatory changes in South America impact export flows. Buyers must navigate volatile pricing linked to energy costs and currency fluctuations, especially in the Middle East. Establishing long-term partnerships with reliable producers, coupled with flexible contracting, can mitigate these risks. Furthermore, the increasing importance of traceability and certification in global trade highlights the need for verified sourcing channels to meet compliance standards across regions.

Illustrative Image (Source: Google Search)

Sustainability has become a cornerstone for B2B buyers in the white corundum sector, reflecting broader global commitments to environmental stewardship and social responsibility. The extraction and processing of white corundum can have significant environmental impacts, including land degradation, water resource depletion, and carbon emissions. Buyers from Africa, Europe, and the Middle East are placing heightened emphasis on minimizing these effects by partnering with suppliers who implement responsible mining practices and invest in rehabilitation efforts.

Ethical sourcing is equally critical, addressing labor rights, community engagement, and transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and Responsible Mining Initiatives are increasingly sought after by buyers to ensure compliance with international standards. Moreover, 'green' materials—white corundum produced with reduced environmental footprints through renewable energy use and waste minimization—are gaining traction. This shift aligns with corporate sustainability goals and regulatory frameworks in regions like the European Union, which prioritize circular economy principles and carbon neutrality.

For B2B buyers, integrating sustainability into procurement strategies enhances brand reputation and mitigates risks associated with regulatory penalties or supply disruptions. Conducting thorough supplier audits, demanding environmental impact disclosures, and incentivizing sustainable innovations can drive continuous improvement across the supply chain. Ultimately, fostering collaboration with eco-conscious suppliers enables buyers to meet evolving market expectations while contributing to long-term resource resilience.

The industrial use of white corundum dates back several decades, initially propelled by the demand for high-performance abrasives in manufacturing and metalworking. Historically, its superior hardness compared to other abrasives established it as a preferred choice for grinding and polishing applications. Over time, technological advancements expanded its role into refractory and electronic industries, where purity and consistency are paramount.

The global trade of white corundum has evolved from localized mining and small-scale distribution to a highly interconnected market shaped by multinational producers and sophisticated logistics networks. This evolution reflects broader trends in globalization and industrial modernization, underscoring the importance of strategic sourcing and quality assurance for international B2B buyers. Understanding this historical progression aids buyers in appreciating current market complexities and anticipating future shifts driven by innovation and sustainability imperatives.

1. How can I effectively vet white corundum suppliers to ensure product quality and reliability?

Start by requesting detailed product specifications and certifications such as ISO, SGS, or other recognized quality standards. Verify supplier credentials through third-party audits or factory visits if possible. Check references from other international buyers, especially those within your region, to understand their experience with the supplier. Utilize platforms that provide supplier verification services. Transparency in production processes and willingness to provide samples for testing are strong indicators of a trustworthy supplier.

2. What customization options are typically available for white corundum, and how do I communicate my requirements?

White corundum can be customized in terms of particle size, purity levels, granularity, and packaging specifications. Clearly outline your technical requirements and end-use applications in your initial inquiry. Providing detailed product datasheets or samples can help suppliers understand your needs. Engage in direct dialogue to confirm feasibility, lead times, and cost implications. Many suppliers are willing to tailor products to meet industry-specific demands, but clarity upfront reduces misunderstandings.

3. What are the standard minimum order quantities (MOQs) and lead times for white corundum shipments to regions like Africa or South America?

MOQs vary widely depending on the supplier and product grade but typically range from 1 to 5 metric tons for bulk orders. Lead times average between 2 to 6 weeks, influenced by production schedules, order size, and shipping logistics. For emerging markets such as Africa or South America, consider potential delays due to customs clearance and local infrastructure. Early communication with suppliers about your timelines and order flexibility can help in negotiating favorable terms.

4. Which payment terms are most common in international white corundum transactions, and how can I mitigate financial risks?

Common payment methods include Letters of Credit (L/C), Telegraphic Transfers (T/T), and Escrow services. L/Cs provide security for both buyer and seller by tying payment to shipment documents. For new suppliers, using escrow or staged payments linked to milestones can reduce risk. Always ensure clear contractual terms covering payment schedules, penalties for late delivery, and dispute resolution mechanisms. Working with reputable banks and payment platforms also adds a layer of protection.

5. What quality assurance certifications should I look for to ensure the white corundum meets international standards?

Look for internationally recognized certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), and product-specific certificates like SGS or Intertek testing reports. Certifications verifying chemical composition, particle size distribution, and absence of harmful impurities are critical. Suppliers with adherence to REACH or RoHS standards demonstrate compliance with environmental and safety regulations, which is essential for European buyers. Always request up-to-date certificates and independent lab test results.

6. How should I plan logistics and shipping when importing white corundum from Asia to regions like the Middle East or Europe?

Consider multimodal shipping options (sea, air, road) based on cost, urgency, and destination infrastructure. Sea freight is cost-effective for bulk orders but involves longer transit times. Ensure your supplier provides complete export documentation including commercial invoices, packing lists, and certificates of origin to facilitate customs clearance. Engage experienced freight forwarders familiar with your target region to handle local regulations and port procedures efficiently. Factor in potential delays during peak seasons or geopolitical disruptions.

7. What are common causes of disputes in international white corundum transactions, and how can I prevent them?

Disputes often arise from product quality discrepancies, delayed deliveries, or miscommunication about specifications. To prevent these, establish clear contracts detailing product parameters, inspection procedures, delivery schedules, and penalties for non-compliance. Conduct pre-shipment inspections or request third-party quality verification. Maintain transparent communication channels and document all agreements. In case of disputes, having arbitration clauses or choosing neutral legal jurisdictions can facilitate resolution without protracted litigation.

8. How can I ensure effective after-sales support and build long-term partnerships with white corundum suppliers?

Select suppliers who offer responsive customer service, technical support, and flexible return policies. Regularly provide feedback and engage in joint quality improvement initiatives. Attend industry trade fairs or virtual meetings to deepen relationships and stay updated on product innovations. Long-term partnerships often result in better pricing, priority production slots, and customized solutions. Prioritize suppliers who demonstrate commitment to your business growth and understand regional market dynamics.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

The strategic sourcing of white corundum offers significant competitive advantages for international B2B buyers across Africa, South America, the Middle East, and Europe. By prioritizing quality, supplier reliability, and transparent supply chains, buyers can secure consistent material performance essential for industries such as abrasives, refractories, and electronics. Understanding regional market dynamics and leveraging local partnerships in key sourcing hubs enhances negotiation power and reduces risks associated with supply disruptions.

Key takeaways for buyers include:

Looking ahead, the demand for high-grade white corundum is expected to grow, driven by technological advancements and expanding industrial applications. Buyers in emerging and established markets should proactively integrate strategic sourcing frameworks that emphasize agility, transparency, and sustainability. Embracing these principles will not only secure supply continuity but also position businesses to capitalize on emerging opportunities in this critical mineral sector.

Illustrative Image (Source: Google Search)

International buyers are encouraged to engage with trusted suppliers early, explore collaborative innovation, and continuously monitor market trends to maintain a resilient and forward-looking procurement strategy.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina