Boron carbide hardness is a critical consideration for international B2B buyers seeking high-performance materials for various applications, from aerospace to defense. One of the primary challenges faced by buyers in regions such as Africa, South America, the Middle East, and Europe is the complexity of sourcing quality boron carbide products that meet stringent specifications while remaining cost-effective. This guide aims to simplify that process by providing an in-depth exploration of boron carbide hardness, encompassing the different types available, their specific applications, supplier vetting techniques, and associated costs.

As you navigate this comprehensive resource, you will discover actionable insights that empower you to make informed purchasing decisions. We delve into the nuances of boron carbide hardness, including its unique properties and how these can be leveraged to enhance product performance. The guide also addresses crucial questions such as: How do you identify reputable suppliers? What are the cost implications of various boron carbide grades? And how can you ensure compliance with international quality standards?

By equipping you with the knowledge necessary to tackle these challenges, this guide serves as an essential tool for B2B buyers looking to optimize their sourcing strategies for boron carbide. Whether you are located in bustling markets like Cairo or emerging economies in South America, the insights within this guide will help streamline your procurement process and enhance your competitive edge in the global market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Boron Carbide | High hardness, excellent wear resistance | Abrasives, armor plating | Pros: Cost-effective, widely available. Cons: May not withstand extreme conditions. |

| Boron Carbide Ceramics | Enhanced structural integrity, thermal stability | Aerospace, nuclear applications | Pros: High durability, excellent thermal resistance. Cons: Higher manufacturing costs. |

| Boron Carbide Composites | Combination with metals or polymers | Cutting tools, military applications | Pros: Improved toughness, tailored properties. Cons: Complex manufacturing process. |

| Nano-Boron Carbide | Ultra-fine particles, superior hardness | Advanced coatings, electronics | Pros: Exceptional performance, lightweight. Cons: Limited availability, higher price point. |

| Boron Carbide Powders | Versatile particle sizes, customizable | Abrasive blasting, filtration systems | Pros: Customizable for various applications. Cons: Requires careful handling and storage. |

Standard boron carbide is known for its remarkable hardness and wear resistance, making it a staple in various industrial applications. Its hardness level is typically around 9.3 on the Mohs scale, which places it just below diamond. This type is primarily used in abrasives and armor plating, providing a cost-effective solution for industries such as manufacturing and defense. Buyers should consider the balance between cost and performance, as standard boron carbide may not perform well under extreme conditions.

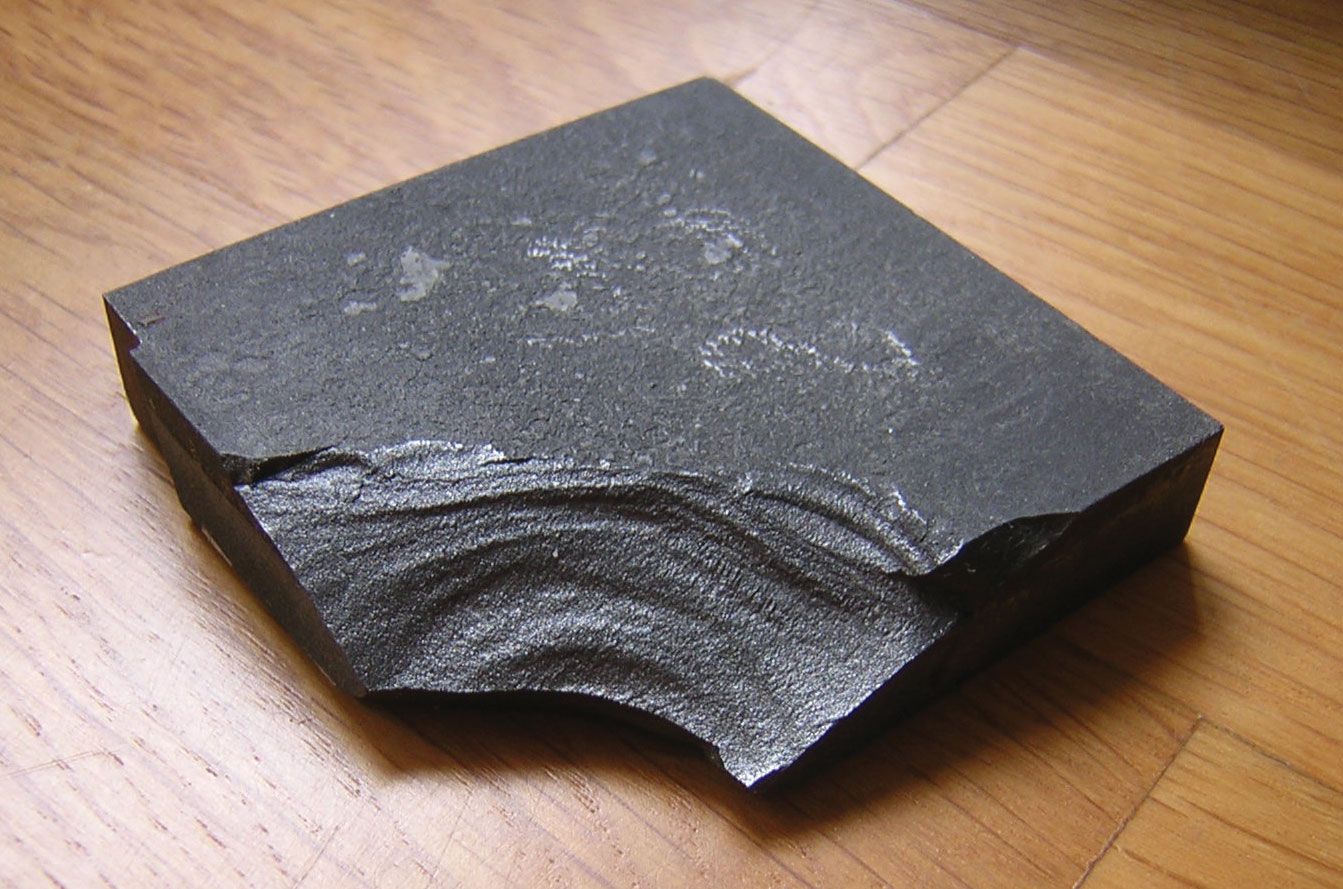

A stock image related to boron carbide hardness.

Boron carbide ceramics offer enhanced structural integrity and thermal stability, making them suitable for high-stress environments. With applications in aerospace and nuclear industries, these materials can withstand extreme temperatures and pressures. While they provide excellent durability, buyers need to be aware that the manufacturing costs are typically higher than standard boron carbide, which may impact budget considerations for large-scale projects.

Boron carbide composites combine boron carbide with metals or polymers to improve toughness and create tailored material properties. This flexibility allows for specialized applications in cutting tools and military-grade materials, where performance is critical. However, the manufacturing process can be complex, potentially leading to longer lead times and increased costs. Buyers should assess the specific requirements of their applications to determine if the benefits justify the investment.

Nano-boron carbide features ultra-fine particles that enhance its hardness and performance characteristics. This variant is increasingly used in advanced coatings and electronic applications due to its lightweight properties and exceptional performance. However, its limited availability and higher price point may pose challenges for buyers looking for cost-effective solutions. It’s essential for B2B purchasers to evaluate the specific performance needs against the potential budget implications.

Boron carbide powders come in various particle sizes, allowing for customization in applications like abrasive blasting and filtration systems. Their versatility makes them attractive for industries requiring tailored solutions. However, careful handling and storage are crucial due to the reactive nature of fine powders. Buyers should consider the specific application requirements and ensure that they have the necessary infrastructure for safe handling to maximize the benefits of boron carbide powders.

Related Video: Boron Carbide: Hardness Unleashed

| Industry/Sector | Specific Application of boron carbide hardness | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of aerospace components | High durability and lightweight, enhancing fuel efficiency | Compliance with aerospace standards and certifications |

| Defense | Production of armor materials | Superior hardness for ballistic protection | Proven performance in military applications and regulations |

| Nuclear Energy | Control rods and neutron absorbers | Effective neutron absorption, increasing safety | Quality assurance and sourcing from certified suppliers |

| Electronics | Abrasives for semiconductor manufacturing | Precision in manufacturing, reducing defects | Availability of high-purity boron carbide |

| Mining and Mineral Processing | Wear-resistant liners and components | Extended equipment lifespan, lowering operational costs | Material compatibility and resistance to chemical wear |

In the aerospace industry, boron carbide hardness is critical for manufacturing lightweight yet durable components. Its application includes parts such as turbine blades and structural supports, where the combination of strength and reduced weight significantly enhances fuel efficiency. Buyers in this sector must ensure that suppliers comply with stringent aerospace standards and certifications, particularly for materials that will endure extreme conditions.

Boron carbide is extensively used in the defense sector for the production of armor materials, including personal protective gear and vehicle armor. Its exceptional hardness provides superior ballistic protection, crucial for safeguarding personnel and assets in combat scenarios. International buyers must prioritize sourcing from manufacturers with proven performance records and compliance with military specifications to ensure reliability and effectiveness.

In the nuclear energy sector, boron carbide hardness is utilized in control rods and neutron absorbers, where its effective neutron absorption capabilities are vital for safety and reactor control. The material helps regulate the fission process, making it an essential component in nuclear reactors. Buyers should focus on quality assurance processes and sourcing from certified suppliers who can demonstrate the material’s effectiveness and safety in high-stakes environments.

In the electronics industry, boron carbide hardness is primarily used as an abrasive in semiconductor manufacturing. Its precision allows for the fine-tuning of components, reducing defects and improving overall product quality. Buyers need to consider the availability of high-purity boron carbide, as impurities can adversely affect semiconductor performance and reliability.

Boron carbide is increasingly being employed in mining and mineral processing for wear-resistant liners and components. Its hardness extends the lifespan of equipment, significantly reducing operational costs associated with frequent replacements. When sourcing boron carbide for these applications, businesses should evaluate material compatibility and resistance to chemical wear, ensuring the longevity and efficiency of their equipment in harsh environments.

The Problem:

B2B buyers often face significant challenges in sourcing boron carbide due to global supply chain disruptions. These disruptions can stem from geopolitical tensions, natural disasters, or fluctuations in demand. For instance, a manufacturing company in Egypt may find that their usual suppliers in Europe are unable to deliver the required boron carbide hardness materials on time, leading to production delays and financial losses. This uncertainty can hinder the ability to meet client deadlines and maintain competitiveness in the market.

The Solution:

To mitigate these supply chain issues, B2B buyers should diversify their supplier base. Establishing relationships with multiple suppliers across different regions, such as South America and the Middle East, can help create a more resilient supply chain. Additionally, buyers should consider leveraging local suppliers who may offer shorter lead times and lower shipping costs. It’s also beneficial to negotiate long-term contracts with key suppliers to ensure consistent availability and pricing stability. Implementing a robust inventory management system can help track stock levels and forecast demand more accurately, allowing businesses to buffer against unexpected disruptions.

The Problem:

Another common pain point for B2B buyers is the complexity surrounding the technical specifications of boron carbide hardness. Companies often struggle to understand the different grades and forms available, which can lead to improper material selection for their applications. For example, a defense contractor in France might require specific hardness levels for ballistic armor, but a lack of technical knowledge could result in choosing an inadequate product, compromising safety and performance.

The Solution:

To address this issue, buyers should invest in training for their procurement teams to better understand the material properties of boron carbide. Engaging with suppliers to provide technical support and product demonstrations can also be invaluable. Moreover, creating a detailed specification document that outlines the exact requirements for each application can facilitate clearer communication with suppliers. Buyers should also consider conducting pilot tests with different grades of boron carbide to evaluate their performance in real-world conditions before committing to large orders. Utilizing resources such as industry publications, webinars, and technical conferences can further enhance knowledge and confidence in selecting the right boron carbide hardness.

The Problem:

Cost management is a critical concern for B2B buyers, especially when dealing with high-value materials like boron carbide hardness. Fluctuations in raw material prices can significantly impact project budgets and profitability. For example, a manufacturing firm in South America may experience rising costs due to increased demand for boron carbide in various industries, straining their financial resources and making it difficult to maintain competitive pricing for their products.

The Solution:

To effectively manage costs, buyers should adopt a strategic approach to procurement. This includes conducting market research to stay informed about price trends and market conditions. Implementing a just-in-time inventory system can also help minimize holding costs while ensuring that materials are available when needed. Additionally, buyers can explore bulk purchasing agreements with suppliers to secure lower prices. Engaging in collaborative purchasing with other companies within the same industry may also provide leverage for negotiating better terms. Lastly, investing in technology that analyzes spending patterns can help identify areas for cost savings and drive more efficient procurement practices.

When selecting materials for boron carbide hardness applications, it is crucial to consider various factors that influence performance, cost, and suitability for specific applications. Below, we analyze four common materials used in conjunction with boron carbide, focusing on their properties, advantages, limitations, and implications for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

Silicon carbide (SiC) is renowned for its exceptional hardness and thermal stability, making it a popular choice in high-performance applications. It can withstand high temperatures (up to 1600°C) and exhibits excellent corrosion resistance in harsh environments. SiC is also known for its high thermal conductivity, which is beneficial in applications requiring efficient heat dissipation.

Pros & Cons:

- Pros: High durability, excellent thermal properties, and resistance to oxidation.

- Cons: Higher manufacturing complexity and cost compared to other materials.

Impact on Application:

Silicon carbide is particularly suited for applications in the aerospace and automotive industries where high-performance components are critical. Its compatibility with various media, including corrosive environments, makes it a versatile choice.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN. Understanding local regulations regarding material sourcing and environmental impact is essential, especially in regions like Europe where sustainability is prioritized.

Aluminum oxide (Al2O3) is another material frequently used in conjunction with boron carbide. It offers good hardness and is less expensive than silicon carbide. Al2O3 can withstand moderate temperatures (up to 1200°C) and has decent chemical resistance, making it suitable for various applications.

Pros & Cons:

- Pros: Cost-effective, readily available, and relatively easy to manufacture.

- Cons: Lower hardness and thermal stability compared to SiC.

Impact on Application:

Aluminum oxide is ideal for applications in ceramics and abrasives. However, its limitations in high-temperature applications may restrict its use in more demanding environments.

Considerations for International Buyers:

Buyers should be aware of the varying quality standards across regions. In Europe, for instance, adherence to specific quality certifications is often required, which may not be the case in other regions.

Boron nitride (BN) is known for its unique properties, such as excellent thermal stability and electrical insulation. It can operate effectively at temperatures exceeding 2000°C and has a low friction coefficient, making it suitable for high-performance applications.

Pros & Cons:

- Pros: Exceptional thermal resistance, low friction, and good chemical stability.

- Cons: Higher cost and limited availability compared to more common materials.

Impact on Application:

Boron nitride is particularly effective in applications requiring high thermal performance and low wear, such as in aerospace and semiconductor industries.

Considerations for International Buyers:

Buyers should consider the availability of boron nitride in their local markets and any import regulations that may apply. Compliance with international standards is also crucial for ensuring product quality.

Titanium carbide (TiC) is another material that exhibits high hardness and excellent wear resistance. It can withstand high temperatures (up to 3000°C) and has good thermal conductivity, making it suitable for applications in cutting tools and wear-resistant coatings.

Pros & Cons:

- Pros: High hardness, good thermal stability, and wear resistance.

- Cons: More expensive and can be challenging to machine.

Impact on Application:

Titanium carbide is widely used in metalworking and machining applications, where durability and performance are paramount.

Considerations for International Buyers:

Buyers should assess the cost-effectiveness of titanium carbide in comparison to other materials. Understanding local market conditions and sourcing options is essential, particularly in regions like Africa and South America, where material availability may vary.

| Material | Typical Use Case for boron carbide hardness | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Aerospace components | High durability and thermal stability | Higher manufacturing complexity | High |

| Aluminum Oxide | Ceramics and abrasives | Cost-effective and readily available | Lower hardness and thermal stability | Medium |

| Boron Nitride | Aerospace and semiconductor applications | Exceptional thermal resistance | Higher cost and limited availability | High |

| Titanium Carbide | Metalworking and machining | High hardness and wear resistance | More expensive and machining challenges | High |

This guide serves as a strategic reference for international B2B buyers looking to make informed decisions about material selection for boron carbide hardness applications. Understanding the properties and implications of each material can significantly impact product performance and compliance with regional standards.

The production of boron carbide, renowned for its exceptional hardness and applications in various industries, follows a systematic manufacturing process. Understanding these stages is crucial for B2B buyers looking to source quality materials.

The first step in manufacturing boron carbide involves the sourcing and preparation of raw materials, primarily boron and carbon. These materials are often obtained from specific suppliers who can guarantee purity and quality. The raw materials are then subjected to a milling process to achieve the desired particle size. This is critical as the size and uniformity of the particles significantly influence the final product's hardness and performance.

Once the materials are prepared, they undergo forming techniques. The most common methods include:

Hot Pressing: This involves applying heat and pressure to the powdered boron carbide mixture to create a dense material. This technique enhances the hardness and structural integrity of the final product.

Cold Isostatic Pressing (CIP): This method applies uniform pressure in all directions, ensuring a homogeneous density and reducing defects.

Injection Molding: For complex shapes, injection molding can be used, where the mixture is injected into molds under pressure. This technique is particularly beneficial for producing intricate components used in various applications.

Quality assurance is a vital aspect of boron carbide production, ensuring that the end product meets industry standards and customer requirements.

A stock image related to boron carbide hardness.

B2B buyers should ensure that their suppliers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are also significant, especially for applications in aerospace, defense, and oil and gas sectors.

Quality control (QC) checkpoints are integrated throughout the manufacturing process to maintain product integrity. Key checkpoints include:

Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials before they enter the production line. Suppliers must provide certificates of analysis to confirm material specifications.

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages ensures that any deviations from quality standards are promptly addressed. This may include regular checks on temperature, pressure, and density during pressing processes.

Final Quality Control (FQC): After production, products undergo rigorous testing to ensure they meet specified hardness and structural requirements. Testing methods include Vickers hardness tests and microstructural analysis.

Testing methods are essential for verifying that boron carbide products meet the desired specifications. Common methods include:

Hardness Testing: Vickers or Knoop hardness tests are frequently employed to determine the material's hardness, ensuring it meets the requisite standards for specific applications.

Density Measurement: The density of the final product is crucial, as it directly correlates with performance in applications such as armor and cutting tools.

Microstructural Analysis: Techniques like Scanning Electron Microscopy (SEM) are used to evaluate the microstructure, identifying any potential defects or inconsistencies.

Verifying a supplier's quality control processes is critical for B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. Here are actionable insights:

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes assessing their compliance with international standards and their internal QC protocols.

Request Quality Reports: Buyers should ask for detailed QC reports that outline testing results and compliance with standards. This transparency is crucial for building trust and ensuring product reliability.

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier's capabilities and quality assurance measures. This is particularly important for international buyers who may not be able to visit suppliers in person.

B2B buyers from different regions may encounter unique challenges regarding quality assurance in boron carbide manufacturing. Understanding these nuances is essential:

Regulatory Differences: Buyers must be aware of regional regulatory requirements that may differ significantly from international standards. For instance, European buyers might prioritize CE certification, while buyers in the Middle East may have specific local standards.

Cultural Considerations: Communication and cultural differences can impact quality assurance processes. Establishing clear expectations and fostering open communication with suppliers can help mitigate misunderstandings.

Logistical Challenges: International shipping can complicate the verification of quality control. Buyers should consider the impact of transportation on product integrity and plan accordingly, ensuring that the products arrive in optimal condition.

A comprehensive understanding of the manufacturing processes and quality assurance measures in boron carbide production is vital for B2B buyers. By focusing on quality at every stage—from material preparation to final testing—buyers can ensure they source the best products for their applications. Adhering to international standards and implementing rigorous QC practices not only enhances product reliability but also builds long-term supplier relationships.

In the competitive landscape of international B2B procurement, sourcing boron carbide hardness requires a methodical approach to ensure you receive high-quality materials that meet your technical specifications. This guide provides a step-by-step checklist tailored for buyers in Africa, South America, the Middle East, and Europe, helping you navigate the complexities of sourcing boron carbide effectively.

Establishing clear technical specifications is the foundation of successful sourcing. Determine the grade, particle size, and intended application of the boron carbide, as these factors significantly influence performance and pricing. Document these requirements to communicate effectively with potential suppliers.

Conduct thorough research to identify suppliers who specialize in boron carbide products. Utilize industry directories, trade shows, and online platforms to compile a list of potential candidates. Pay attention to their market reputation, years of experience, and the regions they serve, particularly in your target markets like Egypt or France.

Before making a commitment, verify the certifications of your shortlisted suppliers. Look for ISO certifications or industry-specific qualifications that demonstrate compliance with international standards. This step is critical to ensuring that the materials you procure meet safety and quality benchmarks required for your operations.

Always request samples before finalizing your order. Testing the material’s hardness and other physical properties will help confirm that it meets your specifications. Consider conducting tests in your own facility or working with a third-party laboratory to ensure unbiased results.

Comparative pricing analysis is essential for ensuring value for money. Obtain detailed quotes from multiple suppliers, including shipping and handling costs. Additionally, discuss payment terms and conditions to avoid any surprises later in the transaction. Flexible payment options can be a deciding factor, especially for buyers in regions with fluctuating currencies.

Effective communication is vital throughout the sourcing process. Ensure that you establish clear channels for dialogue with your suppliers. This includes setting expectations for response times, language preferences, and preferred communication methods, especially if you're dealing with suppliers from different time zones.

Before signing any contracts, carefully review all terms and conditions. Pay special attention to delivery timelines, warranty provisions, and liability clauses. Engaging a legal expert familiar with international trade can help mitigate risks associated with cross-border transactions.

By following this checklist, B2B buyers can navigate the sourcing process for boron carbide hardness more effectively, ensuring that they partner with reliable suppliers who can meet their quality and performance requirements.

When sourcing boron carbide hardness, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The cost of boron carbide itself is the most significant factor. Prices can fluctuate based on market demand and purity levels. Buyers should source from reputable suppliers who can guarantee the material's quality.

Labor: Labor costs vary by region. For instance, sourcing from countries with lower labor costs may offer savings, but it’s essential to ensure that quality standards are not compromised.

Manufacturing Overhead: This encompasses the indirect costs related to production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

Tooling: The initial investment in tooling can be substantial, especially for custom specifications. Buyers should consider this when evaluating suppliers, as some may offer tooling as part of the overall pricing strategy.

Quality Control (QC): Rigorous QC processes are vital to ensure the product meets required specifications. This can add to the overall cost but is essential for maintaining product integrity.

Logistics: Shipping and handling costs can significantly impact total expenses, especially for international transactions. Factors such as distance, mode of transport, and Incoterms play a vital role in logistics costs.

Margin: Suppliers will include their profit margin in the final pricing. Understanding industry standards for margins can help buyers negotiate better deals.

Several factors influence the pricing of boron carbide hardness:

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to determine the most cost-effective order size.

Specifications and Customization: Tailored products typically come at a premium. Clear communication of requirements can help avoid unexpected costs associated with customization.

Material Quality and Certifications: Higher quality materials and necessary certifications (like ISO or industry-specific standards) can lead to increased costs. Buyers should weigh the benefits of certification against the potential price increase.

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers may offer competitive rates to gain market share.

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is essential. They dictate who is responsible for shipping costs, insurance, and risk, which can significantly affect the total cost.

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation can yield substantial savings:

Conduct Market Research: Familiarize yourself with current market prices and trends. This information equips buyers to negotiate from a position of knowledge.

Emphasize Total Cost of Ownership (TCO): Rather than focusing solely on purchase price, consider the total cost of ownership, including maintenance, logistics, and potential downtime. This broader perspective can justify higher initial costs if long-term savings are evident.

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing and terms. Frequent communication and transparency about your needs can foster trust.

Utilize Long-Term Contracts: If possible, negotiate long-term contracts to lock in prices and ensure supply stability. This can provide predictability in budgeting and planning.

Be Cautious with Discounts: While discounts can be appealing, ensure they do not compromise quality. Always verify that lower prices do not come with hidden costs or reduced service levels.

In summary, understanding the comprehensive cost structure and the factors that influence pricing is essential for international B2B buyers of boron carbide hardness. By focusing on cost components, price influencers, and best negotiation practices, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices can vary widely based on location, supplier reliability, and product specifications, so a thorough due diligence process is essential.

Disclaimer: The prices mentioned in this analysis are indicative and subject to fluctuations based on market conditions and supplier terms.

When considering materials for high-performance applications, particularly in industries such as defense, aerospace, and manufacturing, it is essential to explore various options available in the market. Boron carbide (B4C) is renowned for its exceptional hardness and wear resistance, but there are several alternatives that may also suit specific needs. This analysis will compare boron carbide hardness with two viable alternatives: silicon carbide (SiC) and alumina (Al2O3).

| Comparison Aspect | Boron Carbide Hardness | Silicon Carbide (SiC) | Alumina (Al2O3) |

|---|---|---|---|

| Performance | High hardness (9.3 Mohs) | High hardness (9.0 Mohs) | Moderate hardness (9.0 Mohs) |

| Cost | High | Moderate | Low |

| Ease of Implementation | Moderate complexity | Moderate complexity | Easy |

| Maintenance | Low | Low | Very low |

| Best Use Case | Armor, cutting tools | High-temperature applications, abrasives | Electrical insulators, ceramics |

Silicon carbide (SiC) is a widely used alternative that boasts high thermal conductivity and exceptional hardness. Its performance in high-temperature environments makes it suitable for applications such as power electronics and abrasive materials. However, SiC can be more expensive than alumina, and its production process requires advanced techniques, which may complicate implementation in certain settings.

Alumina (Al2O3) is another alternative that offers good hardness and is cost-effective. It is widely used in various applications, including electrical insulators and wear-resistant components. The main advantage of alumina lies in its affordability and ease of processing, making it a popular choice for mass production. However, it does not match the hardness of boron carbide or silicon carbide, which may limit its effectiveness in high-wear applications.

For B2B buyers, the decision to select boron carbide hardness over alternatives like silicon carbide or alumina should be based on specific application needs, budget constraints, and performance requirements. Understanding the strengths and weaknesses of each material is crucial. For instance, if extreme hardness and wear resistance are paramount, boron carbide may be the best choice despite its higher cost. Conversely, for applications that prioritize cost and ease of implementation, alumina could be more suitable. Ultimately, thorough research and an assessment of individual project requirements will lead to the most effective material choice.

Boron carbide is a critical material in various industrial applications, particularly due to its exceptional hardness. Here are some essential technical properties that B2B buyers should consider:

Material Grade

- Definition: Material grade refers to the specific classification of boron carbide based on its purity and composition.

- Importance: Higher grades of boron carbide exhibit superior hardness and wear resistance, making them suitable for demanding applications such as armor plating and abrasive tools. Buyers should evaluate material grades to ensure they meet the performance requirements of their specific applications.

Hardness Value (Mohs Scale)

- Definition: The hardness of boron carbide is typically rated at about 9.5 on the Mohs scale, making it one of the hardest materials available.

- Importance: This property is crucial for applications that require materials to withstand extreme wear and impact. Understanding the hardness value helps buyers select the right material for their specific needs, particularly in sectors such as mining and manufacturing.

Tolerance Levels

- Definition: Tolerance levels refer to the permissible limits of variation in dimensions and properties of boron carbide products.

- Importance: In B2B transactions, tighter tolerances can lead to better fitting and performance in final applications. Buyers must consider tolerance levels to ensure compatibility with other components in their systems.

Density

- Definition: Density measures the mass per unit volume of boron carbide, typically ranging from 2.52 to 2.55 g/cm³.

- Importance: Density affects the overall weight and strength of the material, which can be critical in applications like armor systems where weight-to-strength ratios are essential for mobility and effectiveness.

Thermal Stability

- Definition: Thermal stability indicates the material's ability to maintain its properties under high temperatures.

- Importance: Boron carbide’s thermal stability allows it to perform in high-temperature environments without degrading. Buyers in industries such as aerospace and defense should prioritize this property to ensure longevity and reliability.

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms related to boron carbide:

OEM (Original Equipment Manufacturer)

- Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer.

- Relevance: For buyers, knowing if a supplier is an OEM can ensure they are sourcing high-quality, reliable products designed for specific applications.

MOQ (Minimum Order Quantity)

- Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

- Relevance: Understanding the MOQ is crucial for buyers to assess inventory levels and budget constraints. It helps in negotiating better terms and managing supply chain logistics.

RFQ (Request for Quotation)

- Definition: An RFQ is a document sent to suppliers to request price quotes for specific products or services.

- Relevance: This is a vital step in the procurement process, allowing buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal.

Incoterms (International Commercial Terms)

- Definition: Incoterms are internationally recognized rules that define the responsibilities of sellers and buyers regarding shipping, insurance, and tariffs.

- Relevance: Familiarity with Incoterms helps buyers understand their responsibilities and risks in international transactions, ensuring smoother logistics and cost management.

Lead Time

- Definition: Lead time is the amount of time from when an order is placed until it is fulfilled.

- Relevance: For B2B buyers, lead time affects project timelines and inventory management. Understanding lead times can help in planning procurement strategies effectively.

By grasping these technical properties and trade terms, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can make informed decisions regarding boron carbide hardness and enhance their supply chain effectiveness.

The boron carbide hardness market is witnessing a notable transformation driven by increasing industrial applications and advancements in B2B technologies. As a highly durable and lightweight material, boron carbide is primarily utilized in manufacturing abrasives, armor, and nuclear applications. The demand for boron carbide is escalating, particularly in regions like Africa and South America, where mining and defense industries are expanding.

Key trends include the rise of automation and digitalization in sourcing processes, enabling international buyers to streamline procurement. E-commerce platforms tailored for B2B transactions are gaining traction, allowing buyers from Europe and the Middle East to access global suppliers with ease. Additionally, the focus on material performance, such as improved hardness and thermal stability, is shaping product development.

Emerging markets are also experiencing a shift towards localized production, reducing lead times and shipping costs. This is particularly beneficial for buyers in regions like Egypt and Brazil, where local sourcing can foster economic growth and create jobs. Furthermore, the integration of advanced analytics and AI into supply chain management is enhancing decision-making processes, allowing buyers to identify trends and optimize their sourcing strategies effectively.

Sustainability is becoming a critical factor for B2B buyers in the boron carbide hardness sector. The environmental impact of sourcing materials is under scrutiny, prompting companies to adopt more sustainable practices. This includes evaluating the lifecycle of boron carbide products and considering the ecological footprint of mining activities.

Ethical sourcing is paramount as businesses strive to align with global sustainability goals. Buyers are increasingly looking for suppliers that demonstrate commitment to ethical practices, such as fair labor conditions and reduced environmental impact. The importance of certifications, such as ISO 14001 for environmental management, is growing, providing assurance to buyers regarding the sustainability of their supply chains.

Moreover, the rise of 'green' materials is influencing product innovation in the boron carbide market. Manufacturers are exploring alternative sourcing strategies that prioritize recycled materials or environmentally friendly production methods. For international buyers, particularly in Europe, adopting sustainable sourcing not only enhances brand reputation but can also lead to cost savings and improved operational efficiency in the long run.

The evolution of boron carbide hardness has been marked by significant advancements since its first commercial use in the 1950s. Initially utilized primarily in the defense sector, its applications have diversified over the decades. The material's exceptional hardness and lightweight properties have made it a preferred choice for a variety of industrial applications, including abrasives and protective gear.

As global industrial demands continue to evolve, the boron carbide sector is adapting through innovation and technological advancements. The focus on high-performance materials has driven research and development, leading to improved formulations and production techniques. This evolution has positioned boron carbide as a critical material in modern manufacturing processes, catering to the needs of B2B buyers seeking reliable and high-quality materials.

In conclusion, understanding the market dynamics, sustainability considerations, and historical context of boron carbide hardness is essential for international B2B buyers aiming to make informed sourcing decisions in a rapidly changing landscape.

How do I determine the hardness level of boron carbide?

To assess the hardness of boron carbide, you can utilize a variety of testing methods, including the Vickers or Mohs hardness tests. Vickers testing measures the hardness by applying a specific load on a diamond indenter, providing a precise hardness value. Mohs hardness, on the other hand, ranks materials based on their ability to scratch one another. For B2B buyers, it’s crucial to request detailed test reports from suppliers to ensure that the boron carbide meets the required hardness specifications for your applications.

What is the best application for boron carbide hardness in industrial settings?

Boron carbide is renowned for its exceptional hardness, making it ideal for various industrial applications, including abrasives, armor materials, and nuclear reactors. Its high hardness level allows it to withstand severe wear and tear, making it suitable for cutting tools and grinding wheels. For buyers in sectors such as aerospace or defense, sourcing boron carbide can provide a competitive edge in manufacturing high-performance components.

How do I vet suppliers of boron carbide hardness for international trade?

When vetting suppliers, consider their certifications, production capabilities, and previous client testimonials. Request documentation such as ISO certifications, quality assurance processes, and compliance with international standards. Additionally, conducting site visits or virtual audits can provide insights into their manufacturing processes. For international buyers, understanding the supplier's logistics capabilities and reliability in shipping is also critical to ensure timely delivery.

What are the minimum order quantities (MOQ) for boron carbide hardness products?

Minimum order quantities can vary significantly among suppliers based on their production capabilities and inventory levels. Typically, MOQs for boron carbide products range from 100 kg to several tons. It's advisable to negotiate MOQs with suppliers, especially if you are looking to test the product before committing to larger orders. Understanding the supplier's flexibility on MOQs can help in managing inventory and cash flow effectively.

What payment terms are common for international boron carbide transactions?

Common payment terms for international transactions include Letter of Credit (LC), advance payments, and net payment terms (e.g., net 30, net 60). Using an LC can provide security for both parties, ensuring that payment is made only upon fulfillment of agreed terms. It’s also important to clarify currency preferences and any additional fees associated with international transactions. Establishing clear payment terms can prevent misunderstandings and ensure smoother transactions.

How can I customize boron carbide hardness products to meet my specifications?

Customization options for boron carbide hardness products may include varying the particle size, shape, and hardness levels. Many suppliers offer tailored solutions to meet specific industrial requirements. To initiate customization, provide detailed specifications and discuss your application needs with the supplier. Collaborating closely with the supplier during the design phase can result in a product that better fits your operational needs.

What quality assurance measures should I expect from boron carbide suppliers?

Quality assurance measures should include comprehensive testing protocols for hardness, purity, and grain size. Reputable suppliers will conduct regular quality checks and provide certificates of analysis (CoA) for their products. Additionally, inquire about their adherence to international quality standards, such as ISO 9001, which ensures a systematic approach to quality management. Effective quality assurance practices are crucial to maintaining the integrity of your supply chain.

How do logistics and shipping impact the sourcing of boron carbide hardness?

Logistics and shipping play a vital role in the sourcing process, affecting lead times and overall costs. When sourcing boron carbide internationally, consider the supplier's location, shipping methods, and delivery timelines. It's essential to discuss freight options, customs clearance processes, and any potential tariffs that may apply. Establishing a reliable logistics plan can help mitigate delays and ensure that your boron carbide products arrive on time and in good condition.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Boron carbide hardness is a critical factor for industries requiring materials with exceptional wear resistance and durability. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of sourcing this advanced material, the importance of strategic sourcing becomes increasingly evident. By understanding the nuances of boron carbide properties, buyers can make informed decisions that enhance their supply chains and operational efficiency.

Strategic sourcing not only optimizes procurement costs but also fosters long-term relationships with suppliers who can provide high-quality boron carbide products. This collaboration can lead to innovations in material applications, which are essential for sectors such as aerospace, defense, and manufacturing. Buyers should prioritize suppliers with a proven track record of quality assurance and sustainability practices, ensuring that their sourcing decisions align with global standards and ethical considerations.

Looking ahead, the demand for boron carbide hardness will likely increase as industries seek materials that can withstand extreme conditions. By proactively engaging with suppliers and investing in research and development, B2B buyers can position themselves at the forefront of this evolving market. As you explore your sourcing options, consider participating in industry forums and trade shows to connect with potential suppliers and gain insights into emerging trends. Your commitment to strategic sourcing will not only drive your business success but also contribute to the advancement of material science globally.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina