In an increasingly competitive global marketplace, sourcing high-quality brown fused alumina oxide for flooring presents a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe (including key markets like Thailand and Italy) seek durable and aesthetically pleasing flooring solutions, understanding the nuances of this versatile material becomes paramount. This comprehensive guide aims to equip buyers with the essential knowledge needed to navigate the complexities of sourcing brown fused alumina oxide, from its various types and applications to supplier vetting and pricing strategies.

By delving into critical aspects such as product specifications, quality standards, and market trends, this guide empowers B2B buyers to make informed purchasing decisions that align with their business objectives. Whether you are looking to enhance your supply chain efficiency or ensure compliance with regional regulations, our insights will help you identify reliable suppliers and negotiate favorable terms. Furthermore, we address the unique challenges faced by buyers in emerging markets, offering tailored advice on leveraging local resources while maintaining global standards.

With this guide, international B2B buyers will gain a robust understanding of brown fused alumina oxide's role in flooring applications, enabling them to strategically position their businesses for success in a dynamic and evolving market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Brown Fused Alumina | High purity, consistent grain size | General flooring applications | Pros: Cost-effective, widely available. Cons: Limited slip resistance. |

| High-Performance Brown Fused Alumina | Enhanced toughness and wear resistance | Heavy industrial flooring | Pros: Durable, long lifespan. Cons: Higher initial cost. |

| Coated Brown Fused Alumina | Surface treated for improved slip resistance | Commercial spaces, public buildings | Pros: Increased safety, aesthetic options. Cons: Requires maintenance. |

| Ultra-Fine Brown Fused Alumina | Very fine grain size for smooth finishes | Decorative flooring, high-end applications | Pros: Exceptional finish, high aesthetic value. Cons: More expensive, less durable. |

| Recycled Brown Fused Alumina | Made from recycled materials, eco-friendly | Sustainable building projects | Pros: Environmentally friendly, cost savings. Cons: Variable quality. |

Standard brown fused alumina is a widely used material in flooring due to its high purity and consistent grain size. This type is ideal for general flooring applications, such as warehouses and workshops where durability is key. When purchasing, buyers should consider the cost-effectiveness and availability, but should also note that it may have limited slip resistance, which could be a concern in certain environments.

High-performance brown fused alumina is engineered for enhanced toughness and wear resistance, making it suitable for heavy industrial flooring applications. This type is particularly beneficial in environments subjected to heavy foot traffic and mechanical stress. Buyers should weigh the higher initial investment against the long lifespan and durability, as the long-term savings on maintenance and replacement can justify the cost.

Coated brown fused alumina features a surface treatment that improves slip resistance, making it an excellent choice for commercial spaces and public buildings. Its aesthetic versatility allows for various design options while ensuring safety. Buyers should consider the benefits of increased safety and aesthetics, but also be aware of the need for ongoing maintenance to preserve its properties.

Ultra-fine brown fused alumina is characterized by its very fine grain size, providing a smooth finish that is ideal for decorative flooring and high-end applications. This type offers an exceptional aesthetic value, making it popular in luxury settings. However, buyers should consider the higher cost and the potential trade-off in durability, as ultra-fine materials may be more susceptible to wear and tear.

Recycled brown fused alumina is made from recycled materials, making it an eco-friendly option for sustainable building projects. This type appeals to businesses looking to reduce their environmental impact while still obtaining quality flooring solutions. While it can offer cost savings and environmental benefits, buyers should be cautious of the variable quality that may arise from the recycling process.

Related Video: brown fused alumina manufacturing process at Jiygo

| Industry/Sector | Specific Application of brown fused alumina oxide for flooring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Abrasive flooring materials for commercial spaces | Enhanced durability and slip resistance | Ensure compliance with local safety regulations and standards |

| Manufacturing | Surface preparation for industrial equipment | Improved adhesion of coatings and longevity of surfaces | Assess the compatibility with existing processes and materials |

| Automotive | Flooring in automotive workshops | Resistance to oils and chemicals, ensuring safety and cleanliness | Evaluate the specific chemical resistance required for the environment |

| Mining and Minerals | Flooring in processing plants | High wear resistance, reducing maintenance costs | Consider sourcing from suppliers with proven track records in harsh environments |

| Food and Beverage | Flooring in food processing facilities | Non-porous surfaces to prevent contamination | Ensure compliance with food safety standards and certifications |

In the construction sector, brown fused alumina oxide is utilized as an abrasive material for flooring in commercial spaces. Its exceptional hardness and slip-resistant properties make it ideal for high-traffic areas, enhancing safety and durability. International buyers, especially from regions like Africa and South America, should prioritize suppliers that comply with local safety regulations and standards to ensure optimal performance and longevity of the flooring materials.

Manufacturers leverage brown fused alumina oxide for surface preparation in industrial equipment. This application improves the adhesion of coatings, extending the lifespan of machinery and tools. For B2B buyers in Europe and the Middle East, understanding the compatibility of this material with existing processes is crucial. Suppliers should provide detailed technical data to ensure that the abrasive meets specific manufacturing requirements.

In automotive workshops, flooring made from brown fused alumina oxide offers significant advantages, such as resistance to oils and chemicals, which helps maintain a clean and safe working environment. For international buyers, especially those in regions like Italy and Thailand, it is essential to evaluate the specific chemical resistance required for their operations. Sourcing from reputable suppliers ensures that the flooring meets the necessary durability standards.

In the mining and minerals industry, brown fused alumina oxide is used for flooring in processing plants due to its high wear resistance. This characteristic reduces maintenance costs and downtime, making it a valuable investment for companies operating in harsh environments. Buyers should consider suppliers with proven track records in delivering durable flooring solutions to withstand the rigors of mining operations.

The food and beverage sector benefits from brown fused alumina oxide flooring due to its non-porous nature, which prevents contamination and ensures compliance with food safety standards. B2B buyers must ensure that their suppliers adhere to necessary certifications and regulations to maintain hygiene and safety in processing facilities. This focus on compliance is vital for protecting public health and maintaining brand integrity.

Related Video: How to Produce Alumina Ceramic Parts

The Problem:

B2B buyers often face the challenge of sourcing high-quality brown fused alumina oxide that meets their specific flooring application requirements. Many suppliers may offer products that look similar but vary significantly in terms of purity, hardness, and size distribution. This inconsistency can lead to performance issues, such as premature wear, reduced slip resistance, or poor bonding in flooring applications. Buyers from regions like Africa and South America may find it particularly challenging due to limited local suppliers and variations in product standards.

The Solution:

To ensure you are sourcing the right quality, start by conducting thorough research on potential suppliers. Look for suppliers with a proven track record in the flooring industry and positive reviews from previous clients. Request samples for testing to verify the product's quality against your specifications. It's also beneficial to inquire about their quality control processes and certifications. Establishing clear communication about your needs will help suppliers provide tailored solutions. Consider engaging in partnerships with suppliers who can offer technical support and guidance on product selection, ensuring you receive the best brown fused alumina oxide for your flooring projects.

The Problem:

Installation of brown fused alumina oxide flooring can present several challenges, particularly in terms of achieving the correct application thickness and ensuring proper adhesion. Buyers may experience difficulties during installation, such as uneven surfaces, bubbling, or delamination, which can lead to costly repairs and project delays. These issues are often exacerbated in regions with varying climatic conditions, such as the Middle East, where temperature fluctuations can impact installation efficacy.

The Solution:

To mitigate these installation challenges, invest in comprehensive training for your installation team. Collaborate with your supplier to provide on-site training sessions or detailed installation guides specific to brown fused alumina oxide flooring. Ensure that all surface preparations, including cleaning and priming, are followed meticulously. Additionally, select the right adhesive systems that are compatible with brown fused alumina oxide and suitable for your environmental conditions. Conduct mock installations to identify potential issues before the actual project begins, allowing your team to familiarize themselves with the material and installation techniques.

The Problem:

Another common concern among B2B buyers is the long-term performance and durability of brown fused alumina oxide flooring. Some buyers may have experienced early degradation or failure of flooring surfaces, leading to increased maintenance costs and dissatisfaction among end-users. Buyers in Europe, where stringent performance standards exist, may feel pressured to ensure that their flooring choices are resilient against heavy traffic and environmental factors.

The Solution:

To enhance the longevity of brown fused alumina oxide flooring, prioritize rigorous testing and evaluation before making a bulk purchase. Implement a maintenance plan that includes regular cleaning and inspections to identify wear patterns early. Work closely with manufacturers to understand the expected lifespan of their products under specific usage conditions. Consider investing in surface treatments or sealants that can protect the flooring from wear and improve slip resistance. Additionally, gather feedback from end-users to continuously assess the performance of the flooring and make informed decisions for future projects. By proactively managing these factors, you can ensure the flooring remains functional and appealing over time.

Brown fused alumina oxide (BFA) is a widely used abrasive material in flooring applications due to its exceptional hardness and durability. Its key properties include high-temperature resistance, excellent wear resistance, and good chemical stability. These characteristics make it suitable for various flooring types, especially in industrial and commercial settings where heavy foot traffic and mechanical stress are common.

Key Properties: BFA is known for its hardness (Mohs hardness of 9), which allows it to withstand significant abrasion. It also has a melting point of approximately 2050°C and exhibits excellent thermal stability.

Pros:

Cost-effective in the long run due to its longevity.

Cons:

Requires specialized manufacturing processes, which can complicate production.

Impact on Application: BFA is compatible with various media, including water and oil, making it versatile for different flooring applications. Its hardness ensures that it maintains its integrity under heavy loads.

Considerations for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should ensure that their suppliers comply with international standards such as ASTM or DIN. Understanding local regulations regarding material safety and environmental impact is also crucial.

Key Properties: SiC is another abrasive material known for its high hardness and thermal conductivity. It has a melting point of about 2700°C and is chemically inert.

Pros:

Provides a non-slip surface, enhancing safety in flooring.

Cons:

Generally more expensive than BFA.

Impact on Application: SiC is particularly effective in environments exposed to high temperatures, such as kitchens or foundries. However, its brittleness may limit its use in applications where heavy impact is expected.

Considerations for International Buyers: Buyers should consider the specific application needs and ensure compliance with relevant safety standards. The higher cost may be justified in applications demanding superior thermal performance.

Key Properties: Alumina is known for its excellent hardness and wear resistance, with a melting point around 2050°C. It also has good chemical resistance.

Pros:

Versatile for various flooring applications.

Cons:

May require additional treatments to enhance slip resistance.

Impact on Application: Suitable for residential and light commercial flooring, alumina can be used in various settings but may not perform as well in heavy-duty applications.

Considerations for International Buyers: Buyers should evaluate the specific performance requirements of their flooring applications and ensure that the alumina meets local standards for durability and safety.

| Material | Typical Use Case for Brown Fused Alumina Oxide for Flooring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brown Fused Alumina (BFA) | High-traffic industrial and commercial flooring | Extremely durable and long-lasting | Higher initial cost | Medium |

| Silicon Carbide (SiC) | High-temperature environments (e.g., kitchens, foundries) | Excellent thermal resistance | More brittle, risk of chipping | High |

| Aluminum Oxide (Alumina) | Residential and light commercial flooring | Cost-effective and widely available | Lower hardness compared to BFA and SiC | Low |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding the use of brown fused alumina oxide in flooring applications, considering both performance and compliance with local standards.

The manufacturing process of brown fused alumina oxide, particularly for flooring applications, involves several critical stages that ensure the final product meets the necessary quality and performance standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing this material.

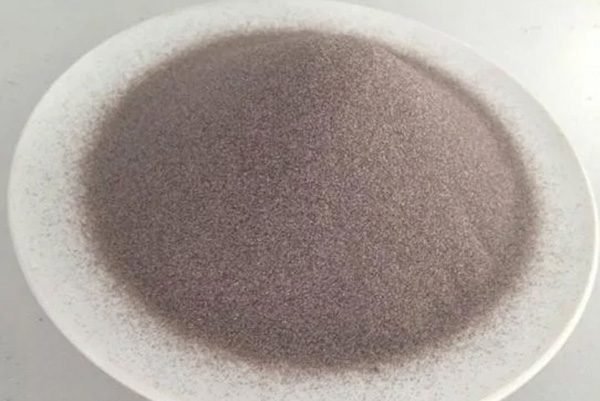

A stock image related to brown fused alumina oxide for flooring.

The first stage involves sourcing high-quality raw materials, mainly bauxite, which is rich in aluminum oxide. The bauxite is crushed and refined to remove impurities. This preparation is crucial as it directly affects the properties of the final product. Additionally, additives may be included to enhance specific characteristics, such as hardness and durability.

Once the materials are prepared, they undergo a forming process. This typically involves mixing the raw materials with a binding agent and pressing them into molds. The pressing process can vary based on the desired shape and size of the final product. The use of advanced techniques such as isostatic pressing can improve density and uniformity, which are essential for flooring applications.

After forming, the products are subjected to high-temperature firing in electric arc furnaces. This stage is crucial for achieving the desired hardness and strength. The firing temperature can range between 1,700°C and 2,000°C, allowing for the crystallization of aluminum oxide. The firing time and temperature must be carefully controlled to ensure consistency in quality.

The final stage in the manufacturing process is finishing, which involves grinding and sizing the fused alumina to meet specific dimensional requirements. This process may also include surface treatments to enhance slip resistance and aesthetic appeal. The finished product is then packaged for shipment.

Quality assurance is critical in ensuring that brown fused alumina oxide meets international standards and customer specifications. This is particularly important for B2B buyers in diverse markets like Africa, South America, the Middle East, and Europe.

Compliance with international standards such as ISO 9001 is essential for manufacturers of brown fused alumina oxide. ISO 9001 focuses on quality management systems and ensures that companies consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications like CE marking in Europe and API standards in the oil and gas sector may be relevant depending on the end-use application.

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. It ensures that all materials meet predetermined specifications before processing begins.

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed at various stages to monitor parameters like temperature, pressure, and material consistency. This helps in identifying any deviations early in the process.

Final Quality Control (FQC): Once the manufacturing process is complete, a thorough inspection is conducted on the finished products. This includes dimensional checks, visual inspections, and performance testing to ensure that the products meet the required standards.

To verify the quality and performance of brown fused alumina oxide, several testing methods are commonly employed:

Hardness Testing: This assesses the material's resistance to wear and abrasion, crucial for flooring applications. Mohs hardness tests or Vickers hardness tests can be used.

Chemical Composition Analysis: Spectroscopic methods such as X-ray fluorescence (XRF) are used to determine the chemical composition of the material, ensuring it meets industry specifications.

Microstructure Analysis: Microscopic examinations can reveal important characteristics of the fused alumina, such as grain structure and porosity, which influence performance.

Slip Resistance Testing: For flooring applications, testing for slip resistance is essential to ensure safety. The coefficient of friction is typically measured using standardized testing methods.

B2B buyers must conduct due diligence to ensure that their suppliers maintain robust quality control practices. Here are some actionable steps:

Supplier Audits: Conduct regular audits of the supplier's manufacturing facility to assess compliance with international standards and internal quality control processes. This can provide insights into their operational practices and quality assurance measures.

Requesting Quality Reports: Buyers should request detailed quality reports from suppliers, including results from IQC, IPQC, and FQC checks. This documentation can help verify that the supplier adheres to their stated quality protocols.

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the supplier's processes and products can add an additional layer of assurance. These agencies can provide unbiased assessments of the supplier's quality control measures.

Understanding the nuances of quality control and certification is vital for international B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

Cultural and Regional Standards: Different regions may have varying quality standards and regulations. Buyers must familiarize themselves with these differences to ensure compliance.

Certification Validity: When reviewing certifications, buyers should confirm their validity and relevance to the specific products being sourced. Some certifications may be recognized globally, while others may be region-specific.

Language Barriers: Documentation and reports may be in different languages, creating potential misunderstandings. Buyers should ensure that they have access to accurate translations or work with suppliers who can provide clear communication.

By understanding the manufacturing processes and quality assurance measures for brown fused alumina oxide, B2B buyers can make informed decisions that align with their quality requirements and industry standards. This knowledge not only aids in selecting reliable suppliers but also enhances the overall quality of flooring products in their respective markets.

This guide provides a structured approach for B2B buyers looking to source brown fused alumina oxide for flooring applications. With this checklist, buyers can ensure they make informed decisions while navigating the complexities of international procurement.

Establishing clear technical specifications is the foundation of a successful procurement process. Understand the required grade, grain size, and purity levels of brown fused alumina oxide that best meet your flooring application needs. This clarity helps in narrowing down suppliers who can meet these precise requirements.

Engage in thorough market research to identify potential suppliers and understand pricing structures. This step is crucial to gain insights into the competitive landscape and to find suppliers who can meet your quality and budget expectations.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don't just rely on their website; conduct a deeper investigation into their capabilities and reputation.

Always request samples before placing a large order. This step allows you to assess the quality of the brown fused alumina oxide firsthand and determine if it meets your specifications.

Once you have identified a suitable supplier, engage in negotiations to finalize terms and pricing. This step is vital to secure favorable conditions that align with your budget and project timelines.

Before finalizing your order, ensure that logistics and compliance aspects are well understood. This step is crucial for international buyers who may face additional regulations and shipping considerations.

After placing your order, maintain communication with the supplier to monitor their performance. This ongoing relationship is crucial for future procurement needs and to ensure that the product quality meets your expectations.

By following this structured checklist, international B2B buyers can streamline their sourcing process for brown fused alumina oxide, ensuring they select the best suppliers to meet their flooring needs.

When sourcing brown fused alumina oxide for flooring, understanding the cost structure is critical. The primary components include:

Materials: The raw materials used in the production of brown fused alumina oxide significantly impact pricing. The quality and availability of aluminum oxide, as well as any additional materials required for specific applications, can fluctuate based on market conditions and sourcing regions.

Labor: Labor costs vary by region and can influence the overall price. In countries with higher labor costs, such as those in Europe, the manufacturing price will be higher than in regions with lower labor costs, such as parts of Africa or South America.

Manufacturing Overhead: This includes the indirect costs of production, such as utilities, maintenance, and factory rent. Efficient manufacturing processes can help reduce these costs, which can be a negotiating point when dealing with suppliers.

Tooling: Costs associated with the machinery and tools used in production. Custom tooling may be necessary for specific orders, which can drive up initial costs but may lead to lower per-unit costs for larger orders.

Quality Control (QC): Implementing strict quality control measures ensures the product meets international standards, especially for flooring applications. QC costs should be factored into the total cost, as they help prevent defects and ensure customer satisfaction.

Logistics: Shipping costs, including freight, customs, and insurance, can vary significantly based on distance and shipping methods. Understanding Incoterms is essential for determining who bears these costs.

Margin: Finally, the supplier's profit margin influences the final price. It’s important to evaluate how much markup is reasonable based on the supplier's costs and market standards.

Several factors can influence the pricing of brown fused alumina oxide, particularly for international B2B buyers:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating bulk discounts or exploring group purchasing options.

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized production processes or materials. Clearly defining requirements upfront can help manage costs.

Quality and Certifications: Products that meet higher quality standards or possess specific certifications (e.g., ISO, CE) may command higher prices. Buyers should assess whether the added cost aligns with their project needs.

Supplier Factors: The reputation, reliability, and financial stability of suppliers can impact pricing. Established suppliers may charge a premium for their assurance of quality and service.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial as they define the responsibilities of buyers and sellers in shipping arrangements. This can significantly affect the total landed cost of the product.

To maximize cost-efficiency when sourcing brown fused alumina oxide, consider the following strategies:

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Flexibility on both sides can lead to better terms.

Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price. Consider logistics, storage, and potential rework costs. A lower purchase price may not always equate to a better deal if TCO is higher.

Research Market Trends: Stay informed about market trends and commodity prices. This knowledge can empower you to negotiate better prices based on current market conditions.

Build Long-term Relationships: Establishing strong relationships with reliable suppliers can lead to better pricing, priority service, and more favorable terms in the long run.

Consider Regional Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing locally can reduce shipping costs and lead times, making the overall procurement process more efficient.

Prices for brown fused alumina oxide can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and consult multiple suppliers to obtain the most accurate and competitive pricing information.

When considering flooring solutions, it's essential to explore various alternatives to brown fused alumina oxide. This analysis focuses on comparing brown fused alumina oxide with two viable alternatives: epoxy flooring and polished concrete. Each option has distinct characteristics that cater to different industrial needs, especially for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Brown Fused Alumina Oxide For Flooring | Epoxy Flooring | Polished Concrete |

|---|---|---|---|

| Performance | High abrasion resistance, long-lasting | Durable, chemical resistant | High durability, low maintenance |

| Cost | Moderate to high | Moderate to high | Low to moderate |

| Ease of Implementation | Requires skilled labor | Relatively easy to install | Labor-intensive preparation |

| Maintenance | Minimal maintenance needed | Requires periodic resealing | Very low maintenance |

| Best Use Case | Heavy industrial environments | Warehouses, commercial spaces | Retail spaces, residential areas |

Epoxy Flooring is a popular choice for industrial and commercial spaces due to its durability and resistance to chemicals. It provides a seamless finish that can withstand heavy foot traffic and impacts. However, while the installation process is relatively straightforward, it requires careful preparation of the substrate. Additionally, epoxy flooring can be more expensive than brown fused alumina oxide, particularly for high-grade formulations. Its maintenance involves periodic resealing, which may add to long-term costs.

Polished Concrete is another alternative that has gained traction for its aesthetic appeal and durability. It is cost-effective, particularly for large areas, and requires minimal maintenance once installed. However, the installation process can be labor-intensive, requiring specialized equipment and skilled labor to achieve a high-quality finish. Polished concrete is less resistant to chemicals compared to epoxy and brown fused alumina oxide, making it less suitable for environments with heavy chemical exposure. Nonetheless, it works well in retail and residential spaces, providing a stylish and modern look.

Choosing the right flooring solution hinges on evaluating specific requirements such as performance, cost, and maintenance. Brown fused alumina oxide is ideal for heavy-duty industrial applications where durability and resistance to wear are paramount. In contrast, epoxy flooring is better suited for environments that require chemical resistance and a seamless finish, while polished concrete offers an attractive, low-maintenance option for commercial and residential settings. B2B buyers should assess their unique needs, including the environment, budget constraints, and aesthetic preferences, to make an informed decision that aligns with their operational goals.

Brown fused alumina oxide is a critical material in the flooring industry, known for its exceptional hardness and durability. Understanding its technical properties is essential for B2B buyers, especially when making informed decisions about procurement and application.

Material grade refers to the specific classification of brown fused alumina based on its chemical composition and performance characteristics. Common grades include A, B, and C, with grade A being the highest quality. For flooring applications, a higher grade ensures better wear resistance and longevity, making it crucial for high-traffic areas. Buyers should consider the grade that aligns with their flooring needs to maximize durability.

The particle size distribution of brown fused alumina affects the finish and texture of the flooring. It is typically measured in microns, and a well-defined distribution is essential for achieving the desired surface quality. For example, finer particles create a smoother finish, while coarser particles enhance slip resistance. Selecting the right particle size is vital for meeting aesthetic and functional requirements.

Hardness is a critical property measured on the Mohs scale, which rates materials from 1 (talc) to 10 (diamond). Brown fused alumina typically scores around 9 on this scale, indicating its high resistance to wear and scratching. This property is particularly important for flooring in commercial and industrial settings, where durability is paramount. Buyers should prioritize hardness when evaluating materials for long-term use.

Tolerance levels refer to the acceptable variation in the dimensions and properties of brown fused alumina particles. Tight tolerances ensure consistency in application, which is especially important for flooring installations. Buyers should seek suppliers who provide detailed tolerance specifications to ensure compatibility with their manufacturing processes.

Bulk density indicates how much material can be packed into a given volume, influencing both transportation and application efficiency. A higher bulk density typically means lower shipping costs and less material waste during application. Buyers should assess bulk density to optimize logistics and ensure cost-effectiveness.

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions involving brown fused alumina oxide.

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of brown fused alumina oxide, buyers should identify OEMs that meet their specific requirements for flooring applications. This understanding helps in establishing partnerships with suppliers who can provide tailored solutions.

MOQ is the minimum quantity of a product that a supplier is willing to sell. For brown fused alumina oxide, MOQs can vary significantly between suppliers. Buyers should negotiate MOQs that align with their production needs to avoid overstocking or production delays.

An RFQ is a formal document issued by buyers to suppliers requesting pricing and terms for specific products. When sourcing brown fused alumina oxide, submitting an RFQ allows buyers to compare offers from multiple suppliers, ensuring they secure the best pricing and terms for their flooring projects.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers clarify who is responsible for shipping, insurance, and tariffs when importing brown fused alumina oxide. Familiarity with Incoterms is essential for avoiding unexpected costs and ensuring smooth logistics.

Lead time refers to the amount of time it takes from placing an order to receiving the product. For brown fused alumina oxide, lead times can vary based on supplier location and production capacity. Buyers should inquire about lead times during negotiations to ensure timely delivery for their flooring projects.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing brown fused alumina oxide for flooring applications. This knowledge not only aids in procurement but also enhances overall project efficiency and success.

The brown fused alumina oxide market is experiencing significant growth, driven by increasing demand for high-performance flooring materials across various sectors, including construction, automotive, and manufacturing. This growth is particularly pronounced in emerging markets in Africa, South America, the Middle East, and Europe, where infrastructural developments are ramping up. The global shift towards sustainable and eco-friendly construction practices is also influencing sourcing trends, as buyers seek materials that not only perform well but also align with environmental standards.

Technological advancements in manufacturing processes are allowing suppliers to offer innovative products that enhance the durability and aesthetic appeal of flooring. For example, the integration of digital technologies in production is leading to enhanced quality control and customization options. Additionally, the rise of online sourcing platforms is transforming the way international B2B buyers engage with suppliers, making it easier to compare products and prices from different regions, including key markets like Thailand and Italy.

Another notable trend is the increasing focus on regional sourcing to mitigate risks associated with global supply chains. This shift is prompting buyers to explore local suppliers in their respective regions, fostering partnerships that can lead to more reliable and cost-effective procurement strategies.

Sustainability is becoming a cornerstone of the brown fused alumina oxide industry, influencing not only product development but also sourcing decisions among B2B buyers. The environmental impact of alumina production, which can involve significant energy consumption and emissions, is prompting companies to seek suppliers who prioritize sustainable practices. Buyers are increasingly looking for certifications that indicate adherence to environmental standards, such as ISO 14001, which focuses on effective environmental management systems.

Moreover, ethical sourcing practices are gaining traction, with companies aiming to ensure that their supply chains are free from human rights abuses and that they support local communities. This trend is particularly important for buyers in regions like Africa and South America, where social responsibility can greatly enhance brand reputation and consumer trust. As a result, suppliers who can demonstrate their commitment to sustainability and ethical practices are likely to gain a competitive edge in the market.

The brown fused alumina oxide industry has evolved significantly over the past few decades. Initially, the focus was primarily on its application in abrasives and refractories. However, as the demand for high-performance flooring materials surged, manufacturers began to explore new applications for brown fused alumina oxide in flooring solutions. This evolution has been marked by technological advancements that have improved the material's strength and aesthetic qualities, allowing it to compete effectively against traditional flooring options.

Over the years, the industry has also seen a shift towards more sustainable practices, reflecting broader trends in the construction sector. This transition is not only driven by regulatory pressures but also by increasing consumer awareness regarding environmental issues. As a result, the brown fused alumina oxide market is poised for continued growth, with innovations that align with sustainability goals expected to shape its future trajectory.

How do I choose the right supplier for brown fused alumina oxide for flooring?

Selecting the right supplier involves assessing their industry experience, reputation, and product quality. Look for suppliers who specialize in brown fused alumina oxide and have a proven track record in flooring applications. Request samples to evaluate the quality and performance of their products. Additionally, check for certifications and compliance with international standards, as this will ensure you are sourcing materials that meet your specific requirements.

What are the key specifications to consider when sourcing brown fused alumina oxide?

When sourcing brown fused alumina oxide, consider specifications such as grain size, purity level, and hardness. The grain size impacts the finish of the flooring, while purity levels influence durability and performance. Hardness is crucial for ensuring the material withstands wear and tear. Additionally, inquire about the material’s application suitability, whether for industrial or residential flooring, to ensure it meets your needs.

What is the minimum order quantity (MOQ) for brown fused alumina oxide?

Minimum order quantities for brown fused alumina oxide can vary significantly by supplier and region. Generally, MOQs range from 1 ton to several tons, depending on the supplier's production capacity and inventory policies. It's advisable to discuss your specific requirements with potential suppliers and negotiate MOQs that align with your project needs. Some suppliers may offer flexibility for first-time buyers or bulk orders.

What payment terms should I expect when sourcing internationally?

International payment terms can vary widely, but common practices include letters of credit, wire transfers, and PayPal. Many suppliers require a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Discuss payment options early in the negotiation process to ensure that terms are agreeable and that you are protected against potential risks associated with international transactions.

How can I ensure quality assurance when purchasing brown fused alumina oxide?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Inquire about their quality control processes, including testing methods and frequency. It’s beneficial to establish a quality assurance agreement that outlines the standards the products must meet. Additionally, consider third-party inspections before shipment to verify that the product aligns with your requirements.

What logistics considerations should I keep in mind when importing brown fused alumina oxide?

Logistics is critical when importing brown fused alumina oxide. Consider factors such as shipping methods, lead times, and customs clearance processes. Determine the best shipping route and method (e.g., sea freight or air freight) based on your urgency and budget. Additionally, ensure that you have the necessary documentation for customs clearance to avoid delays and additional costs.

Can I customize brown fused alumina oxide for specific flooring applications?

Yes, many suppliers offer customization options for brown fused alumina oxide, allowing you to specify grain size, blend ratios, and even packaging requirements. Discuss your specific application needs with the supplier to determine the best formulation for your project. Customization can enhance the performance and aesthetic appeal of your flooring, so it's worth exploring these options.

What are the best practices for maintaining brown fused alumina oxide flooring?

Maintaining brown fused alumina oxide flooring involves regular cleaning and periodic inspections for wear. Use a damp mop or vacuum to remove dirt and debris, and avoid harsh chemicals that can damage the surface. Implement a maintenance schedule to address any wear issues promptly, and consider applying a sealant to enhance durability and longevity. Regular maintenance will ensure that your flooring remains in optimal condition.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

As we conclude this comprehensive guide on brown fused alumina oxide for flooring, it is essential to recognize the strategic advantages of informed sourcing decisions. B2B buyers across Africa, South America, the Middle East, and Europe should focus on establishing relationships with reliable suppliers who can ensure consistent quality and competitive pricing. Understanding the specific requirements of your flooring applications—be it durability, slip resistance, or aesthetic appeal—will enhance your procurement strategy.

Strategic sourcing not only reduces costs but also fosters innovation and sustainability within your supply chain. By leveraging market insights and trends, buyers can anticipate shifts in demand and adapt their sourcing strategies accordingly. Engaging with suppliers who prioritize ethical practices and environmental responsibility can further elevate your brand's reputation in an increasingly conscious market.

Looking ahead, the market for brown fused alumina oxide is poised for growth as industries seek advanced materials for flooring applications. We encourage international buyers to remain proactive in their sourcing efforts, exploring new suppliers and technologies that enhance performance and efficiency. Embrace the opportunity to differentiate your offerings and solidify your position in a competitive landscape. Start your sourcing journey today, and unlock the potential of brown fused alumina oxide for your flooring solutions.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina