Navigating the complexities of sourcing advanced ceramics can present significant challenges for international B2B buyers, especially those based in Africa, South America, the Middle East, and Europe. The diverse applications of ceramica avanzada—from aerospace to biomedical engineering—require buyers to have a deep understanding of material properties, supplier capabilities, and market trends. This guide is designed to empower you with the knowledge needed to make informed purchasing decisions.

In the following sections, we will delve into various types of advanced ceramics, their specific applications, and critical factors to consider when vetting suppliers. You will learn about cost structures, quality standards, and the latest innovations in the field. By equipping yourself with this comprehensive information, you can mitigate risks associated with sourcing and ensure that your procurement processes align with your strategic goals.

This guide is particularly tailored for B2B buyers in regions like Spain and Saudi Arabia, where the demand for high-performance materials is growing. Understanding the global market landscape for ceramica avanzada will enable you to navigate supplier negotiations confidently and identify the best partners for your business needs. Whether you are looking to enhance product performance or reduce costs, this resource will serve as your essential companion in the ever-evolving world of advanced ceramics.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Advanced Structural Ceramics | High strength, thermal stability, and low porosity | Aerospace, automotive, construction | Pros: Excellent durability; Cons: High cost |

| Bioceramics | Bioactive properties, often used in medical implants | Healthcare, dental, orthopedic applications | Pros: Biocompatible; Cons: Limited mechanical strength |

| Ceramic Matrix Composites | Composite materials with ceramic matrices | Defense, aerospace, industrial applications | Pros: Lightweight and strong; Cons: Complex manufacturing |

| Porcelain Insulators | High electrical resistance, low thermal conductivity | Electrical utilities, telecommunications | Pros: Excellent insulator; Cons: Brittle nature |

| Engineered Ceramics | Tailored properties for specific applications | Electronics, energy, automotive | Pros: Customizable; Cons: Requires precise specifications |

Advanced structural ceramics are known for their exceptional strength and thermal stability, making them suitable for high-performance applications in industries such as aerospace and automotive. Their low porosity enhances durability, allowing them to withstand extreme conditions. When considering purchasing advanced structural ceramics, buyers should evaluate the specific performance requirements and be prepared for a higher upfront investment due to the advanced manufacturing processes involved.

Bioceramics are specially designed for medical applications, particularly in implants and prosthetics. Their bioactive nature allows for integration with biological tissues, which is crucial in healthcare settings. Buyers in the medical field must consider factors such as biocompatibility and regulatory compliance when sourcing bioceramics, as these materials play a critical role in patient safety and treatment efficacy.

Ceramic matrix composites combine the lightweight nature of ceramics with enhanced mechanical properties, making them ideal for defense and aerospace applications. These materials can withstand high temperatures and harsh environments, providing significant advantages over traditional materials. B2B buyers should assess the complexity of manufacturing and the associated costs when opting for ceramic matrix composites, as these factors can impact project budgets and timelines.

Porcelain insulators are critical in electrical utilities and telecommunications due to their high electrical resistance and low thermal conductivity. These characteristics ensure reliable performance in various environmental conditions. When purchasing porcelain insulators, buyers should consider the specific voltage and environmental conditions they will face, as these factors can influence the longevity and effectiveness of the insulators.

Engineered ceramics are tailored to meet specific application requirements, making them versatile for industries such as electronics and energy. Their customizable properties allow for enhanced performance in targeted applications. Buyers should focus on the precise specifications needed for their projects and the potential for innovation in engineered ceramics, which can lead to improved product performance and competitiveness in the market.

Related Video: Ikea MALM bed variations explained

| Industry/Sector | Specific Application of ceramica avanzada | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Thermal barrier coatings | Enhanced thermal resistance, reduced weight | Certification standards, supplier reliability |

| Electronics | Substrates for electronic components | Improved electrical insulation and heat dissipation | Material purity, dimensional accuracy |

| Automotive | Engine components and brake systems | Increased durability and performance | Compatibility with existing systems, cost-effectiveness |

| Medical Devices | Bioceramics for implants | Biocompatibility and longevity | Regulatory compliance, sourcing from certified suppliers |

| Energy Production | Components for nuclear reactors | High resistance to radiation and thermal stress | Quality assurance, long-term supply stability |

In the aerospace industry, advanced ceramics are primarily used for thermal barrier coatings (TBCs) on turbine blades and other high-temperature components. These coatings protect metal substrates from extreme heat and oxidation, significantly enhancing engine efficiency and longevity. For international buyers, especially in regions like Europe and the Middle East, it is crucial to ensure that suppliers meet stringent certification standards and demonstrate reliability in their delivery schedules to avoid production delays.

Advanced ceramics serve as substrates for various electronic components, including capacitors and resistors. They provide excellent electrical insulation and thermal stability, which are essential for the performance of electronic devices. Buyers from Africa and South America should prioritize material purity and dimensional accuracy when sourcing these ceramics, as variations can lead to device failure and increased production costs.

In the automotive sector, advanced ceramics are used in engine components and braking systems due to their high durability and resistance to wear. Their lightweight nature contributes to improved fuel efficiency and overall vehicle performance. B2B buyers need to consider compatibility with existing systems and the cost-effectiveness of sourcing these materials, particularly in competitive markets in Europe and South America.

Bioceramics, a subset of advanced ceramics, are increasingly used in medical implants due to their biocompatibility and longevity. These materials can integrate well with biological tissues, making them ideal for orthopedic and dental applications. Buyers must ensure that their suppliers comply with regulatory standards and are certified to provide high-quality bioceramics, which is particularly important in the Middle East and Europe, where regulatory scrutiny is high.

In energy production, advanced ceramics are critical for components in nuclear reactors, where they must withstand high levels of radiation and thermal stress. Their inherent properties provide safety and efficiency, essential for the operation of nuclear facilities. For international buyers, particularly in regions like Africa and the Middle East, sourcing from suppliers with a strong quality assurance process is vital to ensure long-term supply stability and compliance with safety regulations.

Related Video: Uses of Metals and Non Metals

The Problem:

B2B buyers often face the challenge of sourcing advanced ceramics at a cost-effective price. Many suppliers may offer high-quality materials, but the associated costs can significantly impact profit margins, especially for companies in Africa and South America where budget constraints are common. Buyers might struggle to justify the expense when lower-cost alternatives exist, even if they compromise on performance and durability.

The Solution:

To navigate this issue, buyers should focus on strategic sourcing by identifying multiple suppliers and negotiating bulk purchasing agreements. Consider exploring manufacturers that offer tiered pricing based on order volume, which can lower costs significantly. Additionally, it's essential to conduct a cost-benefit analysis that factors in the long-term savings associated with the superior performance and lifespan of advanced ceramics. Investing in materials that reduce maintenance and replacement costs can ultimately lead to better profitability. Buyers can also look for local suppliers to minimize shipping costs and lead times, which can further enhance overall value.

The Problem:

Choosing the appropriate type of advanced ceramic for specific applications can be overwhelming for B2B buyers. With various options available—such as alumina, zirconia, and silicon carbide—each with unique properties and performance characteristics, buyers may find it challenging to match the right material to their application needs. This confusion can lead to costly mistakes, including selecting a ceramic that does not meet the performance standards required for critical applications.

The Solution:

To alleviate this pain point, buyers should invest time in understanding the specific requirements of their applications, such as thermal resistance, mechanical strength, and chemical stability. Engaging with manufacturers or suppliers for technical consultations can provide valuable insights. Buyers should also utilize datasheets and case studies to evaluate how different ceramics have performed in similar applications. Creating a decision matrix that lists application requirements alongside ceramic properties can facilitate a clearer comparison. Furthermore, conducting small-scale trials or pilot projects can help in assessing the selected materials before committing to larger orders.

The Problem:

A prevalent concern among B2B buyers is ensuring the quality and consistency of advanced ceramic products. Variability in material properties can lead to unpredictable performance, impacting product reliability and customer satisfaction. This is particularly critical for industries such as aerospace and medical devices, where precision and compliance with regulatory standards are non-negotiable.

The Solution:

To address quality assurance concerns, buyers should establish a robust supplier evaluation process that includes quality certifications (like ISO 9001) and compliance with industry-specific standards. Regular audits and on-site inspections of manufacturing processes can further ensure that suppliers adhere to high-quality standards. Buyers can also request samples and perform rigorous testing on incoming materials to verify their properties against specified criteria. Building strong relationships with suppliers can facilitate better communication regarding quality expectations and enable quicker resolutions of any issues that arise. Additionally, implementing a quality management system within the purchasing process can help track and document quality metrics over time, ensuring consistent performance from advanced ceramic products.

When selecting materials for advanced ceramics, it is crucial to consider their properties, advantages, disadvantages, and the specific needs of international B2B buyers. Below, we analyze four common materials used in advanced ceramics, providing insights relevant to buyers from Africa, South America, the Middle East, and Europe.

Key Properties:

Alumina is known for its excellent hardness, high melting point (around 2050°C), and good electrical insulation properties. It exhibits strong resistance to wear and corrosion, making it suitable for various applications.

Pros & Cons:

The durability of alumina is a significant advantage, but it can be brittle under certain conditions. While the manufacturing complexity is moderate, the cost is generally low to medium, depending on purity levels. Its suitability for high-temperature applications is a major plus.

Impact on Application:

Alumina is compatible with a wide range of media, including acids and bases, making it ideal for chemical processing industries. However, its brittleness may limit its use in applications requiring high impact resistance.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Europe and the Middle East, the demand for high-purity alumina is increasing, reflecting a trend toward advanced applications.

Key Properties:

Zirconia is characterized by its exceptional toughness, high fracture toughness, and thermal stability. It can withstand temperatures up to 2700°C and is often used in applications requiring thermal insulation.

Pros & Cons:

The primary advantage of zirconia is its high resistance to cracking and thermal shock. However, it is more expensive than alumina and requires advanced manufacturing techniques, which can increase costs.

Impact on Application:

Zirconia is particularly effective in environments with high thermal and mechanical stress, making it suitable for cutting tools and dental applications. Its compatibility with various media is also a benefit.

Considerations for International Buyers:

Zirconia must meet specific standards, especially in medical applications in Europe. Buyers should be aware of the higher costs associated with zirconia and consider the long-term benefits in terms of performance.

Key Properties:

Silicon nitride is known for its high strength, excellent thermal shock resistance, and low thermal conductivity. It can operate effectively at temperatures exceeding 1400°C.

Pros & Cons:

This material is highly durable and resistant to oxidation, making it suitable for harsh environments. However, the manufacturing process can be complex and costly, which may deter some buyers.

Impact on Application:

Silicon nitride is ideal for applications in the aerospace and automotive industries, where high-performance materials are essential. Its compatibility with various media, including corrosive substances, enhances its applicability.

Considerations for International Buyers:

Buyers from regions with stringent aerospace standards, such as Europe and North America, should ensure that silicon nitride components meet relevant certifications. The cost may be a limiting factor for some businesses.

Key Properties:

Silicon carbide possesses outstanding hardness and thermal conductivity, withstanding temperatures up to 1600°C. It also has excellent wear and corrosion resistance.

Pros & Cons:

The durability and thermal stability of silicon carbide are significant advantages, particularly in high-wear applications. However, it is relatively expensive and may require specialized manufacturing techniques.

Impact on Application:

Silicon carbide is commonly used in high-performance applications, such as semiconductor devices and high-temperature gas turbines. Its compatibility with abrasive media makes it a preferred choice in many industries.

Considerations for International Buyers:

International buyers should be aware of the compliance requirements for silicon carbide in various regions. The higher cost may be justified by its performance in demanding applications.

| Material | Typical Use Case for ceramica avanzada | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina | Chemical processing, wear-resistant parts | High durability and corrosion resistance | Brittle under impact | Low |

| Zirconia | Thermal insulation, dental applications | High toughness and thermal stability | Higher cost and complexity | High |

| Silicon Nitride | Aerospace, automotive components | Excellent thermal shock resistance | Complex manufacturing process | High |

| Silicon Carbide | Semiconductor devices, gas turbines | Outstanding hardness and thermal conductivity | Relatively expensive | High |

This strategic material selection guide provides essential insights for international B2B buyers looking to make informed decisions in the advanced ceramics market. Understanding the properties, advantages, and limitations of each material is crucial for selecting the right solution for specific applications.

The manufacturing process for advanced ceramics, or "ceramica avanzada," typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for international B2B buyers looking to ensure quality and reliability in their sourcing.

Material Preparation: This initial stage involves selecting high-purity raw materials, such as alumina, zirconia, or silicon carbide. The materials are then processed to remove impurities and achieve the desired particle size through milling or grinding. The preparation phase may also include the mixing of additives to enhance specific properties, such as strength or thermal resistance.

Forming: Once the materials are prepared, they undergo a forming process, which shapes them into desired configurations. Techniques include pressing, extrusion, and casting. In pressing, powders are compacted into molds under high pressure, while extrusion involves forcing the material through a die to create continuous shapes. Casting allows for intricate designs and is often used for complex components.

Assembly: For products requiring multiple parts, assembly becomes essential. This stage may involve joining components using adhesives, sintering, or mechanical fastening. Advanced ceramics often require precise alignment to ensure optimal performance, particularly in applications like electronics or aerospace.

Finishing: The final stage focuses on achieving the required surface finish and dimensional accuracy. Techniques such as grinding, polishing, or coating are employed to enhance the properties of the ceramic, including wear resistance and aesthetic appeal. This stage is vital for ensuring that the final product meets industry standards and customer specifications.

Advanced ceramics manufacturing employs various techniques that enhance the material properties and performance of the final products:

Quality assurance (QA) is vital in the manufacturing of advanced ceramics, ensuring that products meet international and industry-specific standards. B2B buyers should be familiar with the following aspects of QA:

International Standards: Many manufacturers adhere to ISO 9001, which outlines the requirements for a quality management system. Compliance with this standard indicates a commitment to consistent quality and continuous improvement.

Industry-Specific Standards: Depending on the application, other certifications may be relevant. For instance, CE marking is essential for products sold in the European market, while API (American Petroleum Institute) standards are crucial for ceramics used in oil and gas applications.

Quality Control Checkpoints:

- Incoming Quality Control (IQC): This step involves inspecting raw materials before production begins to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and correct deviations from the set standards.

- Final Quality Control (FQC): Comprehensive testing of the finished product against quality benchmarks to confirm compliance with specifications.

Testing methods play a crucial role in verifying the quality and performance of advanced ceramics. B2B buyers should be aware of the following common testing techniques:

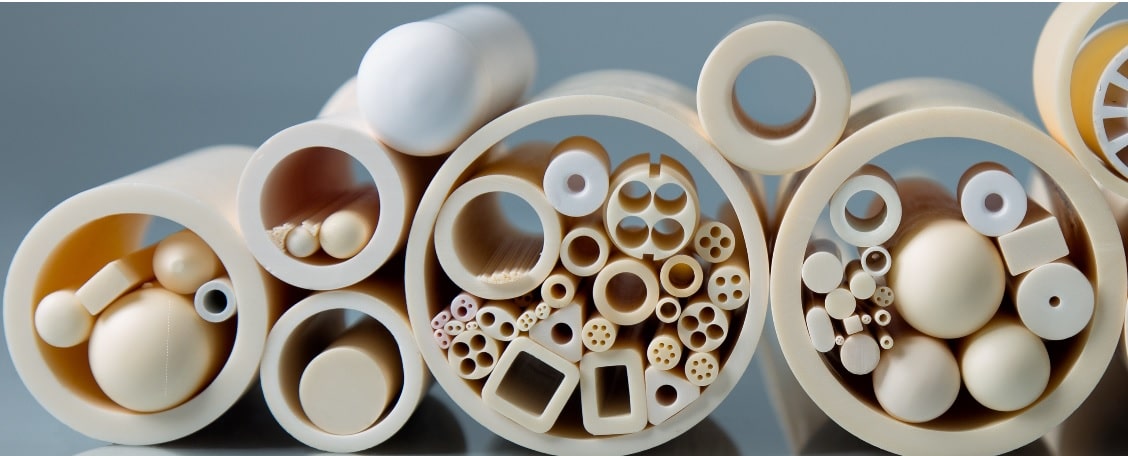

A stock image related to ceramica avanzada.

When sourcing advanced ceramics, B2B buyers must ensure that suppliers maintain rigorous quality control standards. Here are actionable steps to verify supplier QC:

Supplier Audits: Conduct regular audits of the manufacturing facilities to assess compliance with quality standards and operational practices. This on-site evaluation provides insights into the supplier's capabilities and commitment to quality.

Quality Reports: Request detailed quality reports from the supplier, including test results and compliance certifications. These documents should outline the methodologies used and the outcomes of various quality tests.

Third-Party Inspections: Engage independent third-party inspection services to evaluate the manufacturing process and final products. This external validation can provide an unbiased assessment of the supplier’s quality practices.

International B2B buyers must navigate specific quality control nuances when sourcing advanced ceramics. Consider the following:

Cultural and Regulatory Differences: Familiarize yourself with the local regulations and cultural expectations regarding product quality and safety standards in the regions you are sourcing from, such as Africa, South America, the Middle East, and Europe.

Documentation Requirements: Ensure that suppliers provide the necessary documentation to meet import regulations in your country, including compliance certificates, safety data sheets, and test reports.

Language Barriers: Be prepared to address potential language barriers that may affect communication regarding quality expectations and specifications. Engaging bilingual staff or translators can facilitate clearer discussions.

By understanding the manufacturing processes and quality assurance practices associated with advanced ceramics, B2B buyers can make informed decisions and build strong partnerships with suppliers that prioritize quality and reliability.

This practical sourcing guide aims to equip international B2B buyers with a structured approach to procure advanced ceramics ("ceramica avanzada"). With the increasing demand for high-performance materials in various industries, understanding the nuances of sourcing advanced ceramics is essential for making informed purchasing decisions.

Before initiating the procurement process, clearly outline the technical specifications for the advanced ceramics you require. This includes understanding the material properties, dimensions, tolerances, and any specific performance criteria relevant to your application.

- Key Considerations:

- Determine the intended application (e.g., aerospace, automotive, medical).

- Specify the desired mechanical and thermal properties, such as strength, temperature resistance, and chemical stability.

Identifying potential suppliers is critical in ensuring you have a diverse pool of options. Conduct thorough market research using online directories, industry publications, and trade shows relevant to advanced ceramics.

- Tips:

- Utilize platforms like LinkedIn and industry-specific forums to discover reputable suppliers.

- Attend trade fairs to meet suppliers face-to-face and evaluate their offerings.

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- What to Look For:

- Assess their production capabilities and quality control processes.

- Check for certifications such as ISO 9001 or industry-specific standards to ensure compliance.

Once you have shortlisted suppliers, request samples of the advanced ceramics. Testing these samples against your defined specifications will help validate the supplier’s claims.

- Testing Focus:

- Evaluate mechanical and thermal properties through standardized tests.

- Ensure the samples meet your quality expectations before placing larger orders.

Ensure that the suppliers adhere to international standards and regulations applicable to advanced ceramics. This is crucial to avoid compliance issues that could affect your product quality and marketability.

- Checklist:

- Confirm certifications such as REACH, RoHS, or industry-specific qualifications.

- Assess their commitment to sustainability and environmental management practices.

Once you have selected a supplier, negotiate terms that align with your business needs. This includes pricing, delivery schedules, payment terms, and warranties.

- Negotiation Points:

- Discuss bulk order discounts and lead times for production.

- Ensure clear terms regarding quality assurance and liability in case of defects.

Effective communication is vital throughout the sourcing process. Establish clear lines of communication with your chosen supplier to facilitate smooth transactions and address any concerns promptly.

- Best Practices:

- Set regular check-ins to discuss order progress and any potential issues.

- Utilize project management tools to track timelines and responsibilities.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing advanced ceramics effectively, ensuring that they procure materials that meet their technical requirements while fostering strong supplier relationships.

When sourcing ceramica avanzada, understanding the cost structure is paramount for international B2B buyers. The primary cost components include:

Several factors influence the pricing of ceramica avanzada, which international buyers must consider:

For international buyers from Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency and negotiation outcomes:

A stock image related to ceramica avanzada.

While indicative pricing can be useful, it is essential to recognize that prices for ceramica avanzada can vary widely based on the aforementioned factors. Always request detailed quotations tailored to your specific requirements to ensure accuracy and relevance in your budgeting.

In today's competitive B2B landscape, buyers are faced with a plethora of options when selecting products or solutions for their businesses. Evaluating alternatives is crucial not only to ensure cost-effectiveness but also to align with specific operational needs. This analysis focuses on comparing ceramica avanzada, a high-performance ceramic material, with two viable alternatives: metal alloys and composite materials. Each alternative offers distinct benefits and drawbacks that can significantly impact a buyer's decision-making process.

| Comparison Aspect | Ceramica Avanzada | Metal Alloys | Composite Materials |

|---|---|---|---|

| Performance | High wear resistance; excellent thermal stability | Good strength; varies with alloy | Lightweight; high strength-to-weight ratio |

| Cost | Moderate to high | Generally lower | Variable; can be high due to production methods |

| Ease of Implementation | Requires specialized handling | Easy to implement; widely available | Moderate; requires specific processes |

| Maintenance | Low maintenance; durable | Moderate maintenance required | Varies; can be prone to environmental degradation |

| Best Use Case | Aerospace, automotive, and biomedical applications | General manufacturing and construction | Aerospace, automotive, and sports equipment |

Metal alloys are often preferred for their cost-effectiveness and availability. They offer good mechanical strength and are widely used in various industries, making them easy to source and implement. However, they may not provide the same level of thermal stability and wear resistance as ceramica avanzada, especially in high-temperature applications. Maintenance can also be a concern, as metal alloys may corrode or wear down over time, leading to increased lifecycle costs.

Composite materials, known for their lightweight and high strength-to-weight ratios, are increasingly popular in industries such as aerospace and automotive. They can offer superior performance in specific applications, particularly where weight savings are critical. However, they can be expensive to produce and may require specialized handling during manufacturing and installation. Additionally, while they can be designed for high performance, some composites may be susceptible to environmental factors, impacting their long-term reliability.

When selecting between ceramica avanzada and its alternatives, B2B buyers should consider their specific operational needs, budget constraints, and performance requirements. Ceramica avanzada stands out in applications requiring high wear resistance and thermal stability, while metal alloys may be more suitable for cost-sensitive projects. Composite materials excel in scenarios where weight reduction is paramount. A thorough understanding of each option's strengths and weaknesses will empower buyers to make informed decisions that align with their strategic goals.

When engaging with advanced ceramics, understanding the critical technical properties is essential for B2B buyers. Below are some of the most significant specifications to consider:

Material grade refers to the classification of ceramics based on their composition and intended application. High-grade ceramics, for example, exhibit superior mechanical strength and thermal stability. For buyers, selecting the right grade ensures that the ceramic product meets specific performance requirements, reducing the risk of failure in demanding applications.

Tolerance indicates the permissible limits of variation in dimensions and properties of ceramic components. For example, tighter tolerances often lead to higher production costs but result in better fitting and performance in assembled systems. Understanding tolerance is crucial for buyers to ensure compatibility with existing systems and to maintain quality standards in production.

Density measures the mass per unit volume of the ceramic material and is a critical factor in determining its strength and durability. Higher density ceramics generally provide better wear resistance and thermal conductivity. B2B buyers should assess density to ensure that the selected ceramic meets the physical demands of their specific applications, such as aerospace or industrial machinery.

Fracture toughness quantifies a material's ability to resist crack propagation. In advanced ceramics, this property is vital for applications that experience mechanical stress. Understanding fracture toughness helps buyers choose materials that will perform reliably under operational loads, minimizing the risk of catastrophic failure.

Thermal conductivity measures a material's ability to conduct heat. Advanced ceramics are often used in high-temperature applications, making thermal conductivity a key consideration. B2B buyers must assess this property to ensure that the ceramic can withstand thermal stresses and maintain functionality in extreme environments.

Familiarity with industry-specific terminology enhances communication and negotiation efficiency. Here are some essential terms every B2B buyer should understand:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the ceramics industry, buyers often work with OEMs for custom ceramic components tailored to specific applications. Knowing the OEMs involved can help buyers ensure quality and compatibility with their existing systems.

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the ceramics market, understanding MOQ is vital for buyers to manage inventory effectively and negotiate better pricing. Buyers should inquire about MOQs to ensure they can meet their production needs without overcommitting resources.

An RFQ is a document used to solicit price quotes from suppliers. For buyers of advanced ceramics, issuing an RFQ can streamline the procurement process and allow for comparisons among different suppliers. Including detailed specifications in the RFQ can lead to more accurate and competitive pricing.

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand costs related to shipping, insurance, and risk transfer. For instance, terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) can significantly impact total procurement costs.

Lead time refers to the time taken from placing an order to delivery. In the advanced ceramics sector, lead times can vary widely based on production methods and supply chain dynamics. Buyers should factor in lead times when planning projects to avoid delays and ensure timely product availability.

Understanding these essential properties and trade terminologies will empower B2B buyers to make informed decisions when sourcing advanced ceramics, ultimately leading to more successful business transactions.

The ceramica avanzada sector is experiencing significant transformation driven by technological advancements and evolving buyer preferences. Key global drivers include the increasing demand for high-performance materials across various industries, such as construction, aerospace, and healthcare. Innovations in manufacturing processes, such as additive manufacturing and advanced glazing techniques, are also reshaping the market, enabling the production of customized and complex ceramic components.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. Emerging trends in sourcing indicate a shift towards digital procurement platforms that streamline the purchasing process, offering enhanced transparency and efficiency. Buyers are increasingly leveraging data analytics to assess supplier performance and material quality, ensuring they partner with reliable manufacturers.

Furthermore, the rise of e-commerce in B2B transactions is facilitating easier access to a wider range of suppliers and products. This trend is particularly beneficial for buyers in emerging markets who may have previously faced barriers to entry. As sustainability becomes a priority, manufacturers are also adapting their operations to meet the growing demand for eco-friendly products, which is becoming a decisive factor in sourcing decisions.

Sustainability is not just a buzzword; it has become a critical factor in the ceramica avanzada sector. The environmental impact of ceramic production, including energy consumption and waste generation, necessitates a focus on sustainable practices. B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to reducing their carbon footprint and implementing eco-friendly production methods.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are free from exploitation and environmental harm. Certification schemes such as ISO 14001 for environmental management and LEED for green building materials are gaining traction among manufacturers. These certifications not only validate a company’s commitment to sustainability but also provide buyers with confidence that they are sourcing responsibly.

Incorporating 'green' materials, such as recycled ceramics and eco-friendly glazes, into product offerings can significantly enhance a company's market appeal. Buyers are advised to engage with suppliers who prioritize sustainable practices, as this alignment can lead to improved brand reputation and customer loyalty.

The evolution of the ceramica avanzada sector can be traced back to ancient civilizations that utilized clay for pottery and building materials. Over time, advancements in materials science and engineering have transformed ceramics into high-tech materials used in various applications, from electronics to biomedical devices.

In recent decades, the sector has witnessed a surge in research and development, particularly in the realm of advanced ceramics. This has led to the creation of materials with enhanced properties, such as high thermal resistance and durability, making them suitable for modern industrial applications. The historical context underscores the importance of innovation in driving the future of ceramica avanzada, presenting significant opportunities for international B2B buyers to leverage advanced materials in their respective industries.

By understanding these dynamics, buyers can navigate the complexities of sourcing in the ceramica avanzada sector effectively, ensuring they make informed decisions that align with their business objectives and sustainability goals.

What is the best type of ceramica avanzada for industrial applications?

The best type of ceramica avanzada for industrial applications largely depends on the specific use case. For high-temperature environments, consider advanced ceramic materials like alumina or zirconia, known for their thermal stability and strength. In applications requiring electrical insulation, materials like silicon nitride are preferred. Evaluate the mechanical and chemical properties to ensure compatibility with your operational needs.

What are the typical minimum order quantities (MOQ) for ceramica avanzada?

Minimum order quantities (MOQ) for ceramica avanzada can vary significantly by supplier and product type. Generally, MOQs range from 50 to 1,000 units, depending on the complexity and manufacturing processes involved. It’s advisable to discuss your needs directly with suppliers, as they may be flexible for first-time buyers or larger contracts. Understanding MOQs is crucial for budgeting and inventory planning.

What payment terms should I expect when sourcing ceramica avanzada internationally?

Payment terms for international transactions typically include options such as Letter of Credit (LC), advance payment, or open account terms. Most suppliers may request a deposit of 30% to 50% upfront, with the balance due upon shipment or receipt. Negotiate terms that align with your cash flow capabilities while ensuring supplier security. Familiarize yourself with trade finance options available in your region to facilitate smoother transactions.

How can I ensure quality assurance for ceramica avanzada products?

To ensure quality assurance for ceramica avanzada products, establish clear specifications and standards with your suppliers before production begins. Request certificates of analysis and conduct regular quality inspections during manufacturing. Utilizing third-party inspection services can also provide unbiased evaluations of product quality. Additionally, consider implementing a return policy for defective items, ensuring accountability on the supplier's part.

What logistics considerations should I keep in mind when importing ceramica avanzada?

Logistics for importing ceramica avanzada involve assessing shipping methods, customs regulations, and delivery timelines. Choose between air or sea freight based on urgency and cost-effectiveness. Be aware of import duties and tariffs specific to your country; consulting a customs broker can simplify this process. Additionally, ensure proper packaging to avoid damage during transit, which is crucial for fragile ceramic materials.

How can I customize ceramica avanzada products for my specific needs?

Customization of ceramica avanzada can often be arranged through direct communication with your supplier. Discuss your specific requirements, such as size, shape, and material properties. Some manufacturers may offer design services or collaborate on prototypes before full production. Be prepared to provide detailed specifications and consider lead times for custom orders, as these can significantly extend delivery schedules.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the evolving landscape of ceramica avanzada, strategic sourcing emerges as a pivotal process for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By prioritizing quality suppliers who emphasize sustainability and innovation, businesses can enhance their competitive edge while meeting the increasing demand for advanced ceramic materials. Establishing robust supplier relationships not only mitigates risks but also fosters collaboration on research and development, ultimately leading to better product offerings.

As we look ahead, the importance of agility in sourcing strategies cannot be overstated. Buyers should remain vigilant to market trends and technological advancements that influence ceramica avanzada. Engaging in continuous market analysis and leveraging digital tools can facilitate more informed sourcing decisions, allowing businesses to adapt swiftly to changing consumer needs.

International B2B buyers are encouraged to take proactive steps in their sourcing strategies today. By identifying potential partners in emerging markets, investing in local supplier development, and embracing innovative sourcing technologies, companies can position themselves for sustainable growth. The time to act is now—capitalize on the opportunities within the ceramica avanzada sector to drive your business forward.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina