Navigating the complexities of the global market for carbides can be a daunting challenge for international B2B buyers, especially when sourcing high-quality materials that meet specific application requirements. Carbides are critical components in various industries, including manufacturing, aerospace, and construction, where durability and performance are paramount. This guide aims to demystify the definition of carbides, providing a comprehensive overview of their types, applications, and sourcing strategies, essential for informed purchasing decisions.

International buyers from regions such as Africa, South America, the Middle East, and Europe—particularly countries like Argentina and Italy—face unique challenges in sourcing carbides. Factors such as fluctuating market prices, varying quality standards, and the need for reliable supplier vetting can complicate the procurement process. This guide will explore different carbide types, their specific industrial applications, and the criteria for selecting trustworthy suppliers. Additionally, it will delve into cost considerations, helping buyers understand the financial implications of their sourcing decisions.

By equipping B2B buyers with actionable insights and practical strategies, this guide empowers them to navigate the global market effectively. Whether you're looking to enhance product quality or optimize supply chain efficiency, understanding the intricacies of carbide sourcing will ultimately lead to better business outcomes and competitive advantages in your respective markets.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tungsten Carbide | High hardness, excellent wear resistance | Cutting tools, mining equipment | Pros: Long lifespan, superior performance. Cons: Higher cost compared to other carbides. |

| Silicon Carbide | High thermal conductivity, chemical resistance | Semiconductor manufacturing, abrasives | Pros: Effective in high-temperature applications. Cons: More brittle than other types. |

| Titanium Carbide | Lightweight, good hardness, and high melting point | Coatings for cutting tools | Pros: Reduces tool wear, enhances performance. Cons: Requires careful handling during machining. |

| Boron Carbide | Extremely hard, low density, and high chemical stability | Armor materials, abrasives | Pros: Excellent for lightweight armor solutions. Cons: Limited availability and higher costs. |

| Calcium Carbide | Reacts vigorously with water, produces acetylene gas | Welding, carbide lamps | Pros: Useful for specific chemical reactions. Cons: Safety concerns during handling and storage. |

Tungsten carbide is renowned for its exceptional hardness and wear resistance, making it ideal for applications requiring durability, such as cutting tools and mining equipment. Its ability to withstand high temperatures and pressures makes it a favorite in heavy industries. For B2B buyers, investing in tungsten carbide tools can lead to reduced downtime and lower replacement costs, although it comes at a premium price.

Silicon carbide is characterized by its excellent thermal conductivity and chemical resistance, making it suitable for high-temperature applications and semiconductor manufacturing. Its robustness allows it to be utilized in abrasives, offering a longer lifespan compared to traditional materials. Buyers should consider the brittleness of silicon carbide, which may affect its performance in certain applications, particularly where shock resistance is required.

Titanium carbide is lightweight yet offers good hardness and a high melting point, making it an ideal material for coatings on cutting tools. It enhances tool performance by reducing wear and extending operational life. B2B buyers should be aware of the handling requirements during machining, as improper techniques can lead to damage. However, its benefits often outweigh the risks when used correctly.

Boron carbide is one of the hardest materials available, providing excellent performance in armor applications while maintaining a low density. This characteristic makes it particularly valuable in military and personal protective equipment. For B2B buyers, the main considerations include the availability of boron carbide and its higher costs, which may affect budget constraints.

Calcium carbide is notable for its reactivity, especially with water, producing acetylene gas. It has specific applications in welding and carbide lamps, providing essential chemical reactions in these processes. However, buyers must be cautious about safety concerns during handling and storage, as improper management can lead to hazardous situations. Understanding these risks is crucial for companies looking to integrate calcium carbide into their operations.

Related Video: Metal Carbides , Types of carbides (1) Ionic carbides (2) Covalent carbides(3)Interstitial carbides

| Industry/Sector | Specific Application of carbides definition | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Cutting tools for mineral extraction | Enhanced efficiency and reduced operational costs | Quality of carbide material, supplier reliability |

| Manufacturing | Wear-resistant components in machinery | Increased durability and reduced downtime | Customization options, compliance with industry standards |

| Aerospace | Engine components and turbine blades | Improved performance and fuel efficiency | Certification of materials, traceability |

| Construction | Drill bits and concrete cutting tools | Faster project completion and lower labor costs | Availability of specific grades, local vs. international sourcing |

| Oil & Gas | Components for drilling and extraction equipment | Enhanced performance in harsh environments | Supplier expertise in high-stress applications |

In the mining sector, carbides are primarily utilized in cutting tools designed for mineral extraction. These tools are engineered to withstand extreme wear and tear, significantly enhancing operational efficiency. For international buyers, particularly in Africa and South America, sourcing high-quality carbide tools can lead to reduced operational costs and improved productivity. Key considerations include the hardness and toughness of the carbide grades, as well as the supplier's ability to provide timely deliveries to remote locations.

Carbides are essential in manufacturing for their role in producing wear-resistant components such as dies, molds, and cutting tools. These materials help businesses achieve increased durability and minimize downtime due to equipment failure. Buyers from Europe and the Middle East should focus on suppliers who offer customization options to meet specific operational needs. Compliance with international industry standards is also crucial for ensuring product reliability and performance.

In the aerospace industry, carbides are used in critical components such as engine parts and turbine blades. The superior strength and thermal resistance of carbide materials contribute to enhanced performance and fuel efficiency, which are vital in this sector. International buyers must ensure that materials sourced comply with rigorous certification processes and traceability requirements. This is especially important for companies operating in Europe, where regulatory standards are stringent.

Carbides are extensively used in the construction industry for manufacturing drill bits and concrete cutting tools. These tools allow for faster project completion and lower labor costs, making them invaluable for contractors. Buyers should consider the availability of specific carbide grades that meet their project requirements. Additionally, they should weigh the benefits of sourcing locally versus internationally, especially in regions like Africa where logistics can impact project timelines.

A stock image related to carbides definition.

In the oil and gas sector, carbides are critical for producing components used in drilling and extraction equipment. Their ability to perform in harsh environments ensures reliability and efficiency, which are essential for maintaining production levels. Buyers should prioritize suppliers with expertise in high-stress applications, as well as those who can demonstrate a strong track record in the industry. Understanding the specific requirements for carbide grades that can withstand extreme conditions is crucial for successful sourcing.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem: Many B2B buyers, particularly those in manufacturing sectors in Africa and South America, struggle with the fundamental understanding of carbides. The confusion surrounding what carbides are, their properties, and their applications can lead to misinformed purchasing decisions. For instance, a buyer may not fully appreciate the difference between tungsten carbide and silicon carbide, resulting in selecting the wrong material for a specific application, which can lead to inefficiencies and increased costs.

The Solution: To mitigate this issue, buyers should engage in comprehensive training or workshops focused on materials science. Understanding the various types of carbides, their unique properties, and the best applications for each can significantly enhance decision-making. Additionally, creating a detailed specification sheet for each carbide type can aid in making informed choices. Buyers should consult with material experts or manufacturers who can provide insights tailored to their specific industry needs, thereby ensuring they select the right carbide for their applications.

The Problem: International B2B buyers often face challenges in sourcing high-quality carbides, particularly when dealing with suppliers from different regions like the Middle East or Europe. Issues such as varying quality standards, lack of transparency in sourcing processes, and the presence of counterfeit materials can severely affect product quality and business reputation. A buyer may receive a batch of carbide tools that are subpar, leading to tool failures and project delays.

The Solution: To ensure product integrity, buyers should prioritize sourcing from reputable manufacturers with a proven track record. Conducting thorough due diligence, including checking certifications and quality assurance processes, is crucial. Implementing a robust supplier evaluation process that includes on-site audits and requesting product samples for testing can further guarantee quality. Buyers can also leverage technology by using blockchain for traceability in the supply chain, ensuring the authenticity and quality of the carbides procured.

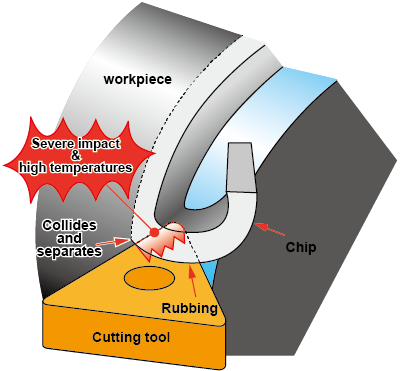

The Problem: A common pain point for B2B buyers is the inefficient use of carbides in their manufacturing processes. Many buyers do not fully understand how to optimize carbide tools for maximum performance, leading to premature wear and increased operational costs. For example, a manufacturing plant might use carbide tools at incorrect speeds or feeds, resulting in excessive tool wear, downtime, and wasted materials.

The Solution: To avoid costly mistakes, buyers should invest in training for their operational teams focusing on the best practices for carbide usage. This can include understanding optimal cutting speeds, feed rates, and the right coolant types. Collaborating with carbide manufacturers to gain insights into tool design and usage can also provide significant benefits. Additionally, establishing a feedback loop where operators can report tool performance can help in continuously optimizing processes and preventing recurring issues related to carbide use. Regularly reviewing and adjusting operational parameters based on real-time data can lead to improved efficiency and cost savings.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their understanding and effective use of carbides, ultimately leading to better procurement decisions and improved operational efficiency.

Carbides are compounds formed between carbon and a more electropositive element, typically metals. They are renowned for their hardness and thermal stability, making them suitable for various industrial applications. Below, we analyze four common carbide materials: Tungsten Carbide, Silicon Carbide, Titanium Carbide, and Boron Carbide, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Key Properties:

Tungsten carbide (WC) is characterized by its exceptional hardness (around 9 on the Mohs scale) and high resistance to wear, making it ideal for cutting tools and wear-resistant applications. It can withstand high temperatures (up to 1,000°C) and pressures, which is crucial in machining and mining operations.

Pros & Cons:

The primary advantage of tungsten carbide is its durability and performance in harsh environments. However, it is relatively expensive and can be brittle, leading to potential failure under extreme impact.

Impact on Application:

Tungsten carbide is highly compatible with various media, including oils and gases, but its brittleness may limit its use in applications requiring high impact resistance.

Considerations for International Buyers:

Buyers from regions such as Africa and South America should consider compliance with international standards such as ASTM and DIN. The high cost may be a barrier, but its longevity can justify the investment.

Key Properties:

Silicon carbide (SiC) is known for its high thermal conductivity and electrical resistance, making it suitable for high-temperature applications and electronic devices. It can operate effectively at temperatures exceeding 1,600°C.

Pros & Cons:

While silicon carbide is less expensive than tungsten carbide, its manufacturing process can be complex, impacting availability. Its resistance to oxidation and corrosion is a significant advantage, especially in chemical processing.

Impact on Application:

Silicon carbide is compatible with a wide range of media, including corrosive chemicals, making it ideal for applications in the semiconductor and automotive industries.

Considerations for International Buyers:

European buyers may find silicon carbide appealing due to stringent environmental regulations. Understanding local compliance and standards is essential for successful procurement.

Key Properties:

Titanium carbide (TiC) offers a unique combination of hardness and lightweight properties, making it suitable for applications in aerospace and automotive industries. It maintains stability at high temperatures and has a melting point around 3,200°C.

Pros & Cons:

The key advantage of titanium carbide is its low density, which reduces overall weight in applications. However, its cost and the complexity of manufacturing can be limiting factors.

Impact on Application:

Titanium carbide is particularly effective in applications requiring weight reduction without sacrificing strength, such as in aerospace components.

Considerations for International Buyers:

Buyers in the Middle East and Europe should evaluate the cost-benefit ratio of titanium carbide for specific applications. Compliance with aerospace standards is critical for procurement.

Key Properties:

Boron carbide (B4C) is one of the hardest materials known, with a hardness rating of 9.5 on the Mohs scale. It is lightweight and has excellent neutron absorption properties, making it suitable for nuclear applications.

Pros & Cons:

Its lightweight nature and high hardness are significant advantages, especially in armor and ballistic applications. However, boron carbide can be brittle and challenging to process.

Impact on Application:

Boron carbide is particularly effective in high-stress environments, such as military and aerospace applications, where weight savings are crucial.

Considerations for International Buyers:

International buyers, especially in Africa and South America, should consider the specific applications and compliance with military standards when sourcing boron carbide.

| Material | Typical Use Case for carbides definition | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tungsten Carbide | Cutting tools, mining equipment | Exceptional hardness and durability | High cost, potential brittleness | High |

| Silicon Carbide | Semiconductor, automotive applications | High thermal conductivity and corrosion resistance | Complex manufacturing process | Medium |

| Titanium Carbide | Aerospace components, automotive parts | Lightweight with high strength | High cost, complex manufacturing | High |

| Boron Carbide | Ballistic armor, nuclear applications | Extremely hard and lightweight | Brittle and difficult to process | Medium |

This guide serves as a strategic resource for international B2B buyers, helping them navigate the complexities of carbide material selection based on performance, application, and regional compliance.

The manufacturing of carbides, particularly tungsten carbide and silicon carbide, involves several intricate stages that ensure the material meets the required specifications for various industrial applications. Understanding these stages is crucial for B2B buyers looking to source high-quality carbide products.

Material preparation is the first step in the carbide manufacturing process. It typically involves the selection and combination of raw materials such as tungsten and carbon for tungsten carbide, or silicon and carbon for silicon carbide. The materials are finely powdered to increase their surface area, which promotes better chemical reactions during sintering.

Key techniques used during this stage include ball milling and jet milling, which help achieve uniform particle size. Buyers should ensure that suppliers utilize high-quality raw materials and advanced milling techniques to guarantee the final product's integrity.

Once the materials are prepared, the next step is forming. This process shapes the powdered materials into the desired forms, typically through methods such as:

For B2B buyers, it is essential to inquire about the forming techniques used by suppliers, as the choice of method can significantly affect the material's final properties.

After forming, the next critical stage is sintering, where the shaped powders are heated to a temperature below their melting points. This step is crucial for densifying the material and achieving the desired hardness and strength.

Common techniques include:

B2B buyers should assess the sintering practices of potential suppliers to ensure that they comply with industry standards and produce high-quality carbides.

A stock image related to carbides definition.

Finishing operations refine the carbide products to meet precise specifications. This stage often includes grinding, polishing, and coating to enhance the material's surface characteristics. Techniques like diamond grinding are commonly used for finishing, especially for tools that require a high degree of precision.

Buyers should request detailed information about the finishing processes employed by suppliers, as they can significantly influence the performance and lifespan of the carbide products.

Quality assurance (QA) is critical throughout the carbide manufacturing process to ensure that the final products meet international standards and customer specifications. Effective QA practices involve multiple checkpoints and adherence to relevant standards.

B2B buyers should ensure that their suppliers comply with international quality standards such as ISO 9001, which provides a framework for quality management systems. Additionally, industry-specific certifications, such as CE marking for products sold in Europe and API standards for oil and gas applications, are vital indicators of product quality and safety.

To maintain high-quality standards, manufacturers typically implement various quality control checkpoints throughout the production process, including:

B2B buyers should inquire about the specific quality control measures in place at their suppliers' facilities to ensure comprehensive oversight throughout the production process.

Testing methods play a crucial role in verifying the quality and performance of carbide products. Common testing techniques include:

Buyers should look for suppliers that conduct rigorous testing and provide detailed reports on their findings.

When sourcing carbide products, B2B buyers must have mechanisms in place to verify the quality control practices of their suppliers. Here are some effective strategies:

Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should develop a checklist based on industry standards and their specific requirements to ensure comprehensive evaluations.

Buyers should always ask for quality control reports that outline the results of testing and inspections. These reports should detail the methodologies used and highlight any deviations from expected standards.

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These organizations often have the expertise to identify potential issues that may not be apparent during regular audits.

International buyers from regions such as Africa, South America, the Middle East, and Europe must navigate additional complexities in quality control due to varying standards and regulations.

Understanding the compliance requirements specific to each region is essential. For instance, products exported to Europe must meet CE requirements, while those intended for the Middle Eastern market may need to comply with local standards.

Effective communication is vital for ensuring that quality standards are clearly understood and adhered to by suppliers. Buyers should consider working with local representatives or using translation services to mitigate potential misunderstandings.

Cultural differences can impact quality control practices. For instance, some regions may have more relaxed regulations or differing attitudes toward quality assurance. Buyers should be culturally aware and adaptable when engaging with suppliers from diverse backgrounds.

In summary, a comprehensive understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the carbide industry. By focusing on supplier capabilities, adhering to international standards, and verifying quality control measures, buyers can ensure they source high-quality carbide products that meet their specific needs.

In the realm of international B2B procurement, understanding the nuances of carbides is essential for making informed purchasing decisions. This guide provides a structured approach for buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to effectively source high-quality carbides.

Clearly outlining your technical requirements is the first step in sourcing carbides. Determine the specific type of carbide you need—tungsten carbide, silicon carbide, etc.—and the applications it will serve. This clarity helps narrow down suppliers who specialize in the particular properties and grades you require, ensuring compatibility with your intended use.

Conduct thorough research to identify potential suppliers. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. This step is crucial to ensure you engage with reputable companies that can meet your needs.

Before committing, it's crucial to vet suppliers thoroughly. Request company profiles, product catalogs, and case studies. This evaluation helps ensure the supplier's capabilities align with your specifications and quality standards.

Once you have shortlisted potential suppliers, request samples of their carbide products. Testing samples will provide insights into the material's performance and suitability for your applications.

Engage in negotiations to establish pricing and payment terms. Transparency in this step is vital to avoid hidden costs later on.

Before finalizing your purchase, check references provided by the supplier. Speaking with previous clients can reveal insights into the supplier's reliability, product quality, and customer service.

Once you select a supplier, focus on building a long-term relationship. This partnership can lead to better pricing, priority service, and collaboration on future projects.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing carbides effectively, ensuring they select the right suppliers and materials for their specific needs.

When sourcing carbides, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Materials: The price of raw materials, such as tungsten or titanium carbide, is a significant factor. Market fluctuations can drastically affect material costs, which are often influenced by mining operations and geopolitical factors.

Labor: Labor costs vary significantly based on geographic location. For example, manufacturing in Europe may incur higher labor costs compared to South America or Africa. It’s crucial to consider the skill level of workers involved in production, as specialized labor can demand premium wages.

Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, enhancing overall profitability.

Tooling: Tooling costs are relevant for custom carbide solutions. Investment in specialized tools can be substantial, but necessary for producing high-quality products that meet specific buyer requirements.

Quality Control (QC): Quality assurance processes are vital in carbide production. The costs associated with QC inspections, testing, and certifications can add to the overall price but are critical for ensuring product reliability and performance.

Logistics: Transportation costs, customs duties, and warehousing should be factored into the total cost. International shipping can be particularly expensive, so understanding Incoterms and their implications on logistics costs is essential.

Margin: The profit margin set by suppliers will impact the final price offered to buyers. Higher margins might be justified by superior quality or service, while lower margins could indicate a more competitive pricing strategy.

Several factors can influence the pricing of carbides, and understanding these can help buyers make informed decisions:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. Negotiating MOQs can significantly impact unit costs, especially for international buyers.

Specifications and Customization: Customized carbide products tailored to specific applications may incur additional costs. Clear communication of specifications can help avoid unexpected price increases.

Materials and Quality Certifications: The choice of materials and required certifications (such as ISO standards) can greatly affect pricing. Higher quality materials generally command higher prices, but they may offer better performance and longevity.

Supplier Factors: Supplier reputation, reliability, and customer service can also influence pricing. Established suppliers may charge a premium for their experience and product guarantees.

Incoterms: The choice of Incoterms can influence the total landed cost of the product. Understanding which terms cover responsibilities for shipping, insurance, and tariffs is crucial for accurate cost assessment.

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, implementing effective negotiation strategies can lead to cost savings:

Conduct Market Research: Understanding current market prices and trends can provide leverage during negotiations. It’s beneficial to gather data on competitors and alternative suppliers.

Build Strong Relationships: Establishing a rapport with suppliers can lead to better pricing, especially for repeat orders. Trust and communication can encourage suppliers to offer favorable terms.

Assess Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, consider the TCO, which includes maintenance, operational efficiency, and lifespan of the carbide products. This approach can justify a higher initial investment for better quality.

Be Aware of Pricing Nuances: Different regions may have varying pricing structures based on local economic conditions. Understanding these nuances can help negotiate more effectively.

In summary, a comprehensive understanding of the cost components and pricing influencers is vital for international B2B buyers sourcing carbides. By leveraging this knowledge and employing effective negotiation strategies, buyers can optimize their purchasing decisions, ensuring they achieve both quality and cost-efficiency in their sourcing efforts. Always remember to evaluate indicative prices and be prepared for fluctuations based on market dynamics.

In today's industrial landscape, businesses are constantly seeking efficient and cost-effective materials and methods to enhance their operations. When it comes to hard materials, carbides are frequently regarded for their durability and performance. However, it is essential for international B2B buyers to explore alternatives that may better suit their specific needs, particularly when considering factors such as performance, cost, and application.

| Comparison Aspect | Carbides Definition | Alternative 1: Ceramics | Alternative 2: High-Speed Steel |

|---|---|---|---|

| Performance | Excellent wear resistance; high hardness. | Good wear resistance; temperature stability. | High toughness; good cutting performance. |

| Cost | Generally higher initial investment. | Moderate cost; varies by type. | Lower initial cost but may require more frequent replacement. |

| Ease of Implementation | Requires specialized handling and machining. | Easier to mold and shape; less specialized equipment needed. | Commonly used and easily machinable. |

| Maintenance | Low maintenance but brittle; careful handling required. | Low maintenance; stable in harsh conditions. | Moderate maintenance; may wear faster than carbides. |

| Best Use Case | Ideal for high-performance applications in extreme conditions. | Suitable for high-temperature environments; electrical insulation. | Best for general machining and cutting tools. |

Ceramics are a viable alternative to carbides, particularly in applications where thermal stability is critical. They exhibit excellent resistance to wear and can withstand high temperatures without deforming. However, ceramics can be more brittle than carbides, which may lead to cracking under shock or impact. This makes them less suitable for applications involving heavy loads or sudden stresses. Their moderate cost and ease of shaping make them attractive for manufacturers looking for effective materials without the high expense associated with carbides.

High-speed steel (HSS) is another alternative that offers a different set of advantages and disadvantages. Known for its high toughness, HSS is ideal for general machining tasks and can withstand high temperatures. While it is generally less expensive than carbides, HSS may wear out faster, necessitating more frequent replacements. This trade-off can lead to higher long-term costs in some applications. HSS is also easier to machine and handle, making it a popular choice among manufacturers who prioritize ease of use and adaptability over extreme wear resistance.

When determining the best solution for industrial applications, B2B buyers must assess their specific requirements, including performance needs, budget constraints, and operational environments. Carbides offer unparalleled durability and performance for high-stress applications, while ceramics and high-speed steel provide cost-effective alternatives for different scenarios. By carefully considering the pros and cons of each option, buyers can make informed decisions that align with their operational goals and financial realities, ultimately enhancing their productivity and efficiency in a competitive market.

Understanding the technical specifications of carbides is crucial for B2B buyers seeking to make informed purchasing decisions. Here are some key properties that define the quality and applicability of carbide products:

Material Grade: Carbides are often classified by their material grade, which indicates their composition and intended application. Common grades include tungsten carbide (WC) and titanium carbide (TiC). Higher grades typically offer superior hardness and wear resistance, making them suitable for demanding applications in mining and manufacturing. Selecting the right grade ensures optimal performance and longevity of the product.

Tolerance: Tolerance refers to the allowable deviation from specified dimensions in carbide components. Tight tolerances are critical in applications where precision is essential, such as in cutting tools and wear parts. Understanding tolerance requirements helps buyers ensure that the components will fit seamlessly into their manufacturing processes, minimizing downtime and waste.

Hardness: The hardness of carbide materials is typically measured on the Rockwell scale. Higher hardness levels indicate better resistance to wear and deformation, which is vital in applications such as drilling and machining. For B2B buyers, selecting carbides with appropriate hardness levels is essential for achieving desired performance and extending the life of tools and components.

Coatings: Many carbide products are enhanced with coatings such as titanium nitride (TiN) or aluminum oxide (Al2O3). These coatings improve wear resistance and reduce friction, which is particularly beneficial in high-speed machining applications. Buyers should consider the type of coating that best suits their operational needs to maximize efficiency and reduce tool replacement costs.

Grain Size: The size of the carbide grains affects the material's toughness and strength. Finer grain sizes typically enhance toughness but may compromise hardness, while coarser grains offer higher hardness at the expense of toughness. Understanding the implications of grain size allows buyers to select carbides that align with their specific operational requirements.

Familiarity with trade terminology is essential for effective communication and negotiation in the carbide market. Here are several key terms:

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company's end product. Understanding OEM relationships is vital for buyers as it often indicates the quality and reliability of carbide products. Partnering with reputable OEMs can enhance supply chain efficiency and product performance.

MOQ (Minimum Order Quantity): MOQ defines the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management. Suppliers with lower MOQs may offer flexibility, especially for smaller businesses or those testing new products.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit pricing for specific quantities of products. This process helps buyers compare prices and terms, ensuring they receive the best value. Crafting a clear and detailed RFQ is essential for successful negotiations and procurement.

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to understand their obligations and risks associated with the transportation of carbide products, facilitating smoother transactions across borders.

Understanding these technical properties and trade terms will empower B2B buyers from Africa, South America, the Middle East, and Europe to make informed decisions, ensuring that they procure the right carbide products for their operational needs.

The global carbides market is experiencing significant growth, driven by increasing demand in industries such as automotive, aerospace, electronics, and manufacturing. As international B2B buyers, especially from Africa, South America, the Middle East, and Europe, navigate this landscape, understanding current and emerging trends is crucial. Notably, there is a shift towards advanced manufacturing technologies, including 3D printing and precision machining, which utilize carbides for their superior hardness and thermal resistance. Additionally, the push for automation and the Internet of Things (IoT) in manufacturing processes is influencing sourcing decisions, with buyers seeking suppliers who can offer high-quality carbides compatible with these technologies.

Furthermore, geopolitical factors and supply chain disruptions are prompting buyers to diversify their supplier bases. This is particularly relevant for companies in regions like Argentina and Italy, where local sourcing can mitigate risks associated with international trade. The rise of digital platforms for procurement is also transforming how B2B buyers source materials, making it essential to leverage e-commerce tools for real-time pricing and inventory updates.

As environmental concerns gain prominence, sustainability and ethical sourcing have become integral to procurement strategies in the carbides sector. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental impact. This includes adopting cleaner production processes, minimizing waste, and utilizing recycled materials in carbide manufacturing.

Moreover, buyers are seeking suppliers with 'green' certifications, such as ISO 14001, which indicates adherence to environmental management standards. In regions like Europe, where regulatory frameworks are stringent, compliance with these standards not only enhances a company's reputation but also provides a competitive edge in the market. Ethical supply chains are becoming non-negotiable; buyers are scrutinizing the sourcing of raw materials, ensuring they come from responsible and sustainable sources.

The evolution of the carbides market is closely tied to advancements in industrial processes and technology. Initially, carbides were primarily used in cutting tools and abrasives due to their hardness and durability. Over the decades, as industries evolved, so too did the applications of carbides, expanding into areas like electronics and aerospace. This historical context is vital for B2B buyers to understand current market dynamics and anticipate future trends.

The introduction of new production technologies, such as sintering and chemical vapor deposition, has enhanced the performance characteristics of carbides, making them more versatile. Buyers today benefit from a wealth of options, but they must also navigate a more complex supply chain landscape, shaped by historical developments and modern demands. Understanding these dynamics allows international buyers to make informed sourcing decisions that align with both their operational needs and sustainability goals.

How do I determine the right type of carbide for my application?

To select the right carbide for your specific application, consider factors such as hardness, wear resistance, and thermal stability. Assess your operational environment, including temperature and pressure, as well as the materials being processed. Consulting with suppliers who offer expert advice can help you understand the different grades of carbide available. Additionally, analyzing past performance data from similar applications can provide insights into which carbide type will yield the best results.

What are the key benefits of using carbides in manufacturing?

Carbides are favored in manufacturing due to their exceptional hardness and wear resistance, making them ideal for cutting tools and industrial machinery. They provide enhanced durability, leading to longer tool life and reduced downtime for replacements. Furthermore, carbides can withstand high temperatures without losing their structural integrity, which is crucial in high-speed machining processes. Overall, the use of carbides can significantly improve efficiency and productivity in manufacturing operations.

What is the typical minimum order quantity (MOQ) for carbides?

The minimum order quantity for carbides varies depending on the supplier and the specific type of carbide being ordered. Generally, MOQs can range from a few kilograms to several tons. It is advisable to discuss your requirements directly with potential suppliers to negotiate favorable terms. Some suppliers may offer flexibility in MOQs for first-time buyers or larger contracts, allowing you to assess the product before committing to larger orders.

How can I vet suppliers of carbides in international markets?

When vetting suppliers, consider factors such as their industry reputation, certifications, and years of experience. Request references from previous clients and check online reviews or ratings to gauge reliability. Additionally, visiting suppliers’ facilities or arranging virtual tours can provide insights into their production processes and quality control measures. Engaging with local trade associations or industry networks can also facilitate connections with reputable suppliers in international markets.

What payment terms are common in international B2B transactions for carbides?

Common payment terms in international B2B transactions include letters of credit, advance payments, and net payment terms (e.g., net 30 or net 60). The choice of payment terms often depends on the relationship between the buyer and supplier, as well as the perceived risk involved in the transaction. It is crucial to clarify payment terms before finalizing any agreement, ensuring both parties understand the conditions to avoid disputes later on.

How is quality assurance handled in carbide production?

Quality assurance in carbide production typically involves a series of stringent tests and inspections throughout the manufacturing process. Suppliers should adhere to international quality standards such as ISO 9001, which ensures that products meet specific quality benchmarks. Buyers can request detailed quality control documentation and certificates of compliance for each batch of carbides. Conducting regular audits and quality assessments of suppliers can further ensure that the materials received meet your specifications.

What logistics considerations should I keep in mind when sourcing carbides internationally?

When sourcing carbides internationally, consider logistics factors such as shipping costs, delivery times, and customs regulations. Ensure that your supplier has a reliable shipping partner to avoid delays. It's also important to understand the import duties and taxes applicable to your country. Collaborating with a logistics expert familiar with international trade can streamline the process and help mitigate potential issues related to shipping and customs clearance.

Can carbides be customized for specific applications?

Yes, many suppliers offer customization options for carbides based on specific application needs. Customization can include altering the composition, size, or shape of the carbide products to enhance performance in particular environments. Discussing your requirements with potential suppliers is essential, as they can provide insights into the feasibility of custom solutions and the associated costs. Be prepared to provide detailed specifications to facilitate the development of tailored carbide products.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

As international B2B buyers navigate the complexities of sourcing carbides, it is essential to recognize the strategic advantages that come with a well-informed approach. Understanding the unique properties and applications of various carbides can lead to more effective procurement strategies, ultimately enhancing product quality and operational efficiency. For businesses in Africa, South America, the Middle East, and Europe, leveraging local and global suppliers can create a competitive edge in terms of cost, quality, and delivery timelines.

Strategic sourcing is not merely about cost savings; it encompasses a holistic view of supplier relationships, market trends, and supply chain dynamics. By adopting a data-driven approach to supplier selection, companies can mitigate risks and ensure a steady supply of high-quality carbides tailored to their specific needs. Additionally, fostering partnerships with suppliers who prioritize sustainability and innovation can further enhance your company's reputation and operational resilience.

Looking forward, B2B buyers should remain proactive in adapting to market changes and technological advancements. Engaging in continuous dialogue with suppliers and participating in industry forums can provide insights into emerging trends and innovations. By staying informed and agile, international buyers can capitalize on new opportunities, ensuring their businesses remain competitive in an ever-evolving marketplace. Embrace the potential of strategic sourcing today to secure a prosperous future for your carbide procurement efforts.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina