The global demand for green grinder wheels continues to accelerate as industries worldwide prioritize precision, durability, and efficiency in their grinding operations. For international B2B buyers—especially those in Africa, South America, the Middle East, and Europe—sourcing the right green grinder wheel is pivotal to maintaining competitive production standards while managing costs and supply chain reliability.

Green grinder wheels, known for their superior hardness and thermal resistance, are essential components in sectors ranging from automotive manufacturing to heavy machinery maintenance. Selecting the appropriate type and grade directly impacts product quality, operational safety, and overall equipment lifespan. However, the complexity of the market—with its diverse materials, manufacturing standards, and supplier options—poses challenges for buyers aiming to optimize their procurement strategies.

This comprehensive guide addresses these challenges head-on by providing:

By leveraging this guide, B2B buyers from Mexico to France, and across emerging and established markets, will gain the expertise necessary to make informed, confident sourcing decisions. The result is a streamlined procurement process that supports sustainable growth and operational excellence in an increasingly interconnected global marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Green Silicon Carbide Wheel | Made from high-purity green silicon carbide; sharp cutting edges | Precision grinding of hard, brittle materials like ceramics and glass | Pros: High precision, excellent for hard materials; Cons: Fragile, shorter lifespan |

| Resin-Bonded Green Grinder Wheel | Silicon carbide grains bonded with resin for flexibility and shock resistance | General-purpose grinding in metal fabrication and tool sharpening | Pros: Good balance of durability and sharpness; Cons: Limited heat resistance |

| Vitrified Green Silicon Carbide Wheel | Bonded with vitrified (ceramic) bonds, rigid and heat-resistant | Heavy-duty grinding in automotive and aerospace sectors | Pros: High durability and heat resistance; Cons: More expensive, less flexible |

| Electroplated Green Grinder Wheel | Single layer of abrasive grains electroplated onto steel core | High-precision grinding of hard metals and superalloys | Pros: Long lifespan, consistent performance; Cons: Higher initial cost |

| Metal-Bonded Green Grinder Wheel | Abrasive grains bonded with metal matrix for toughness | Grinding of hard metals, tool steel, and carbide cutting tools | Pros: Excellent wear resistance; Cons: Can generate heat, requiring coolant |

Conventional Green Silicon Carbide Wheel

This type features high-purity green silicon carbide grains, prized for their sharp cutting ability and precision. It is ideal for grinding brittle, hard materials such as ceramics, glass, and some non-ferrous metals. For B2B buyers, especially in sectors like electronics or glass manufacturing, these wheels offer superior finishing quality but require careful handling due to their fragility. When sourcing, prioritize suppliers that guarantee grain purity and consistent wheel density to avoid premature wear.

Resin-Bonded Green Grinder Wheel

Combining silicon carbide grains with resin bonds, these wheels provide flexibility and shock absorption, making them suitable for general metal fabrication, tool sharpening, and maintenance tasks. They offer a good balance between sharpness and durability, appealing to buyers in metal workshops and small-scale manufacturing in regions like Africa and South America. However, resin bonds limit heat resistance, so buyers should consider operational speeds and cooling solutions to maximize lifespan.

Vitrified Green Silicon Carbide Wheel

Vitrified wheels use ceramic bonds that create a rigid structure with excellent heat resistance, suitable for heavy-duty grinding tasks common in automotive and aerospace industries. These wheels maintain shape and sharpness under intense conditions, ideal for European and Middle Eastern manufacturers handling complex metal components. The higher upfront investment is justified by durability and precision, but buyers must ensure compatibility with their grinding machines and operational protocols.

Electroplated Green Grinder Wheel

Featuring a single abrasive layer electroplated onto a steel core, these wheels excel in high-precision grinding of hard metals and superalloys. Their consistent abrasive exposure extends life and performance stability, which benefits high-end manufacturing clients in sectors like aerospace and precision tooling. Though costlier initially, the reduced downtime and improved quality control offer significant ROI. Buyers should verify electroplating quality and abrasive grain uniformity when negotiating with suppliers.

Metal-Bonded Green Grinder Wheel

Metal bonds provide toughness and wear resistance, making these wheels suitable for grinding hard metals, tool steels, and carbide tools. They are favored in industrial environments requiring robust performance, including heavy manufacturing hubs in South America and Europe. However, metal bonds can generate substantial heat, necessitating proper coolant systems. B2B buyers should assess their cooling infrastructure and production volume to ensure optimal wheel selection and cost-efficiency.

Related Video: How to Change a Grinder Wheel | 4 Different Ways

| Industry/Sector | Specific Application of green grinder wheel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision grinding of engine components and transmission parts | Enhanced surface finish, improved component lifespan, reduced rework rates | Consistent abrasive quality, wheel durability, compatibility with automated grinding systems |

| Aerospace Engineering | Finishing of turbine blades and structural alloys | High precision, reduced thermal damage, compliance with strict safety standards | Certification compliance, availability of specialty grit sizes, supplier reliability |

| Metal Fabrication | Surface grinding of hardened steel and cast iron components | Increased throughput, minimized wheel wear, consistent grinding performance | Abrasive material grade, wheel bonding type, supply chain stability for bulk orders |

| Tool and Die Making | Sharpening and shaping of cutting tools | Improved tool sharpness, extended tool life, higher dimensional accuracy | Customizable wheel specifications, delivery lead times, technical support availability |

| Construction Equipment | Grinding of heavy-duty parts and wear-resistant materials | Enhanced durability of parts, reduced maintenance downtime, cost efficiency | Wheel toughness, resistance to clogging, local after-sales service support |

In automotive manufacturing, green grinder wheels are essential for precision grinding of engine and transmission components. These wheels provide superior surface finish and dimensional accuracy, which are critical for high-performance engines. They help reduce rework by maintaining tight tolerances and extending component life. For international buyers, especially from regions like Africa and South America, sourcing wheels that are compatible with automated grinding machines and offer consistent abrasive quality is crucial to maintain production efficiency and reduce downtime.

The aerospace sector uses green grinder wheels primarily for finishing turbine blades and high-strength structural alloys. These applications demand wheels that minimize thermal damage and deliver exceptional precision to meet stringent safety and quality standards. Buyers from Europe and the Middle East should prioritize suppliers who provide certified products compliant with aerospace regulations, alongside a range of specialty grit sizes to accommodate various alloy compositions and hardness levels.

In metal fabrication, green grinder wheels are widely used for surface grinding hardened steel and cast iron parts. These wheels enable higher throughput by minimizing wear and maintaining consistent grinding performance over long production runs. International B2B buyers must focus on abrasive material grades and bonding types tailored to their specific metal types. Ensuring supply chain stability for bulk purchases is also critical, especially for businesses in Mexico and other emerging markets aiming to scale operations efficiently.

Tool and die makers rely on green grinder wheels for sharpening and shaping cutting tools with high precision. These wheels contribute to improved tool sharpness and longer tool life, which directly impacts production quality and costs. Buyers should seek suppliers offering customizable wheel specifications to match unique tool profiles, along with reliable delivery schedules and technical support, which are vital for maintaining continuous production in competitive markets such as France and the Middle East.

For construction equipment manufacturing, green grinder wheels are used to grind heavy-duty parts and wear-resistant materials. Their toughness and resistance to clogging extend the durability of critical components, reducing maintenance downtime and overall costs. International buyers, particularly in Africa and South America, should consider wheels that balance toughness with cost-effectiveness and ensure access to local after-sales service to address any operational issues promptly.

Key Properties: Aluminum oxide is a widely used abrasive material known for its excellent hardness and toughness. It performs well under high temperature and pressure conditions and exhibits good corrosion resistance, making it suitable for heavy-duty grinding applications.

Pros & Cons: Aluminum oxide wheels offer high durability and consistent performance, which translates to longer service life and reduced downtime. Manufacturing complexity is moderate, allowing for scalable production. However, it may wear faster when used on very hard or heat-sensitive materials, and its cost is generally mid-range.

Impact on Application: This material is ideal for grinding steel, cast iron, and other ferrous metals. It is less effective on non-ferrous metals or softer materials where a finer finish is required.

International B2B Considerations: Buyers in Africa, South America, the Middle East, and Europe should verify compliance with ASTM and DIN standards, which are commonly referenced in these regions. Aluminum oxide wheels are widely accepted and readily available, making them a reliable choice for markets like Mexico and France. Importers should consider local supplier certifications to ensure quality and consistency.

Key Properties: Silicon carbide is a very hard and sharp abrasive with high thermal conductivity and excellent resistance to chemical corrosion. It performs well at lower pressures but is more brittle compared to aluminum oxide.

Pros & Cons: Silicon carbide wheels are cost-effective and provide superior cutting efficiency on non-ferrous metals, ceramics, and glass. However, their brittleness can lead to faster wear and potential breakage under heavy load or impact, which may increase replacement frequency.

Impact on Application: This material is preferred for grinding non-ferrous metals, stone, and abrasive non-metallic materials. Its sharp cutting action makes it suitable for precision grinding tasks.

International B2B Considerations: Compliance with JIS and DIN standards is important for buyers in Asia-Pacific and Europe, respectively. In regions like the Middle East and South America, silicon carbide wheels must meet local safety and quality certifications to ensure durability. Buyers should also consider the availability of technical support for maintenance and replacement parts.

Key Properties: Ceramic alumina is a synthetic abrasive with superior hardness and self-sharpening properties. It maintains performance under high temperature and pressure and offers excellent wear resistance.

Pros & Cons: Ceramic alumina wheels provide longer life and higher grinding efficiency compared to conventional abrasives. Their manufacturing process is more complex and costly, resulting in a higher price point. However, the investment is justified by reduced downtime and improved productivity.

Impact on Application: Best suited for high-precision grinding of hardened steels and superalloys. It excels in applications requiring consistent surface finish and minimal thermal damage.

International B2B Considerations: European buyers, especially in France, often require compliance with stringent DIN and ISO standards for ceramic alumina wheels. African and Middle Eastern buyers should verify adherence to ASTM standards and ensure suppliers provide detailed technical data sheets. The higher cost may be a consideration for buyers in price-sensitive markets but can be offset by performance benefits.

Key Properties: Zirconia alumina is a tough, durable abrasive with excellent resistance to heat and shock. It offers a balance between hardness and toughness, making it suitable for heavy-duty grinding.

Pros & Cons: This material delivers exceptional durability and faster grinding rates, reducing cycle times. It is more expensive than aluminum oxide and silicon carbide but less costly than ceramic alumina. Manufacturing complexity is high due to the blending process.

Impact on Application: Ideal for grinding tough materials like stainless steel and high-tensile alloys. Its toughness allows it to withstand aggressive grinding conditions without premature wear.

International B2B Considerations: Buyers in Europe and the Middle East should ensure zirconia alumina wheels meet DIN and ASTM standards, respectively. In South America and Africa, verifying supplier certifications and quality assurance processes is crucial due to variable local manufacturing capabilities. The material’s robustness suits industries with demanding production environments, such as automotive and aerospace sectors prevalent in Mexico and France.

| Material | Typical Use Case for green grinder wheel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Grinding ferrous metals like steel and cast iron | Durable with good heat resistance | Moderate wear on very hard materials | Med |

| Silicon Carbide | Grinding non-ferrous metals, ceramics, and glass | Sharp cutting action, cost-effective | Brittle, prone to faster wear and breakage | Low |

| Ceramic Alumina | High-precision grinding of hardened steels and superalloys | Long life, self-sharpening, high efficiency | Higher cost and complex manufacturing | High |

| Zirconia Alumina | Heavy-duty grinding of stainless steel and tough alloys | Excellent toughness and durability | Higher cost, complex production process | Med-High |

Green grinder wheels, widely used in precision grinding applications, are manufactured through a multi-stage process that demands strict control to ensure optimal performance and safety. Understanding these stages helps B2B buyers evaluate supplier capabilities and product consistency.

The foundation of a quality green grinder wheel lies in the careful selection and preparation of raw materials. Key components include:

Material preparation involves precise weighing, blending, and conditioning to achieve a homogeneous mix. Suppliers with advanced material handling systems minimize variability and contamination risks.

The blended abrasive and bonding agents are shaped into the wheel form using one of several techniques:

Forming consistency directly affects the wheel’s structural integrity and balance, critical for high-speed grinding.

Post-forming, the wheels undergo curing processes to solidify the bond matrix:

This stage ensures the wheel attains its designed mechanical properties, such as hardness and toughness.

Finishing processes prepare the wheels for final use:

High-end manufacturers often employ CNC grinding and laser marking for consistency and quality.

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding quality assurance (QA) frameworks and how to verify them is crucial for sourcing reliable green grinder wheels.

Buyers should request certification copies and verify their validity with issuing bodies.

Quality control is typically segmented into three key checkpoints to maintain product integrity at every stage:

Suppliers with documented QC protocols and traceability systems provide greater assurance.

Testing methods validate wheel performance and safety:

B2B buyers should inquire whether suppliers conduct these tests internally or use third-party laboratories.

International buyers face challenges in verifying supplier QC, especially when sourcing from different continents. The following strategies enhance due diligence:

Buyers from regions such as Africa and South America should particularly emphasize these practices due to potential logistical and regulatory complexities.

Ensure all QC documents, certificates, and manuals are available in languages understood by the procurement and technical teams. For example, French buyers benefit from documentation in French or English, while Spanish or Portuguese documentation supports South American buyers.

Proper packaging and labeling, verified during QC, are essential to prevent damage during transit. Buyers should confirm suppliers’ compliance with international shipping standards such as IMDG (International Maritime Dangerous Goods) for hazardous materials.

By leveraging these insights, international B2B buyers can make informed procurement decisions, securing green grinder wheels that meet stringent quality, safety, and performance criteria essential for their industrial operations.

Understanding the cost structure behind green grinder wheels is essential for international B2B buyers aiming to optimize procurement expenses and ensure product quality. The primary cost components include:

Raw Materials: The core of green grinder wheels is typically high-grade aluminum oxide or silicon carbide. Material quality directly impacts grinding performance and durability. Prices fluctuate based on global commodity markets and supplier sourcing regions.

Labor Costs: Labor intensity depends on manufacturing location and automation level. Countries with lower labor costs can offer competitive pricing but may vary in craftsmanship quality.

Manufacturing Overhead: This covers energy consumption, equipment depreciation, facility maintenance, and indirect labor. Advanced manufacturing facilities with automated processes may have higher overhead but deliver consistent quality.

Tooling and Equipment: Specialized molds, presses, and curing ovens are necessary for shaping and hardening the wheels. Tooling costs are amortized over production volume but can affect pricing for smaller orders.

Quality Control (QC): Rigorous inspection processes, including dimensional checks and abrasive performance testing, ensure product reliability. Certified QC labs and adherence to standards (e.g., ISO, ANSI) add to cost but reduce risk.

Logistics and Freight: International shipping costs, customs duties, insurance, and inland transportation significantly influence landed cost. Volatile fuel prices and geopolitical factors also affect freight rates.

Supplier Margin: Margins vary based on supplier business models, market positioning, and order volume. High-value or niche suppliers may command premium pricing.

Several factors beyond the base cost affect the final price of green grinder wheels:

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower unit prices due to economies of scale. Buyers from regions like Africa or South America should negotiate MOQs that balance inventory costs with price benefits.

Product Specifications and Customization: Customized dimensions, bonding agents, or abrasive grades often increase costs. Clear technical specifications early in the procurement process help avoid costly revisions.

Material Grade and Quality Certifications: Wheels with higher purity abrasives and certifications (e.g., REACH, RoHS, ISO 9001) command premium prices but ensure compliance with regional regulations, critical for Europe and the Middle East markets.

Supplier Location and Reputation: Suppliers in established industrial hubs may offer better quality assurance but at higher prices. Emerging market suppliers can be cost-competitive but require thorough vetting.

Incoterms and Payment Terms: Shipping terms (FOB, CIF, DDP) influence who bears logistics risk and cost. Buyers should carefully select terms to optimize control over shipping and total landed cost.

To maximize value and mitigate hidden expenses, international buyers should:

Engage in Volume Negotiations: Consolidate orders or partner with other buyers to meet MOQ thresholds and secure bulk discounts.

Evaluate Total Cost of Ownership (TCO): Consider not only purchase price but also wheel lifespan, replacement frequency, and downtime costs. Higher-quality wheels may reduce long-term expenses despite higher upfront costs.

Leverage Local Import Expertise: Work with customs brokers familiar with import regulations in Africa, South America, and the Middle East to avoid delays and unexpected tariffs.

Assess Supplier Certifications and Audits: Prioritize suppliers with recognized certifications and conduct on-site audits or request third-party inspection reports to ensure quality standards.

Clarify Incoterms and Payment Conditions: Negotiate terms that balance risk and cash flow, such as payment upon delivery or letter of credit, especially when dealing with new or distant suppliers.

Monitor Currency and Market Trends: Currency fluctuations can impact cost significantly. Consider hedging strategies or multi-currency payment options to stabilize expenses.

Understand Regional Pricing Nuances: For instance, buyers in Mexico may benefit from NAFTA/USMCA trade agreements reducing tariffs, while European buyers must factor in VAT and compliance costs.

The pricing of green grinder wheels is subject to dynamic market conditions, including raw material availability, geopolitical factors, and shipping costs. The cost components and price influencers discussed provide a framework for analysis but actual prices will vary by supplier, order size, and regional factors. Buyers are encouraged to obtain multiple quotations and conduct thorough due diligence before finalizing procurement decisions.

Understanding the critical technical specifications of green grinder wheels is essential for making informed procurement decisions, especially in international B2B transactions. These properties directly impact the wheel’s performance, durability, and suitability for specific applications.

Abrasive Material Grade

This refers to the type and quality of abrasive particles used, typically silicon carbide for green wheels. The grade affects cutting speed and longevity. For buyers, selecting the right grade ensures compatibility with the materials being processed, optimizing cost-efficiency and product quality.

Grain Size

Grain size indicates the size of the abrasive particles and influences the finish and precision of the grinding process. Finer grains yield smoother finishes but slower material removal, while coarser grains remove material faster but with a rougher finish. Understanding this helps buyers align product choice with manufacturing tolerances and surface finish requirements.

Bond Type and Hardness

The bond holds abrasive grains together; common types include vitrified and resin bonds. Bond hardness determines wheel strength and wear rate. Buyers must balance bond hardness with application demands—harder bonds last longer but may be brittle, while softer bonds wear faster but reduce heat buildup.

Wheel Tolerance

This specifies the allowable deviation in wheel dimensions, such as diameter and thickness. Tight tolerances are crucial for precision grinding and automated production lines. International buyers should verify tolerance standards to ensure seamless integration with existing equipment and maintain product consistency.

Maximum Operating Speed (RPM)

The maximum safe rotational speed is critical for operational safety and efficiency. Exceeding this speed risks wheel failure and accidents. Buyers should match wheel RPM ratings with their machinery capabilities to avoid costly downtime or safety incidents.

Porosity

Porosity refers to the volume of voids within the wheel structure, affecting coolant flow and chip clearance. Higher porosity can improve heat dissipation but may reduce wheel strength. Selecting the appropriate porosity level enhances grinding performance and extends wheel life.

Familiarity with common industry terms streamlines communication and negotiation with suppliers, ensuring clarity and reducing transactional risks.

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment used in another company’s product. For green grinder wheels, sourcing from an OEM can guarantee compatibility and quality standards, which is critical for buyers seeking reliable supply chains.

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity a supplier is willing to sell. Understanding MOQ helps buyers plan inventory and budget, especially when dealing with multiple suppliers or testing new products in different regions.

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers asking for pricing, delivery timelines, and terms. Well-prepared RFQs with detailed technical specs enable buyers to obtain accurate quotes and compare offers effectively.

Incoterms (International Commercial Terms)

These standardized trade terms define responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Clear agreement on Incoterms prevents misunderstandings regarding costs and risk transfer.

Lead Time

Lead time is the period between placing an order and receiving the goods. Shorter lead times improve supply chain responsiveness, which is crucial for manufacturers operating on tight production schedules.

Certification and Compliance

Certifications (e.g., ISO, CE) confirm that the green grinder wheels meet industry safety and quality standards. Compliance is often mandatory for import/export and assures buyers of product reliability and regulatory adherence.

By grasping these technical properties and trade terms, B2B buyers in Africa, South America, the Middle East, and Europe can make strategic purchasing decisions, negotiate effectively, and ensure the green grinder wheels they procure meet operational and quality expectations.

The global green grinder wheel market is experiencing steady growth driven by increasing industrial automation and precision manufacturing demands. Key sectors such as automotive, aerospace, and metal fabrication are propelling the need for high-performance abrasive tools that offer both efficiency and durability. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding regional industrial development is critical. For instance, Mexico's expanding automotive sector and France’s advanced aerospace manufacturing highlight robust demand in these markets.

Emerging sourcing trends reveal a growing preference for suppliers who integrate digital technologies such as IoT-enabled machinery and AI-driven quality control. These innovations enhance consistency in grinding wheel production and reduce downtime, delivering value in cost and efficiency for buyers. Additionally, the rise of just-in-time (JIT) inventory models is influencing procurement strategies, pushing suppliers to offer more flexible delivery and smaller batch sizes without compromising quality.

Market dynamics also show an increased focus on customization, with buyers seeking tailor-made green grinder wheels optimized for specific materials and applications. This trend is particularly relevant for sectors in the Middle East and South America where niche manufacturing processes demand unique abrasive solutions. Furthermore, geopolitical shifts and trade regulations, including tariffs and export controls, require buyers to diversify sourcing to mitigate supply chain risks. Establishing partnerships with regional manufacturers or distributors can help navigate these challenges effectively.

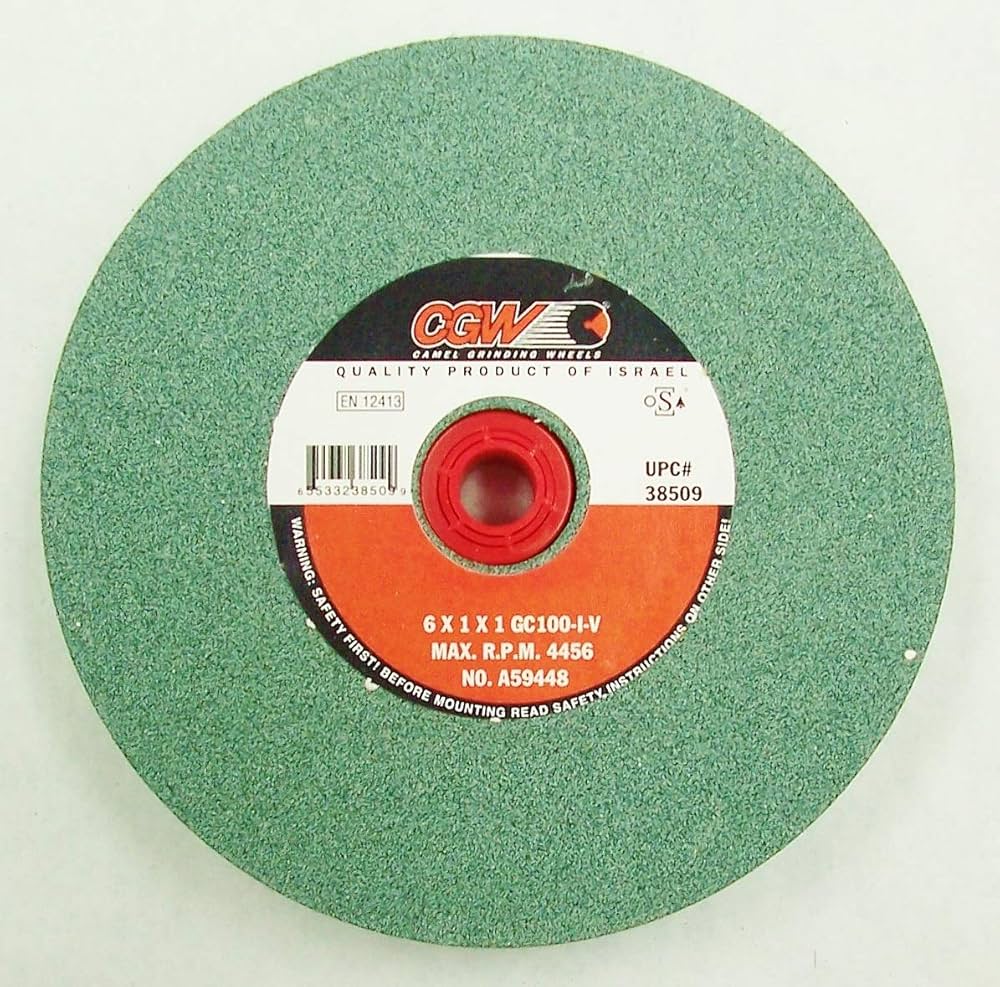

Illustrative Image (Source: Google Search)

Sustainability has become a pivotal consideration in the procurement of green grinder wheels, reflecting broader industrial commitments to reducing environmental footprints. The production of abrasive wheels traditionally involves energy-intensive processes and the use of non-renewable raw materials. However, innovative manufacturers are adopting eco-friendly binders, recycled abrasives, and energy-efficient manufacturing techniques to minimize environmental impact.

For B2B buyers, particularly those in Europe and the Middle East where regulatory pressure and corporate social responsibility standards are stringent, sourcing from suppliers with recognized green certifications is essential. Certifications such as ISO 14001 (Environmental Management Systems) and adherence to REACH regulations ensure compliance with international environmental standards. Additionally, buyers should prioritize suppliers who transparently disclose their sourcing practices and demonstrate commitment to ethical labor conditions, thereby reducing risks related to supply chain disruptions or reputational damage.

The integration of circular economy principles is also gaining traction. Some manufacturers now offer refurbishment or recycling programs for spent grinder wheels, enabling buyers to contribute to waste reduction initiatives. Engaging with suppliers that invest in sustainable R&D and lifecycle assessments can provide buyers with competitive advantages, including eligibility for green procurement tenders and alignment with global sustainability goals.

Green grinder wheels originated as a response to the need for more durable and heat-resistant abrasives in industrial grinding applications. Historically, these wheels were developed using natural abrasives combined with synthetic resins to enhance performance under high-stress conditions. Over the decades, advancements in materials science have introduced novel abrasives such as ceramic and engineered synthetic grains, which significantly extend wheel lifespan and precision.

This evolution has been driven by the increasing complexity of manufacturing processes and tighter tolerances required by modern industries. For international buyers, understanding this progression highlights the importance of selecting advanced green grinder wheels that offer both performance reliability and compliance with evolving industry standards. As the market continues to innovate, buyers can leverage these developments to optimize operational efficiency and product quality across diverse industrial applications.

How can I effectively vet suppliers of green grinder wheels from different regions such as Africa or Europe?

To vet suppliers thoroughly, start by verifying their business credentials and certifications such as ISO 9001 or industry-specific standards. Request samples to evaluate product quality and consistency. Check references and customer reviews, especially from similar markets. Utilize third-party inspection services for factory audits if possible. Confirm their experience exporting to your region to assess logistical capabilities and compliance with local regulations. Engaging in direct communication to clarify production capacity and quality assurance processes also helps mitigate risks.

What customization options are typically available for green grinder wheels, and how can I ensure they meet my specific industrial needs?

Most manufacturers offer customization in terms of wheel size, grit, bonding material, and hardness to suit various grinding applications. When negotiating, provide detailed technical specifications and intended use cases to ensure alignment. Request technical datasheets and conduct trials if possible. Collaborate with suppliers who have R&D capabilities to adapt products for unique requirements. This proactive approach helps optimize performance and lifespan while reducing operational costs.

Illustrative Image (Source: Google Search)

What are common minimum order quantities (MOQs) and lead times for international orders of green grinder wheels?

MOQs can vary widely but generally range from 100 to 500 units per order, depending on customization and supplier scale. Lead times typically span 4 to 8 weeks, factoring in production, quality checks, and shipping. Bulk orders often benefit from reduced unit costs but require longer commitment. Confirm MOQs and timelines upfront to align with your inventory and project schedules. Negotiating partial shipments can help manage cash flow and mitigate stock risks.

Which payment terms are most favorable and secure for international B2B transactions involving green grinder wheels?

Common payment terms include letters of credit (LC), telegraphic transfers (T/T), and escrow services. Letters of credit offer strong security for both buyer and supplier by guaranteeing payment upon shipment confirmation. T/T is faster but riskier without established trust. For new suppliers, consider partial upfront payment with balance after delivery inspection. Always use contracts specifying payment milestones and penalties to protect your interests.

What quality assurance certifications should I look for to ensure green grinder wheels meet international standards?

Look for certifications such as ISO 9001 for quality management systems, OHSAS for occupational health and safety, and specific industry standards like ANSI or EN for abrasive products. Certifications from recognized bodies demonstrate adherence to rigorous production and testing protocols. Request detailed quality control documentation, including batch testing results and material traceability. This ensures compliance with safety and performance standards critical for industrial applications.

How can I optimize logistics and shipping when importing green grinder wheels from distant suppliers like those in South America or the Middle East?

Coordinate with suppliers to consolidate shipments and choose reliable freight forwarders experienced in handling abrasive materials. Opt for sea freight for cost efficiency on bulk orders, but consider air freight for urgent deliveries. Ensure proper packaging to prevent damage and comply with hazardous material regulations. Track shipments actively and plan for customs clearance delays by understanding import regulations in your country. Collaborative planning reduces lead times and unexpected costs.

What are the best practices for handling disputes or quality issues with international green grinder wheel suppliers?

Establish clear contractual terms covering quality standards, inspection procedures, and dispute resolution mechanisms before placing orders. Maintain thorough documentation including purchase orders, inspection reports, and correspondence. In case of disputes, engage in prompt communication to negotiate remedies such as replacements, refunds, or discounts. Utilize third-party arbitration or mediation if needed. Building long-term partnerships with transparent communication minimizes future conflicts.

Illustrative Image (Source: Google Search)

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In today’s competitive manufacturing landscape, strategic sourcing of green grinder wheels is pivotal for businesses aiming to optimize cost, quality, and supply chain resilience. For B2B buyers across Africa, South America, the Middle East, and Europe, leveraging supplier partnerships that emphasize consistent product standards, environmental compliance, and innovation will drive sustained operational excellence.

Key takeaways include prioritizing suppliers with robust quality certifications, transparent pricing structures, and flexible logistics solutions tailored to regional demands. Additionally, aligning procurement strategies with sustainability goals not only meets increasing regulatory pressures but also enhances brand reputation in global markets. Buyers should actively engage in market intelligence and supplier audits to mitigate risks and capitalize on emerging technologies in abrasive materials.

Looking ahead, the green grinder wheel market is poised for growth fueled by advancements in eco-friendly abrasive formulations and digital procurement platforms. International buyers are encouraged to deepen collaboration with manufacturers who demonstrate agility and commitment to continuous improvement. By adopting a proactive, informed sourcing approach, companies can secure competitive advantages and contribute to a greener industrial future. Seize the opportunity now to refine your sourcing strategy and build resilient supply chains that support long-term success.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina