Carborundum printmaking has emerged as a transformative technique within the art and manufacturing sectors, combining innovative materials with versatile applications. For international B2B buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe, understanding the nuances of this printmaking method is essential for sourcing high-quality products and materials that meet diverse client needs.

This guide offers a comprehensive exploration of carborundum printmaking, addressing everything from the different types of carborundum materials and their unique properties to the manufacturing processes and rigorous quality control standards that ensure consistency and performance. By delving into supplier evaluations, cost structures, and current market trends, it equips buyers with actionable insights to optimize procurement strategies and establish reliable supply chains.

Key areas covered include:

For buyers in emerging and established markets such as Kenya, Mexico, or the UAE, this guide empowers decision-makers to navigate complexities, reduce risks, and leverage market opportunities. Ultimately, it serves as an authoritative resource to support informed, strategic sourcing that drives growth and innovation in carborundum printmaking applications worldwide.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Carborundum | Uses carborundum grit mixed with acrylic medium on plates | Fine art printmaking, limited edition prints | Pros: High detail, durable plates; Cons: Labor-intensive, slower production |

| Carborundum Intaglio | Carborundum applied in recessed areas for textural depth | High-quality art editions, museum reproductions | Pros: Rich textures, versatile; Cons: Requires skilled labor, higher cost |

| Carborundum Collagraph | Combines carborundum with various materials on collage plates | Educational kits, experimental art projects | Pros: Cost-effective, creative flexibility; Cons: Less uniformity, variable durability |

| Digital-Assisted Hybrid | Integrates digital design with carborundum application | Commercial art, custom branding, packaging design | Pros: Precision, scalable; Cons: Requires tech investment, learning curve |

| Eco-Friendly Variants | Uses recycled or natural abrasives replacing carborundum grit | Sustainable art production, green business sectors | Pros: Environmentally responsible; Cons: May affect print quality consistency |

Traditional Carborundum printmaking is characterized by the manual mixing of carborundum grit with an acrylic medium, applied onto plates to create textured surfaces. This type is highly suited for fine art printmakers and limited edition production where detail and longevity are paramount. For B2B buyers, especially galleries and art publishers, the key considerations include the labor intensity and slower turnaround time, which may impact cost and delivery schedules.

Carborundum Intaglio involves applying carborundum in recessed areas of the printing plate, producing rich textures and depth. This technique is favored in producing museum-quality reproductions and high-end art editions. Buyers should note the requirement for skilled artisans and the associated higher costs, balanced against the premium quality output that supports luxury branding and exclusivity.

Carborundum Collagraph combines carborundum grit with other collage materials to build plates. It is popular in educational settings and experimental art due to its affordability and creative versatility. For B2B buyers such as art schools and community projects in emerging markets, this type offers cost-effectiveness but may lack uniformity and durability, which should be factored into procurement decisions.

Digital-Assisted Hybrid carborundum printmaking merges digital design technologies with traditional carborundum application, enabling precise and scalable production. This variation is ideal for commercial art, custom branding, and packaging design companies aiming for innovation and efficiency. Buyers must consider initial technology investments and training but benefit from faster production cycles and consistent results.

Eco-Friendly Variants use recycled or natural abrasives as substitutes for traditional carborundum grit, aligning with sustainable production values. These are increasingly relevant for green businesses and environmentally conscious markets across Africa, South America, and Europe. While appealing for sustainability credentials, buyers should evaluate potential trade-offs in print quality and consistency to ensure product standards meet client expectations.

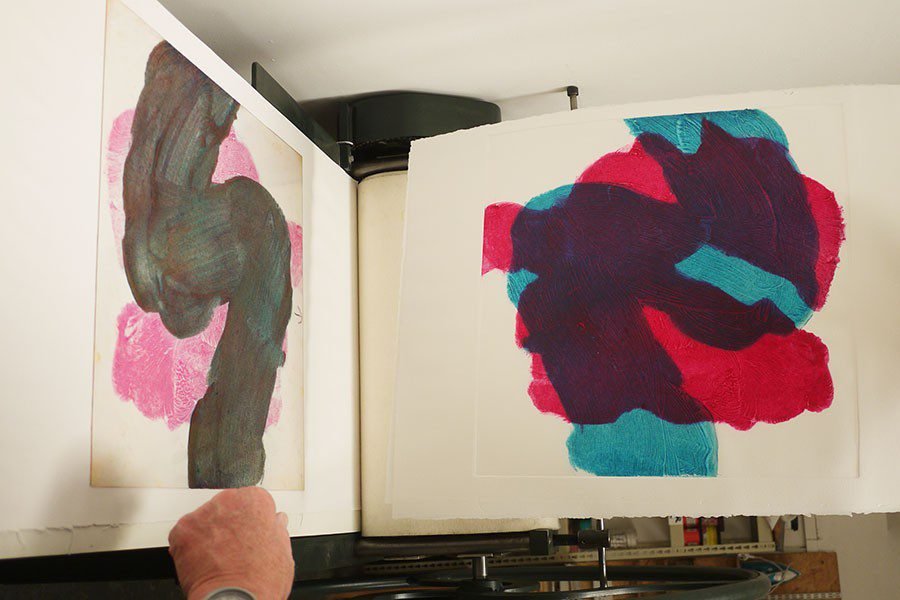

Related Video: Printmaking Master Class Episode 1 - Carborundum & Drypoint

| Industry/Sector | Specific Application of Carborundum Printmaking | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fine Arts & Galleries | Production of limited edition prints and textured artworks | Enables high-quality, durable prints with unique textures; enhances product differentiation and collector value | Quality of carborundum grit, consistency in grain size, supplier reliability, and shipping conditions to preserve material integrity |

| Packaging & Branding | Creation of embossed or textured packaging designs | Adds tactile appeal to luxury packaging, improving brand perception and customer engagement | Ability to supply bulk quantities, compatibility with local printing presses, and adherence to environmental regulations |

| Industrial Design & Prototyping | Surface texturing on prototypes and design models | Provides precise texture replication, speeding up product development and improving prototype realism | Supplier flexibility for custom grit sizes, lead times, and technical support for application methods |

| Educational Institutions | Teaching printmaking techniques in art schools and workshops | Affordable, consistent materials that support hands-on learning and experimentation | Cost-effectiveness, ease of procurement, and availability of technical documentation in multiple languages |

| Advertising & Marketing | Production of high-impact promotional materials with textured effects | Creates memorable tactile marketing collateral that enhances brand recall | Supplier capacity to meet short lead times, customization options, and compliance with export/import regulations |

Fine Arts & Galleries

Carborundum printmaking is extensively used in the fine arts sector for producing limited edition prints and textured artworks. The abrasive quality of carborundum allows artists and printmakers to create rich, varied textures that elevate the aesthetic appeal and uniqueness of their work. For B2B buyers, especially galleries and art publishers in regions like Europe and South America, sourcing high-purity, consistent carborundum grit is essential to maintain artwork quality and ensure reproducibility. Reliable suppliers who can provide stable grain sizes and protect material integrity during international shipping are critical.

Packaging & Branding

In packaging, carborundum printmaking enables the creation of embossed or textured surfaces on luxury packaging materials, offering brands a tactile dimension that enhances consumer experience and perception. Businesses in the Middle East and Africa looking to differentiate their products through packaging innovation benefit from bulk supply capabilities and materials compatible with local printing technologies. Additionally, compliance with environmental standards in these regions must be a priority when selecting suppliers.

Industrial Design & Prototyping

Carborundum’s abrasive properties are leveraged in industrial design for surface texturing prototypes and models, helping companies achieve precise tactile finishes that reflect final product surfaces. This application is particularly valuable for manufacturers and design firms in Mexico and Europe aiming to accelerate product development cycles. Buyers should prioritize suppliers offering customizable grit sizes and prompt delivery, along with technical support to optimize application processes.

Educational Institutions

Art schools and universities utilize carborundum printmaking materials to teach printmaking techniques, providing students with hands-on experience in creating textured prints. For institutions across Africa and South America, sourcing cost-effective and consistent materials is crucial to support large class sizes and ongoing workshops. Availability of multilingual technical documentation and ease of procurement through reliable channels enhance the learning experience and operational efficiency.

Advertising & Marketing

Marketing agencies employ carborundum printmaking to produce promotional materials with striking tactile effects that boost brand recognition. This is particularly important for businesses in the Middle East and Europe that require quick turnaround times for campaigns. Buyers should focus on suppliers capable of meeting tight schedules, offering customization options, and ensuring compliance with international trade regulations to avoid delays.

Related Video: Akua Carborundum Gel with Wax Mediums

Key Properties:

Carborundum powder (silicon carbide) is the fundamental abrasive material in carborundum printmaking. It exhibits exceptional hardness, high thermal resistance (up to 1600°C), and excellent chemical inertness, which ensures durability under repeated press pressure and exposure to various inks and solvents.

Pros & Cons:

Its superior abrasive quality delivers fine textural effects and consistent print quality. However, sourcing high-purity carborundum can be costly, and handling requires safety precautions due to its fine particulate nature. Manufacturing complexity is moderate, involving precise mixing with adhesives.

Impact on Application:

Carborundum powder is compatible with a wide range of printmaking media, including oil-based and water-based inks, making it versatile for diverse artistic and commercial print applications.

International B2B Considerations:

Buyers in Africa, South America, the Middle East, and Europe should verify compliance with international safety standards such as ASTM D5757 for abrasive materials. Regions like Kenya and Mexico may require import documentation aligned with local chemical safety regulations. Bulk purchasing options and supplier certifications (ISO 9001) are critical for consistent quality and cost management.

Key Properties:

Acrylic mediums serve as binders to adhere carborundum powder onto printing plates. They offer excellent adhesion, flexibility, and resistance to cracking under pressure. Acrylics typically tolerate temperatures up to 100°C and resist degradation by water and solvents.

Pros & Cons:

Acrylic binders are cost-effective and easy to work with, facilitating faster production cycles. However, they may have lower heat resistance compared to epoxy alternatives, potentially limiting durability in high-volume industrial printing.

Impact on Application:

Acrylic mediums are ideal for printmakers focusing on moderate-run editions and those using water-based inks. Their flexibility supports varied textures but may not withstand aggressive cleaning solvents used in some industrial settings.

International B2B Considerations:

For buyers in emerging markets, acrylic mediums are widely available and often comply with ASTM D4236 for art materials. Importers should confirm VOC content limits per EU REACH regulations or Middle Eastern environmental standards to ensure compliance and avoid customs delays.

Key Properties:

Epoxy resins provide a highly durable and chemically resistant matrix for carborundum particles, with excellent adhesion and resistance to abrasion, heat (up to 150°C), and solvents.

Pros & Cons:

Epoxy-based plates offer superior longevity and are suited for high-volume commercial print runs. However, they require more complex manufacturing processes, including precise mixing and curing times, and come at a higher cost. They may also demand stricter health and safety controls during handling.

Impact on Application:

These materials excel in industrial printmaking environments where durability and repeatability are paramount. They are compatible with both oil-based and solvent-based inks but less flexible for fine artistic textures.

International B2B Considerations:

Buyers should ensure epoxy suppliers meet international standards such as DIN EN ISO 9001 and comply with regional chemical safety regulations, including OSHA in the US or equivalent standards in Europe (REACH) and the Middle East. Logistics considerations include hazardous material shipping protocols, especially for bulk orders destined for Africa or South America.

Key Properties:

Aluminum plates are commonly used as the substrate for carborundum printmaking. They offer high strength-to-weight ratio, excellent corrosion resistance (especially anodized variants), and good thermal conductivity.

Pros & Cons:

Aluminum substrates provide a stable, reusable base that withstands repeated press runs and cleaning. However, they are more expensive than traditional paper or cardboard substrates and require specialized manufacturing equipment for surface preparation.

Impact on Application:

Ideal for professional studios and commercial printmakers producing large editions, aluminum plates ensure consistent registration and durability. They are compatible with a wide range of inks and printing presses.

International B2B Considerations:

International buyers should verify compliance with ASTM B209 or EN AW standards for aluminum sheet quality. In regions like Europe and the Middle East, anodized aluminum plates are preferred for enhanced corrosion resistance. Supply chain reliability and lead times must be considered, especially for buyers in Africa and South America where import infrastructure may vary.

| Material | Typical Use Case for carborundum printmaking | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carborundum Powder | Primary abrasive for textural effects on print plates | Exceptional hardness and durability | Handling safety and higher purity cost | High |

| Acrylic Mediums | Binder for moderate-run editions and water-based inks | Cost-effective and flexible | Lower heat and solvent resistance | Low |

| Epoxy Resins | Durable matrix for high-volume industrial printmaking | Superior durability and chemical resistance | Complex manufacturing and cost | High |

| Aluminum Plates | Substrate for professional studios and large edition runs | Stable, reusable, corrosion-resistant | Higher cost and specialized prep | Medium |

Carborundum printmaking, a specialized intaglio technique using abrasive carborundum grit to create textured printing plates, demands precise manufacturing and stringent quality control to ensure consistent, high-quality outputs. For international B2B buyers—especially those sourcing from or distributing to markets in Africa, South America, the Middle East, and Europe—understanding the manufacturing nuances and quality assurance protocols is essential for selecting reliable suppliers and maintaining product standards.

The production of carborundum plates involves several critical stages, each contributing to the final plate’s durability, texture, and print fidelity. These stages include:

The core material for carborundum printmaking plates is typically a metal base such as copper, aluminum, or zinc. Preparation involves:

This stage is vital to prevent delamination or inconsistent grit adherence, which can affect print quality and plate longevity.

This phase imparts the characteristic roughness necessary for ink retention:

Key techniques here focus on uniform grit distribution and adhesion strength, which directly influence the final print’s tonal richness and texture consistency.

While carborundum plates are often standalone, some manufacturers may assemble multi-layered plates or apply protective coatings:

These steps enhance plate durability and handling convenience, critical for high-volume printmaking operations.

Final finishing ensures the plates meet exact dimensional and surface specifications:

Robust quality assurance (QA) and quality control (QC) frameworks underpin reliable manufacturing, ensuring plates meet international standards and client specifications.

Quality control is typically divided into three main stages:

For buyers in Africa, South America, the Middle East, and Europe, ensuring supplier quality requires proactive engagement beyond relying on certificates alone:

Summary for B2B Buyers: Understanding the detailed manufacturing stages—from material preparation to finishing—and the comprehensive QC framework is key to sourcing high-quality carborundum printmaking plates. Prioritize suppliers with documented ISO 9001 systems, transparent QC checkpoints (IQC, IPQC, FQC), and willingness to facilitate audits and third-party inspections. Tailor your quality requirements to regional certification standards and import regulations to ensure smooth procurement and long-term supplier partnerships.

When sourcing carborundum printmaking materials and equipment, understanding the key cost components is essential for effective budgeting and negotiation:

Several factors influence the final pricing of carborundum printmaking supplies, especially for buyers in Africa, South America, the Middle East, and Europe:

To optimize procurement costs and ensure value in carborundum printmaking sourcing, consider the following strategies:

Due to variability in raw material costs, production methods, supplier capabilities, and geopolitical factors, prices for carborundum printmaking materials can fluctuate widely. This analysis provides a framework for understanding cost drivers rather than fixed price points. Buyers are encouraged to request detailed quotations tailored to their specific order profiles and sourcing locations.

By carefully analyzing these cost and pricing factors, international B2B buyers can make informed decisions, optimize procurement budgets, and build resilient supply chains for carborundum printmaking materials.

Understanding the critical technical specifications of carborundum printmaking materials is essential for international B2B buyers to ensure product quality, consistency, and suitability for specific artistic or industrial applications. Here are the primary technical properties to consider:

Abrasive Grain Size (Mesh or Micron Rating):

Carborundum powder comes in various grain sizes, typically measured in microns or mesh numbers. Finer grains (e.g., 1200 mesh) yield smoother textures and more detailed prints, while coarser grains (e.g., 80 mesh) create rougher surfaces with bolder effects. For buyers, selecting the correct grain size affects the final print quality and process efficiency.

Material Grade and Purity:

The purity of silicon carbide (carborundum) directly influences its abrasive strength and consistency. High-grade, industrial-purity carborundum ensures uniform performance and longevity in print plates. Buyers should verify grade certifications to avoid variability that can impact batch-to-batch reliability.

Particle Shape and Hardness:

Carborundum particles vary in shape from angular to blocky, affecting how they adhere to the printing plate and the texture produced. Hardness, measured on the Mohs scale (typically 9-9.5 for carborundum), guarantees durability during repeated press runs. Selecting materials with consistent particle shape and hardness improves print repeatability.

Tolerance and Consistency:

Tight manufacturing tolerances on particle size distribution and chemical composition reduce defects and ensure predictable results. For B2B buyers, suppliers offering strict quality control and tolerance documentation help minimize waste and rework in production.

Binder Compatibility:

Since carborundum powders are often mixed with binders or adhesives for application on plates, compatibility with local binders or proprietary formulations is key. Buyers should confirm that the abrasive does not chemically react or degrade binders, which could affect adhesion and print quality.

Moisture Content:

Low moisture content in carborundum powder prevents clumping and facilitates even dispersion during mixing and application. Buyers sourcing from humid regions or suppliers should request moisture analysis to maintain consistent product handling.

Navigating global trade requires familiarity with common industry terms that impact pricing, logistics, and contractual obligations. Here are vital terms every B2B buyer should know:

OEM (Original Equipment Manufacturer):

Refers to manufacturers who produce carborundum materials or printmaking supplies that other companies rebrand or integrate into their products. Buyers may engage OEMs for custom formulations or private labeling, often with minimum order quantities and exclusivity clauses.

MOQ (Minimum Order Quantity):

The smallest quantity a supplier is willing to sell per order. MOQs vary widely depending on production scale and material type. Understanding MOQ helps buyers from smaller markets (e.g., Kenya, Mexico) plan inventory and negotiate flexible purchase volumes to reduce upfront costs.

RFQ (Request for Quotation):

A formal inquiry sent by buyers to suppliers requesting detailed pricing, lead times, and terms for carborundum materials. Well-prepared RFQs with clear technical specifications streamline supplier responses and enable effective cost comparison across regions like South America or the Middle East.

Incoterms (International Commercial Terms):

Standardized trade terms that define responsibilities for shipping, insurance, and customs clearance between buyer and seller. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting appropriate Incoterms impacts total landed cost and logistics complexity.

Lead Time:

The time interval between placing an order and receiving the goods. In carborundum printmaking supplies, lead times can vary due to production schedules, shipping routes, and customs processes. Buyers should factor lead times into project timelines and negotiate expedited options if needed.

Batch Number/Traceability:

Suppliers often assign batch numbers to carborundum powder shipments for quality control and traceability. This allows buyers to track material origin and resolve issues related to consistency or defects, which is critical in maintaining production standards across international markets.

For B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe, mastering these technical properties and trade terms empowers better sourcing decisions, supplier negotiations, and supply chain management. Prioritizing quality specifications alongside clear contractual language ensures smooth procurement and optimal printmaking outcomes.

The carborundum printmaking sector is experiencing dynamic growth driven by increasing demand for innovative artistic techniques and durable printmaking materials. Globally, the market is influenced by rising interest in mixed media and experimental print processes, with carborundum powder serving as a crucial abrasive and textural additive. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding regional supply chain nuances and technological advancements is essential to optimizing sourcing strategies.

Key market drivers include:

Emerging B2B sourcing trends:

Understanding these dynamics allows buyers to identify reliable suppliers, negotiate favorable terms, and leverage technological innovations to enhance their product offerings.

Sustainability is becoming a non-negotiable aspect of sourcing carborundum printmaking materials, particularly as international buyers face increasing scrutiny from environmentally conscious stakeholders. Carborundum, primarily composed of silicon carbide, involves energy-intensive manufacturing processes, often linked to significant carbon emissions and resource consumption.

Key sustainability considerations include:

For international buyers, especially in regions like Africa and South America where environmental regulations may vary, partnering with suppliers who demonstrate a commitment to sustainability can enhance brand reputation and meet growing consumer demand for green products. Additionally, engaging in long-term contracts with such suppliers often leads to improved supply chain resilience and cost efficiencies.

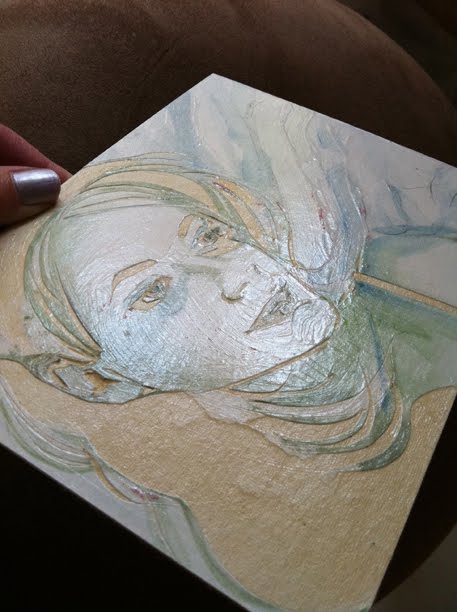

Illustrative Image (Source: Google Search)

Carborundum printmaking originated in the early 20th century, evolving from the broader use of silicon carbide as an abrasive material. Its application in printmaking was pioneered by artists seeking novel textures and depth beyond traditional etching techniques. Over decades, the technique gained traction in Europe and North America, with printmakers experimenting with various carborundum grades and binders.

For B2B buyers, this historical context underscores the material’s proven versatility and durability, which supports its sustained demand in contemporary artistic and industrial markets. Recognizing the evolution of carborundum printmaking also helps buyers appreciate the importance of sourcing materials that meet both traditional quality standards and modern innovation requirements. This balance is particularly relevant for buyers aiming to serve diverse markets across Africa, South America, and the Middle East, where printmaking traditions are rapidly expanding.

1. How can I effectively vet suppliers of carborundum printmaking materials and equipment for international B2B transactions?

Begin by verifying the supplier’s business credentials, including export licenses and industry certifications relevant to printmaking materials. Request detailed product specifications and samples to assess quality firsthand. Check for references or case studies involving clients from your region (Africa, South America, Middle East, Europe) to confirm reliability. Utilize third-party audits or factory inspections where possible. Also, evaluate their communication responsiveness and after-sales support, as these are critical for long-term partnerships in international trade.

2. What customization options are typically available for carborundum printmaking supplies, and how can buyers request them?

Many suppliers offer customization in grain size, binder composition, and sheet dimensions to suit specific printmaking techniques or artistic styles. Buyers should clearly communicate their technical requirements early, ideally providing samples or detailed drawings. Customization requests should be documented in the purchase agreement to avoid misunderstandings. For bulk orders, discuss feasibility and cost implications upfront, as custom formulations or sizes may require minimum order quantities and longer lead times.

3. What are typical minimum order quantities (MOQs) and lead times for carborundum printmaking products, especially for buyers in emerging markets?

MOQs vary widely based on product type and supplier scale but often start around 50 to 100 units for standard materials. For custom products, MOQs may be higher due to production setup costs. Lead times generally range from 3 to 8 weeks, influenced by order complexity and shipping logistics. Buyers in regions like Kenya or Mexico should factor in additional customs clearance time and potential delays. Early planning and clear communication on delivery expectations are essential to avoid production downtime.

4. Which payment terms are commonly accepted in international B2B transactions for carborundum printmaking, and how can buyers mitigate payment risks?

Suppliers typically accept letters of credit (LC), telegraphic transfers (TT), or escrow services. For new partnerships, letters of credit offer security by ensuring payment only upon document compliance. Established buyers may negotiate net 30-60 day terms. To mitigate risks, request pro forma invoices detailing all costs, confirm supplier bank details independently, and avoid full upfront payments unless a trusted relationship exists. Using trade finance solutions or working with export credit agencies can also provide additional safeguards.

5. What quality assurance measures and certifications should B2B buyers expect when sourcing carborundum printmaking materials internationally?

Look for suppliers who comply with ISO 9001 quality management standards or equivalent certifications. Material safety data sheets (MSDS) and compliance with international chemical safety regulations (such as REACH or RoHS) are crucial, particularly for European buyers. Request batch testing reports and ensure traceability of raw materials. For high-volume or repeat orders, consider third-party lab testing or on-site inspections to verify consistency and safety compliance.

6. How should international buyers handle logistics and shipping challenges when importing carborundum printmaking products?

Opt for suppliers experienced in international shipping and familiar with your region’s customs regulations. Clarify Incoterms (e.g., FOB, CIF) to define responsibility for freight and insurance. Use consolidated shipping options to reduce costs if ordering smaller quantities. Prepare for import duties, taxes, and customs documentation well in advance to avoid delays. Partnering with freight forwarders or customs brokers knowledgeable about regional trade protocols in Africa, South America, or the Middle East can streamline clearance and reduce bottlenecks.

7. What are best practices for resolving disputes with carborundum printmaking suppliers in cross-border transactions?

Establish clear contractual terms covering product specifications, delivery schedules, and payment conditions. Include dispute resolution clauses specifying mediation or arbitration venues familiar with international trade law, such as ICC arbitration. Maintain comprehensive records of all communications and transactions. If issues arise, address them promptly with documented evidence and seek amicable solutions before escalating. Leveraging industry associations or trade chambers in your country can also facilitate dispute resolution.

8. How can buyers from emerging markets leverage bulk purchasing and partnerships to optimize costs and supply stability?

Forming buying consortia or partnerships with other printmaking studios or distributors can increase order volumes, enabling better negotiation leverage on pricing and MOQs. Engage suppliers in long-term contracts to secure preferential terms and priority production slots. Explore local warehousing solutions to reduce shipping frequency and costs. Additionally, participating in international trade shows or supplier webinars can uncover new sources and foster direct relationships that improve supply chain resilience.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Carborundum printmaking presents a unique opportunity for international B2B buyers to tap into an innovative and versatile art form that combines traditional techniques with modern materials. For businesses across Africa, South America, the Middle East, and Europe, strategic sourcing of quality carborundum supplies and equipment is critical to ensuring consistent product excellence and competitive advantage. Key considerations include selecting reliable suppliers with proven expertise, optimizing logistics for cost-effective delivery, and leveraging regional partnerships to navigate local market dynamics efficiently.

Emphasizing supply chain resilience and sustainability can also enhance long-term value, especially as demand for eco-conscious art materials grows globally. Buyers should prioritize suppliers who demonstrate transparency, certifications, and commitment to environmental standards, which can also open doors to new markets and collaborations.

Illustrative Image (Source: Google Search)

Looking ahead, the carborundum printmaking sector is poised for growth driven by rising interest in contemporary print arts and expanding creative industries worldwide. For businesses in emerging markets like Mexico and Kenya, early engagement with innovative sourcing strategies can position them as leaders in this niche. By adopting a proactive approach—incorporating thorough supplier vetting, regional market insights, and sustainability criteria—B2B buyers can unlock significant opportunities and foster lasting partnerships in the evolving carborundum printmaking landscape.

Illustrative Image (Source: Google Search)

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina