Carburo de boro (boron carbide) stands as a critical material in diverse high-performance industrial applications due to its exceptional hardness, thermal stability, and chemical resistance. For B2B buyers across Africa, South America, the Middle East, and Europe—regions experiencing rapid industrial growth and technological advancement—understanding the nuances of sourcing carburo de boro is essential to maintaining competitive advantage and operational excellence.

This guide provides a thorough exploration of carburo de boro, tailored to meet the strategic needs of international buyers. It covers the full spectrum of product types and material grades, helping you identify the best fit for applications ranging from abrasives and armor plating to nuclear reactors and cutting tools. Detailed insights into manufacturing processes and quality control standards ensure you can assess supplier reliability and product consistency confidently.

Furthermore, the guide examines global supplier landscapes, highlighting key producers and emerging markets relevant to regions like Poland and Colombia. Transparent discussions on pricing structures and cost drivers empower you to negotiate effectively and forecast procurement budgets with accuracy. To address common challenges, a comprehensive FAQ section offers practical solutions to typical sourcing dilemmas.

By leveraging this knowledge, B2B buyers can navigate the complexities of the global carburo de boro market with clarity and confidence. The actionable intelligence contained herein supports informed decision-making, optimizes supply chain resilience, and drives long-term value for businesses operating across diverse industrial sectors worldwide.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hexagonal Boron Carbide (B4C) | High hardness, low density, excellent chemical stability | Abrasives, armor plating, nuclear industry | Pros: Lightweight, wear-resistant; Cons: Higher cost, brittle |

| Boron Carbide Powder | Fine particle size, customizable purity levels | Ceramics manufacturing, refractory materials | Pros: Versatile, adaptable; Cons: Handling requires care, dust generation |

| Boron Carbide Composite | Combined with metals or ceramics for enhanced toughness | Cutting tools, wear parts, industrial machinery | Pros: Improved toughness, durability; Cons: Complex manufacturing, costlier |

| Boron Carbide Coatings | Thin film application, enhanced surface properties | Tool coatings, corrosion resistance | Pros: Extends tool life, corrosion protection; Cons: Requires specialized application equipment |

| Nanostructured Boron Carbide | Ultra-fine grain size, superior mechanical properties | Advanced electronics, aerospace components | Pros: Exceptional strength, lightweight; Cons: Limited large-scale availability, premium pricing |

Hexagonal Boron Carbide (B4C)

This is the most common and commercially significant form of carburo de boro, known for its exceptional hardness (third hardest material after diamond and cubic boron nitride) and low density. Its chemical inertness makes it highly suitable for abrasive applications, ballistic armor, and neutron absorption in nuclear reactors. For B2B buyers, especially in defense and heavy industry sectors, sourcing high-purity B4C with consistent particle size is crucial. Consider logistics and supplier certifications to ensure material authenticity and performance reliability.

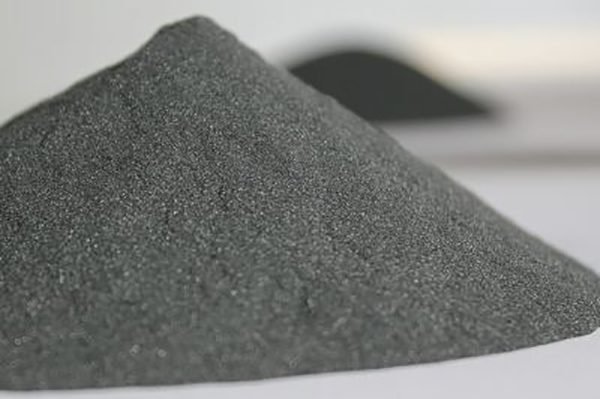

Boron Carbide Powder

Available in various particle sizes and purity grades, boron carbide powder is a fundamental raw material for producing advanced ceramics and refractory products. Its adaptability allows customization to meet specific manufacturing needs. Buyers in ceramics and refractory industries should prioritize suppliers offering tailored particle distributions and stable supply chains. Proper handling protocols are essential to mitigate dust hazards during transport and processing.

Boron Carbide Composite

By integrating boron carbide with metals or other ceramics, composites achieve enhanced toughness and impact resistance, overcoming the brittleness of pure B4C. These composites are widely used in cutting tools, wear-resistant parts, and industrial machinery components. B2B purchasers must evaluate the composite's formulation and production process to align with application demands, balancing cost with performance gains. Collaboration with manufacturers for custom composite solutions can add significant value.

Boron Carbide Coatings

Applied as thin films on substrates, boron carbide coatings improve surface hardness, wear resistance, and corrosion protection. These coatings extend the operational life of cutting tools and industrial equipment exposed to harsh environments. Buyers should assess coating uniformity, adhesion quality, and compatibility with base materials. Investing in suppliers with advanced deposition technologies ensures consistent coating performance, critical for sectors like automotive and aerospace.

Nanostructured Boron Carbide

This emerging variation features ultra-fine grain sizes that enhance mechanical strength and toughness beyond conventional forms. Nanostructured B4C is increasingly relevant in high-tech applications such as aerospace components and advanced electronics, where material performance is paramount. For B2B buyers, availability remains limited and prices are premium. Strategic partnerships with specialized producers can secure supply, while thorough testing is advised to validate material properties for critical applications.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of carburo de boro | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace & Defense | Abrasive materials for cutting and polishing tools | Enhances precision and durability in machining high-strength alloys | Consistent particle size, purity, and reliable supply chain essential for quality and safety standards |

| Automotive Manufacturing | High-performance brake pads and clutch components | Improves wear resistance and thermal stability, extending component lifespan | Compliance with environmental regulations and certification for performance required |

| Electronics & Semiconductors | Substrates and heat sinks in electronic devices | Superior thermal conductivity and electrical insulation improve device efficiency | Material grade and thermal properties must meet stringent industry standards |

| Chemical Processing | Catalyst support and wear-resistant coatings | Increases catalyst efficiency and equipment lifespan under harsh conditions | Chemical purity and resistance to corrosion critical for process stability |

| Construction & Mining | Cutting and grinding tools for stone and concrete | Provides enhanced hardness and wear resistance, reducing tool replacement frequency | Bulk availability and cost-effectiveness important for large-scale operations |

Aerospace & Defense:

In aerospace manufacturing, carburo de boro is primarily utilized in abrasive tools for cutting and polishing advanced alloys used in aircraft components. Its extreme hardness and thermal resistance enable precision machining of materials like titanium and composites, ensuring component integrity and safety. Buyers from Europe and the Middle East must prioritize suppliers who guarantee consistent particle size distribution and high purity to meet strict aerospace quality standards, while also securing a stable supply chain to avoid costly production delays.

Automotive Manufacturing:

Carburo de boro enhances the performance of brake pads and clutch components by providing exceptional wear resistance and thermal stability. This results in longer-lasting parts that maintain effectiveness under high friction and temperature conditions, reducing maintenance costs. For automotive manufacturers in South America and Africa, sourcing considerations include verifying compliance with environmental regulations and obtaining certifications that confirm product performance and safety, ensuring market acceptance and regulatory compliance.

Electronics & Semiconductors:

In the electronics sector, carburo de boro serves as a substrate material and heat sink due to its superior thermal conductivity and electrical insulation properties. This improves the efficiency and longevity of semiconductor devices and electronic components. Buyers, particularly in technologically advanced regions like Poland and the Middle East, should focus on acquiring materials that meet stringent thermal performance criteria and industry-specific standards to support high-reliability applications.

Chemical Processing:

Carburo de boro is used in chemical processing as a catalyst support and in wear-resistant coatings for equipment exposed to corrosive environments. Its chemical inertness and durability enhance catalyst effectiveness and prolong equipment life, minimizing downtime. International buyers must ensure the material’s chemical purity and resistance to corrosion align with their specific process requirements to maintain operational stability and safety.

Construction & Mining:

In construction and mining, carburo de boro is incorporated into cutting and grinding tools for stone, concrete, and other hard materials. Its hardness significantly improves tool lifespan and cutting efficiency, leading to lower operational costs. For large-scale projects in Africa and South America, sourcing priorities include bulk availability and cost-effectiveness without compromising on material quality, enabling sustained productivity in demanding environments.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

Key Properties: Boron carbide powders are characterized by their exceptional hardness (third hardest material after diamond and cubic boron nitride), high melting point (~2763°C), and excellent chemical inertness. They exhibit outstanding resistance to wear, corrosion, and thermal shock, making them ideal for high-temperature and abrasive environments.

Pros & Cons: The powders offer superior durability and wear resistance, which translates to long service life in cutting tools and armor applications. However, their manufacturing complexity is high due to the need for precise particle size distribution and purity control, which can increase costs. The powders require specialized sintering processes to achieve optimal density and mechanical properties.

Impact on Application: Boron carbide powders are well-suited for producing cutting tools, abrasives, and ballistic armor. Their chemical inertness makes them compatible with aggressive media, including acids and alkalis, which is advantageous in chemical processing industries.

International B2B Considerations: Buyers from Africa, South America, the Middle East, and Europe should verify compliance with ASTM C799 and ISO 20307 standards for powder quality and particle size. Regions like Poland and Colombia often prioritize suppliers with ISO certification and traceability documentation. Import regulations related to chemical powders should also be reviewed to ensure smooth customs clearance.

Key Properties: Ceramic components made from boron carbide combine extreme hardness with low density and high compressive strength. They maintain structural integrity under high pressure and temperature, with excellent resistance to oxidation and corrosion.

Pros & Cons: These ceramics provide outstanding wear resistance and thermal stability, suitable for harsh industrial environments. However, their brittleness can be a limitation under tensile or impact loads, requiring careful design consideration. Manufacturing involves complex processes like hot pressing or spark plasma sintering, which can increase lead times and costs.

Impact on Application: Ideal for nozzles, seals, and armor plates, boron carbide ceramics excel in abrasive slurry handling, ballistic protection, and high-pressure sealing. Their chemical resistance makes them compatible with a wide range of industrial fluids.

International B2B Considerations: Compliance with DIN EN 60672 and JIS R 1601 standards is often required in European and Asian markets. Buyers in emerging markets should ensure suppliers provide mechanical testing certificates and batch consistency reports. Logistics planning should account for the fragile nature of ceramic parts to minimize damage during transit.

Key Properties: Boron carbide coatings applied via chemical vapor deposition (CVD) or physical vapor deposition (PVD) enhance substrate materials with extreme hardness, low friction, and chemical inertness. Coatings typically range from a few microns to tens of microns in thickness.

Pros & Cons: Coated tools benefit from extended wear life and improved performance in cutting, drilling, and machining applications. The coating process adds complexity and cost but can be applied to various substrates, including metals and ceramics. Adhesion quality and coating uniformity are critical factors affecting durability.

Impact on Application: Coated tools are preferred in metalworking, mining, and petrochemical industries where abrasive wear and corrosion are prevalent. The coatings improve tool life when working with hard or corrosive materials.

International B2B Considerations: Buyers should ensure coatings meet ASTM B757 or ISO 20502 standards for thickness and adhesion. Regional preferences may vary, with Middle Eastern and South American buyers often seeking suppliers with local service support for recoating and maintenance. Warranty terms and coating performance guarantees are important procurement criteria.

Key Properties: Composite materials combine boron carbide with binders such as silicon carbide or carbon to enhance toughness and reduce brittleness. These composites maintain high hardness while improving impact resistance and thermal shock tolerance.

Pros & Cons: Composites offer a balanced combination of hardness and toughness, making them versatile for structural and protective applications. The trade-off includes slightly reduced hardness compared to pure boron carbide and more complex manufacturing requiring precise control of binder content and distribution.

Impact on Application: Widely used in armor systems, wear-resistant linings, and high-performance cutting tools, composites provide enhanced durability in dynamic and impact-heavy environments. Their improved toughness broadens application scope where pure ceramics might fail.

International B2B Considerations: Compliance with military and industrial standards such as MIL-DTL-32332 (US) and EN 1522 (Europe) is often required for armor composites. Buyers from Europe and the Middle East should verify certifications and supplier capabilities for custom composite formulations. Supply chain reliability and lead times are critical for project planning in these regions.

| Material | Typical Use Case for carburo de boro | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Boron Carbide Powders | Abrasives, cutting tools, ballistic armor | Exceptional hardness and chemical inertness | High manufacturing complexity and cost | High |

| Boron Carbide Ceramic Components | Nozzles, seals, armor plates | High wear resistance and thermal stability | Brittleness and fragile handling | High |

| Boron Carbide-Coated Tools | Metalworking, mining, petrochemical tools | Extended tool life and low friction | Coating adhesion sensitivity and cost | Medium |

| Boron Carbide Composite Materials | Armor systems, wear linings, cutting tools | Improved toughness and impact resistance | Slight hardness reduction, complex manufacturing | Medium |

Carburo de boro (boron carbide) is a highly durable ceramic material widely used in industrial applications such as abrasives, armor plating, and nuclear reactors. For international B2B buyers, understanding the manufacturing process helps ensure the procurement of high-quality material tailored to specific operational needs.

Raw Material Preparation

The process begins with sourcing high-purity boron and carbon precursors. Common raw materials include boric acid, carbon black, and boron oxide. These are carefully weighed and mixed to achieve the precise stoichiometric ratio necessary for boron carbide synthesis. Material cleanliness and particle size distribution are critical at this stage to influence the final product's performance.

Forming the Boron Carbide Powder

The mixture undergoes a high-temperature carbothermal reduction in a controlled furnace atmosphere (usually argon or nitrogen) at temperatures above 2000°C. This step forms boron carbide powder. Advanced techniques such as plasma synthesis or microwave heating may be employed to enhance purity and control particle morphology.

Shaping and Assembly

The synthesized powder is shaped into final forms using pressing methods—uniaxial, isostatic, or cold/hot pressing—depending on application requirements. For complex shapes, injection molding or slip casting may be applied. In cases where composites are produced, boron carbide powder is combined with binders or other ceramics to improve mechanical properties.

Sintering and Finishing

Sintering consolidates the shaped parts at high temperatures (around 2100-2200°C) under inert atmospheres to achieve densification and desired mechanical strength. Post-sintering, finishing processes like grinding, lapping, or polishing ensure dimensional accuracy and surface quality. Coatings or treatments may be applied to enhance wear resistance or chemical stability.

Illustrative Image (Source: Google Search)

Quality assurance (QA) in carburo de boro manufacturing is critical to meet stringent performance criteria demanded by industries such as defense, aerospace, and chemical processing. QA frameworks incorporate international standards, rigorous in-process controls, and comprehensive testing.

Incoming Quality Control (IQC)

Raw materials are inspected for chemical purity, particle size, and contamination. Techniques include X-ray fluorescence (XRF) and laser diffraction particle analysis. IQC ensures that only materials meeting strict specifications enter the production line.

In-Process Quality Control (IPQC)

Monitoring critical parameters during synthesis and forming stages, such as furnace temperature, atmosphere composition, and pressing pressure. This stage often uses real-time sensors and periodic sampling to detect deviations early.

Final Quality Control (FQC)

Finished products undergo dimensional inspection, mechanical testing (hardness, fracture toughness), and microstructural analysis (scanning electron microscopy). Chemical composition verification confirms phase purity.

For buyers from Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is essential to mitigate risks associated with material failure or non-compliance.

By thoroughly understanding the manufacturing and quality assurance processes of carburo de boro, international B2B buyers can make informed decisions, ensure material performance, and establish robust supplier partnerships aligned with their regional compliance needs and operational demands.

When sourcing carburo de boro (boron carbide) for industrial applications, understanding the detailed cost structure is essential for making informed purchasing decisions. The overall price is influenced by multiple components:

Several factors influence the final pricing of carburo de boro in B2B transactions:

For buyers from Africa, South America, the Middle East, and Europe (including countries like Poland and Colombia), optimizing cost efficiency requires strategic negotiation and thorough cost analysis:

Prices for carburo de boro vary widely based on purity, particle size, order volume, and supplier location. Indicative prices can range from $5 to $20 per kilogram or more for specialized grades. Buyers are advised to request detailed quotations and perform comparative analyses to determine the best value proposition aligned with their technical and commercial requirements.

By comprehensively analyzing cost components and understanding the key pricing drivers, international B2B buyers can effectively negotiate and optimize their procurement of carburo de boro, ensuring both cost efficiency and product quality tailored to their market needs.

Understanding the fundamental technical specifications of carburo de boro (boron carbide) is crucial for international B2B buyers to ensure product suitability and optimize supply chain decisions. Here are the primary properties to consider:

Material Grade

Boron carbide is available in various grades, typically differentiated by purity levels (e.g., 95%, 98%, 99%). Higher purity grades offer superior hardness and chemical resistance, essential for applications like abrasives or armor plating. For buyers, selecting the correct grade impacts performance and cost-efficiency.

Particle Size and Distribution

This refers to the granularity of the boron carbide powder or granules, measured in microns or mesh size. Finer particles enhance sintering and surface finish in ceramics, while coarser particles are preferred for abrasive purposes. Accurate specification helps avoid production issues and ensures product consistency.

Hardness (Mohs Scale)

Boron carbide ranks around 9.5 on the Mohs hardness scale, making it one of the hardest materials after diamond and cubic boron nitride. This property is critical for industries requiring wear resistance, such as mining and defense. Buyers should verify hardness values aligned with their intended use.

Density

Typical density ranges from 2.45 to 2.52 g/cm³. Density influences material strength and weight, particularly important in applications like lightweight armor or high-performance ceramics. Precise density data guides engineering and quality control processes.

Chemical Stability and Corrosion Resistance

Boron carbide exhibits excellent resistance to acids, alkalis, and oxidation at high temperatures. This characteristic makes it suitable for harsh environments, including chemical processing plants. Buyers must confirm chemical compatibility to prevent premature material degradation.

Tolerance and Dimensional Accuracy

For shaped boron carbide components, tolerance levels (e.g., ±0.01 mm) define acceptable dimensional variation. Tight tolerances are mandatory in precision engineering sectors to ensure component fit and function. Understanding tolerance standards prevents costly rework or assembly failures.

Navigating global procurement of carburo de boro requires familiarity with common trade terms that streamline communication and contract negotiation:

OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products for use in another company’s end product. Buyers working with OEMs must ensure boron carbide materials meet specific OEM standards and certifications to maintain product integrity and warranty compliance.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. MOQs affect inventory planning and cash flow. International buyers from emerging markets or smaller businesses should negotiate MOQs that align with their demand forecasts to optimize capital use.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for price, availability, and terms for specific quantities and grades of boron carbide. An effective RFQ includes detailed technical specs and delivery requirements, facilitating accurate and comparable supplier responses.

Incoterms (International Commercial Terms)

Standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties. Common Incoterms include FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps buyers clarify logistics costs and risk transfer points.

Lead Time

The total time from order placement to delivery. Boron carbide production and shipping lead times vary by supplier location and product complexity. Buyers should factor lead times into project schedules to avoid delays and ensure continuous production.

Certificate of Analysis (CoA)

A document provided by the supplier detailing the product’s chemical composition and physical properties. The CoA is essential for quality assurance and regulatory compliance, particularly in industries such as aerospace or defense.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and foster strong supplier partnerships in the carburo de boro market. This knowledge is especially valuable for stakeholders in Africa, South America, the Middle East, and Europe, where supply chain efficiency and product reliability are critical to competitive advantage.

The global carburo de boro (boron carbide) market is experiencing steady growth driven by its critical applications across diverse industries such as abrasives, armor plating, nuclear reactors, and advanced ceramics. For international B2B buyers—especially those in Africa, South America, the Middle East, and Europe—understanding these market drivers is essential to strategic sourcing and supply chain optimization.

Key Market Drivers:

- Industrial Demand: The rapid industrialization in emerging economies (e.g., Colombia and parts of Africa) is boosting demand for high-performance materials, including boron carbide, for manufacturing and infrastructure projects.

- Defense and Security: Boron carbide's lightweight and high-hardness properties make it a preferred material for ballistic armor in military and security applications, particularly relevant for regions with growing defense budgets such as the Middle East and Eastern Europe.

- Technological Advancements: Innovations in nanostructured carburo de boro and composites are expanding applications in electronics, aerospace, and energy sectors, creating new procurement opportunities for tech-forward buyers.

Sourcing Trends:

- Diversification of Supply Sources: Due to geopolitical uncertainties and supply chain disruptions, buyers are increasingly diversifying suppliers beyond traditional producers in China and the US, exploring emerging markets in Africa and South America.

- Digital Procurement Platforms: Adoption of digital B2B marketplaces and AI-driven sourcing tools is streamlining supplier discovery and contract management, enabling buyers to access real-time market pricing and quality verification.

- Customization and Value-added Services: Suppliers offering tailored particle sizes, purity levels, and composite formulations are gaining preference, allowing buyers to optimize product performance for specific industrial applications.

Market Dynamics:

- Price Volatility: Fluctuations in raw material costs, particularly boron ore and energy prices, directly impact carburo de boro pricing. Buyers must monitor commodity indices and negotiate flexible contracts.

- Regulatory Environment: Compliance with export controls, especially regarding dual-use materials, is critical. European buyers, for example, face stringent REACH regulations affecting product certification and import logistics.

- Regional Trade Agreements: Leveraging regional trade agreements like the African Continental Free Trade Area (AfCFTA) or Mercosur can reduce tariffs and improve supply chain resilience for buyers sourcing within these regions.

Sustainability is becoming a decisive factor in the procurement of carburo de boro, reflecting growing environmental concerns and regulatory pressures worldwide. For B2B buyers aiming to align with global sustainability goals, integrating green procurement practices can enhance corporate reputation and reduce operational risks.

Environmental Impact Considerations:

- Energy-Intensive Production: The manufacture of boron carbide involves high-temperature processes consuming significant energy, often derived from fossil fuels. Buyers should assess suppliers’ energy sources and efficiency measures.

- Mining Footprint: Extraction of boron ores can cause habitat disruption and water pollution if not managed responsibly. Demand for transparency in mining practices is rising, particularly from European and Middle Eastern buyers focused on ESG (Environmental, Social, Governance) compliance.

Ethical Supply Chains:

- Traceability and Certification: Ethical sourcing requires full visibility into the supply chain, from raw material extraction to final processing. Certifications such as ISO 14001 (environmental management) and conflict-free sourcing attestations are increasingly valued.

- Supplier Audits and Partnerships: Establishing long-term partnerships with suppliers committed to sustainability initiatives helps mitigate risks related to labor practices, environmental violations, and supply disruptions.

Green Certifications and Materials:

- While no universal “green” certification exists specifically for carburo de boro, buyers should prioritize suppliers implementing renewable energy usage, waste reduction programs, and circular economy principles such as recycling boron carbide scrap.

- Emerging eco-friendly alternatives and process innovations, like low-carbon synthesis methods or bio-based binders in composite materials, are areas to watch for future procurement opportunities.

Carburo de boro was first synthesized in the late 19th century, but its commercial relevance surged in the mid-20th century with the expansion of nuclear technology and military applications. Initially prized for its extreme hardness—second only to diamond—it became a cornerstone material for abrasive tools and armor systems.

Over time, advances in material science have broadened its utility beyond traditional industries into cutting-edge fields such as electronics and nanotechnology. This evolution underscores the importance for B2B buyers to stay informed about technological breakthroughs that can enhance product performance and open new market segments.

Understanding the historical progression of carburo de boro helps buyers appreciate the material’s strategic importance and anticipate future shifts in demand driven by innovation and sustainability imperatives.

How can I effectively vet suppliers of carburo de boro for international B2B purchases?

When sourcing carburo de boro internationally, conduct thorough due diligence by verifying supplier certifications such as ISO 9001 and relevant product quality standards. Request product samples and test reports to confirm material specifications. Utilize third-party inspection services to audit manufacturing facilities, especially for suppliers in regions like South America and the Middle East. Check references from existing international clients and review trade history on platforms like Alibaba or Global Sources. Prioritize suppliers who demonstrate transparency in production processes and compliance with export regulations to minimize risks.

What customization options are typically available for carburo de boro, and how can I communicate requirements effectively?

Carburo de boro can often be customized in terms of particle size, purity, shape, and packaging to meet specific industrial applications. Clearly define your technical specifications, including chemical composition and physical properties, in written form. Share detailed drawings or samples if applicable. Engage in direct dialogue with the supplier’s technical team to ensure feasibility and discuss any additional costs or lead times. Buyers from Europe or Africa should also inquire about compliance with regional standards to ensure seamless integration into their supply chain.

Illustrative Image (Source: Google Search)

What are common minimum order quantities (MOQs) and lead times for carburo de boro, and how can I negotiate better terms?

MOQs for carburo de boro vary widely depending on supplier capacity and product grade but typically start from 500 kg to 1 metric ton. Lead times often range from 3 to 8 weeks, factoring in production and international shipping. To negotiate better terms, consolidate orders with other buyers or commit to longer-term contracts. Highlight your market potential and payment reliability to encourage flexibility. Buyers in emerging markets such as Colombia or Nigeria can leverage regional trade agreements or logistics hubs to reduce delivery times and costs.

Which quality assurance certifications should I require from carburo de boro suppliers to ensure product reliability?

Request certifications like ISO 9001 for quality management systems and ISO 14001 for environmental management. For chemical products, compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in Europe is crucial. Additionally, certificates of analysis (CoA) for each batch provide detailed insights into purity and physical properties. Suppliers who adhere to industry-specific standards, such as ASTM or JIS, demonstrate higher reliability. These certifications are essential for regulatory compliance and reduce risks related to product inconsistencies.

What are the best practices for managing logistics and shipping of carburo de boro internationally?

Plan shipments by selecting reliable freight forwarders experienced in handling chemical powders and hazardous materials. Ensure proper packaging to prevent contamination or moisture ingress during transit. Clarify Incoterms (e.g., FOB, CIF) upfront to define responsibilities and costs. For buyers in Africa and the Middle East, consider port proximity and customs clearance efficiency to avoid delays. Track shipments using digital tools and maintain clear communication with all parties involved. Early coordination with customs brokers can prevent compliance issues and unexpected fees.

How should I structure payment terms to mitigate risks when importing carburo de boro?

Common payment methods include Letters of Credit (LC), Telegraphic Transfers (T/T), and Escrow services. For new suppliers, LCs offer protection by ensuring payment only upon meeting agreed conditions, such as delivery and inspection. Negotiate partial upfront payments combined with balance upon receipt for trust-building. Buyers from South America and Europe should also verify supplier banking credentials and use trade finance solutions like factoring to optimize cash flow. Always document payment terms clearly in contracts to avoid disputes.

What steps can I take if there is a dispute regarding the quality or delivery of carburo de boro?

Immediately document all discrepancies with photos, test results, and communication records. Engage the supplier in good faith to seek resolution through replacement, refund, or price adjustment. Refer to the arbitration or dispute resolution clause in your contract, often specifying mediation or arbitration in a neutral jurisdiction. For buyers in different continents, consider involving trade chambers or industry associations that offer dispute resolution services. Maintaining clear documentation and professional communication is critical for successful outcomes.

Are there specific regulatory or import restrictions for carburo de boro in markets like Poland, Colombia, or the Middle East?

Yes, regulatory requirements vary by region. The European Union, including Poland, enforces strict REACH compliance and chemical safety standards. Colombia requires import permits and adherence to local environmental regulations. Middle Eastern countries may impose restrictions related to hazardous material handling and customs documentation. Engage local customs brokers to ensure compliance with tariff classifications and import duties. Staying updated on regulatory changes is essential to avoid shipment delays and penalties.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In navigating the complexities of sourcing carburo de boro, international buyers must prioritize a strategic approach that balances quality, cost-efficiency, and supply chain resilience. Understanding the nuances of supplier capabilities, regional market dynamics, and regulatory environments is critical—especially for buyers in Africa, South America, the Middle East, and Europe, where logistical and geopolitical factors can significantly impact procurement outcomes.

Illustrative Image (Source: Google Search)

Key takeaways for successful sourcing include:

Looking ahead, demand for carburo de boro is poised to grow across industries such as aerospace, automotive, and electronics, driven by its superior hardness and thermal properties. Buyers who adopt a proactive sourcing strategy today will be better positioned to capitalize on these opportunities while navigating market volatility.

For international B2B buyers, especially in emerging and established markets alike, now is the time to deepen supplier networks, invest in supply chain agility, and leverage data-driven insights to secure a competitive advantage in carburo de boro procurement.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina