Navigating the global market for SiC (Silicon Carbide) semiconductors can be a daunting task for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, including countries such as Mexico and Turkey. As industries increasingly seek high-efficiency solutions for power electronics, the demand for SiC semiconductors is rising. However, the challenge lies in sourcing the right products that meet specific application needs while ensuring cost-effectiveness and supplier reliability.

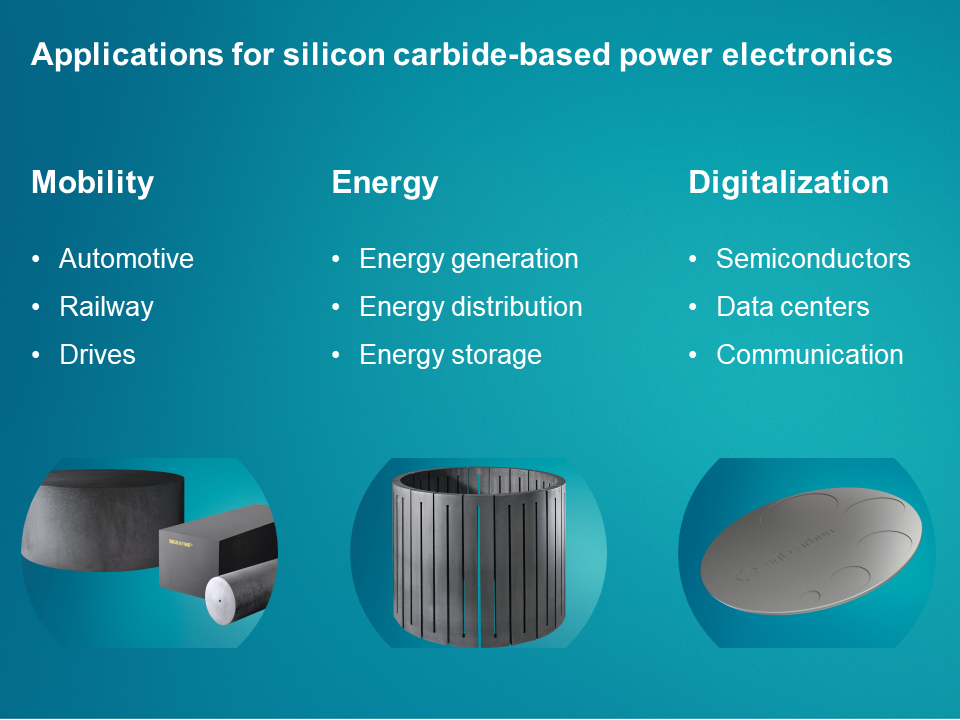

This comprehensive guide delves into the multifaceted world of SiC semiconductors. It covers essential aspects such as the various types of SiC devices, their diverse applications across sectors like automotive, renewable energy, and industrial automation, and the critical process of vetting suppliers. Additionally, it provides insights on cost considerations, helping you navigate pricing strategies and supply chain dynamics effectively.

By equipping international B2B buyers with actionable insights and expert knowledge, this guide empowers you to make informed purchasing decisions. Whether you are exploring partnerships with manufacturers or seeking to understand the latest technological advancements, this resource serves as a valuable tool in your sourcing strategy. In an ever-evolving market landscape, understanding SiC semiconductors is not just an advantage; it's a necessity for driving innovation and maintaining competitiveness.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 4H-SiC | High thermal conductivity, high breakdown voltage | Power electronics, automotive | Pros: Excellent thermal performance; Cons: Higher cost compared to other types. |

| 6H-SiC | Good balance between conductivity and thermal stability | RF devices, industrial applications | Pros: Moderate performance; Cons: Less efficient at high frequencies. |

| Polycrystalline SiC | Lower production costs, less purity | General-purpose applications | Pros: Cost-effective; Cons: Inferior performance compared to single-crystal variants. |

| Single-Crystal SiC | High purity, superior electronic properties | High-performance devices | Pros: Best performance; Cons: Expensive and complex manufacturing. |

| SiC MOSFETs | High efficiency, fast switching capabilities | Renewable energy, electric vehicles | Pros: Reduces energy losses; Cons: Requires careful thermal management. |

4H-SiC is recognized for its exceptional thermal conductivity and high breakdown voltage, making it ideal for power electronics and automotive applications. Its ability to operate at higher temperatures allows for more compact designs in power modules, which is crucial for industries focused on efficiency and space-saving. B2B buyers should consider the initial higher costs against long-term performance benefits, especially in sectors where reliability and durability are paramount.

6H-SiC strikes a balance between conductivity and thermal stability, making it suitable for RF devices and various industrial applications. While it delivers moderate performance, it is less efficient at high frequencies compared to its 4H counterpart. Buyers should weigh the cost-effectiveness of 6H-SiC for applications that do not demand the highest efficiency, as it can provide adequate performance without breaking the budget.

Polycrystalline SiC offers a cost-effective alternative due to its lower production costs and broader availability. It is suitable for general-purpose applications, providing a practical solution for businesses looking to minimize expenses while still leveraging the advantages of silicon carbide technology. However, buyers should note that its performance does not match that of single-crystal variants, which may limit its use in high-performance applications.

Single-crystal SiC is the gold standard in terms of purity and electronic properties, making it the preferred choice for high-performance devices. Industries that require the utmost reliability and efficiency, such as aerospace and advanced automotive sectors, often opt for this type. Despite the higher manufacturing costs and complexity, the superior performance justifies the investment for B2B buyers focused on cutting-edge technology.

SiC MOSFETs are gaining traction in renewable energy and electric vehicle applications due to their high efficiency and fast switching capabilities. They significantly reduce energy losses, which is critical for systems that prioritize sustainability and performance. However, careful thermal management is essential to fully exploit their benefits. B2B buyers should consider the specific thermal requirements of their applications when integrating SiC MOSFETs into their systems.

Related Video: What Are the Main Types of Semiconductors Used in Electronics?

| Industry/Sector | Specific Application of sic-halbleiter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric Vehicle (EV) Power Electronics | Enhanced efficiency and reduced energy losses | Supplier reliability, technological compatibility, and compliance with automotive standards. |

| Renewable Energy | Solar Inverters | Increased conversion efficiency and reduced footprint | Certifications for renewable energy technologies and local market regulations. |

| Industrial Automation | Motor Drives for Industrial Equipment | Higher performance with lower cooling requirements | Technical support, integration capabilities, and warranty terms. |

| Telecommunications | RF Power Amplifiers for 5G Networks | Improved signal strength and energy efficiency | Availability of advanced packaging solutions and thermal management systems. |

| Aerospace and Defense | High-Temperature Power Devices | Reliability in extreme environments and reduced weight | Compliance with aerospace standards, long-term availability, and testing certifications. |

In the automotive industry, particularly in electric vehicles (EVs), sic-halbleiter are pivotal in power electronics. They enable efficient power conversion, allowing for smaller, lighter components that improve vehicle performance. This reduces energy losses during operation, enhancing overall vehicle range. B2B buyers in this sector must ensure that suppliers meet stringent automotive standards and provide reliable products that can withstand rigorous testing and operational conditions.

In renewable energy, particularly in solar inverters, sic-halbleiter significantly boost conversion efficiency. They handle higher voltages and temperatures, allowing for more compact designs that occupy less space. This not only improves system performance but also reduces installation costs. International buyers should consider suppliers that offer certifications for renewable energy technologies and are familiar with local regulations, ensuring compliance and operational efficiency.

In industrial automation, sic-halbleiter are used in motor drives to enhance performance while reducing cooling requirements. Their high efficiency allows for more compact systems, which can lead to lower operational costs and increased productivity. Buyers in this sector should focus on sourcing from suppliers who provide strong technical support and have proven integration capabilities, as well as favorable warranty terms to mitigate risks.

In telecommunications, sic-halbleiter are essential for RF power amplifiers used in 5G networks. They improve signal strength while reducing power consumption, which is critical for network reliability and performance. B2B buyers should prioritize sourcing from manufacturers that offer advanced packaging solutions and thermal management systems, as these factors can greatly influence performance in high-demand applications.

In aerospace and defense, sic-halbleiter are utilized in high-temperature power devices, providing reliability in extreme environments while minimizing weight. This is crucial for enhancing the performance and efficiency of aerospace systems. Buyers in this sector must ensure that their suppliers comply with aerospace standards and provide long-term availability of components, as well as necessary testing certifications to ensure safety and reliability.

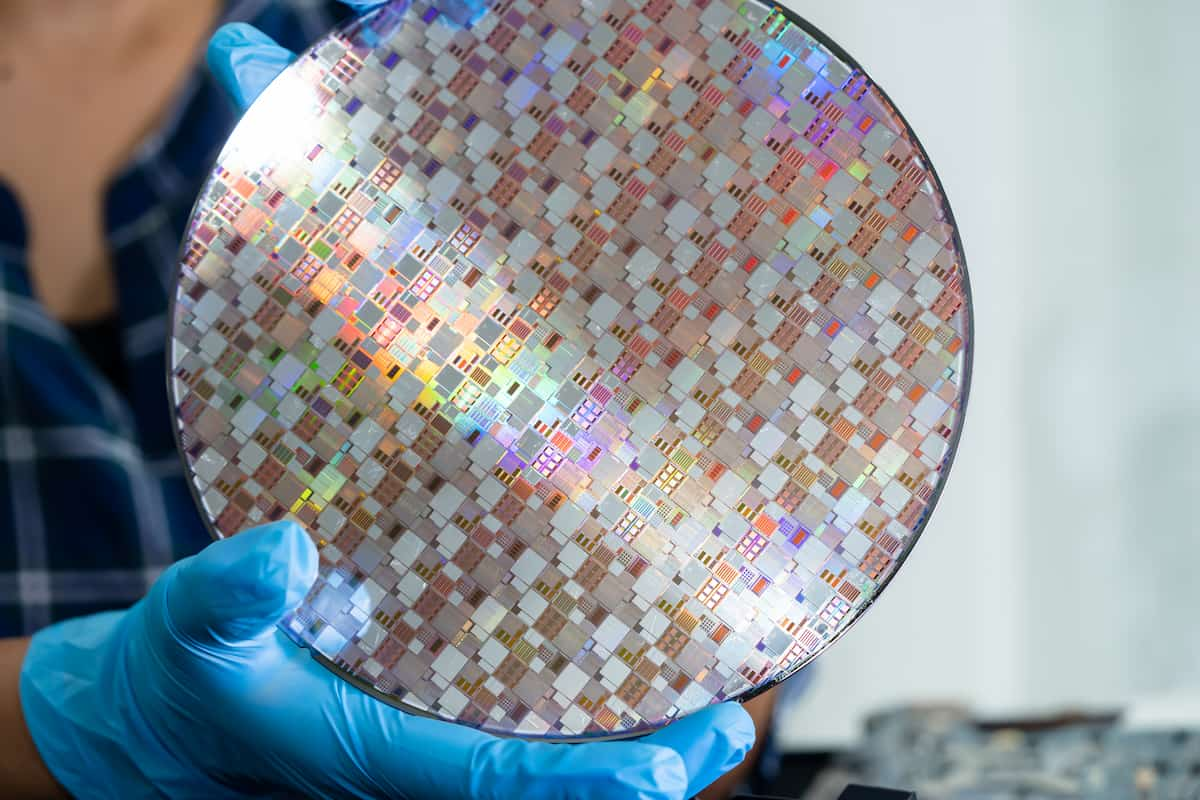

A stock image related to sic-halbleiter.

The Problem: B2B buyers often face the daunting task of selecting the right Sic-Halbleiter (silicon carbide semiconductors) for their specific applications. The technical specifications can be overwhelming, and a lack of clear understanding may lead to misalignment with project requirements. This confusion can result in delays, increased costs, and ultimately, dissatisfaction with the performance of the chosen components. Buyers in regions like Africa and South America may find limited access to knowledgeable suppliers who can offer guidance on these technical complexities.

The Solution: To effectively navigate these challenges, it is crucial to establish a clear set of criteria based on application needs before engaging with suppliers. Start by conducting a thorough analysis of your project's requirements, including power ratings, temperature ranges, and switching frequencies. Create a detailed specification sheet that includes these parameters, which can be shared with potential suppliers. This proactive approach not only streamlines the communication process but also ensures that suppliers can provide the most relevant options. Additionally, consider leveraging online resources and forums dedicated to semiconductor technologies, where industry experts share insights and recommendations. This can further enhance your understanding and help in making informed decisions.

The Problem: Supply chain disruptions have become increasingly common in the semiconductor industry, impacting the availability of Sic-Halbleiter. Buyers from regions such as the Middle East and Europe may experience delays in receiving orders, which can jeopardize project timelines and lead to financial penalties. The uncertainty surrounding lead times and delivery schedules creates a challenging environment for procurement teams trying to maintain production schedules.

The Solution: To mitigate supply chain risks, it is essential to diversify your supplier base. Engage with multiple manufacturers and distributors of Sic-Halbleiter to ensure you have alternative sources in case of shortages. Building strong relationships with these suppliers can facilitate better communication and priority handling during shortages. Additionally, consider implementing just-in-time inventory practices to reduce the impact of delays. By ordering components based on real-time project needs rather than holding excessive stock, you can optimize cash flow while being prepared for potential disruptions. Regularly monitoring global semiconductor market trends and geopolitical factors can also help anticipate issues before they affect your supply chain.

The Problem: Different regions have varying compliance requirements and industry standards for semiconductor components, including Sic-Halbleiter. B2B buyers in Europe, for instance, must adhere to strict environmental regulations and certifications, while buyers in Africa may encounter different compliance challenges. Navigating these regulations can be complex and may lead to costly mistakes if products do not meet the necessary standards.

The Solution: It is imperative for buyers to familiarize themselves with the relevant compliance standards in their regions. This can be achieved by consulting with industry associations and regulatory bodies that provide guidance on semiconductor standards. Additionally, when sourcing Sic-Halbleiter, prioritize suppliers who are transparent about their certification processes and can provide documentation verifying compliance with local regulations. Engage in discussions about the environmental impact of the components, and request detailed information on materials used in manufacturing. By establishing a checklist of required certifications and maintaining open communication with suppliers, buyers can ensure that they procure compliant components that meet both local and international standards, thus avoiding potential legal and financial repercussions.

A stock image related to sic-halbleiter.

In the realm of silicon carbide (SiC) semiconductors, the choice of materials is crucial for optimizing performance and ensuring reliability in various applications. Below, we analyze four common materials used in SiC semiconductors, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Key Properties: SiC exhibits exceptional thermal conductivity, high breakdown voltage, and superior thermal stability, making it ideal for high-temperature and high-voltage applications.

Pros & Cons: The durability of SiC is notable, as it can withstand harsh environments. However, the manufacturing complexity is higher compared to traditional silicon, leading to increased costs. SiC is particularly well-suited for power electronics, electric vehicles, and renewable energy systems.

Impact on Application: In applications involving high-frequency and high-temperature operations, SiC enhances efficiency and reduces energy losses. Its compatibility with various media, including aggressive chemicals, makes it versatile.

Considerations for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should ensure compliance with international standards such as ASTM and DIN. Understanding local regulations regarding semiconductor materials is also essential.

Key Properties: GaN is known for its high electron mobility and saturation velocity, which translates to high efficiency in power conversion applications.

Pros & Cons: The key advantage of GaN is its ability to operate at higher voltages and frequencies than SiC, making it suitable for RF applications. However, GaN can be more expensive and less durable under extreme conditions compared to SiC.

Impact on Application: GaN is particularly effective in wireless communication and radar systems, where high efficiency and compact size are critical. Its compatibility with existing semiconductor technology allows for easier integration.

Considerations for International Buyers: Buyers must consider the availability of GaN components in their respective markets and the associated costs. Compliance with international standards is necessary for successful market entry.

Key Properties: Silicon is the most widely used semiconductor material, known for its good thermal and electrical properties.

Pros & Cons: While silicon is cost-effective and has a well-established manufacturing process, it lacks the high-temperature and high-voltage capabilities of SiC and GaN. This limits its use in advanced applications.

Impact on Application: Silicon is ideal for low-power applications and consumer electronics. However, its limitations in extreme conditions make it less suitable for high-performance applications.

Considerations for International Buyers: Buyers should be aware of the extensive supply chains for silicon components and the potential for price fluctuations. Compliance with local and international standards is essential for quality assurance.

Key Properties: AlN is characterized by excellent thermal conductivity and electrical insulation properties, making it suitable for high-power applications.

Pros & Cons: The primary advantage of AlN is its ability to dissipate heat efficiently, which prolongs the lifespan of electronic devices. However, its manufacturing process can be complex and costly.

Impact on Application: AlN is particularly beneficial in high-power electronic devices and optoelectronics, where heat management is crucial. Its compatibility with various substrates enhances its applicability.

Considerations for International Buyers: Buyers should consider the availability of AlN in their regions and the associated costs. Ensuring compliance with relevant standards is vital for successful integration into existing systems.

| Material | Typical Use Case for sic-halbleiter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | Power electronics, electric vehicles | High thermal stability and efficiency | Higher manufacturing complexity | High |

| Gallium Nitride (GaN) | RF applications, wireless systems | High efficiency at high frequencies | More expensive and less durable | High |

| Silicon (Si) | Consumer electronics, low-power apps | Cost-effective and widely available | Limited performance in extreme conditions | Low |

| Aluminum Nitride (AlN) | High-power electronics | Excellent heat dissipation | Complex and costly manufacturing | Medium |

This guide provides a strategic overview of material selection for SiC semiconductors, helping international B2B buyers make informed decisions based on performance requirements, cost considerations, and compliance with regional standards.

The manufacturing of silicon carbide (SiC) semiconductors, commonly referred to as Sic-Halbleiter, involves several critical stages that ensure the production of high-quality devices. Understanding these processes is essential for international B2B buyers aiming to procure SiC components, particularly from regions like Africa, South America, the Middle East, and Europe.

The initial stage in SiC manufacturing involves the preparation of raw materials. High-purity silicon carbide crystals are synthesized using methods such as the Acheson process or chemical vapor deposition (CVD). The choice of method impacts the quality and uniformity of the SiC wafers produced.

Once the raw materials are prepared, the next step is forming the SiC wafers. This process includes several techniques:

The assembly phase includes several critical processes to integrate the SiC wafers into functional semiconductor devices:

Finishing processes are essential to ensure that the SiC devices meet stringent performance and reliability criteria:

Quality assurance in SiC manufacturing is paramount, particularly for B2B buyers concerned about reliability and performance. Several international standards are applicable:

Quality control (QC) is integrated at various stages of the SiC manufacturing process:

For international B2B buyers, verifying the quality control processes of potential suppliers is critical to ensure product reliability. Here are some actionable steps:

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific challenges in quality control:

By understanding the manufacturing processes and quality assurance practices associated with SiC semiconductors, B2B buyers can make informed decisions and establish reliable partnerships within the industry.

In the fast-evolving semiconductor market, particularly with silicon carbide (SiC) semiconductors, international B2B buyers must adopt a meticulous approach when sourcing these critical components. This guide provides a practical checklist to ensure that you make informed and strategic decisions when procuring SiC semiconductors for your business needs.

Understanding your specific requirements is crucial for sourcing SiC semiconductors effectively. Clearly outline the parameters such as voltage ratings, thermal conductivity, and switching frequency. This clarity will help you communicate effectively with suppliers and ensure that the components meet your operational needs.

Before approaching suppliers, it's essential to conduct thorough market research. Identify key manufacturers and distributors of SiC semiconductors and analyze their market presence, product offerings, and pricing strategies. This will give you a broader perspective on the available options and help you identify potential partners.

Before committing to a supplier, it is crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Ensure that the suppliers can meet your technical specifications and deliver on time.

Check for relevant certifications and compliance with international standards such as ISO 9001 or industry-specific certifications. This step is vital to ensure that the suppliers adhere to quality management systems and maintain high standards in their manufacturing processes.

Once you have shortlisted potential suppliers, request samples of the SiC semiconductors. Testing these samples in your actual application can provide insights into their performance and compatibility with your systems.

Engage in negotiations to determine favorable pricing, payment terms, and delivery schedules. Be transparent about your budget and expectations, and look for options that align with your financial constraints while ensuring quality.

Once you have finalized your supplier, set up a clear communication channel. Regular updates on order status, delivery timelines, and any potential issues will facilitate a smoother procurement process.

By following this comprehensive checklist, B2B buyers can navigate the complex landscape of sourcing SiC semiconductors with confidence, ensuring they secure the best products for their business needs.

When sourcing sic-halbleiter (silicon carbide semiconductors), understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The raw materials for sic-halbleiter, primarily silicon carbide, can fluctuate in price based on market demand and availability. High-purity materials are essential for performance, leading to higher costs.

Labor: Skilled labor is required for manufacturing and quality control. Countries with lower labor costs may offer competitive pricing, but be mindful of the potential trade-off in quality.

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can significantly reduce these overhead costs.

Tooling: Specialized equipment and tooling are necessary for the production of sic-halbleiter. This initial investment can be substantial but is crucial for achieving scale and maintaining quality.

Quality Control (QC): Rigorous QC processes are vital to ensure that the semiconductors meet industry standards. Investing in quality assurance can prevent costly defects and returns.

Logistics: Shipping and handling costs can vary widely depending on the origin and destination of the products. This includes freight charges, customs duties, and warehousing costs.

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers negotiate better deals.

Several factors can influence the pricing of sic-halbleiter, making it essential for buyers to be aware of them:

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, while smaller orders might incur higher per-unit costs. Buyers should assess their needs and negotiate MOQs accordingly.

Specifications and Customization: Customized products that meet specific technical requirements can lead to increased costs. Buyers should evaluate whether the benefits of customization outweigh the additional expenses.

Materials and Quality Certifications: The quality of materials used and the presence of certifications (such as ISO) can significantly affect pricing. Higher-quality products often come at a premium.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge higher prices but provide better assurance of product reliability.

Incoterms: Understanding Incoterms is crucial for managing shipping costs and responsibilities. Different terms can affect overall pricing and should be negotiated upfront.

International B2B buyers should adopt strategic approaches to negotiate favorable pricing for sic-halbleiter:

Conduct Market Research: Understanding current market prices and trends can provide leverage during negotiations. Buyers should gather data on competitor pricing and industry benchmarks.

Leverage Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing. Long-term contracts may encourage suppliers to offer discounts in exchange for guaranteed business.

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the total cost of ownership, which includes maintenance, operational costs, and the potential for product failures. This holistic view can guide better purchasing decisions.

Communicate Volume Commitments: If buyers can commit to larger volumes over time, they can negotiate better pricing. Suppliers are often willing to offer discounts for guaranteed future orders.

Be Open to Alternative Suppliers: Exploring multiple suppliers can provide insights into competitive pricing and options. This approach can also mitigate risks associated with supply chain disruptions.

It's important for international buyers to recognize that prices for sic-halbleiter can vary widely based on several factors, including market conditions, supply chain dynamics, and geopolitical influences. As such, prices should be viewed as indicative rather than fixed. Regularly reviewing market conditions and maintaining open lines of communication with suppliers can help buyers make informed purchasing decisions and adapt to changing circumstances.

In the fast-evolving landscape of semiconductor technology, particularly with the increasing adoption of silicon carbide (SiC) semiconductors, it is crucial for B2B buyers to understand the available alternatives. This analysis will compare SiC semiconductors with two notable alternatives: Gallium Nitride (GaN) and traditional Silicon (Si) semiconductors. Each option presents unique advantages and challenges, making it essential for international buyers, especially from regions like Africa, South America, the Middle East, and Europe, to evaluate which solution best fits their operational needs.

| Comparison Aspect | Sic-Halbleiter | Gallium Nitride (GaN) | Silicon (Si) |

|---|---|---|---|

| Performance | High efficiency; handles high voltages and temperatures | Excellent efficiency; superior thermal performance | Moderate efficiency; limited to lower voltages and temperatures |

| Cost | Higher initial investment; long-term savings on energy | Competitive pricing; still more expensive than Si | Lower upfront costs; higher energy costs over time |

| Ease of Implementation | Requires specialized equipment and training | Generally straightforward; some existing infrastructure can be adapted | Widely understood; existing equipment readily available |

| Maintenance | Low maintenance due to durability | Low maintenance; however, can be sensitive to thermal stresses | Moderate; technology is mature but can degrade faster |

| Best Use Case | High-power applications (e.g., electric vehicles, renewable energy) | High-frequency applications (e.g., RF devices, chargers) | General-purpose electronics (e.g., consumer electronics) |

Gallium Nitride (GaN) is a promising alternative to SiC semiconductors. It offers superior efficiency and is particularly well-suited for high-frequency applications, such as RF devices and fast chargers. Its ability to handle high voltages with minimal heat generation makes it an attractive option. However, GaN technology can be more sensitive to thermal management issues, requiring careful design considerations to prevent performance degradation. Additionally, while GaN prices are becoming more competitive, they still generally exceed those of traditional silicon solutions.

Silicon semiconductors are the most established technology in the industry, known for their affordability and ease of use. They are widely used in consumer electronics and general-purpose applications. However, silicon's limitations in efficiency and thermal performance become apparent in high-power applications. As a result, while silicon offers lower upfront costs, the long-term operational costs may rise due to higher energy consumption and shorter lifespan compared to SiC and GaN alternatives.

When selecting between SiC semiconductors and their alternatives, B2B buyers must consider several factors, including application requirements, budget constraints, and long-term operational goals. SiC is ideal for high-power, high-efficiency applications, particularly in industries such as electric vehicles and renewable energy. In contrast, GaN serves well in high-frequency environments, while traditional silicon remains a viable choice for cost-sensitive, general-purpose electronics.

Ultimately, a thorough evaluation of each option's performance, cost, and specific application suitability will enable buyers to make informed decisions that align with their business objectives and technological needs.

When dealing with Silicon Carbide (SiC) semiconductors, understanding their technical specifications is crucial for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. Here are some key properties to consider:

Material grade refers to the purity and composition of the SiC used in semiconductor manufacturing. Higher grades, like 4H-SiC, offer superior electronic properties, including higher breakdown voltages and thermal conductivity. This is essential for applications in high-power and high-temperature environments, making it a critical factor for buyers looking to enhance the efficiency and lifespan of their devices.

Tolerance indicates the allowable deviation from specified dimensions in the manufacturing process. Tight tolerances are essential for ensuring the reliability and performance of semiconductors in sensitive applications. For B2B buyers, selecting suppliers who adhere to strict tolerances can minimize the risk of defects and improve overall system performance.

Breakdown voltage is the maximum voltage that a semiconductor can withstand before it becomes conductive. SiC devices typically have higher breakdown voltages compared to traditional silicon devices, making them ideal for high-voltage applications. Understanding this property allows buyers to select components that can handle their specific operational requirements without risk of failure.

Thermal conductivity measures the material's ability to conduct heat. SiC has a high thermal conductivity, which is beneficial for managing heat in high-power applications. This property is particularly important for buyers in industries such as automotive and renewable energy, where efficient thermal management can lead to better performance and reliability.

Switching speed refers to how quickly a semiconductor can turn on and off. SiC devices offer faster switching speeds, which can lead to reduced energy losses and improved efficiency. For international buyers, this translates into lower operational costs and enhanced performance in applications like electric vehicles and industrial drives.

Understanding trade terminology is just as important as grasping the technical properties. Here are some common terms that international B2B buyers should know:

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, working with OEMs can ensure that they receive high-quality components that are specifically designed to integrate seamlessly into existing systems.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQs as they can affect inventory management and initial investment costs. Understanding MOQs helps businesses plan their purchasing strategies effectively.

An RFQ is a document that a buyer sends to suppliers requesting a quote for specific products or services. This process is essential for comparing prices and terms, allowing buyers to make informed purchasing decisions.

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in a transaction. They clarify issues such as shipping costs, insurance, and risk transfer. Familiarity with Incoterms helps buyers negotiate better terms and avoid misunderstandings in international trade.

Lead time refers to the amount of time it takes from placing an order until it is fulfilled. For B2B buyers, understanding lead times is critical for inventory planning and project timelines. Knowing the expected lead time can help businesses maintain smooth operations and avoid delays in production.

By grasping these essential properties and terminology, international B2B buyers can navigate the complexities of sourcing SiC semiconductors more effectively, ensuring they make informed decisions that align with their operational needs.

The sic-halbleiter (silicon carbide semiconductor) market is witnessing significant growth, driven by the increasing demand for efficient power electronics in various applications such as electric vehicles (EVs), renewable energy systems, and industrial automation. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is vital to understand the current and emerging trends shaping this market.

One prominent trend is the shift towards electric mobility, which is propelling the demand for high-performance semiconductors. Sic-halbleiter, known for their high thermal conductivity and efficiency, are increasingly being adopted in EV powertrains. Additionally, the renewable energy sector, especially solar and wind, is leveraging sic-halbleiter for improved energy conversion and management.

Moreover, the growing emphasis on Industry 4.0 is driving innovation in automation technologies that rely on advanced semiconductor solutions. B2B buyers should focus on suppliers who not only offer cutting-edge products but also demonstrate agility in adapting to rapidly changing market conditions. Strategic partnerships and collaborations within the supply chain will be essential for accessing the latest technologies and maintaining competitive advantage.

Sustainability is becoming a central concern for B2B buyers in the sic-halbleiter sector. The environmental impact of semiconductor manufacturing is significant, involving energy-intensive processes and the use of hazardous materials. Buyers should prioritize suppliers who implement sustainable practices throughout their operations. This includes minimizing waste, reducing energy consumption, and utilizing renewable energy sources in production.

Furthermore, ethical sourcing is gaining traction as companies face increasing scrutiny from consumers and regulatory bodies. Buyers should seek suppliers committed to transparency in their supply chains, particularly those who are certified for environmental and social governance (ESG) standards. Certifications such as ISO 14001 (environmental management) and responsible sourcing certifications can serve as indicators of a supplier's commitment to sustainable practices.

Incorporating 'green' materials into sourcing strategies is also beneficial. For instance, utilizing recycled materials or those sourced from sustainable suppliers can enhance a company's sustainability profile and appeal to environmentally-conscious customers.

The development of sic-halbleiter can be traced back to the late 20th century, when researchers began exploring silicon carbide as a semiconductor material. Its unique properties, including high breakdown voltage and thermal stability, made it an attractive alternative to traditional silicon-based semiconductors, particularly for high-power applications.

Over the years, advancements in manufacturing techniques and materials science have propelled the adoption of sic-halbleiter in various industries. By the 2010s, the proliferation of electric vehicles and renewable energy applications catalyzed a surge in demand, positioning sic-halbleiter as a critical component in the transition towards greener technologies.

For B2B buyers, understanding this evolution is crucial, as it highlights the material's growing significance in modern technological applications and emphasizes the need for strategic sourcing from reputable suppliers who can meet the demands of this dynamic market.

How do I choose the right supplier for sic-halbleiter?

Choosing the right supplier for sic-halbleiter involves several critical steps. Start by assessing the supplier's industry experience and reputation. Look for certifications that demonstrate compliance with international standards. Request samples to evaluate quality and performance. Additionally, consider suppliers who offer customization options to meet specific application needs. For international buyers, ensure that the supplier has a robust logistics framework capable of handling cross-border transactions efficiently.

What are the key factors to consider when sourcing sic-halbleiter internationally?

When sourcing sic-halbleiter internationally, key factors include supplier reliability, quality assurance processes, and compliance with local regulations in your country. It's crucial to understand the supplier's production capabilities and technology used in manufacturing. Additionally, evaluate shipping options, lead times, and costs to ensure they align with your project timelines. Establishing clear communication channels is also essential to avoid misunderstandings regarding specifications and requirements.

What customization options are available for sic-halbleiter products?

Customization options for sic-halbleiter products can vary by supplier. Common customization includes specific doping levels, substrate sizes, and packaging types tailored to your application needs. Some suppliers may offer design services to optimize the semiconductor for particular use cases, such as automotive or industrial applications. When discussing customization, ensure that the supplier can meet your technical specifications while adhering to quality standards.

What is the minimum order quantity (MOQ) for sic-halbleiter?

The minimum order quantity (MOQ) for sic-halbleiter varies by supplier and can depend on factors such as the type of product and customization requirements. Typically, suppliers may have an MOQ ranging from a few hundred to several thousand units. It's important to discuss your needs directly with suppliers to negotiate terms that align with your purchasing strategy, especially if you are a smaller business or a startup.

What payment terms should I expect when sourcing sic-halbleiter?

Payment terms for sourcing sic-halbleiter can differ significantly among suppliers. Common terms include net 30, 60, or 90 days, while some may require upfront payments or deposits, especially for custom orders. International buyers should also consider exchange rates and potential transaction fees. Ensure you have a clear understanding of the payment structure before finalizing agreements to avoid unexpected costs.

How can I ensure quality assurance for sic-halbleiter products?

To ensure quality assurance for sic-halbleiter products, request detailed documentation on the supplier's quality control processes. Look for suppliers who conduct rigorous testing and provide certifications for their products. It’s beneficial to establish a quality agreement that outlines your specifications and standards. Regular audits or on-site visits can also help verify compliance and build trust with your supplier.

What logistics considerations should I keep in mind when importing sic-halbleiter?

When importing sic-halbleiter, logistics considerations include shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder experienced in handling semiconductor shipments to minimize delays. Understand the import regulations in your country, including duties and taxes, to avoid unexpected costs. Additionally, ensure that the packaging meets international standards to prevent damage during transit.

What are the common applications for sic-halbleiter in various industries?

Sic-halbleiter are widely used across various industries due to their high efficiency and thermal stability. Common applications include electric vehicles, renewable energy systems, industrial automation, and telecommunications. In the automotive sector, they are crucial for power electronics in electric and hybrid vehicles. Understanding the specific applications relevant to your industry can help you select the appropriate sic-halbleiter products for your projects.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

As the global demand for SiC semiconductors continues to surge, international B2B buyers from Africa, South America, the Middle East, and Europe must strategically position themselves to leverage this growing market. The key takeaways from our exploration of strategic sourcing for SiC semiconductors include the importance of establishing strong relationships with suppliers, understanding regional market dynamics, and prioritizing sustainable sourcing practices. By focusing on these areas, businesses can enhance their supply chain resilience and capitalize on the unique advantages that SiC technology offers.

What are the future trends in SiC semiconductor sourcing? Looking ahead, the integration of advanced technologies such as artificial intelligence and machine learning into the sourcing process will play a crucial role in optimizing procurement strategies. Furthermore, as geopolitical considerations increasingly influence supply chains, being proactive in diversifying suppliers and securing contracts will be vital.

In conclusion, international B2B buyers are encouraged to embrace innovative sourcing strategies that not only align with their operational needs but also contribute to sustainable development goals. By taking these steps, businesses can position themselves as leaders in the SiC semiconductor market, ready to meet the challenges and opportunities of the future.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina