Navigating the complexities of sourcing alumina fused cast refractories can be a daunting task for international B2B buyers, especially those operating in diverse and rapidly evolving markets across Africa, South America, the Middle East, and Europe. With the increasing demand for high-performance materials in sectors such as steel, glass, and ceramics, understanding the nuances of these refractories is crucial for maintaining operational efficiency and product quality. This guide serves as a comprehensive resource, delving into various types of alumina fused cast refractories, their specific applications, and the critical factors to consider when selecting suppliers.

International buyers will benefit from an in-depth exploration of supplier vetting processes, enabling them to identify reliable partners who can meet their unique requirements. Additionally, the guide addresses cost considerations, providing insights into pricing structures and how to negotiate favorable terms. By equipping B2B buyers with actionable knowledge and strategies, this guide empowers them to make informed purchasing decisions that align with their operational goals and market demands.

Whether you're based in France, Argentina, or any other region, understanding the global market landscape for alumina fused cast refractories will position you to leverage opportunities and mitigate risks effectively. This resource is designed to enhance your sourcing capabilities and ensure that you remain competitive in an increasingly interconnected world.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Alumina Castables | High alumina content, excellent thermal stability | Steel, cement, glass industries | Pros: High resistance to thermal shock; Cons: Higher cost compared to other refractories. |

| Low Cement Castables | Low water content, dense structure | Foundries, petrochemical industries | Pros: Lower porosity; Cons: More complex mixing and installation. |

| Medium Alumina Castables | Balanced alumina content for versatility | Non-ferrous metallurgy, heat treatment | Pros: Good thermal and mechanical properties; Cons: Moderate resistance to corrosion. |

| Fused Cast Refractories | Produced via melting and casting, high purity | Glass manufacturing, aluminum smelting | Pros: Exceptional wear resistance; Cons: Requires specialized handling and installation. |

| Corundum-Based Castables | Contains corundum, high durability | Iron and steel production | Pros: Superior mechanical strength; Cons: Limited thermal shock resistance. |

High alumina castables are characterized by their high alumina content, which provides them with exceptional thermal stability and resistance to thermal shock. They are suitable for applications in industries such as steel, cement, and glass manufacturing. When considering procurement, buyers should evaluate their specific thermal and mechanical requirements, as well as the higher costs associated with these materials.

Low cement castables are designed with reduced water content, resulting in a denser structure. This makes them ideal for use in foundries and petrochemical industries where lower porosity is crucial. However, the complexity of mixing and installation may present challenges for some buyers, necessitating a thorough understanding of application methods.

Medium alumina castables strike a balance between thermal and mechanical properties, making them suitable for a variety of applications, including non-ferrous metallurgy and heat treatment processes. Buyers should consider the moderate resistance to corrosion, which can affect longevity in specific environments, and weigh this against the overall performance characteristics.

Fused cast refractories are produced through a melting and casting process that results in high purity and exceptional wear resistance. They are commonly used in glass manufacturing and aluminum smelting. Buyers must be aware of the specialized handling and installation requirements, which may increase overall project costs and complexity.

Corundum-based castables contain a significant amount of corundum, providing them with superior mechanical strength. They are particularly effective in iron and steel production environments. However, buyers should note the limitations in thermal shock resistance, which may necessitate additional considerations in high-temperature applications.

Related Video: Production Process of Refractory Bricks-- Alumina Bubble Brick

| Industry/Sector | Specific Application of alumina fused cast refractories | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Steel Manufacturing | Linings for electric arc furnaces | Enhances thermal efficiency and reduces energy costs | Ensure compatibility with furnace design and operating conditions |

| Glass Production | Furnace linings and blocks | Increases lifespan of equipment and reduces downtime | Verify thermal shock resistance and chemical stability |

| Cement and Lime Production | Kiln linings | Improves operational efficiency and reduces maintenance costs | Assess abrasion resistance and thermal conductivity |

| Petrochemical Industry | Reactor linings and insulation | Extends service life and improves safety | Focus on high-temperature performance and corrosion resistance |

| Aluminum Smelting | Crucible linings | Minimizes metal contamination and improves yield | Evaluate thermal properties and chemical resistance |

In the steel manufacturing sector, alumina fused cast refractories are primarily utilized for linings in electric arc furnaces (EAFs). These refractories enhance thermal efficiency, thereby reducing energy consumption and operational costs. Buyers in this sector must consider the specific compatibility of these materials with their furnace designs and the operating conditions, ensuring that the selected refractories can withstand the high temperatures and aggressive environments typical of EAF operations.

In glass production, alumina fused cast refractories serve as furnace linings and blocks, providing essential thermal insulation and protecting against chemical attack from molten glass. Their use significantly increases the lifespan of furnace equipment, leading to reduced downtime and maintenance costs. International buyers should prioritize sourcing refractories that offer excellent thermal shock resistance and chemical stability to meet the rigorous demands of glass manufacturing processes.

Cement and lime production facilities utilize alumina fused cast refractories for kiln linings, which are critical in maintaining high operational efficiency. These refractories resist abrasion and thermal degradation, resulting in lower maintenance costs and enhanced productivity. Buyers in this industry should assess the specific thermal conductivity and abrasion resistance of the refractories to ensure they meet the operational demands of their kilns.

In the petrochemical industry, alumina fused cast refractories are employed as linings for reactors and insulation materials. Their high-temperature performance and corrosion resistance extend the service life of critical equipment, thereby improving safety and operational reliability. B2B buyers must focus on sourcing materials that can withstand the harsh chemical environments typical in petrochemical applications, ensuring that the refractories can maintain integrity under extreme conditions.

Alumina fused cast refractories find significant application in aluminum smelting, particularly as crucible linings. They help minimize metal contamination, which is crucial for maintaining the quality of the aluminum produced. Additionally, these refractories improve yield by enhancing thermal efficiency during the smelting process. Buyers should evaluate the thermal properties and chemical resistance of the refractories to ensure they can operate effectively in high-temperature environments typical of aluminum production.

The Problem:

B2B buyers often struggle with sourcing high-quality alumina fused cast refractories due to the variability in supplier standards and the lack of transparency in the manufacturing processes. This is particularly challenging for companies in regions like Africa and South America, where local suppliers may not meet international quality benchmarks. Buyers may receive materials that do not perform as expected, leading to increased operational costs, downtime, and potential safety hazards.

The Solution:

To overcome this sourcing challenge, buyers should conduct thorough due diligence on potential suppliers. Start by verifying certifications such as ISO 9001 and industry-specific standards that ensure product quality. Engage in direct communication with suppliers to understand their production processes and material sourcing. Request samples and conduct in-house testing to evaluate the performance of the refractories under your specific operational conditions. Additionally, consider partnering with suppliers that have a proven track record in your industry, and leverage references from other businesses to validate their reliability.

The Problem:

Another common pain point for B2B buyers is a lack of knowledge regarding the specific technical specifications required for alumina fused cast refractories. Buyers may not fully understand the implications of different grades, thermal shock resistance, or chemical composition, leading to miscalculations in their procurement processes. This can result in selecting the wrong type of refractories, which could compromise the integrity of industrial equipment and lead to costly repairs.

The Solution:

Investing in education and training for your procurement team is crucial. Attend industry workshops, seminars, and webinars focused on refractory materials and their applications. Collaborate with manufacturers to gain insights into the latest advancements in refractory technology. Furthermore, creating a detailed specifications checklist that includes thermal properties, mechanical strength, and compatibility with specific operational environments can streamline the selection process. Utilize software tools that assist in matching your operational needs with the technical specifications of available refractories.

The Problem:

International buyers, particularly those from the Middle East and Europe, often face long lead times and delivery issues when sourcing alumina fused cast refractories. These delays can disrupt production schedules, leading to significant financial losses. Factors such as customs delays, inadequate logistics planning, and the global supply chain disruptions can exacerbate this problem, making it difficult for buyers to maintain consistent operations.

The Solution:

To mitigate these delivery issues, buyers should adopt a proactive approach in logistics management. Develop strong relationships with logistics providers who specialize in handling industrial materials, and ensure they understand the critical nature of timely delivery. Implement a just-in-time inventory system that allows for better alignment between procurement and production schedules. Additionally, consider diversifying your supplier base to include local manufacturers that can provide quicker turnaround times. Regularly assess and adjust your logistics strategies based on changing market conditions to maintain operational efficiency.

Alumina fused cast refractories are essential in high-temperature applications, particularly in industries such as steel, glass, and ceramics. Selecting the right material can significantly influence the performance and longevity of refractory products. Below, we analyze four common materials used in alumina fused cast refractories, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

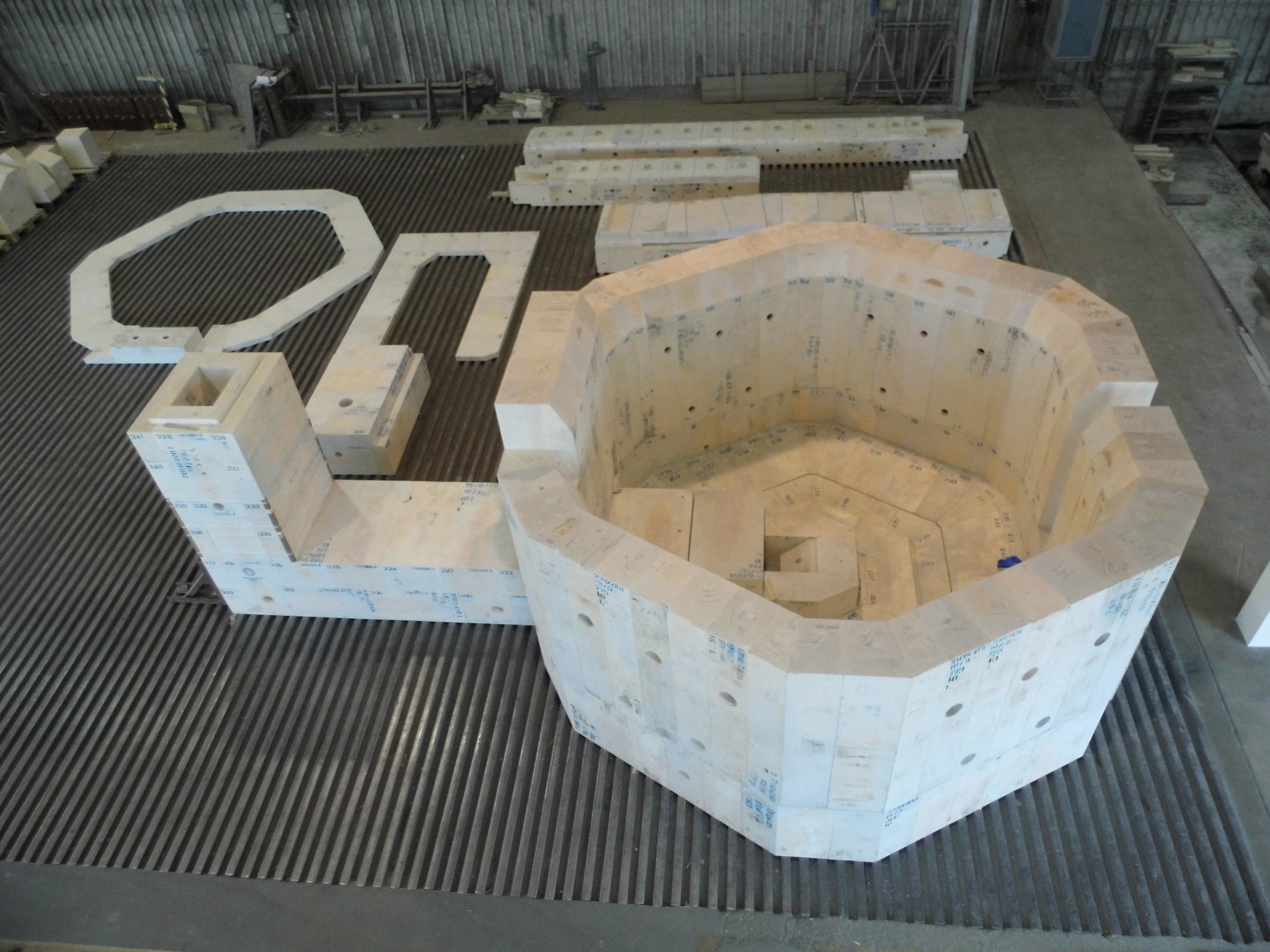

A stock image related to alumina fused cast refractories.

High-alumina fused cast refractories typically contain over 90% alumina content. They are known for their excellent thermal stability and resistance to thermal shock, making them suitable for extreme temperature applications.

Pros: High thermal resistance allows them to withstand temperatures exceeding 1600°C, making them ideal for steelmaking and glass production. Their low thermal conductivity also contributes to energy efficiency.

Cons: While they offer superior performance, the manufacturing process is complex and can lead to higher costs. Additionally, their brittleness may pose challenges during handling and installation.

Impact on Application: High-alumina refractories are particularly effective in environments with molten metal and glass, where they resist corrosion and wear.

Considerations for Buyers: International buyers should ensure compliance with relevant standards such as ASTM C 27 and DIN 51032. Understanding local market preferences for material specifications is crucial, especially in regions like Europe and South America.

Magnesia-alumina spinel refractories are composed of a combination of magnesia and alumina, which enhances their properties.

Pros: They exhibit excellent corrosion resistance against basic slags and have good thermal shock resistance. Their unique composition allows for better performance in steelmaking applications.

Cons: The production of magnesia-alumina spinels can be more expensive due to the sourcing of high-purity magnesia. Additionally, they can be more susceptible to hydration if not properly stored.

Impact on Application: These refractories are particularly effective in environments where basic slag is present, making them suitable for steelmaking and non-ferrous metal applications.

Considerations for Buyers: Buyers from Africa and the Middle East should be aware of local sourcing capabilities for high-purity magnesia, as availability can impact costs and lead times.

Zirconia-containing refractories are designed to withstand extreme conditions, particularly in glass and ceramics production.

Pros: They provide outstanding thermal stability and resistance to thermal shock. Their ability to resist corrosion from aggressive glass compositions makes them invaluable in glass manufacturing.

Cons: The high cost of zirconia and the complexity of manufacturing can lead to elevated prices for these refractories. Additionally, their weight can complicate installation.

Impact on Application: Zirconia refractories excel in applications involving molten glass and ceramics, where their durability significantly extends service life.

Considerations for Buyers: Buyers in Europe and South America should consider the regulatory requirements for zirconia materials, as compliance with EU REACH regulations can impact sourcing and costs.

Silica-alumina refractories combine silica and alumina, providing a cost-effective solution for various applications.

Pros: They are generally less expensive than high-alumina or zirconia refractories and offer decent thermal stability. Their versatility makes them suitable for a range of applications.

Cons: However, they may not withstand as high temperatures as their high-alumina counterparts and can be more susceptible to chemical attack in certain environments.

Impact on Application: Silica-alumina refractories are often used in less demanding applications, such as in the cement industry and for lining furnaces.

Considerations for Buyers: International buyers should evaluate the specific thermal and chemical requirements of their applications to ensure that silica-alumina refractories meet their needs.

| Material | Typical Use Case for alumina fused cast refractories | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Alumina Fused Cast | Steel and glass production | Excellent thermal stability | High manufacturing complexity | High |

| Magnesia-Alumina Spinel | Steelmaking and non-ferrous metal applications | Superior corrosion resistance | Higher sourcing costs for magnesia | Medium |

| Zirconia-Containing Refractories | Glass and ceramics production | Outstanding thermal stability | High cost and weight | High |

| Silica-Alumina Refractories | Cement industry and furnace linings | Cost-effective and versatile | Lower temperature resistance and chemical attack | Low |

This guide serves as a strategic material selection resource for international B2B buyers, ensuring informed decisions that align with their specific operational needs and regional compliance requirements.

The manufacturing process of alumina fused cast refractories is intricate, involving several critical stages to ensure the final product meets the required specifications for high-temperature applications. The main stages include:

Material Preparation: The process begins with the selection and preparation of raw materials, primarily high-purity alumina and other additives. These materials are meticulously sourced to ensure they meet stringent quality standards. The preparation phase also involves grinding and mixing these materials to achieve a uniform particle size, which is crucial for consistent melting and casting.

Melting: The prepared materials are then subjected to high temperatures in an electric arc furnace, where they are melted. This stage is vital as it transforms the raw materials into a homogeneous liquid that can be cast into molds. The melting temperature typically exceeds 2000°C, and precise temperature control is essential to avoid defects in the final product.

Forming and Casting: Once melted, the liquid alumina is poured into molds. The casting process can vary depending on the desired shape and application of the refractories. Common techniques include gravity casting and low-pressure casting, which help to minimize air inclusion and ensure structural integrity.

Finishing: After cooling, the cast refractories undergo finishing processes, which may include grinding, machining, and surface treatment. This stage is crucial for achieving the required dimensional tolerances and surface quality. The finished products are then inspected for any defects before being packaged for shipment.

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the refractories produced are of the highest quality and meet international standards. Key elements of QA in the manufacturing of alumina fused cast refractories include:

Adherence to International Standards: Many manufacturers comply with ISO 9001 standards, which outline criteria for a quality management system. Additionally, industry-specific standards such as CE marking for European markets and API specifications for oil and gas applications are critical. These standards ensure that products are safe, reliable, and of good quality.

Quality Control Checkpoints: Quality control (QC) is systematically integrated at various checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality criteria.

- In-Process Quality Control (IPQC): During production, regular checks are conducted to monitor the melting and casting processes. This includes temperature checks, material consistency, and mold integrity.

- Final Quality Control (FQC): Finished products undergo comprehensive testing for mechanical properties, thermal resistance, and dimensional accuracy. Non-destructive testing methods, such as ultrasonic and X-ray inspections, may be employed to detect internal defects.

Testing Methods Used in Quality Assurance: Common testing methods include:

- Physical Testing: Assessing properties like density, porosity, and thermal conductivity.

- Mechanical Testing: Evaluating compressive strength, flexural strength, and thermal shock resistance.

- Chemical Analysis: Ensuring the chemical composition of the refractories aligns with industry requirements.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential for ensuring product reliability. Here are some actionable strategies:

Conducting Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should evaluate the supplier's adherence to international standards and their internal quality management systems.

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that include information on material sources, production processes, and quality testing results. These reports can help buyers assess the reliability of the supplier.

Engaging Third-Party Inspections: Utilizing third-party inspection services can further validate the quality of the products being supplied. This is especially important when dealing with suppliers from regions with varying standards of quality assurance.

Understanding QC Certification Nuances: B2B buyers should be aware of the nuances of QC certifications across different regions. For example, certifications that are recognized in Europe may not hold the same weight in Africa or South America. Thus, it is essential to ensure that the supplier’s certifications are relevant and accepted in the buyer’s market.

Incorporating a robust quality assurance strategy can provide B2B buyers with a competitive edge. Here’s how:

Enhancing Product Reliability: By sourcing high-quality alumina fused cast refractories, buyers can ensure the longevity and performance of their applications, reducing downtime and maintenance costs.

Building Strong Supplier Relationships: Establishing clear quality expectations with suppliers fosters trust and collaboration. This can lead to better pricing, priority service, and access to new product developments.

Mitigating Risks: A thorough understanding of the manufacturing and QC processes allows buyers to identify potential risks early, such as supply chain disruptions or quality issues, enabling proactive management strategies.

Improving Market Positioning: Buyers who prioritize quality can differentiate themselves in their respective markets, appealing to customers who value reliability and performance, thus enhancing their brand reputation.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions that ultimately contribute to their operational success and sustainability in a competitive market.

The procurement of alumina fused cast refractories is a critical process for businesses involved in high-temperature applications, particularly in industries such as metallurgy and glass manufacturing. This guide offers a structured checklist to ensure international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Before you start sourcing, it’s essential to establish clear technical specifications for the alumina fused cast refractories you need. This includes determining the required properties such as thermal conductivity, chemical resistance, and mechanical strength.

- Consider the application: Different applications may require specific refractoriness grades.

- Collaborate with engineering teams: Ensure that your technical team is involved in defining these specifications to avoid mismatches.

Conduct thorough research on current market trends and potential suppliers. Understanding market dynamics can help you identify reputable manufacturers and competitive pricing.

- Analyze industry reports: Look for data on pricing trends, demand forecasts, and major players in the market.

- Utilize trade platforms: Leverage online B2B marketplaces to find potential suppliers and read reviews.

Before making any commitments, thoroughly vet your potential suppliers. This step is crucial to ensure reliability and quality.

- Request documentation: Ask for company profiles, product certifications, and case studies from previous clients.

- Seek references: Contact other businesses that have worked with the supplier to gauge their reliability and service quality.

Ensure that your chosen suppliers hold relevant certifications and comply with international quality standards. This is vital to ensure the refractories meet safety and performance criteria.

- Check ISO certifications: Look for certifications like ISO 9001, which indicates a commitment to quality management.

- Understand local regulations: Be aware of any local compliance requirements in your region that may affect the sourcing process.

Before placing a large order, request samples of the alumina fused cast refractories for testing. This allows you to evaluate the product's performance in your specific application.

- Conduct performance tests: Assess the samples under conditions that replicate your operational environment.

- Gather feedback from your team: Involve relevant stakeholders in the testing process to ensure all aspects are covered.

Once you have selected a supplier, negotiate the terms and conditions of your purchase. Clear agreements on pricing, delivery schedules, and payment terms are essential for a smooth transaction.

- Discuss bulk pricing: If you anticipate large orders, inquire about discounts or flexible payment options.

- Clarify delivery timelines: Ensure both parties agree on expected delivery dates to avoid production delays.

After procurement, set up a quality assurance process to continuously monitor the quality of the alumina fused cast refractories received. This step helps maintain the integrity of your supply chain.

- Implement regular inspections: Schedule periodic assessments of the refractories to catch any quality issues early.

- Maintain open communication: Foster a relationship with your supplier to address any concerns that may arise quickly.

By following these steps, international B2B buyers can effectively navigate the sourcing process for alumina fused cast refractories, ensuring they select the right products for their operational needs while minimizing risks.

Understanding the cost structure of alumina fused cast refractories is essential for B2B buyers aiming to optimize their sourcing strategies. The main cost components include:

Materials: The primary raw materials for alumina fused cast refractories are alumina and silica, which significantly influence the overall cost. The quality of these materials can vary, affecting the final product's performance and price.

Labor: Skilled labor is required for manufacturing and quality control processes. Labor costs can vary by region, impacting the overall pricing, especially for buyers in Africa and South America where wage structures differ.

Manufacturing Overhead: This includes costs related to factory operations, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead costs.

Tooling: Custom tooling for specific refractories can add to the initial investment. Buyers should consider these costs when evaluating suppliers.

Quality Control (QC): Ensuring high-quality standards involves additional costs for testing and inspection. Certifications such as ISO can also influence pricing.

Logistics: Transportation costs can vary widely based on the supplier's location and the buyer's destination. International shipping, tariffs, and handling fees should be factored into the total cost.

Margin: Suppliers typically include a profit margin that can vary based on market demand, competition, and the supplier's positioning.

Several factors can influence the pricing of alumina fused cast refractories, including:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted prices. Understanding the MOQ can help buyers negotiate better rates and reduce per-unit costs.

Specifications and Customization: Customized products may incur additional costs for design and manufacturing. Buyers should clearly define their specifications to avoid unexpected expenses.

Materials Quality and Certifications: Higher-quality materials and certifications (e.g., ASTM standards) can lead to increased costs but may offer better performance and longevity, impacting the Total Cost of Ownership.

Supplier Factors: Supplier reputation, reliability, and service level can influence pricing. Established suppliers may charge more but offer better quality assurance and customer support.

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and duties, which can significantly affect the total landed cost.

For B2B buyers, especially those operating in diverse markets such as Europe, Africa, the Middle East, and South America, effective negotiation strategies can lead to significant cost savings:

Research Market Prices: Familiarize yourself with current market trends and pricing benchmarks to negotiate from a position of knowledge.

Leverage Volume Discounts: If possible, consolidate orders across multiple projects to meet MOQs and secure bulk pricing.

Consider Total Cost of Ownership: Evaluate not just the upfront costs but also the long-term implications, such as durability and maintenance, which can impact overall expenditure.

Build Relationships with Suppliers: Developing strong relationships can lead to better terms, priority service, and potential discounts.

Be Open to Alternative Suppliers: Diversifying your supplier base can lead to competitive pricing and reduce dependency on a single source.

Buyers should be aware that prices for alumina fused cast refractories can fluctuate based on global market conditions, including raw material availability and geopolitical factors. Therefore, it's essential to request indicative pricing and remain flexible with sourcing strategies. Always seek multiple quotes and assess the comprehensive value offered by each supplier to ensure the best deal.

While this analysis provides a framework for understanding costs and pricing in the alumina fused cast refractories market, actual prices can vary widely. Therefore, conducting thorough research and maintaining a proactive negotiation stance is crucial for achieving cost-effective sourcing solutions.

When considering the most suitable materials for high-temperature applications, particularly in industries such as steel, glass, and ceramics, it is essential to evaluate the available alternatives to alumina fused cast refractories. These alternatives can offer varying benefits and drawbacks depending on the specific requirements of a project. Here, we compare alumina fused cast refractories with two viable alternatives: silicon carbide refractories and fireclay refractories.

| Comparison Aspect | Alumina Fused Cast Refractories | Silicon Carbide Refractories | Fireclay Refractories |

|---|---|---|---|

| Performance | Excellent thermal stability; high resistance to thermal shock | Superior thermal conductivity; high abrasion resistance | Moderate thermal stability; lower thermal shock resistance |

| Cost | Higher initial investment; long-term cost-effective | Moderate to high initial costs; excellent durability justifies price | Lower initial costs; limited lifespan |

| Ease of Implementation | Requires skilled labor for installation | Can be complex to install due to brittleness | Relatively easy to install; widely available |

| Maintenance | Low maintenance needs; can last longer | Moderate maintenance; prone to wear in harsh conditions | Higher maintenance due to lower durability |

| Best Use Case | Ideal for high-temperature furnaces and glass production | Best for applications requiring high thermal conductivity and abrasion resistance | Suitable for lower temperature applications or where cost is a significant factor |

Silicon carbide refractories are known for their exceptional thermal conductivity and resistance to wear, making them ideal for applications that involve high abrasion and thermal shock. They can withstand extreme temperatures, which makes them suitable for use in foundries and other industrial settings where durability is paramount. However, the brittleness of silicon carbide can complicate installation, requiring skilled labor and careful handling to prevent damage during setup. Additionally, while the initial costs may be moderate to high, their long lifespan can justify the investment for many applications.

Fireclay refractories are one of the most common and cost-effective options available. They are easier to install and widely accessible, making them a preferred choice for many industries. However, they offer moderate thermal stability and lower resistance to thermal shock compared to alumina fused cast refractories. Their lifespan is generally shorter, leading to higher maintenance needs over time. Fireclay refractories are best suited for applications that do not reach extreme temperatures and where budget constraints are a significant consideration.

When selecting the right refractory material for your needs, it is crucial to consider the specific demands of your application, including temperature range, durability requirements, and budget constraints. Alumina fused cast refractories excel in high-temperature environments with minimal maintenance needs but come with a higher upfront cost. In contrast, silicon carbide refractories offer excellent performance in abrasive conditions but require careful handling during installation. Fireclay refractories provide a budget-friendly option but may not withstand extreme conditions as effectively. By evaluating these aspects against your operational priorities, you can make an informed decision that aligns with your business objectives and operational needs.

Alumina fused cast refractories are essential materials in high-temperature applications, particularly in industries such as steel, glass, and ceramics. Understanding their technical properties is crucial for international B2B buyers to ensure optimal performance and longevity in their operations. Here are some critical specifications:

Material Grade

The material grade defines the purity and composition of the alumina used in the refractory. Higher-grade alumina (e.g., 95% or more) generally offers superior thermal stability, resistance to chemical attack, and mechanical strength. This is particularly important for applications exposed to harsh environments.

Thermal Conductivity

This property measures how well the material can conduct heat. Alumina fused cast refractories usually exhibit low thermal conductivity, which is beneficial for energy savings and maintaining temperature stability in furnaces. Buyers should consider this property to optimize their energy efficiency and operational costs.

Compressive Strength

This specification indicates the maximum load the material can withstand without deforming. High compressive strength is vital for refractories used in load-bearing applications, ensuring they maintain their shape and integrity under extreme conditions. Buyers should look for refractories with compressive strengths exceeding 200 MPa for demanding applications.

Thermal Shock Resistance

The ability of a material to withstand rapid temperature changes without cracking or failing is known as thermal shock resistance. This property is essential for refractories in environments where temperature fluctuations are common. Buyers should prioritize materials with high thermal shock resistance to minimize downtime and maintenance costs.

Chemical Resistance

This property indicates how well a refractory can withstand chemical attack from slag, fluxes, or other aggressive materials. Alumina fused cast refractories are known for their excellent chemical resistance, making them suitable for applications in the metallurgical and glass industries. Buyers need to assess the specific chemical exposures in their processes when selecting refractories.

Navigating the B2B landscape requires familiarity with industry terminology. Here are some essential trade terms relevant to alumina fused cast refractories:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the refractory industry, understanding OEM relationships is crucial for ensuring the quality and compatibility of materials with existing systems.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the context of refractories, buyers must be aware of MOQs to manage inventory effectively and avoid overstocking or understocking issues.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. For B2B buyers, crafting a clear and detailed RFQ can facilitate better negotiations and ensure that all technical specifications are met in the quotes received.

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risk management, and delivery obligations, which are crucial for smooth procurement processes.

Lead Time

Lead time refers to the duration between the initiation of an order and its fulfillment. Understanding lead times for alumina fused cast refractories helps buyers plan their projects and manage operational timelines effectively.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can make informed decisions that enhance their operational efficiency and procurement strategies.

The alumina fused cast refractories market is experiencing robust growth driven by increasing demand from various industries, particularly metal, glass, and cement manufacturing. As global infrastructure projects ramp up, particularly in emerging markets across Africa and South America, there is a heightened need for durable and high-performance refractories. Notably, the Middle East is witnessing a surge in construction and industrial activities, further amplifying demand.

Several key trends are shaping the market landscape. Firstly, technological advancements in manufacturing processes, such as 3D printing and automation, are enhancing production efficiency and reducing lead times. Secondly, the rise of smart manufacturing techniques and Industry 4.0 is prompting suppliers to adopt data-driven decision-making, which improves inventory management and supply chain transparency. Thirdly, the trend towards customization is gaining traction, with buyers seeking tailored solutions that meet specific operational requirements.

A stock image related to alumina fused cast refractories.

For international B2B buyers, understanding these dynamics is crucial for strategic sourcing. Buyers from Europe, especially countries like France, should focus on suppliers who demonstrate adaptability and innovation. In contrast, buyers from Africa and South America should prioritize suppliers with a robust distribution network to ensure timely delivery and support.

Sustainability and ethical sourcing are becoming increasingly critical in the alumina fused cast refractories sector. The environmental impact of refractory materials, particularly in their production and disposal, is under scrutiny. B2B buyers are now expected to consider the lifecycle of these materials and their effects on the environment. Companies that adopt sustainable practices not only comply with regulatory requirements but also enhance their brand image and appeal to environmentally-conscious customers.

Incorporating 'green' certifications into procurement strategies can provide a competitive edge. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can help buyers ensure that their suppliers adhere to sustainable practices. Additionally, sourcing refractories made from recycled materials or those with lower carbon footprints can significantly reduce overall environmental impact.

For buyers in regions like the Middle East and Africa, aligning with suppliers who prioritize ethical sourcing can mitigate risks associated with supply chain disruptions and enhance long-term partnerships. As global markets increasingly shift towards sustainable practices, buyers must be proactive in integrating these considerations into their procurement processes.

The evolution of alumina fused cast refractories can be traced back to the increasing demands of high-temperature industrial processes. Initially developed in the mid-20th century, these materials were primarily used in steelmaking and other heavy industries due to their exceptional thermal resistance and durability. Over the decades, advancements in material science and production techniques have led to enhanced properties, making alumina fused cast refractories essential in diverse applications beyond traditional sectors.

Today, the sector continues to innovate, focusing on developing refractories that not only meet the high-performance criteria of modern industries but also align with sustainability goals. This evolution reflects a broader trend in manufacturing where performance, environmental responsibility, and cost-effectiveness must coexist to meet the demands of today's global market. For B2B buyers, understanding this historical context is vital for making informed decisions that align with both current trends and future market trajectories.

How do I choose the right supplier for alumina fused cast refractories?

Choosing the right supplier involves assessing their experience, reputation, and production capabilities. Look for suppliers with a proven track record in the refractories industry and positive customer reviews. Verify their certifications and quality assurance processes, as these indicate their commitment to producing high-quality materials. Additionally, request samples to evaluate the product quality before making a larger commitment. Networking through industry contacts can also provide insights into reliable suppliers.

What are the benefits of using alumina fused cast refractories in industrial applications?

Alumina fused cast refractories are known for their exceptional thermal stability and resistance to chemical attack, making them ideal for high-temperature applications such as steel and glass production. Their low thermal conductivity helps maintain energy efficiency, while their durability reduces the frequency of replacements, leading to lower operational costs. Additionally, they are versatile and can be customized to meet specific application requirements, enhancing their overall effectiveness.

What is the minimum order quantity (MOQ) for alumina fused cast refractories?

The minimum order quantity for alumina fused cast refractories can vary widely depending on the supplier and the specific product. Generally, MOQs can range from a few tons to several dozen tons. It’s crucial to discuss your requirements with potential suppliers to understand their MOQ policies, as negotiating smaller orders may be possible, especially for first-time buyers or pilot projects.

What payment terms should I expect when purchasing alumina fused cast refractories?

Payment terms for alumina fused cast refractories typically include options such as a deposit upfront with the balance due upon delivery or after inspection. Common terms may range from 30 to 60 days after delivery, depending on the supplier’s policies and your relationship with them. Ensure to clarify these terms before finalizing any contracts to avoid misunderstandings and to facilitate smoother transactions.

How can I ensure the quality of alumina fused cast refractories?

To ensure the quality of alumina fused cast refractories, request detailed product specifications and quality assurance documentation from suppliers. Look for ISO certifications and adherence to international quality standards. Conducting third-party inspections or audits can provide additional assurance. Additionally, consider establishing a trial order to evaluate the product performance in your specific application before committing to larger orders.

What logistics considerations should I keep in mind when importing alumina fused cast refractories?

When importing alumina fused cast refractories, consider shipping costs, lead times, and customs regulations in your country. Work with suppliers who have experience in international shipping to ensure compliance with import regulations and to facilitate smooth logistics. It’s also essential to discuss packaging options that protect the refractories during transport. Establishing a reliable logistics partner can help streamline the process and reduce potential delays.

Can alumina fused cast refractories be customized for specific applications?

Yes, alumina fused cast refractories can often be customized based on specific application requirements. Many suppliers offer options for varying compositions, dimensions, and shapes to meet the unique needs of different industries. Discussing your specific application with potential suppliers can help you determine the best customization options available, ensuring optimal performance in your operations.

What are the common applications of alumina fused cast refractories in various industries?

Alumina fused cast refractories are widely used in industries such as steelmaking, glass manufacturing, and cement production. Their high resistance to thermal shock and corrosion makes them ideal for furnace linings, kiln structures, and other high-temperature environments. Additionally, they are utilized in non-ferrous metal processing and petrochemical industries due to their durability and performance under extreme conditions. Understanding the specific applications can help you leverage their properties effectively.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In navigating the complexities of sourcing alumina fused cast refractories, international B2B buyers must prioritize strategic sourcing to enhance supply chain resilience and cost-effectiveness. By focusing on long-term partnerships with reliable suppliers, businesses can mitigate risks associated with fluctuating market conditions and ensure consistent quality in their refractory materials. Moreover, understanding regional market dynamics, particularly in Africa, South America, the Middle East, and Europe, is crucial for making informed purchasing decisions.

As the demand for high-performance refractories continues to rise, buyers should leverage data analytics and market intelligence to forecast trends and adapt their sourcing strategies accordingly. Engaging with local suppliers can also unlock unique advantages, such as reduced shipping costs and improved lead times.

Looking ahead, it is essential for B2B buyers to embrace innovation and sustainability in their sourcing practices. Investing in advanced materials and eco-friendly alternatives not only enhances operational efficiency but also aligns with global sustainability goals. By proactively seeking out new opportunities and fostering collaborative relationships, businesses can position themselves for success in the evolving refractories market.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina