Navigating the complexities of sourcing boron carbide with the right density can be a significant challenge for international B2B buyers. With its unique properties, boron carbide is essential in various industries, including defense, nuclear technology, and abrasives. Understanding the optimal density of boron carbide can impact product performance and cost-effectiveness, making it crucial for companies in Africa, South America, the Middle East, and Europe, including regions like South Africa and Mexico, to make informed purchasing decisions.

This comprehensive guide delves into the intricacies of boron carbide density, covering key aspects such as its types, applications, and the factors influencing its density. We will also explore the critical process of supplier vetting, ensuring that buyers can identify reliable sources that meet their specific needs. Additionally, we will provide insights into cost considerations, helping businesses to budget effectively while maximizing value.

By empowering international B2B buyers with actionable insights and a deeper understanding of boron carbide density, this guide aims to facilitate smarter sourcing strategies. Whether you are looking to enhance product quality, improve operational efficiency, or ensure compliance with industry standards, this resource equips you with the knowledge needed to navigate the global market confidently. Embrace this opportunity to transform your procurement processes and make informed decisions that drive success in your industry.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Boron Carbide | Typical density around 2.52 g/cm³ | Abrasives, cutting tools | Pros: Cost-effective, widely available. Cons: Limited performance in extreme conditions. |

| High-Density Boron Carbide | Density exceeding 2.60 g/cm³ | Armor materials, nuclear applications | Pros: Superior strength and durability. Cons: Higher costs, less availability. |

| Low-Density Boron Carbide | Density below 2.50 g/cm³ | Lightweight composites, aerospace | Pros: Reduced weight, improved handling. Cons: Lower mechanical strength. |

| Boron Carbide Nanoparticles | Nano-scale particles with unique properties | Advanced ceramics, electronics | Pros: Enhanced reactivity and performance. Cons: Specialized sourcing, higher prices. |

| Boron Carbide Ceramics | Formed into ceramic structures with varied densities | Industrial applications, cutting tools | Pros: Versatile, customizable properties. Cons: Processing complexity, longer lead times. |

Standard boron carbide typically has a density of about 2.52 g/cm³, making it a common choice for various industrial applications. Its affordability and widespread availability make it suitable for abrasives and cutting tools. When considering this type, B2B buyers should evaluate the performance requirements of their applications, as standard boron carbide may not perform optimally in extreme conditions or specialized uses.

High-density boron carbide, with densities exceeding 2.60 g/cm³, is particularly valued in applications that demand exceptional strength and durability, such as armor materials and nuclear applications. This variation offers enhanced performance but comes at a premium price. Buyers should assess their budget against the potential benefits of using high-density boron carbide in critical applications where failure is not an option.

Low-density boron carbide, characterized by densities below 2.50 g/cm³, is ideal for lightweight composite applications, particularly in aerospace. Its reduced weight allows for improved handling and efficiency. B2B buyers should consider this type when weight reduction is a primary goal, but they must also be aware of its lower mechanical strength, which might not be suitable for all applications.

Boron carbide nanoparticles possess unique properties due to their nano-scale size, making them suitable for advanced ceramics and electronic applications. These materials offer enhanced reactivity and performance, which can lead to innovative solutions in various sectors. However, sourcing these specialized nanoparticles can be challenging and expensive, requiring buyers to weigh the potential benefits against the costs and availability.

Boron carbide ceramics are formed into various structures with tailored densities, making them versatile for a range of industrial applications, including cutting tools. Their customizable properties allow manufacturers to meet specific performance requirements. However, the complexity of processing these ceramics can lead to longer lead times, which B2B buyers must consider in their supply chain planning.

| Industry/Sector | Specific Application of Density of Boron Carbide | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight armor for aircraft and spacecraft | Enhances safety and performance while reducing overall weight | Ensure compliance with aerospace standards and certifications |

| Defense & Military | Ballistic protection in personal and vehicle armor | Provides superior protection against projectiles and shrapnel | Look for suppliers with military-grade materials and testing |

| Nuclear Energy | Control rods and neutron absorbers | Increases safety by effectively managing neutron flux | Source from certified vendors with a focus on quality assurance |

| Industrial Manufacturing | Abrasives in cutting and grinding applications | Improves efficiency and longevity of cutting tools | Verify grit size and bonding agents for specific applications |

| Electronics | Semiconductor substrates and radiation shielding | Enhances device performance while providing radiation protection | Ensure compatibility with existing manufacturing processes |

In the aerospace sector, boron carbide's density plays a crucial role in creating lightweight armor for aircraft and spacecraft. The material's high strength-to-weight ratio allows manufacturers to enhance safety without compromising fuel efficiency. For international buyers, especially from regions like Africa and South America, sourcing boron carbide that meets stringent aerospace standards is essential. Buyers should prioritize suppliers who can provide certifications and compliance documentation to ensure reliability and performance in critical applications.

Boron carbide is extensively used in the defense and military industries for ballistic protection in personal armor and vehicle shielding. Its density contributes to its effectiveness in stopping bullets and shrapnel, making it a preferred choice for body armor and armored vehicles. Buyers in regions such as the Middle East and Europe should consider sourcing from manufacturers that specialize in military-grade materials and have a proven track record in rigorous testing and compliance with defense standards.

In the nuclear energy sector, boron carbide's density is vital for the production of control rods and neutron absorbers. Its ability to absorb neutrons efficiently helps in managing the fission process, thereby enhancing safety. For international B2B buyers, particularly in Europe, it is crucial to source boron carbide from certified vendors who adhere to nuclear industry standards. This ensures that the material meets the necessary quality and safety requirements for use in nuclear reactors.

In industrial manufacturing, boron carbide is commonly used as an abrasive in cutting and grinding applications. Its high density and hardness improve the efficiency and lifespan of cutting tools, leading to cost savings for manufacturers. Buyers from South America and Africa should verify the grit size and bonding agents used in the abrasives to ensure they are suitable for their specific applications. Partnering with reliable suppliers who can provide detailed specifications and quality assurance is essential for optimal performance.

Boron carbide's unique properties make it an excellent choice for semiconductor substrates and radiation shielding in the electronics industry. Its density contributes to enhanced device performance while simultaneously providing protection from harmful radiation. International buyers, particularly from regions with growing electronics markets, should ensure compatibility with existing manufacturing processes. Sourcing from reputable suppliers who specialize in advanced materials can help businesses stay competitive and ensure high-quality production.

Related Video: How to recycle solid carbide with Sandvik Coromant

The Problem: Many B2B buyers of boron carbide encounter significant issues with the inconsistency of density measurements in the products they source. For instance, a manufacturer in South Africa may receive batches of boron carbide that vary widely in density, impacting the performance and reliability of the final product. This inconsistency can lead to quality control failures, increased production costs, and ultimately, dissatisfied customers.

The Solution: To mitigate this issue, buyers should establish stringent quality control protocols with their suppliers. This includes specifying the required density range clearly in the procurement documents and requesting that suppliers provide certification of density for each batch. Additionally, investing in density measurement equipment, such as hydrostatic weighing systems, can help verify the product's density upon arrival. Regular audits of suppliers and establishing long-term relationships can also ensure better consistency and trust in the materials provided.

The Problem: A common challenge faced by B2B buyers is the misalignment of boron carbide density specifications with their specific application requirements. For example, a company in the Middle East specializing in armor materials might require a specific density to ensure the protective capabilities of their products. If the supplied boron carbide does not meet these specifications, it can lead to product failures and increased liability.

The Solution: To avoid this pitfall, it is crucial for buyers to engage in thorough discussions with their engineering teams and suppliers to define precise density requirements based on the intended application. Creating a detailed specifications document that outlines not only the required density but also other relevant physical properties can help ensure that suppliers understand the importance of these parameters. Furthermore, conducting pilot tests using samples of the boron carbide before large-scale purchases can help validate that the material meets all necessary criteria.

The Problem: B2B buyers often struggle to find suppliers who can provide high-purity boron carbide with consistent density levels. This is particularly true for industries such as electronics or advanced ceramics, where impurities can drastically affect performance. A buyer from Europe may find that many suppliers offer lower grades of boron carbide, leading to discrepancies in density and quality.

The Solution: To address this challenge, buyers should focus on establishing relationships with specialized suppliers known for their high-purity products. Conducting comprehensive market research to identify manufacturers that invest in quality control and purification processes is essential. Additionally, buyers can request detailed technical sheets and certificates of analysis to verify the purity and density of the boron carbide before making significant investments. Collaborating with suppliers on custom formulations that meet specific purity and density requirements can also foster innovation and improve overall product performance.

When selecting materials for applications involving the density of boron carbide, it is essential to consider various alternatives that can complement or enhance its properties. Below, we analyze several common materials relevant to this context, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

Silicon carbide (SiC) is renowned for its exceptional hardness and thermal stability, making it an excellent candidate for applications requiring high-density materials. It can withstand temperatures exceeding 1600°C and exhibits impressive corrosion resistance, particularly in acidic environments. SiC's mechanical strength and durability contribute to its suitability in abrasive applications and protective coatings.

Pros & Cons: The primary advantage of SiC is its high wear resistance, which translates to longer service life in demanding applications. However, its manufacturing complexity can lead to higher production costs, which may deter some buyers. Additionally, while SiC is compatible with various media, it may not be suitable for all chemical environments, necessitating careful selection.

Impact on Application: SiC's compatibility with high-temperature and corrosive media makes it ideal for industries such as aerospace and automotive. However, buyers must ensure compliance with international standards, such as ASTM and DIN, to guarantee product reliability.

Aluminum oxide (Al2O3) is another material that often comes into play when discussing density in boron carbide applications. It boasts a high melting point (over 2000°C) and excellent hardness, making it suitable for wear-resistant applications. Furthermore, aluminum oxide exhibits good chemical stability, which is crucial for applications in harsh environments.

Pros & Cons: The cost-effectiveness of aluminum oxide is one of its standout features, making it accessible for various industries. However, its brittleness can be a limitation, particularly in applications requiring high impact resistance. Additionally, while it performs well in many environments, its compatibility with specific media should be evaluated carefully.

Impact on Application: Aluminum oxide is commonly used in grinding and cutting tools, as well as in protective coatings. Buyers in regions like South America and Africa should consider local standards and regulations that may affect the use of aluminum oxide in their specific applications.

Zirconium oxide (ZrO2) is recognized for its exceptional toughness and thermal insulation properties. It can withstand high temperatures and has a lower thermal conductivity compared to boron carbide, making it suitable for thermal barrier applications. Its chemical stability also allows it to perform well in corrosive environments.

Pros & Cons: The key advantage of zirconium oxide is its high fracture toughness, which enhances its durability in demanding applications. However, the relative cost of zirconium oxide can be high, which may limit its use in cost-sensitive projects. Additionally, its manufacturing process can be complex, potentially leading to longer lead times.

Impact on Application: ZrO2 is often utilized in applications requiring thermal protection and wear resistance, such as in the aerospace and biomedical fields. B2B buyers must consider compliance with international standards, as well as the specific requirements of their local markets in the Middle East and Europe.

Boron nitride (BN) is another material that can complement boron carbide in applications requiring high density. It possesses excellent thermal stability and is chemically inert, making it suitable for high-temperature applications. BN can also act as a lubricant in certain contexts, reducing friction in mechanical systems.

Pros & Cons: The primary advantage of boron nitride is its versatility and ability to perform well in extreme environments. However, its cost can be a disadvantage, especially for large-scale applications. Additionally, the availability of boron nitride may vary by region, impacting procurement strategies for international buyers.

Impact on Application: Boron nitride is often used in electronics, aerospace, and high-performance coatings. Buyers from Africa and South America should ensure that their suppliers comply with relevant international standards to maintain product integrity.

| Material | Typical Use Case for density of boron carbide | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Abrasive applications, protective coatings | High wear resistance | High manufacturing complexity | High |

| Aluminum Oxide | Grinding tools, protective coatings | Cost-effective | Brittle, limited media compatibility | Medium |

| Zirconium Oxide | Thermal barriers, aerospace applications | High fracture toughness | High relative cost | High |

| Boron Nitride | Electronics, high-performance coatings | Versatile in extreme environments | Higher cost, variable availability | Medium |

This guide provides a strategic overview of material options for density applications involving boron carbide, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

The manufacturing process of boron carbide, a material prized for its hardness and lightweight properties, involves several key stages. Understanding these stages is crucial for international B2B buyers looking to source high-quality boron carbide products.

The first step involves the careful selection and preparation of raw materials. Boron carbide is typically synthesized from boron oxide and carbon sources. The quality of the starting materials significantly affects the final density and properties of the boron carbide produced. Suppliers should ensure that the raw materials meet international standards for purity and composition. Buyers should inquire about the source and quality assurance processes for these materials to ensure they align with their specifications.

After material preparation, the next stage is forming, where the powdered boron carbide is compacted into desired shapes. This can be done using various techniques, including:

Buyers should assess the forming techniques employed by suppliers, as these directly influence the density and mechanical properties of the final product.

In cases where boron carbide is part of a composite material or a larger assembly, the next step involves assembling the components. This may include bonding boron carbide with other materials to enhance performance characteristics, such as toughness or thermal resistance. Buyers should verify that the assembly methods used are compatible with their application requirements.

The finishing stage involves surface treatment and final adjustments to meet specific dimensional and surface quality standards. Techniques such as grinding, polishing, and coating may be used to achieve the desired finish. Buyers must ensure that the finishing processes adhere to their specifications, as surface quality can significantly affect performance in applications like armor and industrial components.

Quality assurance (QA) is critical in the manufacturing of boron carbide, ensuring that the final products meet both international and industry-specific standards.

International standards such as ISO 9001 play a vital role in guiding quality management systems within manufacturing environments. Compliance with ISO 9001 ensures that suppliers maintain consistent quality through documented processes. Additionally, specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application of the boron carbide products.

Quality control (QC) checkpoints are crucial in maintaining product integrity throughout the manufacturing process. These include:

B2B buyers should request detailed QC procedures from suppliers to understand how these checkpoints are managed.

Various testing methods are employed to verify the quality and performance of boron carbide products. These include:

Buyers should ensure that suppliers have established protocols for these tests and can provide documented results.

Verifying a supplier's quality control processes is essential for B2B buyers, particularly in international markets. Here are actionable steps buyers can take:

Regular audits allow buyers to evaluate the supplier's compliance with quality standards and their manufacturing processes. This can include reviewing documentation, inspecting facilities, and interviewing key personnel.

Buyers should ask for comprehensive quality reports that detail the results of various tests performed on the boron carbide products. This documentation should include data on density, hardness, and any other relevant properties.

Utilizing third-party inspection services provides an unbiased assessment of the supplier's quality control processes. These services can conduct random inspections and testing, ensuring that the products meet the agreed-upon specifications before shipment.

International B2B buyers must navigate various quality control and certification nuances when sourcing boron carbide. Different regions may have specific regulations and standards that suppliers must meet. For instance:

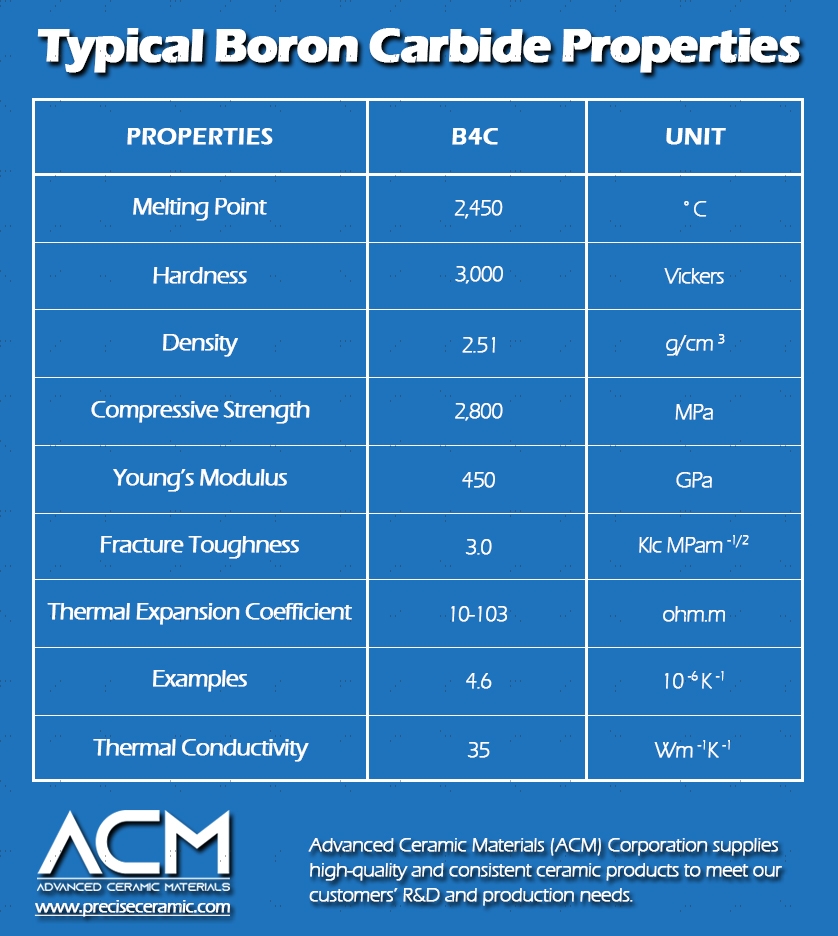

A stock image related to density of boron carbide.

Understanding these nuances will help buyers make informed decisions and ensure that the boron carbide products they source meet their quality requirements.

In the competitive landscape of international B2B procurement, sourcing materials like boron carbide requires a strategic approach, particularly when considering its density specifications. This guide provides a step-by-step checklist tailored for buyers from Africa, South America, the Middle East, and Europe, ensuring a successful sourcing process for boron carbide.

Before initiating the sourcing process, it is essential to clearly define your technical specifications for boron carbide. This includes the desired density, purity levels, and intended applications. For instance, different industries may require varying densities, so understanding your specific needs helps in narrowing down suitable suppliers.

Understanding current market trends and pricing dynamics for boron carbide is crucial. Analyze how factors such as raw material availability, regional supply chains, and demand fluctuations affect pricing. This knowledge not only helps you budget appropriately but also provides leverage in negotiations with suppliers.

Thoroughly vet potential suppliers before making any commitments. Request comprehensive company profiles, certifications, and case studies that highlight their experience with boron carbide. Additionally, reach out to other businesses in your sector for references, ensuring that the supplier has a proven track record of reliability and quality.

Once you have shortlisted suppliers, request samples of boron carbide with specified densities. Conduct rigorous testing to ensure that the samples meet your technical requirements. This step is vital as it verifies the supplier's claims and ensures the material will perform as expected in your applications.

Negotiation is a critical phase in the sourcing process. Discuss pricing, payment terms, delivery schedules, and warranty conditions with your selected supplier. Ensure that the agreement includes clauses that protect your interests, such as penalties for late deliveries or non-compliance with specified densities.

Quality assurance is paramount when sourcing boron carbide. Collaborate with your supplier to establish clear quality control protocols, including regular inspections and testing of shipments. This ensures that you consistently receive material that meets your density specifications and overall quality standards.

Finally, devise a logistics plan that addresses the transportation and storage of boron carbide. Consider factors such as shipping costs, customs regulations, and local infrastructure. Effective logistics management ensures that you can maintain a steady supply of boron carbide, minimizing disruptions in your production processes.

By following these steps, international B2B buyers can effectively navigate the complexities of sourcing boron carbide, ensuring they meet their specific density requirements while establishing robust supplier relationships.

When sourcing boron carbide, understanding the cost structure is vital for international B2B buyers. The primary cost components include:

Materials: Boron carbide is synthesized from boron and carbon, with the purity and quality of these raw materials directly impacting the final cost. Higher purity levels often command a premium price.

Labor: Labor costs can vary significantly based on the region and the skill level required for production. In regions with lower labor costs, such as parts of South America and Africa, buyers may find more competitive pricing.

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs.

Tooling: Initial tooling costs can be substantial, particularly for customized or high-spec products. Buyers should factor in these costs when negotiating with suppliers.

Quality Control (QC): Ensuring that the boron carbide meets required specifications involves rigorous QC processes. High-quality certifications can add to the overall cost but are essential for applications in industries such as defense and aerospace.

Logistics: Shipping and handling costs are critical, especially for international shipments. Factors such as distance, mode of transport, and local tariffs can significantly influence logistics expenses.

Margin: Suppliers will add a markup to their costs to maintain profitability. Understanding typical margins in different regions can aid buyers in negotiations.

Several factors influence the pricing of boron carbide, making it crucial for buyers to consider:

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often results in lower per-unit costs. Buyers should assess their needs and negotiate bulk pricing where possible.

Specifications and Customization: Customized boron carbide products tailored to specific applications typically come at a higher price point. Clear communication about specifications can help suppliers provide accurate quotes.

Materials: The quality and sourcing of raw materials affect the overall price. Buyers should inquire about the source of materials to ensure compliance with their quality standards.

Quality and Certifications: Products that meet international quality standards, such as ISO certifications, may carry higher prices. However, investing in certified products can mitigate risks associated with inferior quality.

Supplier Factors: The reputation, reliability, and financial stability of the supplier can influence pricing. Established suppliers may charge more but offer greater assurance of product quality and delivery timelines.

Incoterms: Understanding the terms of sale (such as FOB, CIF, etc.) is crucial as they determine who bears the cost of shipping and insurance, impacting the total cost.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to cost savings:

Research Market Prices: Familiarize yourself with current market prices for boron carbide. Use this information as leverage during negotiations.

Establish Relationships: Building long-term relationships with suppliers can lead to better pricing and terms over time. Trust can be a significant factor in negotiations.

Total Cost of Ownership (TCO): When evaluating offers, consider the TCO rather than just the initial price. This includes logistics, potential quality issues, and the costs associated with sourcing inferior products.

Flexibility in Terms: Be open to negotiating terms that can benefit both parties, such as payment terms or delivery schedules, which can lead to more favorable pricing.

International B2B buyers should be mindful of several pricing nuances:

Currency Fluctuations: Variations in currency exchange rates can significantly impact costs. Locking in prices or using contracts that account for currency fluctuations can mitigate risks.

Import Duties and Taxes: Be aware of any import tariffs or taxes that may apply to boron carbide shipments, as these can affect the overall cost.

Cultural Considerations: Different regions may have varying expectations regarding negotiation styles and pricing transparency. Being culturally aware can enhance negotiation outcomes.

Prices for boron carbide sourcing can fluctuate based on market conditions, supplier negotiations, and changes in raw material costs. It is advisable to obtain multiple quotes and conduct thorough market research to ensure competitive pricing.

When considering materials for applications requiring high density and exceptional hardness, boron carbide is a leading choice. However, various alternative materials and solutions may offer competitive advantages depending on specific use cases, budget constraints, and regional availability. This analysis provides B2B buyers with a comparative overview of boron carbide against other viable alternatives, enabling informed purchasing decisions.

| Comparison Aspect | Density Of Boron Carbide | Alternative 1: Silicon Carbide | Alternative 2: Tungsten Carbide |

|---|---|---|---|

| Performance | High hardness, excellent neutron absorption | High thermal conductivity, good wear resistance | Exceptional hardness, great impact resistance |

| Cost | Moderate to high | Moderate | High |

| Ease of Implementation | Requires specialized handling | Easier to process and shape | Requires advanced machining |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance |

| Best Use Case | Nuclear applications, armor | Electronics, wear-resistant components | Tool manufacturing, mining equipment |

Silicon carbide (SiC) is a robust alternative to boron carbide, particularly in applications requiring high thermal conductivity and wear resistance. Its advantages include a more straightforward processing and shaping capability, making it an attractive option for manufacturers. However, while SiC performs well in high-temperature environments, it may not match the neutron absorption properties of boron carbide, which can be critical in nuclear applications. The cost of silicon carbide is generally moderate, making it accessible for a variety of industries, especially in electronics and automotive sectors.

Tungsten carbide (WC) is renowned for its exceptional hardness and impact resistance, making it ideal for heavy-duty applications such as mining and manufacturing tools. While its density is comparable to that of boron carbide, the cost is often higher, which may deter some buyers. Tungsten carbide requires advanced machining techniques, which can complicate the manufacturing process. Despite these challenges, its low maintenance needs and long lifespan make it a popular choice among businesses looking for durable solutions in demanding environments.

Choosing the right material depends on several factors, including the specific application, budget, and processing capabilities. Buyers from Africa, South America, the Middle East, and Europe should evaluate the performance characteristics of each alternative in relation to their operational requirements. For instance, if neutron absorption is critical, boron carbide may remain the best choice despite its higher cost. Conversely, for applications prioritizing thermal management or wear resistance, silicon carbide could be more suitable. Meanwhile, for extreme durability in tool manufacturing, tungsten carbide stands out. Ultimately, a thorough analysis of each option's pros and cons in the context of the buyer's needs will lead to the most effective decision.

A stock image related to density of boron carbide.

Understanding the essential technical properties of boron carbide density is crucial for B2B buyers, particularly in sectors like defense, aerospace, and manufacturing. Here are some of the critical specifications to consider:

Material grade refers to the quality of boron carbide and can significantly impact its density. Higher-grade boron carbide typically exhibits superior density, which translates to better performance in applications such as armor materials and abrasives. Buyers should evaluate the grade based on their specific requirements to ensure optimal performance.

The density of boron carbide is usually measured in grams per cubic centimeter (g/cm³). This property is pivotal in applications where weight and strength are critical factors. For example, in armor applications, a higher density material will provide better ballistic protection while remaining lightweight. Buyers should request density specifications to ensure the material meets their needs.

Tolerance levels indicate the allowable deviations from specified dimensions in the material. For boron carbide, tight tolerances are often necessary in precision applications like semiconductor fabrication. Buyers must specify tolerance requirements in their orders to ensure compatibility with their processes and avoid costly rework or material waste.

Purity levels of boron carbide can affect its density and overall performance. High-purity boron carbide (typically over 99%) will demonstrate enhanced properties, making it suitable for high-stakes applications. Buyers should inquire about the purity of the product to ascertain its suitability for their intended use.

The particle size distribution of boron carbide influences its density and performance characteristics. Finer particles may provide higher density and better packing efficiency, which is advantageous in various applications. Buyers should consider the required particle size when sourcing boron carbide for specific industrial applications.

Understanding trade terminology is essential for navigating the complexities of international B2B transactions involving boron carbide. Here are some key terms that buyers should be familiar with:

OEM refers to companies that manufacture products that may be marketed under another company's brand. For boron carbide suppliers, being an OEM can indicate their capability to produce materials tailored for specific applications, which is vital for buyers looking for customized solutions.

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the context of boron carbide, this term is crucial for buyers who may need to assess their purchasing power and budget. Understanding MOQ can help buyers negotiate better terms and ensure they do not overcommit on inventory.

An RFQ is a document sent to suppliers to solicit price quotes for specific materials or services. For boron carbide buyers, issuing an RFQ can help clarify pricing, terms, and delivery schedules, making it easier to compare different suppliers and make informed purchasing decisions.

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, risk, and insurance. Familiarity with Incoterms is essential for B2B buyers to understand their obligations and rights during the import/export process of boron carbide.

Lead time refers to the time taken from placing an order to delivery. For boron carbide buyers, understanding lead times is crucial for project planning and inventory management. It can help in making timely decisions and ensuring that production schedules are met without delay.

By grasping these essential properties and trade terminologies, international B2B buyers can make informed decisions when sourcing boron carbide, ultimately enhancing their operational efficiency and product performance.

The density of boron carbide is increasingly becoming a focal point for various industries, particularly due to its applications in defense, nuclear technology, and abrasive materials. Global drivers such as escalating defense budgets, the need for lightweight materials in automotive and aerospace sectors, and rising demand for nuclear shielding are propelling market growth. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are witnessing a surge in interest in boron carbide due to its unique properties, including high hardness and thermal stability.

Emerging B2B technologies are reshaping sourcing strategies. The integration of AI and machine learning in supply chain management is enhancing predictive analytics, enabling buyers to forecast demand more accurately. Additionally, digital platforms are facilitating direct connections between manufacturers and international buyers, reducing reliance on intermediaries. For instance, sourcing platforms tailored for specific regions can aid buyers from South Africa and Mexico in navigating local suppliers more effectively, ensuring they have access to competitive pricing and quality assurance.

Moreover, geopolitical dynamics and trade policies are influencing sourcing trends. Buyers must stay informed about tariffs and trade agreements that could impact the cost and availability of boron carbide. Understanding these market dynamics allows international buyers to make informed decisions, minimizing risks associated with supply chain disruptions.

Sustainability has become a pivotal consideration in the sourcing of boron carbide. The environmental impact of mining and processing boron carbide is significant, prompting buyers to seek suppliers committed to sustainable practices. This includes the use of eco-friendly extraction methods and responsible waste management strategies.

The importance of ethical supply chains cannot be overstated. International B2B buyers are increasingly prioritizing suppliers who demonstrate transparency and accountability in their operations. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for verifying the sustainability credentials of suppliers. Buyers from regions like Europe are particularly stringent about these standards, often requiring proof of compliance before engaging in business.

Furthermore, the availability of 'green' materials is gaining traction. Suppliers that can offer boron carbide produced with minimal environmental impact may find themselves at a competitive advantage. B2B buyers should actively seek partnerships with manufacturers who are investing in sustainable practices, not only to enhance their corporate social responsibility (CSR) profile but also to meet the growing demand from eco-conscious consumers.

The journey of boron carbide in B2B markets dates back to its discovery in the early 20th century, primarily for use in abrasives and armor materials. Over the decades, its unique properties have made it a critical component in various high-tech applications. As industries evolved, so too did the demand for more advanced materials, leading to significant innovations in boron carbide production and processing techniques.

In recent years, the focus has shifted towards enhancing the density and purity of boron carbide, catering to specialized applications in defense and aerospace. Understanding this historical context is essential for international B2B buyers, as it provides insights into the material's evolving role and potential future applications in global markets. By recognizing past trends, buyers can better anticipate future developments, ensuring they remain competitive and well-informed in their sourcing strategies.

How do I determine the ideal density of boron carbide for my application?

To identify the optimal density of boron carbide for your specific needs, start by evaluating the end-use application. Boron carbide is known for its hardness and is used in armor, abrasives, and nuclear applications. Consider factors such as the required mechanical properties, thermal stability, and environmental conditions. Collaborate with suppliers to obtain samples with varying densities and conduct performance tests to assess which density meets your application requirements best.

What are the most common uses of boron carbide in B2B industries?

Boron carbide is widely used in industries such as defense, aerospace, and manufacturing. Its high hardness makes it ideal for ballistic armor and protective gear. Additionally, it serves as an abrasive in grinding and cutting applications. In the nuclear industry, its neutron-absorbing properties are utilized in control rods. Understanding these applications can guide your purchasing decisions based on the specific needs of your sector.

How can I verify the quality of boron carbide products from suppliers?

To ensure the quality of boron carbide products, request certifications and quality assurance documentation from suppliers. Look for compliance with international standards such as ISO 9001, which indicates effective quality management systems. Additionally, ask for product samples and conduct independent testing to verify properties like density, hardness, and purity. Establishing a long-term relationship with reputable suppliers can also enhance product quality assurance.

What are the typical minimum order quantities (MOQs) for boron carbide?

Minimum order quantities for boron carbide can vary significantly between suppliers and depend on factors like production capabilities and product specifications. Typically, MOQs range from 100 kilograms to several tons. When sourcing, it’s crucial to communicate your requirements clearly, as some suppliers may offer flexibility based on your long-term purchasing plans or the specific density variations you need.

What payment terms should I expect when sourcing boron carbide internationally?

Payment terms for international boron carbide transactions can vary widely. Common terms include upfront payments, net 30-60 days, or letters of credit for larger orders. Always clarify payment conditions before finalizing any agreements. Consider negotiating terms that align with your cash flow while also assessing the supplier’s credibility. Establishing a good relationship can lead to more favorable terms over time.

How do logistics impact the sourcing of boron carbide across different regions?

Logistics play a crucial role in sourcing boron carbide, especially for international buyers. Factors such as shipping methods, customs regulations, and lead times can significantly affect delivery schedules and costs. Ensure that your supplier has experience with shipping to your region and can provide reliable logistics solutions. Additionally, consider local suppliers to minimize shipping costs and reduce lead times.

What should I know about customizing boron carbide products for my needs?

Customizing boron carbide products often involves specifying parameters such as particle size, density, and form (e.g., powder, ceramic). Engage with your supplier early in the design process to discuss your requirements. Be prepared to provide technical specifications and performance criteria. Many suppliers offer customization services, but this may require longer lead times and potentially higher costs, so factor these into your planning.

What are the best practices for vetting suppliers of boron carbide?

When vetting suppliers for boron carbide, prioritize those with a proven track record in your industry. Research potential suppliers through online reviews, industry forums, and trade shows. Request references and conduct site visits if possible. Evaluate their production capabilities, quality control processes, and customer service responsiveness. Establishing a strong partnership with a reliable supplier can significantly impact your procurement efficiency and product quality.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the evolving landscape of boron carbide sourcing, understanding its density characteristics remains crucial for international B2B buyers. The density of boron carbide not only influences its performance in applications such as armor systems and abrasives but also impacts logistical considerations and cost efficiency. Buyers from Africa, South America, the Middle East, and Europe should prioritize strategic sourcing to navigate market fluctuations and ensure access to high-quality materials.

What key strategies can enhance your boron carbide sourcing efforts? Engaging with reputable suppliers who can provide detailed specifications and consistent product quality is essential. Additionally, leveraging regional partnerships can facilitate better pricing and reduce lead times, especially in areas with developing infrastructure.

Looking ahead, the demand for boron carbide is expected to rise, driven by advancements in technology and increased applications across various industries. International buyers are encouraged to stay informed about market trends and to build flexible sourcing strategies that can adapt to changing conditions. By doing so, you position your business not just to meet current needs but to seize future opportunities in this critical market.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina