The global landscape for sourcing density sic—a critical component across diverse industrial applications—has grown increasingly complex and competitive. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe (including regions like Australia and Thailand), understanding the nuances of density sic is paramount to securing high-performance materials that meet stringent quality and cost requirements.

This comprehensive guide delivers an authoritative roadmap to mastering the density sic supply chain. It covers essential facets such as the various types and grades of density sic, material properties, and manufacturing and quality control processes that ensure product reliability. Buyers will gain insights into evaluating global suppliers, navigating pricing structures, and assessing market trends that influence availability and cost-efficiency.

By consolidating critical information—including detailed FAQs—this guide empowers procurement professionals to make informed sourcing decisions that minimize risk and maximize value. Whether you are establishing new supplier relationships or optimizing existing procurement strategies, the knowledge provided here is designed to enhance your competitive edge in the international marketplace.

For B2B buyers committed to excellence, this guide is an indispensable resource to confidently navigate the complexities of density sic, ensuring your supply chain is resilient, cost-effective, and aligned with your business goals.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bulk Density | Mass per unit volume including pore spaces | Raw material sourcing, logistics, storage | + Easy to measure; - May vary with moisture and compaction |

| Apparent Density | Mass per unit volume excluding pore spaces | Material quality control, formulation design | + Reflects solid material quality; - Requires precise testing |

| Tapped Density | Density after mechanically tapping to reduce volume | Powder processing, packaging, transport | + Indicates packing efficiency; - Equipment-dependent |

| Particle Density | Density of individual particles excluding pores | Product formulation, quality assurance | + Critical for formulation accuracy; - Difficult to measure |

| Bulk Specific Gravity | Ratio of material density to water density at 4°C | Construction materials, composites | + Useful for comparative analysis; - Limited to certain materials |

Bulk Density represents the mass of material including the voids or pore spaces within a given volume. This type is crucial for B2B buyers involved in sourcing raw materials, warehousing, and transportation logistics, especially when dealing with granular or powdered substances. Buyers should consider variability due to moisture content and compaction, which can affect storage requirements and shipping costs. Ensuring consistent measurement methods is vital for reliable procurement and inventory management.

Apparent Density excludes the pore spaces in the calculation, focusing on the mass of the solid material per unit volume. It is widely used in quality control and product formulation, where the intrinsic material density impacts performance. For B2B buyers, understanding apparent density helps in predicting material behavior in manufacturing and end-use applications. Precise laboratory testing is necessary, which may require partnerships with specialized suppliers or testing labs.

Tapped Density measures density after a sample is mechanically tapped or vibrated to minimize volume by settling particles. This is particularly relevant in powder processing industries where packing efficiency influences packaging design and transport optimization. Buyers should assess the compatibility of tapping methods with their materials, as equipment and process variations can lead to inconsistent density values, impacting production planning and cost estimation.

Particle Density relates to the density of individual particles excluding internal pores and voids. It is fundamental in product formulation, especially in pharmaceuticals, chemicals, and advanced materials, where particle characteristics affect mixing and reactivity. B2B buyers must ensure suppliers provide accurate particle density data, as it directly influences product consistency and quality assurance standards.

Bulk Specific Gravity compares the material’s density to that of water at 4°C, providing a relative measure useful in construction and composite material industries. It facilitates comparative analysis across different batches or suppliers. Buyers should be aware of its limitations, as it is only applicable to materials where water displacement methods are valid. This measure aids in material selection and specification compliance for international projects.

Related Video: Wide Bandgap SiC and GaN Devices - Characteristics & Applications

| Industry/Sector | Specific Application of density sic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics & Semiconductors | Substrate materials for power devices and high-frequency components | Enhances thermal conductivity and electrical insulation, improving device reliability and performance | Ensure material purity, consistent density, and supplier certifications; consider logistics for fragile, high-value materials |

| Automotive & Electric Vehicles (EVs) | High-performance ceramic components in braking systems and power electronics | Increases durability and heat resistance, reducing maintenance and improving safety | Verify compliance with automotive industry standards; assess supplier capacity for volume and quality consistency |

| Aerospace & Defense | Lightweight, high-strength structural ceramics and thermal barriers | Reduces component weight while maintaining strength and thermal stability, leading to fuel efficiency | Prioritize suppliers with aerospace-grade quality control and traceability; consider long-term supply agreements |

| Industrial Manufacturing | Wear-resistant coatings and insulating parts in heavy machinery | Extends equipment lifespan and reduces downtime through superior hardness and thermal resistance | Focus on suppliers with proven industrial-grade products and customization capabilities for specific machinery requirements |

| Renewable Energy | Components in solar inverters and wind turbine electronics | Improves efficiency and longevity of energy conversion devices under harsh conditions | Source from vendors with expertise in renewable sector applications and international compliance certifications |

Electronics & Semiconductors

Density SiC (silicon carbide) is widely used as a substrate material in power electronics and high-frequency devices due to its excellent thermal conductivity and electrical insulating properties. For international buyers, especially in regions like Africa and South America where infrastructure demands are rising, sourcing high-purity, consistently dense SiC is critical to ensure device reliability and efficiency. Buyers should prioritize suppliers with strong quality certifications and the ability to provide detailed material specifications to meet stringent semiconductor manufacturing standards.

Automotive & Electric Vehicles (EVs)

In the automotive sector, particularly for electric vehicles, density SiC is employed in braking systems and power electronics to enhance heat resistance and mechanical durability. This reduces component wear and improves safety, critical for markets in the Middle East and Europe where automotive regulations are strict. B2B buyers must verify supplier compliance with automotive standards such as ISO/TS 16949 and evaluate production capacity to meet large-scale deployment needs.

Aerospace & Defense

Density SiC’s lightweight and high-strength characteristics make it ideal for aerospace structural ceramics and thermal barriers. This contributes to fuel efficiency and thermal management in aircraft and defense equipment. Buyers from regions like Europe and Australia should focus on suppliers with aerospace-grade certifications (e.g., AS9100) and traceability systems, ensuring materials meet rigorous performance and safety requirements. Long-term contracts with reliable vendors can secure supply stability.

Industrial Manufacturing

In heavy machinery, density SiC is used for wear-resistant coatings and insulating components, significantly extending equipment life and reducing downtime. For industrial buyers in Africa and South America, selecting suppliers capable of customizing SiC products to specific operational environments is essential. Material consistency and industrial-grade quality certifications should be key criteria in supplier evaluation to withstand harsh manufacturing conditions.

Renewable Energy

Density SiC components are critical in solar inverters and wind turbine electronics, where they improve energy conversion efficiency and operational durability under extreme environmental conditions. Buyers across the Middle East and Europe should source from vendors experienced in renewable energy applications who comply with international standards such as IEC 61215 for solar products. Supplier expertise in handling export logistics and regulatory compliance is also paramount for seamless international procurement.

Related Video: Types Of Flowmeters And Their Industrial Applications.

Key Properties:

Silicon carbide ceramics are known for their exceptional hardness, high thermal conductivity, and outstanding chemical inertness. They maintain structural integrity at temperatures exceeding 1600°C and exhibit excellent resistance to thermal shock and corrosion, especially against acids and alkalis.

Pros & Cons:

SiC ceramics offer superior wear resistance and low thermal expansion, making them ideal for high-temperature, high-pressure environments. However, their brittleness can pose challenges during manufacturing and handling. The production cost is relatively high due to complex sintering processes.

Impact on Application:

SiC ceramics are highly suitable for abrasive media and corrosive environments, such as in pumps and valves handling slurry or aggressive chemicals. Their resistance to oxidation and erosion extends equipment lifespan significantly.

International Buyer Considerations:

Buyers in Africa, South America, the Middle East, and Europe should verify compliance with international standards like ASTM C799 and DIN EN 60672. Import regulations and local manufacturing capabilities may affect lead times. Preference for SiC ceramics is strong in industries requiring durable, high-performance components, especially in mining and chemical processing sectors prevalent in these regions.

Key Properties:

SiC composites combine silicon carbide with other materials like carbon fibers or metals, enhancing toughness and mechanical strength while retaining high-temperature resistance up to approximately 1400°C. They also provide improved fracture toughness compared to pure ceramics.

Pros & Cons:

These composites offer better impact resistance and reduced brittleness, which simplifies machining and assembly. However, they typically have slightly lower corrosion resistance than pure SiC ceramics and are more expensive due to complex fabrication techniques.

Impact on Application:

Ideal for applications requiring a balance between strength and chemical resistance, such as mechanical seals and heat exchangers. Their enhanced toughness suits dynamic environments with mechanical stresses.

International Buyer Considerations:

Compliance with ASTM C1424 and ISO 10350 standards is common. Buyers should assess supplier certifications and quality control processes. Regions with emerging industrial sectors, like parts of Africa and South America, may benefit from composites due to their versatility and durability in demanding conditions.

Key Properties:

Metal substrates coated with silicon carbide layers provide a hybrid solution combining metal's ductility with SiC's hardness and corrosion resistance. Coatings typically withstand temperatures up to 1200°C and resist chemical attack.

Pros & Cons:

This approach reduces material costs and improves mechanical flexibility. However, coating adhesion and uniformity are critical and can vary by manufacturer, potentially affecting durability. Coating processes add complexity and may increase lead times.

Impact on Application:

Widely used in pump impellers, valve seats, and wear parts where metal strength is required alongside surface hardness. Suitable for corrosive fluids and abrasive slurries but less effective in extremely high-temperature scenarios.

International Buyer Considerations:

Buyers should ensure coatings meet ASTM B487 or equivalent standards and consider local environmental regulations on coating processes. Middle Eastern and European markets often demand strict certification and traceability for coated components.

Key Properties:

SiC fibers possess high tensile strength, excellent thermal stability up to 1500°C, and chemical inertness. They are primarily used as reinforcement in composite materials to enhance mechanical properties.

Pros & Cons:

These fibers significantly improve composite toughness and thermal resistance but require specialized handling and manufacturing expertise. The cost is relatively high due to advanced production methods.

Impact on Application:

Best suited for aerospace, automotive, and high-performance industrial applications where lightweight and high-strength materials are critical. Their use in density SiC composites enhances overall performance under thermal and mechanical stress.

International Buyer Considerations:

Compliance with JIS R 7601 and ASTM C1245 is common. Buyers in technologically advanced markets like Europe and parts of Asia (including Thailand and Australia) prioritize fiber quality and supplier reliability. Emerging markets may face challenges in sourcing due to limited local production.

| Material | Typical Use Case for density sic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide Ceramics | High-temperature, corrosion-resistant components | Exceptional hardness and chemical resistance | Brittleness and high manufacturing complexity | High |

| Silicon Carbide Composites | Mechanical seals, heat exchangers | Improved toughness and impact resistance | Slightly lower corrosion resistance, costly | High |

| Silicon Carbide Coated Metals | Wear parts requiring metal strength and surface hardness | Combines metal ductility with SiC hardness | Coating adhesion variability, added process complexity | Medium |

| Silicon Carbide Fibers | Reinforcement in high-performance composites | High tensile strength and thermal stability | High cost and specialized handling | High |

The production of density silicon carbide (SiC) involves sophisticated manufacturing steps designed to achieve high purity, precise density, and excellent structural integrity. For international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, understanding these processes is critical for selecting reliable suppliers and ensuring product performance.

1. Material Preparation

The process starts with sourcing high-purity raw materials, primarily silicon and carbon precursors. These materials undergo purification to remove impurities that could compromise the final product's density and mechanical properties. The carbon source is typically high-grade petroleum coke or charcoal, while silicon is refined to semiconductor-grade purity. Careful blending and milling ensure uniform particle size distribution, which is essential for consistent sintering and densification.

2. Forming

Once prepared, the SiC powder is shaped into the desired form using pressing or casting techniques:

- Cold Isostatic Pressing (CIP): This method applies uniform pressure around the powder compact, producing a green body with uniform density.

- Injection Molding: For complex shapes, SiC powder mixed with binders is injected into molds.

- Slip Casting: A slurry of SiC particles is poured into molds, allowing for precision in intricate geometries.

Each forming technique affects the density and microstructure of the final product, so suppliers often specialize in methods optimized for specific applications.

3. Sintering and Assembly

The green bodies are subjected to high-temperature sintering, often above 2000°C, to bond the SiC particles and achieve the target density. Sintering can be:

- Pressureless Sintering: Common for simpler shapes, relying on temperature and time to densify.

- Hot Pressing or Hot Isostatic Pressing (HIP): Applies pressure during sintering for superior density and mechanical strength.

In cases where multiple components are assembled, precision joining techniques such as brazing or diffusion bonding are used to maintain structural integrity without compromising density.

4. Finishing

Post-sintering, the SiC parts undergo finishing processes like grinding, lapping, and polishing to meet dimensional tolerances and surface quality requirements. This stage is crucial for applications demanding tight specifications, such as semiconductor manufacturing or high-performance automotive parts.

For B2B buyers, robust quality assurance (QA) ensures that density SiC products meet international standards and perform reliably in demanding applications.

Relevant International and Industry Standards

- ISO 9001: A foundational quality management system standard ensuring consistent production and continual improvement.

- CE Marking: Required for products entering the European market, confirming compliance with health, safety, and environmental protection standards.

- API (American Petroleum Institute) Standards: Relevant if SiC products are used in oil and gas sectors, ensuring material suitability under harsh conditions.

- ASTM Standards: Specific to ceramic materials, including density, hardness, and microstructural criteria.

Buyers should verify that suppliers are certified under these standards and request up-to-date certification documents.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection and testing of raw materials to verify purity, particle size, and chemical composition. This stage prevents defects from entering the production line.

- In-Process Quality Control (IPQC): Continuous monitoring during forming and sintering, including dimensional checks and temperature controls, ensures process stability and prevents deviations affecting density.

- Final Quality Control (FQC): Comprehensive testing of finished products, including density measurement, mechanical strength testing, and surface inspection, guarantees that products meet specifications.

Common Testing Methods

- Density Measurement: Using Archimedes’ principle or helium pycnometry to confirm target density values.

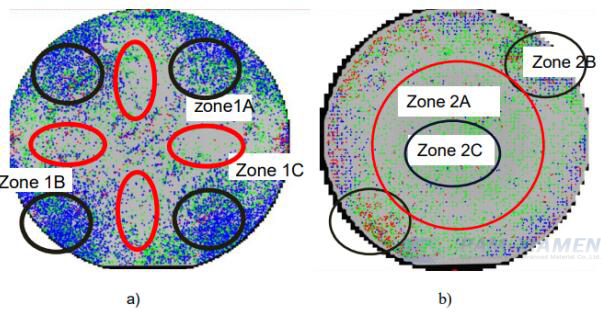

- Microstructural Analysis: Optical and electron microscopy assess grain size, porosity, and phase distribution.

- Mechanical Testing: Hardness, fracture toughness, and flexural strength tests evaluate durability.

- Chemical Analysis: X-ray fluorescence (XRF) or inductively coupled plasma (ICP) spectroscopy verify elemental composition and impurity levels.

For B2B buyers from Africa, South America, the Middle East, and Europe, ensuring supplier quality means going beyond certifications to practical verification.

1. Factory Audits

On-site audits allow buyers to assess manufacturing capabilities, process controls, and QA systems firsthand. Audits can be conducted by the buyer’s quality team or trusted third-party inspection agencies. Key audit focus areas include:

- Process flow and equipment condition

- Calibration and maintenance of testing instruments

- Staff qualifications and training programs

- Traceability and documentation practices

2. Review of Quality Documentation

Request detailed quality reports, including:

- Raw material certificates of analysis

- In-process inspection records

- Final inspection and test reports

- Non-conformance and corrective action logs

Documentation transparency indicates a mature QA culture and reduces risks associated with product defects.

3. Third-Party Inspection and Testing

Engaging independent labs or inspection bodies to verify product claims adds an extra layer of assurance, particularly for critical applications. Third-party inspections can include sampling, destructive testing, and certification issuance.

International buyers face unique challenges when sourcing density SiC, requiring awareness of regional and logistical factors:

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the detailed manufacturing processes and stringent quality assurance measures for density SiC is essential. By focusing on material preparation, forming techniques, sintering methods, and finishing processes, buyers can assess supplier capabilities effectively. Coupled with adherence to international standards like ISO 9001, CE, and API, and through rigorous IQC, IPQC, and FQC checkpoints, buyers can ensure consistent product quality.

Illustrative Image (Source: Google Search)

Engaging in factory audits, reviewing comprehensive quality documentation, and leveraging third-party inspections are critical steps in validating supplier claims. Awareness of regional compliance nuances and logistical considerations further safeguards procurement decisions. This holistic approach enables international buyers to source density SiC products that meet their technical requirements and deliver reliable performance in their respective industries.

When sourcing density sic, understanding the full cost and pricing landscape is critical for international B2B buyers aiming to optimize procurement and maintain competitive margins. This analysis breaks down the key cost components, pricing influencers, and actionable buyer strategies tailored for markets in Africa, South America, the Middle East, and Europe (including Australia and Thailand).

Raw Materials

The primary cost driver is the quality and grade of raw silicon carbide powder and additives. Variations in purity, particle size, and sourcing origin directly impact material costs. Premium raw materials that meet stringent industrial standards command higher prices but ensure better performance.

Labor Costs

Labor expenses vary widely based on manufacturing location. Regions with advanced automation may have lower labor inputs, while manual or semi-automated processes in emerging markets can raise costs. Buyers should assess the labor intensity of the production process to anticipate pricing shifts.

Illustrative Image (Source: Google Search)

Manufacturing Overhead

Includes facility costs, energy consumption (notably high for sintering and machining silicon carbide), and maintenance. Overhead is often embedded in the quoted unit price but can escalate with production complexity or smaller batch sizes.

Tooling and Equipment

Specialized tooling for shaping, sintering, or machining density sic components involves upfront capital expenditure. Tool wear and replacement frequency also affect unit costs, particularly for custom or low-volume orders.

Quality Control (QC)

Rigorous QC protocols—such as dimensional inspection, mechanical testing, and certification compliance—add to cost but are essential for reliability. Buyers targeting regulated markets or critical applications must factor in these expenses.

Logistics and Shipping

Silicon carbide products are dense and often fragile, requiring careful packaging and handling. International freight charges, customs duties, and insurance are significant cost elements, especially for buyers importing to regions with complex customs regimes.

Supplier Margin

Margins vary based on supplier positioning, brand reputation, and value-added services. Established suppliers with certifications (ISO, REACH, RoHS) may price higher but reduce risk and downstream costs.

Order Volume & Minimum Order Quantity (MOQ)

Larger volumes typically secure volume discounts and reduce per-unit costs. Buyers should negotiate MOQs aligned with their consumption patterns to avoid excess inventory or higher unit prices.

Product Specifications and Customization

Tailored particle sizes, shapes, or composite blends increase complexity and cost. Standardized products are generally more cost-effective.

Material Quality and Certifications

Certified materials for aerospace, automotive, or medical sectors command premium pricing. Certifications also influence eligibility for certain markets.

Supplier Location and Capabilities

Proximity to raw material sources or end markets affects pricing through reduced logistics costs. Suppliers with integrated manufacturing capabilities may offer better cost control.

Incoterms and Payment Terms

Incoterms such as FOB, CIF, or DDP impact who bears shipping and insurance costs, affecting the landed cost. Flexible payment terms can improve cash flow but may influence pricing.

Negotiate Beyond Price

Engage suppliers on value-added services like technical support, flexible packaging, and extended warranties. These can reduce Total Cost of Ownership (TCO) even if unit prices are slightly higher.

Calculate Total Cost of Ownership

Consider not just purchase price but also logistics, customs clearance, inventory holding, and potential rework costs. For buyers in Africa and South America, where import delays are common, factoring in lead times is essential.

Leverage Volume Consolidation

Pooling demand across subsidiaries or partners in Europe, the Middle East, or Asia-Pacific can unlock better pricing tiers and reduce logistics complexity.

Validate Supplier Certifications and Compliance

Ensure suppliers comply with environmental and safety standards relevant to your region. This avoids costly regulatory hurdles and reputational risks.

Understand Pricing Nuances in Target Markets

Currency fluctuations, local taxes, and import tariffs vary significantly. For example, Middle Eastern buyers should be aware of GCC-specific import regulations, while European buyers must consider VAT and REACH compliance costs.

Plan for Logistics Challenges

In regions with less developed infrastructure, factor in potential delays and additional handling fees. Using Incoterms that transfer risk appropriately can safeguard your interests.

Prices for density sic products are indicative and subject to change based on global raw material markets, energy costs, and geopolitical factors. Buyers are advised to request detailed quotations and confirm all terms before finalizing procurement decisions.

By dissecting the cost structure and understanding pricing drivers, international B2B buyers can make informed sourcing choices for density sic. Strategic negotiation and thorough total cost analysis are key to securing quality products at optimal prices across diverse global markets.

When sourcing density Sic (Silicon Carbide), understanding its core technical properties is vital for ensuring product performance and compatibility with your applications. Here are the key specifications international B2B buyers should consider:

Material Grade

Silicon Carbide is available in various grades, such as alpha and beta Sic, each with distinct crystalline structures and purity levels. Higher purity grades offer superior hardness and thermal conductivity, essential for high-performance industrial uses. Selecting the correct grade ensures reliability and longevity in your end product.

Bulk Density

This refers to the mass of Sic per unit volume, usually expressed in grams per cubic centimeter (g/cm³). Bulk density affects packing efficiency, thermal properties, and mechanical strength. Buyers should verify density values to match their application needs, especially in abrasives or refractory materials.

Particle Size Distribution

Sic is supplied in different particle sizes ranging from fine powders to coarse grains. The particle size impacts surface finish, reactivity, and sintering behavior in manufacturing. Accurate specification here helps optimize processing parameters and final product quality.

Tolerance and Purity Levels

Tolerance defines acceptable deviations in dimensions or properties, while purity indicates the percentage of silicon carbide versus impurities. Tight tolerances and high purity are crucial for sensitive industrial applications, such as semiconductors or precision machining tools, where consistency is non-negotiable.

Thermal Conductivity

Silicon Carbide is prized for its excellent heat dissipation capabilities. Buyers should confirm thermal conductivity ratings to ensure the material can withstand operational temperatures without degradation, which is critical in electronics and high-temperature industrial components.

Hardness (Mohs Scale)

Sic’s hardness typically ranges around 9-9.5 on the Mohs scale, making it one of the hardest materials available. This property is vital for wear resistance and cutting efficiency in abrasive applications. Verifying hardness ensures the material meets durability requirements.

Understanding and specifying these properties upfront will help you negotiate better with suppliers, reduce quality risks, and align product features with your operational demands.

Navigating international B2B trade for density Sic requires familiarity with common terms that streamline communication and contractual clarity. Here are essential trade terms explained:

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or components used in another company’s final product. When purchasing density Sic, you may be dealing directly with OEMs who require specific quality standards or custom formulations.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. MOQs vary by supplier and impact your inventory and cost management. Understanding MOQ helps you plan procurement efficiently, especially when balancing budget constraints with production needs.

RFQ (Request for Quotation)

A formal invitation to suppliers to submit price and delivery proposals for specified quantities and qualities of density Sic. RFQs are critical for obtaining competitive bids and detailed supplier information before finalizing purchase agreements.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities, risks, and costs between buyers and sellers during shipment. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Knowing Incoterms ensures clarity on who handles shipping, insurance, customs, and delivery.

Lead Time

The period between placing an order and receiving the goods. Lead times affect your supply chain planning and production schedules. Request clear lead time estimates to avoid delays and optimize inventory levels.

Certificate of Analysis (CoA)

A document provided by the supplier detailing the chemical composition and physical properties of the delivered density Sic batch. CoAs are essential for quality assurance and regulatory compliance, helping you verify the material meets agreed specifications.

Familiarity with these terms empowers you to negotiate effectively, reduce misunderstandings, and establish transparent procurement processes across diverse international markets, including Africa, South America, the Middle East, and Europe.

By prioritizing these technical properties and mastering the trade terminology, international B2B buyers can make informed decisions, secure optimal pricing, and ensure supply chain reliability when sourcing density Sic.

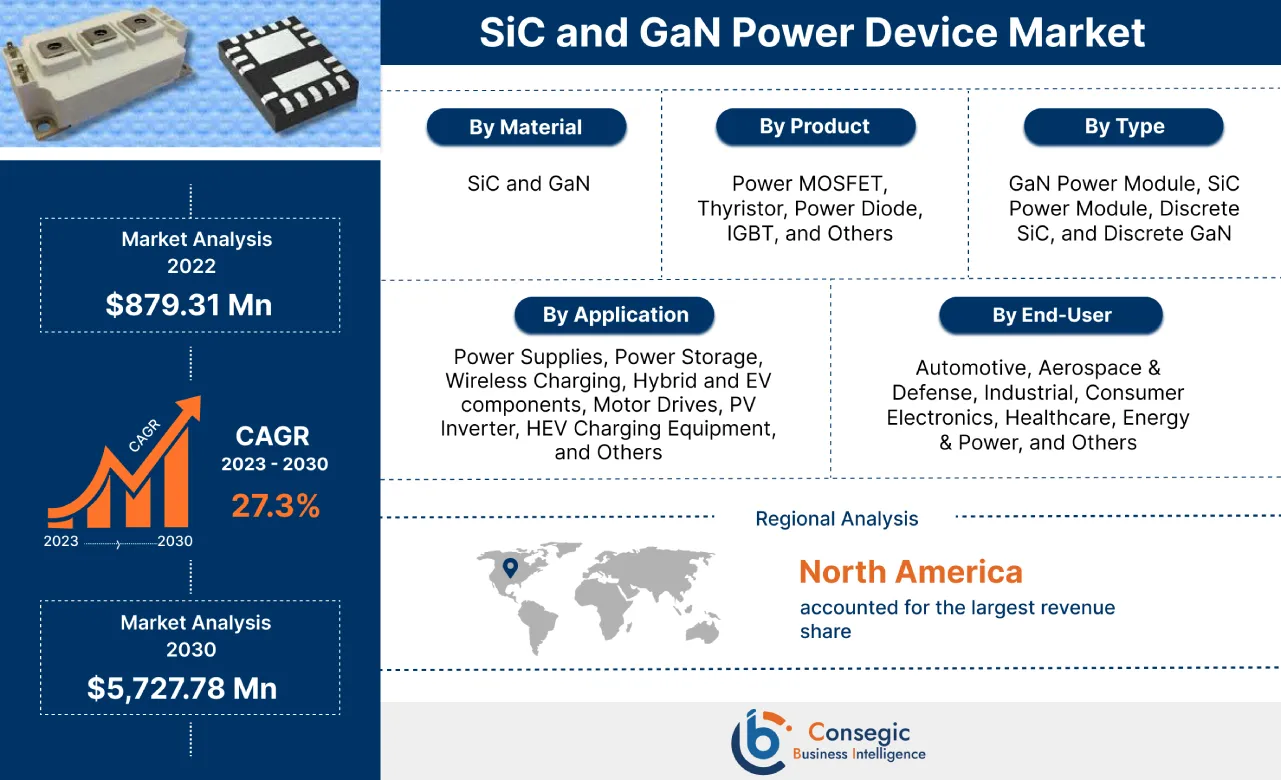

The density silicon carbide (SiC) sector is witnessing robust growth driven by its critical role in high-performance applications such as power electronics, automotive, aerospace, and renewable energy systems. Globally, the surge in electric vehicle (EV) adoption and the expansion of renewable energy infrastructure are primary drivers increasing demand for dense SiC materials, which offer superior thermal conductivity, high voltage resistance, and exceptional durability compared to traditional silicon.

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe (including markets such as Australia and Thailand), understanding regional supply chain dynamics is crucial. Asia, particularly China and Japan, currently dominates SiC production, but geopolitical shifts and rising demand have led to diversification efforts with emerging suppliers in Europe and North America. Buyers should monitor these evolving supply bases to mitigate risks related to trade restrictions and supply shortages.

Key sourcing trends include:

International buyers should prioritize suppliers with proven R&D capabilities and flexible production scales. Establishing strategic partnerships and long-term contracts can secure stable supply and favorable pricing amid rising demand.

Sustainability is becoming a decisive factor in the density SiC sector, as the production processes are energy-intensive and may involve environmentally sensitive raw materials. Buyers are increasingly scrutinizing the environmental footprint of their suppliers, focusing on carbon emissions, waste management, and resource efficiency.

Key considerations for ethical sourcing include:

For B2B buyers, integrating sustainability criteria into supplier evaluation not only aligns with global ESG mandates but also enhances brand reputation and reduces regulatory risks. Collaborating with suppliers on eco-design initiatives and circular economy practices can drive innovation and cost savings over the product lifecycle.

The density SiC sector has evolved significantly since its inception in the mid-20th century when SiC was primarily used as an abrasive. Advances in crystal growth techniques and sintering technology in recent decades have transformed SiC into a high-value semiconductor material critical for power electronics and harsh environment applications.

Initially dominated by traditional silicon, the semiconductor industry’s shift towards wide bandgap materials like SiC has accelerated innovation in electric vehicles, 5G telecommunications, and renewable energy systems. This evolution has prompted suppliers to focus on achieving higher density, purity, and defect-free SiC wafers to meet stringent performance requirements.

For international buyers, understanding this historical progression underscores the importance of selecting suppliers who continuously invest in R&D and maintain cutting-edge production capabilities, ensuring access to the latest high-density SiC materials that meet evolving industry standards and application demands.

How can I effectively vet suppliers of density sic for international B2B procurement?

Begin by verifying the supplier’s business credentials, including export licenses and company registration details. Request samples to evaluate product quality firsthand. Use third-party inspection agencies to audit manufacturing facilities, especially for compliance with international standards. Check references and customer reviews, focusing on similar export markets. Finally, assess their experience with international logistics and customs procedures to ensure smooth cross-border transactions.

Is customization of density sic products possible to meet specific industry requirements?

Yes, many suppliers offer customization options such as adjusting density grades, particle sizes, or packaging formats to suit your industry needs. Engage early with suppliers to discuss technical specifications and feasibility. Custom orders may require minimum order quantities (MOQs) and longer lead times. Clear communication and detailed technical documentation help prevent misunderstandings and ensure the product meets your exact requirements.

What are typical minimum order quantities (MOQs) and lead times for density sic shipments?

MOQs vary widely depending on the supplier and product type but generally range from a few tons to several dozen tons. Lead times depend on order size, customization, and current demand, typically spanning 2 to 8 weeks. It is critical to negotiate MOQs and lead times upfront, especially when coordinating with overseas suppliers to align with your inventory and production schedules. Early planning helps avoid costly delays.

What payment terms are standard in international density sic transactions?

Common payment methods include Letters of Credit (LC), Telegraphic Transfers (T/T), and Escrow services to mitigate risk. LCs offer security for both buyer and supplier but can involve higher banking fees. T/T payments often require a deposit upfront (30-50%) with balance paid upon shipment or receipt. Clarify payment milestones in contracts and consider using escrow accounts for new supplier relationships to protect your investment.

How do I ensure quality assurance (QA) and certification compliance for density sic?

Request certificates of analysis (CoA) and compliance documents such as ISO certifications or industry-specific standards (e.g., REACH, RoHS). Independent laboratory testing before shipment is advisable, especially for critical applications. Implement quality control checkpoints at production and pre-shipment stages. Establish clear contractual terms on quality expectations and dispute resolution mechanisms to safeguard against substandard products.

Illustrative Image (Source: Google Search)

What logistics considerations should I keep in mind when importing density sic?

Density sic is often shipped in bulk or bags; ensure packaging is suitable for long transit to prevent contamination or moisture damage. Verify the supplier’s experience with international freight, including handling customs clearance and export documentation. Choose reliable freight forwarders familiar with your destination country’s regulations, and consider multimodal transport options to optimize costs and delivery times. Planning for warehousing and distribution on arrival is equally important.

How can I handle disputes or quality issues with international suppliers of density sic?

Clearly define dispute resolution procedures in your contract, including arbitration venues and governing law. Maintain thorough documentation of all communications, contracts, and quality reports. In case of quality disputes, engage third-party inspectors or laboratories to provide impartial assessments. Early and transparent communication with the supplier often resolves issues amicably. If disputes escalate, utilize international trade mediation services or legal counsel experienced in cross-border trade.

Are there regional regulatory or import restrictions I should be aware of for density sic?

Yes, import regulations vary by country and may include restrictions on chemical composition, environmental compliance, or hazardous material classification. Research your target market’s import tariffs, customs duties, and required certifications before purchase. Engage with local trade authorities or customs brokers to ensure compliance. Staying informed helps avoid shipment delays, fines, or product seizures, ensuring your supply chain remains uninterrupted and cost-effective.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of density sic offers international B2B buyers a powerful lever to optimize supply chain efficiency and product quality while managing costs effectively. By leveraging a deep understanding of regional market dynamics, technological advancements, and supplier capabilities, businesses across Africa, South America, the Middle East, and Europe can secure competitive advantages in their procurement strategies.

Key takeaways for buyers include prioritizing supplier partnerships that align with sustainability goals, investing in data-driven sourcing decisions, and maintaining agility to adapt to shifting global trade environments. Emphasizing transparency and risk mitigation ensures resilience against supply disruptions, which is critical in today’s interconnected markets.

Looking ahead, the density sic landscape will increasingly favor buyers who embrace innovation and strategic collaboration. International buyers are encouraged to proactively engage with emerging suppliers, explore localized sourcing opportunities, and integrate digital tools that enhance visibility and control over procurement processes. By doing so, they not only future-proof their supply chains but also contribute to sustainable growth across diverse global markets.

Take decisive action now: evaluate your current sourcing framework, identify areas for strategic improvement, and partner with experts who understand the nuanced demands of density sic procurement. This approach will unlock long-term value and position your business as a leader in an evolving global marketplace.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina