Navigating the global market for schaumkeramik can be a daunting task for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. The challenge often lies in sourcing the right materials that meet specific industry requirements while ensuring cost-effectiveness and quality. Schaumkeramik, known for its lightweight, thermal insulating, and sound-absorbing properties, has become increasingly popular across various sectors, including construction, automotive, and electronics.

This comprehensive guide aims to demystify the world of schaumkeramik by exploring its different types, applications, and advantages. Buyers will gain insights into the critical aspects of supplier vetting processes, pricing structures, and the latest technological advancements in schaumkeramik manufacturing. By providing a detailed analysis of market trends and best practices, this guide equips B2B buyers with the knowledge needed to make informed purchasing decisions.

Understanding the nuances of schaumkeramik not only helps in selecting the right supplier but also in optimizing procurement strategies tailored to regional markets. Whether you are a buyer from Poland looking for innovative construction materials or a Saudi Arabian manufacturer seeking thermal insulation solutions, this guide will serve as a valuable resource in navigating the complexities of the global schaumkeramik market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open-Cell Schaumkeramik | High porosity, lightweight, excellent thermal insulation | Aerospace, automotive | Pros: Lightweight, effective insulation. Cons: Lower mechanical strength. |

| Closed-Cell Schaumkeramik | Denser structure, moisture-resistant, higher strength | Construction, electronics | Pros: High durability, moisture resistance. Cons: Heavier, less insulation efficiency. |

| Composite Schaumkeramik | Combination of materials for enhanced properties | Industrial applications, medical devices | Pros: Tailored properties, versatility. Cons: Higher cost, complex manufacturing. |

| Fire-Resistant Schaumkeramik | Designed to withstand high temperatures | Energy, chemical processing | Pros: Excellent heat resistance, safety. Cons: Limited availability, higher cost. |

| Custom-Molded Schaumkeramik | Tailored shapes and sizes for specific needs | Custom machinery, prototyping | Pros: Precise fit, optimized performance. Cons: Longer lead times, potentially higher costs. |

Open-cell schaumkeramik is characterized by its high porosity, which allows for excellent thermal insulation while remaining lightweight. This type is particularly suitable for applications in aerospace and automotive industries, where weight reduction is crucial. Buyers should consider the trade-off between insulation properties and mechanical strength, as open-cell variants may not withstand heavy loads as effectively as their closed-cell counterparts.

Closed-cell schaumkeramik features a denser structure, providing moisture resistance and higher mechanical strength. It is commonly used in construction and electronics, where durability is paramount. B2B buyers should evaluate their specific needs for moisture resistance and strength, as this type may be heavier and less efficient in insulation compared to open-cell options.

Composite schaumkeramik combines various materials to achieve enhanced properties tailored to specific applications. This versatility makes it ideal for industrial applications and medical devices. However, buyers must weigh the benefits of customized performance against the potential for higher costs and complex manufacturing processes.

Fire-resistant schaumkeramik is engineered to withstand extreme temperatures, making it essential for industries such as energy and chemical processing. Its excellent heat resistance enhances safety in high-risk environments. Buyers should be aware of its limited availability and potentially higher costs, which can influence procurement decisions.

Custom-molded schaumkeramik allows for the creation of specific shapes and sizes to meet unique requirements in custom machinery and prototyping. This tailored approach can optimize performance but may result in longer lead times and higher costs. Buyers should plan accordingly to ensure that their projects align with production timelines and budgets.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of schaumkeramik | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight thermal insulation in aircraft | Reduces weight, improving fuel efficiency | Certification standards, compliance with aviation regulations |

| Automotive | Exhaust system components | Enhances durability, reduces emissions | High-temperature resistance, compatibility with existing systems |

| Chemical Processing | Filtration systems for corrosive substances | Increases process efficiency and safety | Chemical resistance, custom sizes for specific applications |

| Electronics | Substrates for electronic components | Improves thermal management and performance | Precision manufacturing, availability of various sizes |

| Construction | Lightweight building materials | Cost savings in transportation and labor | Local availability, compliance with building codes |

In the aerospace sector, schaumkeramik is employed as lightweight thermal insulation in aircraft. This material effectively reduces overall weight, which is critical for enhancing fuel efficiency and reducing operational costs. Buyers in this sector must ensure that the schaumkeramik meets stringent certification standards and complies with aviation regulations. Additionally, the material must withstand extreme temperatures and environmental conditions typically encountered during flight.

Schaumkeramik finds significant application in automotive exhaust systems, where it serves as a durable component that can withstand high temperatures and corrosive exhaust gases. This application not only enhances the longevity of the exhaust system but also contributes to reduced emissions, aligning with global environmental standards. B2B buyers in the automotive industry should consider the material's high-temperature resistance and its compatibility with existing exhaust systems to ensure seamless integration.

In chemical processing, schaumkeramik is utilized in filtration systems designed to handle corrosive substances. Its unique properties allow for increased efficiency and safety in processes that involve hazardous materials. Buyers should focus on sourcing schaumkeramik that offers excellent chemical resistance and can be customized to fit specific filtration needs. This is particularly relevant for industries in Africa and South America, where local sourcing can also reduce lead times and costs.

Schaumkeramik is increasingly used as substrates for electronic components due to its superior thermal management capabilities. This application is crucial for maintaining optimal performance and longevity of electronic devices. International buyers, particularly from Europe and the Middle East, should prioritize precision manufacturing capabilities when sourcing schaumkeramik, ensuring that the substrates meet the required specifications for size and thermal conductivity.

In the construction industry, schaumkeramik is valued for its lightweight properties, making it an ideal choice for building materials. This characteristic leads to significant cost savings in transportation and labor, especially in large-scale projects. Buyers in this sector should consider the local availability of schaumkeramik and ensure that it complies with relevant building codes and regulations to facilitate smooth project execution.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem: B2B buyers sourcing schaumkeramik often face the challenge of quality inconsistency. As a lightweight ceramic material, schaumkeramik is used in various applications, from insulation to construction. However, variations in manufacturing processes can lead to inconsistent physical properties, such as thermal conductivity or compressive strength. This inconsistency can significantly impact product performance and reliability, causing disruptions in production and potentially leading to costly failures.

The Solution: To ensure quality consistency, buyers should establish strong relationships with reputable suppliers who adhere to stringent quality control measures. It is crucial to request detailed product specifications and certifications, such as ISO standards, to verify the quality of schaumkeramik. Additionally, conducting periodic audits and site visits to the manufacturing facilities can provide insights into the production processes and help identify any potential issues early on. Collaborating with suppliers to develop tailored quality assurance protocols can also mitigate risks and enhance product reliability, ensuring that the schaumkeramik meets the required standards consistently.

The Problem: Many B2B buyers, especially in emerging markets in Africa and South America, may lack the technical expertise needed to fully understand the properties and best applications of schaumkeramik. This gap in knowledge can lead to improper usage, which can compromise the performance of the final product. Buyers may struggle with selecting the right type of schaumkeramik for specific applications, resulting in inefficiencies and increased costs.

The Solution: To bridge the technical knowledge gap, buyers should prioritize engaging with suppliers that provide comprehensive technical support and resources. Suppliers should offer training sessions, detailed product documentation, and case studies that highlight successful applications of schaumkeramik. Additionally, leveraging online resources such as webinars and industry forums can help buyers stay updated on the latest developments and best practices. Establishing a collaborative relationship with suppliers where technical questions can be addressed promptly will empower buyers to make informed decisions, enhancing their overall operational efficiency.

The Problem: Global supply chain disruptions can significantly impact the availability of schaumkeramik, especially for B2B buyers in regions like the Middle East and Europe. Fluctuations in demand, transportation delays, and geopolitical factors can lead to shortages or increased costs, jeopardizing project timelines and budgets. Buyers often find themselves scrambling to secure alternative sources, which can further exacerbate the situation.

The Solution: To mitigate supply chain risks, it is essential for buyers to diversify their supplier base and not rely solely on a single source for schaumkeramik. Establishing relationships with multiple suppliers across different regions can provide more flexibility and options in times of disruption. Additionally, implementing a just-in-time inventory strategy can help buyers manage stock levels more effectively, reducing the financial impact of supply chain issues. Buyers should also engage in proactive communication with suppliers to stay informed about potential disruptions and collaborate on contingency plans. By taking these steps, buyers can enhance their resilience against supply chain challenges and maintain smoother operations.

Schaumkeramik, or foam ceramics, is a versatile material used in various industrial applications due to its unique properties. Selecting the right material is crucial for ensuring optimal performance in specific applications. Below, we analyze several common materials used in schaumkeramik, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Key Properties:

Alumina is known for its high melting point (over 2000°C) and excellent hardness. It exhibits good thermal stability and is resistant to chemical corrosion, making it suitable for high-temperature applications.

Pros & Cons:

The durability of alumina is a significant advantage, as it can withstand harsh environments. However, its manufacturing process can be complex and costly, which may impact overall project budgets. Additionally, while alumina is suitable for many applications, it may not be the best choice for those requiring high thermal shock resistance.

Impact on Application:

Alumina is often used in applications involving molten metals and high-temperature furnaces. It is compatible with various media, including aggressive chemicals.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Europe and the Middle East, the demand for high-quality alumina is increasing, necessitating a thorough understanding of local regulations.

Key Properties:

Silicon carbide is renowned for its exceptional hardness and thermal conductivity. It can withstand temperatures up to 1600°C and has excellent resistance to oxidation and corrosion.

Pros & Cons:

The primary advantage of silicon carbide is its ability to perform well in extreme conditions. However, it can be more expensive than other materials, and its brittleness may limit its applications in certain scenarios.

Impact on Application:

Silicon carbide is particularly effective in applications involving abrasive materials and high-temperature environments, such as in the aerospace and automotive industries.

Considerations for International Buyers:

Buyers from Africa and South America should be aware of the sourcing challenges related to silicon carbide. Understanding local supply chains and potential import regulations is essential for successful procurement.

Key Properties:

Zirconia has a high fracture toughness and can withstand temperatures up to 2400°C. It is also known for its excellent thermal insulation properties.

Pros & Cons:

Zirconia's ability to resist thermal shock makes it an excellent choice for applications requiring rapid temperature changes. However, it is relatively costly and may not be suitable for all budget constraints.

Impact on Application:

Zirconia is often used in thermal barrier coatings and applications involving high-temperature ceramics, such as in gas turbines.

Considerations for International Buyers:

In Europe, compliance with environmental regulations is critical when sourcing zirconia. Buyers should also consider the availability of high-quality zirconia in their local markets.

Key Properties:

Cordierite exhibits excellent thermal shock resistance and low thermal expansion, making it ideal for applications that experience rapid temperature changes.

Pros & Cons:

The main advantage of cordierite is its affordability and ease of manufacturing compared to other materials. However, it may not have the same level of mechanical strength as alumina or silicon carbide.

Impact on Application:

Cordierite is commonly used in kiln furniture and catalytic converters due to its thermal stability and cost-effectiveness.

Considerations for International Buyers:

For buyers in the Middle East and Africa, understanding local material sourcing and manufacturing capabilities is crucial. Compliance with standards like JIS and ASTM can also influence procurement decisions.

| Material | Typical Use Case for schaumkeramik | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina | High-temperature furnaces | High durability and thermal stability | Complex manufacturing process | High |

| Silicon Carbide | Aerospace and automotive applications | Exceptional hardness and thermal conductivity | Brittle nature | High |

| Zirconia | Thermal barrier coatings | High fracture toughness | Relatively costly | High |

| Cordierite | Kiln furniture and catalytic converters | Excellent thermal shock resistance | Lower mechanical strength | Medium |

This guide provides a comprehensive overview of material options for schaumkeramik, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

Schaumkeramik, or foam ceramics, is a specialized material known for its lightweight and insulating properties, widely used in various applications, including construction, aerospace, and automotive industries. The manufacturing process of schaumkeramik typically consists of several critical stages: material preparation, forming, assembly, and finishing.

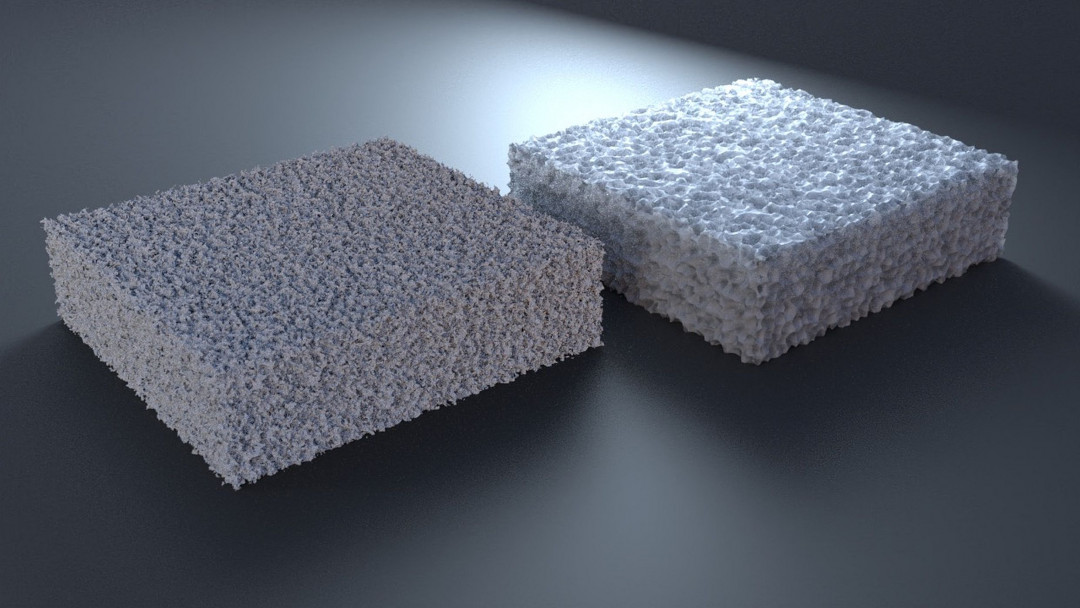

A stock image related to schaumkeramik.

The primary materials used in the production of schaumkeramik include ceramic powders, foaming agents, and additives. The ceramic powders, often made from alumina, silica, or zirconia, provide the structural framework, while the foaming agents, such as organic or inorganic compounds, create the porous structure during the firing process. Additionally, additives may be incorporated to enhance specific properties like thermal resistance or mechanical strength. The selection of high-quality raw materials is crucial, as they significantly impact the final product's performance and durability.

Once the materials are prepared, the next step is forming the schaumkeramik. This process often involves mixing the ceramic powders with water and foaming agents to create a slurry. The slurry is then shaped into the desired form through various techniques, such as casting, extrusion, or pressing. Each method has its advantages: casting allows for complex shapes, extrusion is efficient for long products, and pressing is ideal for achieving high density. The choice of forming technique depends on the specific application and required characteristics of the final product.

After forming, the schaumkeramik undergoes a drying process to remove excess moisture. This is followed by firing in a kiln at high temperatures, which solidifies the material and enhances its structural integrity. Finishing techniques may include grinding, cutting, or surface treatment to achieve the desired dimensions and surface quality. These processes are essential for ensuring the schaumkeramik meets industry standards and customer specifications.

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the schaumkeramik meets international standards and customer expectations. Effective QA practices involve several checkpoints and methods of verification.

For B2B buyers, understanding the relevant international standards is vital. The ISO 9001 standard for quality management systems is widely applicable and ensures that manufacturers maintain consistent quality throughout their processes. Additionally, industry-specific standards such as CE marking for products sold in the European Economic Area and API specifications for the oil and gas industry may apply depending on the intended use of the schaumkeramik.

Quality control typically involves several checkpoints during the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC):

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified standards. Testing may include particle size analysis, chemical composition verification, and physical property assessments.

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular monitoring is conducted to ensure that production parameters remain within acceptable limits. This may involve checking the viscosity of slurries, monitoring temperatures during firing, and assessing the density of formed products.

Final Quality Control (FQC): Before products are shipped, a thorough inspection is performed to evaluate the final product against customer specifications and relevant standards. This may involve dimensional checks, visual inspections, and performance testing.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, it’s essential to verify a supplier's quality control practices to mitigate risks associated with product quality and compliance.

Conducting thorough supplier audits is one of the most effective ways to assess quality control practices. Buyers should consider the following steps:

Request Documentation: Ask for quality management system documentation, including quality manuals, process flowcharts, and records of previous audits or certifications.

On-Site Inspections: If feasible, conduct on-site inspections to observe the manufacturing processes, quality control checkpoints, and overall facility conditions. This provides insight into the supplier's adherence to quality standards.

Review Testing Reports: Request copies of testing reports for previous batches of schaumkeramik. This should include results from IQC, IPQC, and FQC stages, showcasing the supplier's commitment to maintaining quality.

Third-Party Inspections: Consider engaging third-party inspection services to conduct independent assessments of the supplier's quality control processes. These organizations can provide unbiased evaluations and recommendations.

Understanding the nuances of quality control in different regions is crucial for B2B buyers. Buyers from Africa and South America may encounter varying levels of regulatory compliance and quality standards compared to those in Europe or the Middle East. It is important to be aware of local market conditions, certification requirements, and cultural differences in business practices.

For instance, European buyers often prioritize certifications such as ISO and CE, while Middle Eastern markets may emphasize compliance with local standards. Buyers should adapt their quality assurance strategies accordingly and maintain open lines of communication with suppliers to ensure all parties are aligned on quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance practices for schaumkeramik is essential for B2B buyers. By focusing on material selection, forming techniques, finishing methods, and rigorous quality control standards, buyers can ensure they partner with reputable suppliers who deliver high-quality products that meet their specific needs.

The procurement of schaumkeramik, or foam ceramics, requires a structured approach to ensure quality, reliability, and compliance with specific technical requirements. This guide serves as a comprehensive checklist for international B2B buyers looking to source schaumkeramik effectively, particularly in regions such as Africa, South America, the Middle East, and Europe.

Clearly outlining your technical requirements is crucial when sourcing schaumkeramik. Consider the specific application, such as thermal insulation or filtration, and detail parameters like porosity, density, and thermal conductivity. This clarity not only helps in communicating with suppliers but also ensures that the materials meet your project’s needs.

Begin by identifying potential suppliers who specialize in schaumkeramik. Utilize online platforms, industry directories, and trade shows to create a list. Focus on suppliers with a proven track record in your region and those who have experience serving industries similar to yours.

Before committing, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key aspects to examine include:

- Quality Assurance Processes: Ensure they have robust quality control measures in place.

- Production Capabilities: Verify if they can meet your order volume and specifications.

Confirm that your chosen suppliers hold relevant certifications that demonstrate compliance with industry standards. Look for certifications such as ISO 9001 for quality management and any specific environmental or safety certifications pertinent to schaumkeramik production. This verification helps mitigate risks associated with product quality and regulatory compliance.

Before making a large purchase, request samples of the schaumkeramik. This allows you to assess the material's performance under your specific conditions. Conduct tests that evaluate:

- Physical Properties: Check for density and strength.

- Functional Properties: Evaluate thermal and acoustic insulation properties.

Once you have selected a supplier, negotiate terms that are favorable for both parties. Discuss pricing, payment terms, and delivery schedules. Ensure that all agreements are documented clearly to avoid misunderstandings later. Consider including clauses for quality assurance and penalties for non-compliance.

Finally, develop a logistics plan for the shipment and delivery of the schaumkeramik. This should include selecting a reliable freight forwarder and considering customs regulations in your country. Plan for potential delays by discussing timelines with your supplier and ensuring adequate buffer periods in your project schedule.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing schaumkeramik with confidence, ensuring they select the right materials for their specific applications while establishing reliable supplier relationships.

When sourcing schaumkeramik, understanding the cost structure is essential for effective budgeting and strategic purchasing. Key components include:

Materials: The primary cost factor is the raw materials used in the production of schaumkeramik. These materials vary based on the desired properties of the final product, such as thermal insulation or structural integrity. The price of materials can fluctuate based on global supply and demand, making it critical to monitor market trends.

Labor: Labor costs can vary significantly depending on the region of manufacturing. In countries with lower wage standards, such as some in Africa and South America, labor costs may be more favorable. However, the quality and skill level of the workforce must also be considered.

Manufacturing Overhead: This includes expenses related to the production process that are not directly tied to labor or materials, such as utilities, rent, and administrative costs. Efficient manufacturing processes can help reduce overhead, impacting overall pricing.

Tooling: Initial tooling costs can be significant, especially for customized products. Depending on the complexity of the schaumkeramik design, these costs may be spread out over larger production runs, making it crucial to negotiate minimum order quantities (MOQs) to achieve cost efficiency.

Quality Control (QC): Ensuring product quality is vital, particularly for industries that require specific certifications. Implementing rigorous QC protocols can incur additional costs but may prevent costly returns and enhance customer satisfaction.

Logistics: Transportation and shipping costs are critical, particularly for international buyers. These costs can be influenced by distance, shipping methods, and regional tariffs. Understanding local logistics can help optimize supply chain efficiency.

Margin: Suppliers will add a profit margin to their costs, which can vary widely based on market conditions and competition. Buyers should seek transparency regarding how margins are calculated to evaluate the fairness of pricing.

Several factors influence the pricing of schaumkeramik, and international buyers should be aware of these nuances:

Volume/MOQ: Suppliers often offer lower prices per unit for larger orders. Buyers should evaluate their demand forecasts to negotiate favorable terms that align with their purchasing capacity.

Specifications and Customization: Custom products typically incur higher costs due to the unique tooling and processes involved. Clearly defining specifications can help avoid unexpected charges and delays.

Materials and Quality Certifications: The choice of materials directly impacts the price. Higher-quality materials that meet specific certifications may lead to increased costs but can enhance the product’s performance and longevity.

Supplier Factors: Supplier reputation, reliability, and location can also influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

Incoterms: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Misunderstandings can lead to unexpected costs.

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, optimizing costs in schaumkeramik sourcing involves several strategic approaches:

Negotiation: Engage suppliers in open discussions about pricing, payment terms, and delivery schedules. Building a relationship can lead to better deals and terms.

Focus on Total Cost of Ownership (TCO): Instead of simply comparing purchase prices, consider the total cost over the product's lifecycle, including maintenance, shipping, and potential wastage.

Research Market Trends: Stay informed about material costs and market demand fluctuations. This knowledge can provide leverage during negotiations and help in timing purchases.

Leverage Technology: Use digital platforms to streamline sourcing processes. Online marketplaces and supply chain management software can provide insights into pricing trends and supplier reliability.

Understand Pricing Nuances: Familiarize yourself with the specific cost drivers in different regions. This understanding can lead to informed decision-making and better supplier selection.

By applying these strategies, international buyers can enhance their sourcing effectiveness for schaumkeramik, ensuring they achieve the best possible value.

When evaluating the best materials or technologies for industrial applications, it's crucial for B2B buyers to consider alternatives that may offer comparable or superior benefits to schaumkeramik. This analysis focuses on two viable alternatives, providing a comprehensive comparison based on performance, cost, implementation, maintenance, and best use cases.

| Comparison Aspect | Schaumkeramik | Aerogel | Expanded Polystyrene (EPS) |

|---|---|---|---|

| Performance | High thermal insulation; lightweight; fire resistant | Excellent thermal insulation; very lightweight; moisture resistant | Good thermal insulation; lightweight; cost-effective |

| Cost | Moderate | High | Low |

| Ease of Implementation | Moderate complexity; requires skilled labor for installation | Complex; requires specialized handling | Easy; widely used and understood in various applications |

| Maintenance | Low; durable and long-lasting | Low; stable under normal conditions | Moderate; can degrade over time in moisture |

| Best Use Case | High-performance applications in construction and automotive | Aerospace, cryogenics, and high-end thermal applications | Packaging, insulation in buildings, and lightweight structures |

Aerogel is known for its exceptional thermal insulation properties and lightweight nature, making it a strong contender in fields such as aerospace and cryogenics. Its ability to withstand high temperatures and resist moisture adds to its appeal in specialized applications. However, the high cost and complexity of handling aerogel can deter some buyers, particularly in regions with budget constraints such as parts of Africa and South America. The installation process often requires specialized skills, making it less accessible for projects with limited technical resources.

A stock image related to schaumkeramik.

Expanded Polystyrene (EPS) is a widely used alternative due to its low cost and ease of implementation. It offers decent thermal insulation and is lightweight, making it suitable for various applications, including packaging and building insulation. However, EPS does not match the thermal performance of schaumkeramik or aerogel and can degrade when exposed to moisture, leading to potential long-term issues. For buyers focused on budget-friendly solutions, particularly in emerging markets, EPS can be a practical choice, but it may not provide the durability or performance required for high-stakes applications.

Choosing the right solution depends on various factors, including project requirements, budget constraints, and the specific application. Buyers should assess their performance needs against the cost and ease of implementation of each option. For projects demanding high thermal resistance and durability, schaumkeramik may be the best fit. However, for cost-sensitive applications, EPS could serve as an adequate alternative, while aerogel may be ideal for specialized sectors where performance justifies the higher investment. Ultimately, understanding the unique advantages and limitations of each material will guide B2B buyers in making informed decisions tailored to their operational needs.

Schaumkeramik, or ceramic foam, is increasingly utilized across various industries due to its unique properties. Understanding these technical specifications is crucial for B2B buyers seeking to make informed decisions.

Material Grade: The grade of schaumkeramik often refers to its density and porosity. Common grades range from low-density (less than 0.5 g/cm³) to high-density (greater than 1.0 g/cm³). The material grade directly influences the mechanical strength, thermal insulation, and weight of the final product. For industries such as aerospace and automotive, selecting the appropriate material grade can impact performance and safety.

Thermal Conductivity: This property measures how well heat is transferred through schaumkeramik. Typically expressed in watts per meter Kelvin (W/mK), low thermal conductivity is essential for applications requiring insulation, such as in kilns or furnaces. Buyers must evaluate the thermal requirements of their applications to select the right schaumkeramik with the appropriate thermal conductivity.

Compressive Strength: This is a measure of the material's ability to withstand axial loads without failing. Expressed in megapascals (MPa), schaumkeramik can have varying compressive strengths depending on its formulation and structure. For B2B buyers, understanding compressive strength is vital for ensuring that the material can support the intended application, especially in construction and industrial sectors.

Porosity: This refers to the volume fraction of voids within the material. High porosity can enhance insulation properties but may compromise structural integrity. For applications like soundproofing or lightweight structures, buyers need to balance porosity with strength to meet their operational requirements.

Tolerance: Tolerance defines the permissible limits of variation in a physical dimension. In schaumkeramik manufacturing, tight tolerances are often required to ensure compatibility with other components in a system. Understanding tolerances is critical for B2B buyers to avoid costly rework and ensure seamless integration into their products.

Navigating the trade terminology associated with schaumkeramik can be daunting for international buyers. Here are some key terms that are essential for effective communication and negotiation.

By familiarizing themselves with these essential properties and trade terms, international B2B buyers can enhance their purchasing strategy for schaumkeramik and ensure that their projects are successful and cost-effective.

The schaumkeramik sector is experiencing significant growth driven by advancements in technology and a rising demand for lightweight, high-performance materials across various industries, including construction, automotive, and aerospace. One major global driver is the increasing focus on energy efficiency and sustainability, leading to the adoption of schaumkeramik products that offer superior insulation properties. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, it's crucial to stay informed about these trends as they can significantly impact sourcing strategies.

Emerging B2B tech trends include the integration of smart manufacturing processes and the use of data analytics for demand forecasting. Companies are increasingly leveraging digital platforms to streamline procurement processes, enhance supplier collaboration, and improve inventory management. For instance, buyers in Poland or Saudi Arabia can benefit from adopting these technologies to create more agile supply chains that respond swiftly to market fluctuations. Additionally, the move towards Just-In-Time (JIT) inventory systems allows for reduced carrying costs and minimized waste, aligning with global sustainability goals.

Furthermore, the rise of e-commerce in the B2B landscape is transforming how schaumkeramik products are sourced. Buyers can now access a wider range of suppliers and products online, enabling better comparison and selection. This shift emphasizes the need for buyers to develop robust digital competencies to navigate the increasingly competitive market landscape effectively.

Sustainability and ethical sourcing are becoming paramount for international B2B buyers in the schaumkeramik sector. The environmental impact of manufacturing processes, such as emissions and waste generation, has prompted buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This trend is particularly relevant for buyers in regions like Africa and South America, where environmental regulations are becoming stricter and consumer awareness is rising.

Ethical supply chains are essential for ensuring transparency and accountability in sourcing decisions. Buyers should seek out suppliers that hold 'green' certifications, such as ISO 14001 for environmental management or LEED certification for sustainable building practices. These certifications not only validate a supplier's commitment to sustainability but also provide assurance that the materials used in schaumkeramik products are sourced responsibly.

Additionally, the use of eco-friendly materials in the production of schaumkeramik is gaining traction. For example, incorporating recycled materials or bio-based alternatives can significantly reduce the carbon footprint of products. International B2B buyers should actively engage with suppliers to explore these options, as they not only meet growing consumer demands for sustainability but can also enhance brand reputation and customer loyalty.

The evolution of schaumkeramik, or foam ceramics, has been marked by innovations that have expanded its applications beyond traditional uses. Initially developed for high-temperature insulation, schaumkeramik has gained popularity in various fields due to its lightweight, thermal resistance, and durability. This evolution is particularly relevant for B2B buyers who are looking for advanced materials that can meet the rigorous demands of modern applications.

As industries increasingly prioritize energy efficiency and sustainability, schaumkeramik's unique properties position it as a valuable solution. The historical development of this material highlights its adaptability, which is crucial for buyers seeking innovative products that can provide competitive advantages. Understanding this evolution allows B2B buyers to make informed decisions about sourcing schaumkeramik products that align with current market demands and technological advancements.

How do I determine the quality of schaumkeramik suppliers?

When assessing the quality of schaumkeramik suppliers, consider their certifications and adherence to international quality standards, such as ISO 9001. Request samples to evaluate material properties, including density, thermal resistance, and mechanical strength. Additionally, look for suppliers with a proven track record in your industry and positive customer feedback. Visiting the manufacturing facility, if feasible, can provide deeper insights into their production processes and quality control measures.

What are the typical minimum order quantities (MOQ) for schaumkeramik?

Minimum order quantities for schaumkeramik can vary significantly based on the supplier and product specifications. Generally, MOQs range from 100 to 1,000 units. For custom products, the MOQ may be higher due to setup costs. It’s advisable to discuss your specific needs with potential suppliers to find flexibility in MOQs, especially if you are testing a new product line or entering a new market.

What payment terms should I negotiate when purchasing schaumkeramik?

When negotiating payment terms for schaumkeramik, consider options such as letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60). It's crucial to evaluate the financial stability of the supplier and their payment history. Discussing partial payments upon order confirmation and final payment upon delivery can also mitigate risk. Always ensure that terms are documented clearly in the purchase agreement.

How can I customize schaumkeramik products to meet my specific requirements?

Customization of schaumkeramik products typically involves collaborating closely with the supplier to specify dimensions, density, thermal properties, and surface finishes. Many suppliers offer design services to help you optimize your product specifications. Be prepared to provide detailed technical drawings and performance requirements. Discuss lead times and any additional costs associated with customizations during the initial negotiation phase.

What are the best logistics practices for shipping schaumkeramik internationally?

Effective logistics practices for shipping schaumkeramik internationally include selecting reliable freight forwarders who understand handling fragile materials. Ensure proper packaging to prevent damage during transit. Consider choosing Incoterms that define responsibilities clearly, such as DDP (Delivered Duty Paid), which can simplify customs clearance. Familiarize yourself with customs regulations in the destination country to avoid unexpected delays.

How do I ensure quality assurance (QA) during the sourcing of schaumkeramik?

To ensure quality assurance during sourcing, implement a multi-step QA process that includes supplier audits, material testing, and regular inspections. Require suppliers to provide detailed documentation of their QA processes and results. Consider third-party inspection services for additional assurance. Establish clear quality benchmarks in your contract, including repercussions for non-compliance, to safeguard your interests.

What should I consider when evaluating the long-term partnership with a schaumkeramik supplier?

When evaluating a long-term partnership with a schaumkeramik supplier, assess their capacity for scalability, reliability in meeting delivery timelines, and responsiveness to your needs. Consider their willingness to engage in product development and innovation. A supplier with a robust after-sales support system can enhance your operational efficiency. Building a strong relationship can lead to better pricing and priority service, benefiting your business in the long run.

How does the regional market impact the pricing of schaumkeramik?

The regional market can significantly impact schaumkeramik pricing due to factors such as local demand, shipping costs, and tariffs. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America, influenced by production costs and labor rates. Understanding these dynamics can help you negotiate better deals. Additionally, staying informed about market trends and competitor pricing in your region can aid in making strategic sourcing decisions.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of schaumkeramik presents a unique opportunity for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. The lightweight and thermal insulating properties of schaumkeramik make it an invaluable material in various sectors, including construction, automotive, and energy. By leveraging strategic sourcing, businesses can secure high-quality materials at competitive prices, enhancing their operational efficiency and reducing costs.

Moreover, establishing strong relationships with reliable suppliers can lead to innovation, improved product quality, and better supply chain resilience. As global demand for sustainable and efficient materials continues to rise, buyers must prioritize partnerships that align with their long-term goals.

As you consider your sourcing strategies, focus on conducting thorough market research and engaging with suppliers who demonstrate a commitment to quality and sustainability. This proactive approach not only positions your business for success but also ensures you remain competitive in a rapidly evolving market. The future of schaumkeramik sourcing looks promising; now is the time to act decisively and unlock its potential for your business.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina