In today's fast-paced global marketplace, sourcing high-quality filamento delgado presents unique challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The demand for thin filament materials is on the rise, driven by innovations in various industries including textiles, electronics, and packaging. However, navigating the complexities of international sourcing—from understanding local regulations to vetting reliable suppliers—can be daunting.

This comprehensive guide delves into the multifaceted world of filamento delgado, covering essential aspects such as types, applications, and cost considerations. It provides actionable insights on how to effectively assess supplier capabilities, ensuring that buyers make informed decisions that align with their operational needs. By exploring the nuances of filamento delgado, including its various applications in different sectors, this guide empowers international B2B buyers to optimize their procurement strategies.

For buyers in regions like Nigeria and Germany, where market dynamics and consumer preferences differ significantly, this resource serves as an invaluable tool. It not only equips them with the knowledge to identify quality products but also enhances their ability to negotiate better terms and build sustainable supplier relationships. As the global market continues to evolve, understanding the intricacies of sourcing filamento delgado becomes essential for maintaining a competitive edge.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PLA (Polylactic Acid) | Biodegradable, easy to print, low warping | Prototyping, small-scale production | Pros: Eco-friendly, user-friendly; Cons: Less durable than other types. |

| ABS (Acrylonitrile Butadiene Styrene) | High strength, good heat resistance, requires heated bed | Industrial parts, automotive components | Pros: Strong and durable; Cons: Emits fumes, requires careful handling. |

| PETG (Polyethylene Terephthalate Glycol) | Excellent clarity, good chemical resistance, flexible | Packaging, medical devices | Pros: Strong, recyclable; Cons: Can be challenging to print for beginners. |

| Nylon | High flexibility, strong, and durable | Functional prototypes, textiles | Pros: Excellent strength-to-weight ratio; Cons: Absorbs moisture, difficult to print. |

| TPU (Thermoplastic Polyurethane) | Flexible, rubber-like properties, good abrasion resistance | Consumer products, wearable tech | Pros: Highly elastic, resistant to wear; Cons: Slower print speeds, requires specific settings. |

PLA, or Polylactic Acid, is a popular choice among B2B buyers due to its biodegradable nature and ease of use. This filament is derived from renewable resources like cornstarch, making it an eco-friendly option. It is particularly suitable for prototyping and small-scale production where environmental impact is a concern. When purchasing PLA, buyers should consider its printability, as it adheres well to various surfaces and has low warping tendencies. However, it is less durable than other filaments, which may limit its use in high-stress applications.

ABS (Acrylonitrile Butadiene Styrene) is known for its strength and heat resistance, making it a favored choice for industrial applications. It is commonly used in the production of automotive components and industrial parts that require durability and toughness. Buyers should be aware that ABS requires a heated bed during printing to prevent warping and ensure optimal results. While it offers excellent mechanical properties, it does emit fumes during the printing process, necessitating proper ventilation and safety precautions.

PETG (Polyethylene Terephthalate Glycol) is recognized for its clarity and chemical resistance, making it ideal for packaging solutions and medical device components. Its ease of printing and durability allows B2B buyers to produce high-quality parts that can withstand various environmental conditions. When considering PETG, it is essential to note that while it is strong and recyclable, it can be challenging for beginners to print due to its tendency to string and require specific settings.

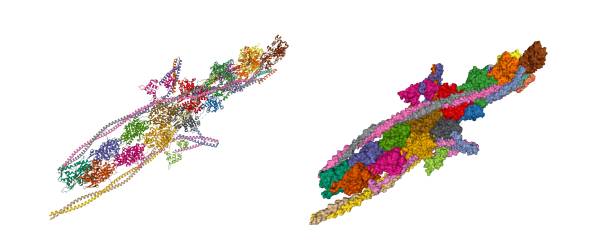

A stock image related to filamento delgado.

Nylon is characterized by its exceptional flexibility and strength, making it suitable for functional prototypes and textile applications. B2B buyers often choose nylon for its excellent strength-to-weight ratio, which is crucial in applications where performance is paramount. However, it is important to consider that nylon absorbs moisture, which can affect print quality and material properties. Therefore, buyers should ensure proper storage and handling to maintain the filament’s integrity.

A stock image related to filamento delgado.

TPU (Thermoplastic Polyurethane) is distinguished by its rubber-like flexibility and high abrasion resistance, making it an ideal choice for consumer products and wearable technology. Its elastic properties allow for the creation of comfortable and durable items, such as phone cases and straps. However, buyers should be cautious as TPU can have slower print speeds and may require specific printer settings to achieve optimal results. Understanding these factors is crucial for B2B buyers looking to invest in TPU for their product lines.

| Industry/Sector | Specific Application of filamento delgado | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile Manufacturing | Custom Apparel Production | Enables personalized designs, increasing customer engagement. | Quality control, delivery timelines, and material sustainability. |

| Promotional Merchandise | Branded Merchandise Creation | Enhances brand visibility and customer loyalty through unique items. | Supplier reliability, customization options, and pricing flexibility. |

| Sportswear and Activewear | Performance Clothing Development | Meets specific athletic needs, improving performance and comfort. | Fabric technology, moisture-wicking properties, and durability. |

| Home Decor | Customized Home Textiles | Adds unique aesthetic appeal, catering to individual customer tastes. | Material sourcing, design capabilities, and production lead times. |

| Event Merchandise | Festival and Event Apparel | Drives sales through unique offerings tailored to specific events. | Seasonal demand forecasting, design adaptability, and cost efficiency. |

In the textile manufacturing industry, 'filamento delgado' is utilized for custom apparel production. Businesses leverage this filament to create unique, personalized clothing items that resonate with consumer preferences. This application not only boosts customer engagement but also allows brands to stand out in a competitive market. International B2B buyers, especially from regions like Africa and South America, should focus on quality control measures and sustainable sourcing to meet local market expectations.

For promotional merchandise, 'filamento delgado' is essential in the creation of branded items such as T-shirts, caps, and bags. These products enhance brand visibility and customer loyalty by providing unique and memorable promotional items. B2B buyers in Europe, particularly in Germany, should consider the reliability of suppliers and customization options available to ensure that the products align with their brand identity and marketing strategies.

In the sportswear sector, 'filamento delgado' is crucial for developing performance clothing that meets the specific needs of athletes. This filament can be engineered to provide moisture-wicking properties and enhance comfort, thereby improving athletic performance. Buyers in the Middle East and Africa should prioritize sourcing materials that offer durability and advanced fabric technologies to cater to the rigorous demands of sports enthusiasts.

The home decor industry utilizes 'filamento delgado' for customized home textiles, such as curtains, cushions, and table linens. This application allows businesses to offer products that cater to individual aesthetic preferences, thereby enhancing consumer satisfaction. B2B buyers should evaluate the design capabilities and material sourcing options available to ensure that the products meet their quality standards and consumer expectations.

In the realm of event merchandise, 'filamento delgado' is employed to create unique apparel tailored for festivals and special events. This application not only drives sales but also enables brands to connect with audiences through customized offerings. For B2B buyers, especially in Europe, understanding seasonal demand forecasting and design adaptability is key to maximizing profitability during peak event periods.

Related Video: Uses and Gratifications Theory

The Problem: B2B buyers, especially in manufacturing sectors in regions like Africa and South America, often struggle to find high-quality 'filamento delgado' that meets specific project requirements. Many suppliers offer generic products that may not align with the technical specifications needed for specialized applications, such as 3D printing or textile production. This can lead to delays, increased costs, and compromised product quality, impacting the buyer's reputation and operational efficiency.

The Solution: To effectively source quality 'filamento delgado', buyers should start by conducting thorough market research to identify reputable suppliers with proven track records. Utilize platforms like Alibaba or ThomasNet to evaluate supplier ratings, customer reviews, and certifications. Engage in direct communication with potential suppliers to discuss specific requirements, such as tensile strength, flexibility, and colorfastness. Request samples before committing to larger orders to ensure that the product meets your expectations. Establishing a clear set of quality criteria and maintaining ongoing communication can foster strong supplier relationships, ensuring consistent quality and timely deliveries.

The Problem: International B2B buyers often face significant challenges in managing inventory levels of 'filamento delgado', particularly when dealing with fluctuating demand and supply chain disruptions. This is especially true for businesses in the Middle East and Europe that rely on just-in-time inventory systems. Over-ordering can lead to excess stock, while under-ordering can halt production lines, causing financial strain and loss of customer trust.

The Solution: Implementing a robust inventory management system can help buyers effectively manage their stock levels of 'filamento delgado'. Tools such as ERP (Enterprise Resource Planning) systems can provide real-time data on inventory levels, demand forecasting, and lead times. Establishing strong relationships with multiple suppliers can also mitigate risks associated with supply chain disruptions. Consider using a just-in-case inventory strategy for critical projects, where you maintain a small buffer stock of essential materials. Regularly review and adjust inventory policies based on market trends and customer feedback to ensure optimal stock levels.

The Problem: B2B buyers from diverse regions, including Europe and Africa, often encounter compliance issues with 'filamento delgado' due to varying regional standards and regulations regarding material safety, environmental impact, and product quality. Non-compliance can lead to legal repercussions, financial penalties, and damage to brand reputation, especially when exporting products to stringent markets.

The Solution: To navigate compliance challenges, buyers should familiarize themselves with the relevant regulations in their target markets. This includes understanding standards set by organizations such as ISO (International Organization for Standardization) and regional bodies specific to their industry. Work closely with suppliers who can provide documentation proving compliance with these standards. Consider hiring a compliance consultant familiar with both local and international regulations to ensure all aspects of sourcing, manufacturing, and distribution meet the required standards. Regular audits and staying updated on regulatory changes will further strengthen compliance efforts and protect your business from potential risks.

When selecting materials for filamento delgado, international B2B buyers must consider various factors that can significantly impact product performance, manufacturing processes, and compliance with regional standards. Below, we analyze four common materials used in the production of filamento delgado, highlighting their key properties, advantages, disadvantages, and considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

PLA is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. It is known for its ease of use and excellent printability.

ABS is a widely used thermoplastic known for its toughness and impact resistance, making it a popular choice for functional parts.

PETG is a modified version of PET, known for its clarity and strength, making it a versatile choice for various applications.

Nylon is a strong, flexible material known for its resilience and versatility in various applications.

| Material | Typical Use Case for filamento delgado | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, educational models | Eco-friendly and easy to print | Lower durability and heat resistance | Low |

| ABS | Functional parts, automotive components | High durability and impact resistance | Emits fumes, requires good ventilation | Medium |

| PETG | Packaging, medical devices | Excellent chemical resistance and clarity | Higher cost, specific print settings needed | Medium |

| Nylon | Gears, functional prototypes | High strength and flexibility | Moisture sensitive and challenging to print | High |

This guide provides international B2B buyers with actionable insights into material selection for filamento delgado, ensuring they can make informed decisions that align with their specific application needs and regional compliance requirements.

The manufacturing process of filamento delgado, a crucial material used in various applications, involves several well-defined stages. Understanding these stages is essential for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, as it can influence sourcing decisions and quality assurance.

The first step in the manufacturing process is material preparation. This involves selecting the appropriate raw materials, which can vary based on the specific type of filamento delgado being produced. Common materials include various polymers, such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol). The quality of the raw materials is critical, as impurities can affect the final product's performance and durability.

Once the materials are selected, they undergo a cleaning and drying process to remove moisture and contaminants. This preparation ensures that the subsequent forming processes yield high-quality filamento.

The forming stage is where the actual transformation of raw materials into filamento delgado occurs. This is typically done through extrusion, where the prepared materials are melted and forced through a die to create long strands of filament. Key techniques in this stage include:

The extruded filament is then cooled and solidified, ensuring it maintains the desired diameter and consistency.

In many cases, filamento delgado may require assembly with other components or materials, especially in specialized applications. This could involve additional processes like blending different types of filaments or incorporating additives for enhanced properties, such as UV resistance or improved tensile strength.

The finishing stage involves cutting the extruded filament into standard lengths and packaging it for shipment. Quality checks are crucial at this stage to ensure that the filament meets specifications regarding diameter, roundness, and surface finish. Any defects can significantly affect the usability of the filament in various applications, such as 3D printing or textile manufacturing.

Quality assurance (QA) is a critical aspect of the manufacturing process for filamento delgado, ensuring that the final product meets both international and industry-specific standards. B2B buyers must be aware of these QA measures to make informed purchasing decisions.

B2B buyers should familiarize themselves with several key international standards that govern quality in manufacturing:

Quality control (QC) is integrated throughout the manufacturing process. Here are the essential checkpoints:

Several testing methods are employed to ensure the quality and performance of filamento delgado:

For international B2B buyers, particularly in regions like Africa and South America, verifying a supplier's quality control processes is crucial. Here are some actionable steps:

Navigating the landscape of quality control and certification can be complex for international buyers. Here are some nuances to consider:

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing filamento delgado, ultimately ensuring they receive high-quality products that meet their specific needs.

To effectively source 'filamento delgado' for your business needs, it's essential to follow a structured approach that ensures quality, cost-effectiveness, and reliability. This guide offers a step-by-step checklist tailored for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Before you start sourcing, it’s critical to clearly outline your technical requirements for 'filamento delgado'. This includes specifications such as diameter, material type, tensile strength, and intended application. Having precise technical specifications helps in narrowing down potential suppliers who can meet your specific needs, ensuring compatibility with your production processes.

Next, conduct thorough research to identify potential suppliers of 'filamento delgado'. Utilize online directories, trade shows, and industry publications to compile a list of candidates.

Verify that the suppliers you are considering have relevant certifications. This is crucial to ensure the quality and safety of the products they provide.

Before making a bulk purchase, request samples of 'filamento delgado' to evaluate quality. Testing samples allows you to assess the filament's performance in real-world applications.

Once you have identified a suitable supplier, it’s time to negotiate terms and pricing. Clear communication during this phase can help establish a mutually beneficial relationship.

Planning for logistics is crucial to ensure timely delivery of 'filamento delgado'. Discuss shipping options, lead times, and costs with your supplier.

After procurement, continue to monitor the supplier's performance to ensure they meet your expectations. Establishing a feedback loop can help in addressing any issues proactively.

By following this structured checklist, you can streamline your sourcing process for 'filamento delgado', ensuring that you partner with the right suppliers who meet your business needs effectively.

When sourcing 'filamento delgado', a thorough understanding of the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

Materials: The quality of raw materials significantly influences the final cost. For 'filamento delgado', different types of polymers or composites can vary widely in price. Buyers should evaluate suppliers based on the quality and source of materials used.

Labor: Labor costs can fluctuate based on the region and the skill level of the workforce. In regions like Africa or South America, labor costs might be lower than in Europe, but the availability of skilled labor can affect production efficiency.

Manufacturing Overhead: This includes costs related to factory operation such as utilities, rent, and equipment maintenance. Understanding the overhead structure can help buyers gauge the supplier's pricing strategy.

Tooling: For custom or specialized 'filamento delgado', tooling costs can be significant. Buyers should factor in these costs when evaluating suppliers who offer tailored solutions.

Quality Control (QC): Implementing a rigorous QC process ensures that the final product meets required specifications. While this adds to the cost, it is crucial for maintaining quality and avoiding returns or defects.

Logistics: Transportation costs can vary greatly depending on the supplier's location and the chosen shipping method. Buyers need to consider the total logistics cost, including customs duties and tariffs, especially when importing from different regions.

Margin: Suppliers will typically add a profit margin to their costs. Understanding the typical margins in the industry can help buyers negotiate better prices.

Several factors affect the pricing of 'filamento delgado', which international B2B buyers must consider:

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should assess their needs and negotiate volume discounts accordingly.

Specifications and Customization: Custom specifications can significantly increase costs. Buyers should determine whether they need customized products or if standard offerings will suffice.

Materials and Quality Certifications: Higher-quality materials and certifications can justify higher prices. Buyers should inquire about the supplier’s compliance with industry standards to ensure product reliability.

Supplier Factors: The reputation, reliability, and experience of the supplier can influence pricing. Established suppliers might charge a premium for their proven track record.

Incoterms: The chosen Incoterms can affect the overall cost of procurement. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for calculating total landed costs.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost efficiency:

Negotiate Strategically: Use the knowledge of cost components to negotiate with suppliers. Highlight the potential for larger orders to secure discounts.

Focus on Total Cost of Ownership (TCO): Evaluate the total cost beyond the initial purchase price. Include considerations for shipping, handling, and potential future costs related to quality issues.

Understand Pricing Nuances: Pricing can vary significantly between regions. Buyers in Germany might experience different pricing structures compared to those in Nigeria or Brazil. Research local market conditions to inform negotiations.

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often result in more favorable conditions.

Request Samples and Prototypes: Before committing to large orders, request samples to evaluate quality. This can prevent costly mistakes and ensure satisfaction with the product.

In conclusion, navigating the complexities of 'filamento delgado' sourcing requires a comprehensive understanding of cost structures and pricing influencers. By leveraging strategic negotiation and thorough research, buyers can optimize their purchasing decisions and ensure value for their investments.

When evaluating the options available for your manufacturing needs, it is essential to consider various alternatives to 'filamento delgado'. This section provides a comparative analysis of 'filamento delgado' against other viable solutions, helping B2B buyers make informed decisions based on performance, cost, and usability.

| Comparison Aspect | Filamento Delgado | Alternative 1: PLA Filament | Alternative 2: ABS Filament |

|---|---|---|---|

| Performance | High precision, flexible | Good detail, biodegradable | Strong, impact-resistant |

| Cost | Moderate cost | Generally lower cost | Higher cost |

| Ease of Implementation | Easy to use | User-friendly, compatible | Requires careful handling |

| Maintenance | Minimal | Minimal, but needs careful storage | Moderate, prone to warping |

| Best Use Case | Prototyping, custom parts | Eco-friendly products, art | Functional prototypes, industrial applications |

PLA (Polylactic Acid) filament is a popular alternative to 'filamento delgado', particularly for those prioritizing environmental sustainability. Its biodegradable nature makes it a preferred choice for projects aimed at reducing carbon footprints. PLA offers good detail and is compatible with most 3D printers, making it user-friendly. However, it may not withstand high temperatures, which limits its application in functional prototypes that require durability.

ABS (Acrylonitrile Butadiene Styrene) filament is another alternative that provides high strength and impact resistance, making it ideal for functional prototypes and industrial applications. While it typically comes at a higher cost than 'filamento delgado', its durability can justify the investment for businesses focused on producing long-lasting products. However, ABS requires more careful handling due to its tendency to warp during printing, which may necessitate additional equipment or adjustments.

When selecting the appropriate filament or material for your business needs, consider the specific requirements of your projects. If precision and flexibility are paramount, 'filamento delgado' may be the best choice. However, if sustainability is a key concern, PLA could be more suitable. For projects requiring robust and durable components, ABS might be the better option despite its higher price. Evaluating these factors will enable B2B buyers to align their choices with their operational goals, ensuring optimal results in their manufacturing processes.

Filamento delgado, or thin filament, is a crucial component in various manufacturing processes, especially in textiles and 3D printing. Understanding its technical properties is essential for international B2B buyers to ensure quality and compliance with industry standards.

The material grade of filamento delgado refers to the specific type of material used in its production, such as polyester, nylon, or polypropylene. Different grades offer varying levels of strength, elasticity, and durability, which impact the final product's quality. For B2B buyers, selecting the appropriate material grade is vital for meeting application requirements and ensuring product longevity.

Diameter tolerance indicates the permissible deviation from the specified diameter of the filament. This property is critical as it affects the uniformity and consistency of the filament during production. A tighter tolerance can lead to higher-quality products and reduce waste in manufacturing processes. For buyers, understanding diameter tolerance helps ensure compatibility with machinery and prevents production downtime.

Tensile strength measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. For filamento delgado, this property is essential in applications that require durability and resilience. Buyers must consider tensile strength to ensure that the filament can endure the demands of their specific use case, such as clothing or industrial applications.

The melting point of filamento delgado is the temperature at which the material transitions from solid to liquid. This property is crucial for manufacturing processes that involve heat, such as 3D printing or fabric welding. Knowing the melting point allows buyers to select filaments suitable for their processing methods, ensuring optimal performance and avoiding material degradation.

Elongation at break refers to the percentage increase in length that a material can sustain before it fractures. This property is essential in applications requiring flexibility and stretchability, such as clothing or elastic components. For B2B buyers, understanding elongation at break helps in selecting filaments that meet specific design requirements.

Navigating the international market requires familiarity with key trade terminology. Here are some essential terms related to filamento delgado that B2B buyers should know:

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of filamento delgado, understanding OEM relationships is vital for buyers looking to integrate specific filament types into their products. It allows for better supply chain management and quality assurance.

MOQ refers to the minimum quantity of a product that a supplier is willing to sell. This term is significant for buyers, as it impacts inventory management and cost efficiency. Understanding MOQ helps B2B buyers plan their purchases to avoid overstocking or understocking situations.

An RFQ is a standard business process to invite suppliers to bid on the provision of specific goods or services. For buyers of filamento delgado, issuing an RFQ can help compare prices and terms from multiple suppliers, facilitating informed purchasing decisions.

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping responsibilities, risk management, and cost allocation when sourcing filamento delgado globally.

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For international B2B buyers, knowing lead times is essential for effective planning and inventory management, ensuring that production schedules align with supply chain capabilities.

In summary, understanding the technical properties and trade terminology associated with filamento delgado is vital for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances operational efficiency and product quality.

The filamento delgado sector, integral to various industries including textiles and 3D printing, is experiencing significant transformations driven by technological advancements and changing consumer preferences. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. One of the most prominent trends is the increasing demand for customizable products. Businesses are leveraging digital printing technologies to offer personalized solutions, which resonate well with a global market looking for unique, tailored offerings.

Moreover, the rise of e-commerce platforms has streamlined sourcing processes, allowing B2B buyers to access a wider range of suppliers and products. This shift is particularly beneficial for buyers from emerging markets, who can now connect directly with manufacturers worldwide, thereby bypassing traditional distribution channels that may have previously limited their options.

Another key trend is the focus on speed and efficiency in supply chains. Companies are adopting just-in-time inventory practices to minimize waste and reduce holding costs, thus enhancing their operational agility. This is increasingly important for buyers in fast-paced markets, where timely delivery can be a competitive advantage.

Sustainability is becoming a cornerstone of sourcing strategies in the filamento delgado sector. International B2B buyers are increasingly aware of the environmental impact of their procurement choices, particularly as consumers demand transparency and ethical practices from brands. This awareness extends to sourcing materials that are certified as sustainable or eco-friendly.

Buyers should prioritize suppliers who adhere to sustainable practices, such as using organic or recycled materials in their filamento delgado products. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® can serve as benchmarks for assessing the environmental credentials of potential suppliers.

Additionally, integrating sustainability into the supply chain not only mitigates environmental risks but also enhances brand reputation. Companies that can demonstrate commitment to ethical sourcing are likely to attract more business from eco-conscious consumers and partners. For B2B buyers, this means actively seeking out suppliers who can provide detailed information about their sourcing practices and certifications.

The evolution of filamento delgado can be traced back to the advancements in textile manufacturing and the introduction of digital printing technologies. Initially, filamento delgado was primarily used in traditional textile applications, but the rise of 3D printing in the early 2000s transformed its utility. As industries sought innovative ways to enhance production efficiency and customization, filamento delgado became a critical component in 3D printing processes.

Over the years, as technology has progressed, the versatility of filamento delgado has expanded, leading to its adoption across diverse applications, including fashion, automotive, and even medical fields. This historical context provides B2B buyers with insights into the material's potential and the opportunities it presents for innovation and growth in their respective industries. Understanding the trajectory of filamento delgado will help buyers make informed decisions about their sourcing strategies and product development initiatives.

How do I choose the right filamento delgado for my business needs?

When selecting filamento delgado, consider the specific applications you have in mind, such as 3D printing or textile manufacturing. Evaluate the material properties, including flexibility, durability, and compatibility with your equipment. It's also essential to assess the supplier's offerings regarding color options, sizes, and customization capabilities. Conducting small-scale tests with samples can help ensure the chosen filamento delgado meets your performance expectations before committing to larger orders.

What is the best type of filamento delgado for 3D printing?

For 3D printing, PLA (Polylactic Acid) is often recommended due to its ease of use, eco-friendliness, and excellent print quality. However, if you require higher durability and heat resistance, consider using ABS (Acrylonitrile Butadiene Styrene) or PETG (Polyethylene Terephthalate Glycol). The choice ultimately depends on the specific demands of your project, such as strength, flexibility, and thermal stability.

What minimum order quantity (MOQ) should I expect when sourcing filamento delgado?

MOQs for filamento delgado can vary significantly by supplier and material type. Typically, you may encounter MOQs ranging from 100 kg to 500 kg, depending on the manufacturer’s production capacity and the specific material being ordered. It’s advisable to discuss your requirements directly with suppliers to negotiate favorable terms, especially if you are a smaller business or looking for customized solutions.

What payment terms are standard for international B2B transactions involving filamento delgado?

Payment terms can differ based on the supplier's policies and the buyer's location. Common options include advance payment, letters of credit, or payment upon delivery. For international transactions, it’s crucial to clarify these terms upfront and consider using secure payment methods such as escrow services to protect your investment. Always ensure that the payment terms align with your cash flow requirements.

How can I ensure quality assurance when sourcing filamento delgado?

To ensure quality assurance, request certifications and test reports from suppliers that demonstrate compliance with industry standards. Establish a clear quality control process, including inspection of samples upon arrival and regular audits of the supplier’s production practices. Additionally, consider implementing a trial order to evaluate the product's performance before scaling up your purchases.

What are the best practices for logistics when importing filamento delgado?

Effective logistics practices involve selecting reliable shipping partners and understanding the customs regulations of your destination country. Ensure that all documentation is accurate and complete to avoid delays. Consider the mode of transport (air vs. sea) based on urgency and cost. Additionally, maintaining open communication with your supplier and logistics provider can help manage expectations and streamline the shipping process.

How do I vet suppliers of filamento delgado for reliability and quality?

To vet suppliers, start by reviewing their online presence, including customer reviews and testimonials. Request references from other clients, especially those in similar industries. It’s also beneficial to visit the supplier’s facility if possible or conduct virtual audits. Verify their certifications and compliance with international quality standards to ensure they can consistently meet your requirements.

What customization options are available for filamento delgado?

Many suppliers offer customization options for filamento delgado, including specific colors, blends of materials, and tailored formulations to meet unique application needs. When discussing your requirements with suppliers, be clear about the desired characteristics such as tensile strength, flexibility, and resistance to environmental factors. Custom formulations may come with additional costs and longer lead times, so factor these into your planning process.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the rapidly evolving market for filamento delgado, strategic sourcing emerges as a pivotal approach for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By leveraging a diverse supplier base and optimizing procurement processes, businesses can enhance their competitive edge while ensuring quality and sustainability. Key takeaways include the importance of establishing strong relationships with suppliers, understanding regional market dynamics, and embracing technology to streamline sourcing operations.

Looking ahead, the demand for innovative and sustainable filamento delgado solutions is expected to rise. International buyers should stay attuned to emerging trends such as eco-friendly materials and advanced manufacturing techniques. Engaging in continuous market research will help businesses identify potential suppliers who align with their sustainability goals and operational needs.

Now is the time for B2B buyers to reassess their sourcing strategies for filamento delgado. By prioritizing strategic partnerships and investing in technology-driven solutions, companies can not only meet current demand but also position themselves for future growth. Engage with local and international suppliers to build a resilient supply chain that can adapt to market changes. The proactive steps you take today will determine your success in the dynamic landscape of filamento delgado procurement.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina