In the complex landscape of international trade, understanding the meaning of fused alumina is crucial for B2B buyers seeking high-quality materials for diverse applications. Sourcing the right fused alumina can be challenging, especially when navigating varying quality standards and supplier reliability across different regions, including Africa, South America, the Middle East, and Europe. This guide serves as a comprehensive resource, addressing key aspects such as the types of fused alumina available, their industrial applications, and the intricacies of supplier vetting processes.

Our aim is to empower B2B buyers with actionable insights that enhance their purchasing decisions. By exploring topics like cost considerations and market trends, buyers will be equipped to identify suppliers that meet their specific needs while ensuring product integrity. Understanding fused alumina's unique properties and applications—ranging from abrasives in manufacturing to its role in refractory materials—can significantly impact operational efficiency and product performance.

This guide not only clarifies the fundamental aspects of fused alumina but also provides a strategic framework for international buyers. By leveraging this knowledge, companies can streamline their procurement processes, minimize risks, and establish long-term partnerships with trustworthy suppliers, ultimately driving business growth and innovation in their respective markets.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

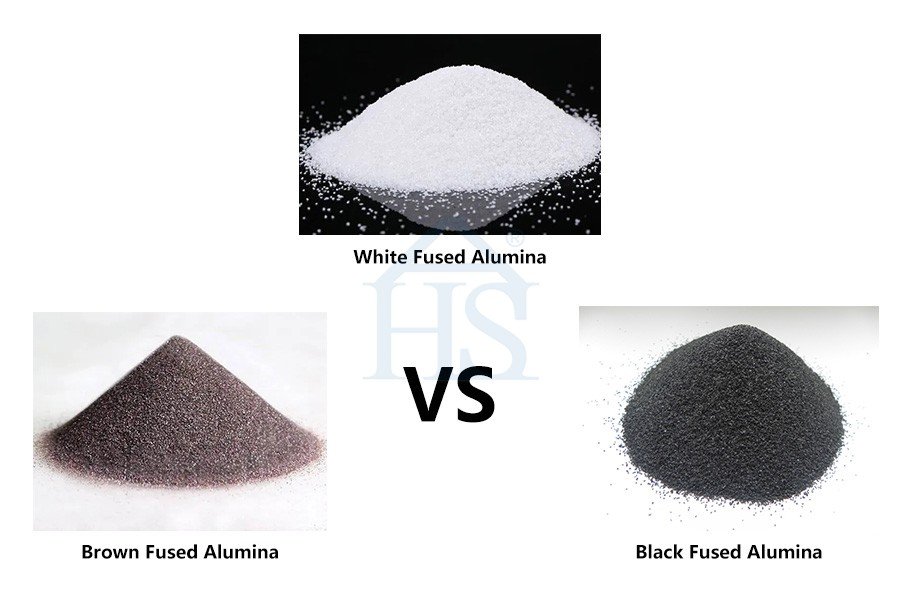

| Fused White Alumina | High purity, low iron content, fine particle size | Precision grinding, ceramics, and coatings | Pros: Excellent finish; Cons: Higher cost due to purity. |

| Fused Brown Alumina | Coarser structure, high toughness | Metalworking, abrasive products, and blasting | Pros: Cost-effective; Cons: Less refined finish. |

| Fused Tabular Alumina | Large, tabular crystals, high thermal stability | Refractories and kiln linings | Pros: High thermal shock resistance; Cons: Limited availability. |

| Fused Alumina Zirconia | Enhanced toughness and wear resistance | Heavy-duty applications, such as grinding wheels | Pros: Superior durability; Cons: More expensive than standard options. |

| Fused Alumina Spinel | Combination of alumina and magnesium oxide | Specialty ceramics and refractory applications | Pros: High thermal stability; Cons: Niche use cases may limit demand. |

Fused White Alumina is known for its high purity and low iron content, making it ideal for applications requiring a fine finish. Its fine particle size contributes to its effectiveness in precision grinding and coatings. B2B buyers in industries such as ceramics and abrasives should consider this type for projects where product integrity and finish quality are paramount. The primary drawback is its higher cost, which may deter budget-conscious buyers.

Fused Brown Alumina features a coarser structure and high toughness, making it a popular choice for metalworking and abrasive products. It is particularly suitable for blasting applications due to its resilience. B2B buyers seeking a cost-effective solution without sacrificing performance will find this type advantageous. However, its less refined finish might not meet the standards required for more delicate applications.

Fused Tabular Alumina is characterized by its large, tabular crystals that provide exceptional thermal stability. This makes it a preferred choice in refractory applications, particularly for kiln linings. Buyers in industries that require materials to withstand extreme temperatures should prioritize this type. The main limitation is its availability, which may affect procurement timelines and costs.

Fused Alumina Zirconia is designed for heavy-duty applications, offering enhanced toughness and wear resistance. This type is particularly effective for grinding wheels and other high-impact uses. B2B buyers looking for superior durability will appreciate its performance, although the higher price point may necessitate a careful cost-benefit analysis.

Fused Alumina Spinel combines alumina with magnesium oxide, providing high thermal stability suitable for specialty ceramics and refractory applications. This type is particularly beneficial in environments where thermal shock is a concern. However, its niche applications may limit demand, making it a consideration primarily for specialized projects or industries.

Related Video: White fused alumina

| Industry/Sector | Specific Application of fused alumina meaning | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives Manufacturing | Used as a key component in abrasive materials for grinding and cutting | Enhances the durability and efficiency of abrasive products | Quality of fused alumina, grain size specifications, and sourcing reliability |

| Electronics | Insulation and substrate material in semiconductor applications | Provides excellent thermal stability and electrical insulation | Consistency in material properties and compliance with industry standards |

| Construction | Component in refractory materials for high-temperature applications | Increases the lifespan of construction materials under extreme conditions | Certification of material for high-temperature resistance and local regulations |

| Automotive | Used in brake linings and friction materials | Improves safety and performance of automotive components | Sourcing from suppliers with proven track records in automotive standards |

| Coatings and Paints | Filler in protective coatings and paints | Enhances abrasion resistance and durability of the final product | Compatibility with other materials and environmental compliance |

Fused alumina is a crucial ingredient in the production of various abrasive materials, such as grinding wheels and sandpapers. Its hardness and durability allow for effective material removal and surface finishing. For B2B buyers, especially those in regions like South America and Africa, sourcing high-quality fused alumina is essential to ensure the longevity and efficiency of their abrasive products. Buyers should consider grain size specifications and the supplier's ability to provide consistent quality over time.

In the electronics sector, fused alumina is utilized as an insulation and substrate material in semiconductor applications. Its excellent thermal stability and electrical insulation properties make it ideal for high-performance electronic devices. International buyers, particularly from Europe and the Middle East, must prioritize sourcing fused alumina that meets stringent industry standards to ensure reliability and performance in their electronic components.

Fused alumina is incorporated into refractory materials used in construction, particularly in applications that require high-temperature resistance. This application is critical for industries involved in steel production or other high-heat processes. B2B buyers in this sector should focus on the certification of the material for high-temperature applications and ensure compliance with local regulations to avoid costly failures.

In the automotive industry, fused alumina is primarily used in brake linings and other friction materials. Its properties enhance the safety and performance of automotive components, making vehicles more reliable. Buyers from regions like Saudi Arabia and Europe should seek suppliers with a proven track record in automotive standards to ensure that the materials sourced contribute positively to the safety and efficiency of their products.

Fused alumina serves as a filler in protective coatings and paints, significantly enhancing their abrasion resistance and durability. This application is particularly beneficial for industries requiring long-lasting protective finishes. Buyers should consider the compatibility of fused alumina with other materials used in coatings and ensure that the sourced products comply with environmental regulations to meet global standards.

Related Video: Alumina Ceramics: The Complete Guide

The Problem:

B2B buyers often struggle to comprehend the various applications and grades of fused alumina, leading to confusion when selecting the right product for their needs. For instance, a company in the construction sector may require a specific type of fused alumina for abrasive blasting, but without a clear understanding of the material’s properties, they might choose a grade that does not meet their performance expectations. This can result in subpar results, increased costs, and project delays.

The Solution:

To effectively navigate this challenge, buyers should invest time in understanding the technical specifications and applications of different fused alumina grades. They can start by consulting detailed product datasheets and technical guides that outline the properties, such as hardness, purity, and grain size, of various fused alumina types. Engaging with suppliers who offer expert guidance can also help clarify which specific grade is suitable for their application. It’s beneficial to conduct small-scale tests before full-scale procurement, allowing companies to evaluate performance in real-world scenarios. Additionally, leveraging online forums or industry-specific webinars can provide insights from peers who have faced similar challenges.

The Problem:

International B2B buyers, particularly from regions like Africa and South America, often encounter supply chain disruptions when sourcing fused alumina. Factors such as geopolitical tensions, shipping delays, and inconsistent supplier reliability can lead to unexpected shortages, forcing companies to halt production or seek costly last-minute alternatives.

The Solution:

To mitigate supply chain risks, buyers should develop a diversified sourcing strategy that involves multiple suppliers across different regions. Establishing relationships with local distributors can also minimize shipping times and costs. Buyers should consider utilizing technology such as supply chain management software to monitor inventory levels and forecast demand accurately. Additionally, creating a safety stock of critical materials can provide a buffer against unexpected disruptions. Engaging in long-term contracts with suppliers can also ensure more consistent supply, allowing buyers to plan and execute their operations without interruptions.

The Problem:

As raw material prices fluctuate, B2B buyers face the challenge of managing costs associated with purchasing fused alumina. For businesses in competitive industries, even minor price increases can significantly impact profit margins, making it crucial to find cost-effective solutions without compromising quality.

The Solution:

Buyers can implement several strategies to manage costs effectively. First, conducting a thorough market analysis to identify price trends and potential suppliers can help buyers negotiate better deals. Bulk purchasing is another effective strategy; by ordering larger quantities, companies can often secure lower prices per unit. Buyers should also consider exploring alternative grades of fused alumina that may offer similar performance at a reduced cost. Additionally, fostering long-term partnerships with suppliers can lead to favorable pricing agreements and priority access during shortages. Finally, implementing a value analysis approach—assessing the performance benefits against costs—can help ensure that any savings do not come at the expense of product quality or operational efficiency.

Fused alumina, a synthetic corundum, is primarily known for its exceptional hardness and thermal stability, making it a preferred choice in various industrial applications. The key properties that make fused alumina suitable for B2B applications include:

A stock image related to fused alumina meaning.

When considering fused alumina for industrial applications, it is essential to weigh its advantages against its limitations.

Fused alumina is widely used in several applications due to its unique properties. In the abrasives industry, for example, it is favored for its ability to maintain sharp cutting edges and withstand high temperatures. In refractory materials, its thermal stability makes it an excellent choice for linings in furnaces and kilns. However, its compatibility with specific media must be considered, particularly in chemical processing industries, where corrosive substances can affect performance.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should keep several factors in mind when selecting fused alumina:

| Material | Typical Use Case for fused alumina meaning | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused Alumina | Abrasives, refractory linings, and cutting tools | High durability and thermal stability | Manufacturing complexity and rigidity | Medium |

| Synthetic Corundum | Grinding wheels and polishing compounds | Versatile applications in various industries | Limited flexibility in certain applications | Medium |

| Alumina Ceramics | Insulation and structural components | Excellent thermal and electrical insulation | Brittle nature can lead to cracking | High |

| Calcined Alumina | Coatings and fillers in various products | Good chemical resistance and stability | Higher production costs compared to raw alumina | Medium |

This guide provides a comprehensive overview of the strategic material selection process for fused alumina, enabling international B2B buyers to make informed decisions tailored to their specific industrial needs.

Fused alumina, a high-purity aluminum oxide, is produced through a series of well-defined manufacturing processes. Understanding these stages is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, as it impacts both product quality and supply chain efficiency.

The manufacturing process begins with the careful selection and preparation of raw materials. Bauxite ore, which contains aluminum oxide, is the primary source. The ore undergoes crushing and grinding to achieve the desired particle size.

Key Considerations:

- Purity Levels: Ensure that suppliers use high-purity bauxite to minimize impurities in the final product.

- Supplier Credentials: Verify that raw materials are sourced from certified suppliers to ensure quality and consistency.

Once the raw materials are prepared, the next step is the forming process, which typically involves melting. The prepared alumina is subjected to high temperatures in an electric arc furnace, where it melts and then crystallizes into fused alumina. This stage may also include various techniques such as:

Key Techniques:

- Controlled Cooling: Proper cooling techniques are essential to prevent defects and ensure uniformity in the fused alumina structure.

- Batch Processing: For large orders, batch processing may be used to maintain consistency across production runs.

After forming, the fused alumina undergoes assembly and finishing processes. This may involve crushing the fused material into specific grain sizes suitable for various applications, such as abrasives, refractories, or ceramics.

Finishing Techniques:

- Sieving and Classification: To ensure uniform particle sizes, sieving is used, along with air classification techniques.

- Surface Treatment: Some applications may require additional surface treatments to enhance properties such as hardness or wear resistance.

Quality assurance (QA) is a critical aspect of the manufacturing process for fused alumina. It ensures that the final product meets industry standards and customer expectations. Here’s an overview of the QA measures typically employed.

International standards, such as ISO 9001, provide a framework for quality management systems in manufacturing. Compliance with these standards is vital for suppliers aiming to serve international markets.

Relevant Certifications:

- ISO 9001: Focuses on quality management systems to enhance customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety and environmental standards.

- API Standards: Relevant for applications in the oil and gas industry, ensuring that products meet specific performance criteria.

Quality control (QC) involves systematic checks at various stages of the manufacturing process to ensure product quality. The following checkpoints are commonly implemented:

IQC focuses on verifying the quality of raw materials before they enter the production process. This includes:

During production, IPQC measures are taken to monitor the manufacturing process. This includes:

FQC is performed once the product is completed. This stage involves:

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential. Here are actionable steps to ensure supplier credibility:

Regular audits can help assess the supplier’s compliance with international standards. Audits should focus on:

Buyers should ask for detailed QA reports that outline the testing methods used and the results obtained. These reports provide insights into the effectiveness of the supplier's QC processes.

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier's quality control measures. These inspections often include:

B2B buyers must navigate various nuances in quality control, especially when dealing with international suppliers. Here are key considerations:

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing fused alumina, ultimately ensuring that they receive high-quality products that meet their specific needs.

In the competitive landscape of B2B procurement, understanding the nuances of materials such as fused alumina is critical for making informed purchasing decisions. This guide offers a structured checklist to assist international buyers—particularly those from Africa, South America, the Middle East, and Europe—in sourcing fused alumina effectively.

Clearly outline the technical requirements for the fused alumina you need. This includes understanding the desired grain size, purity levels, and specific applications such as abrasives or refractories. Defining these parameters helps in narrowing down suppliers who can meet your precise needs.

Before reaching out to suppliers, conduct thorough market research to identify leading manufacturers and distributors of fused alumina. This involves understanding regional availability, pricing trends, and the competitive landscape.

Ensuring that your suppliers hold the necessary certifications is crucial for quality assurance. Look for ISO certifications or other relevant industry standards that indicate compliance with international quality benchmarks.

Before finalizing your order, request samples of fused alumina to test against your specifications. This step is vital to confirm the quality and suitability of the material for your intended applications.

Investigate the reliability and reputation of potential suppliers. This can be done through customer reviews, testimonials, and case studies. A supplier's track record can significantly influence your decision.

Once you have shortlisted suppliers, engage in negotiations to secure favorable pricing and terms. This includes discussing payment options, lead times, and delivery logistics.

Finally, plan the logistics of your order. Understanding the shipping process, customs regulations, and delivery timelines is crucial for timely procurement.

By following this checklist, international B2B buyers can streamline their procurement process for fused alumina, ensuring they source high-quality materials that meet their operational needs.

When sourcing fused alumina, understanding the cost structure is crucial for international B2B buyers. The cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The primary cost driver is the raw materials used in producing fused alumina, which can fluctuate based on global market trends. Buyers should monitor commodity prices and consider long-term contracts to stabilize costs.

Labor: Labor costs vary significantly by region. Countries with lower labor costs can offer competitive pricing, but this may impact quality. It’s essential to assess the labor practices of suppliers to ensure compliance with international standards.

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities and maintenance. Efficient production processes can help minimize overhead costs.

Tooling: Initial tooling costs can be substantial, especially for custom specifications. Buyers should consider whether the supplier can provide the necessary tooling or if they need to invest in it themselves.

Quality Control: Investing in quality control processes ensures that the product meets specified standards. Certifications can add to the cost but can also enhance the product's marketability.

Logistics: Shipping and handling costs depend on the distance and chosen Incoterms. Understanding these costs is vital for calculating the total landed cost.

Margin: Finally, suppliers will include a profit margin in their pricing. This can vary widely based on supplier reputation, market demand, and the relationship with the buyer.

Several factors influence the pricing of fused alumina. These include order volume, specifications, material quality, certifications, supplier capabilities, and Incoterms.

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact price. Larger orders typically benefit from volume discounts, making it essential for buyers to assess their needs carefully.

Specifications and Customization: Custom specifications can lead to higher prices due to additional processing and material requirements. Buyers should clearly define their specifications to avoid unexpected costs.

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO or ASTM) can increase costs but also provide assurance of product reliability. Buyers should weigh the benefits of these certifications against potential price increases.

Supplier Factors: Supplier reliability, production capacity, and historical performance can all influence pricing. Establishing long-term relationships with reputable suppliers can lead to better pricing and terms.

Incoterms: The choice of Incoterms affects the distribution of costs and responsibilities between buyers and sellers. Understanding these terms can help buyers negotiate better shipping arrangements and overall costs.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings.

Conduct Market Research: Before entering negotiations, conduct thorough research on market prices and supplier offerings. This knowledge can empower buyers during discussions.

Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider logistics, quality assurance, and potential operational costs over the product's lifecycle.

Leverage Relationships: Building strong relationships with suppliers can lead to more favorable terms and pricing. Engage with suppliers to understand their constraints and capacities.

Be Transparent About Needs: Clearly communicate your requirements and any potential for future orders. This openness can encourage suppliers to offer better pricing.

Explore Alternative Suppliers: Don’t hesitate to seek multiple quotes. Comparing offers can provide leverage in negotiations and reveal competitive pricing.

Prices for fused alumina can vary widely based on the factors discussed above. Buyers should treat any indicative prices as a starting point for negotiations and conduct their due diligence before finalizing any agreements.

When considering the best materials and solutions for industrial applications, it's essential to evaluate not only the primary choice—fused alumina—but also viable alternatives. This comparative analysis focuses on alternative materials or methods that can fulfill similar roles in various applications, particularly for international B2B buyers. By understanding the strengths and weaknesses of each option, businesses can make informed decisions tailored to their specific needs.

| Comparison Aspect | Fused Alumina Meaning | Alternative 1 Name: Silicon Carbide | Alternative 2 Name: Zirconia |

|---|---|---|---|

| Performance | High hardness and wear resistance | Superior thermal conductivity and hardness | Excellent toughness and wear resistance |

| Cost | Moderate to high | Generally lower than fused alumina | Higher due to production complexity |

| Ease of Implementation | Standard processing methods | Similar processing but requires specific tools | Often requires specialized techniques |

| Maintenance | Low maintenance | Low maintenance but needs careful handling | Moderate maintenance, sensitive to environment |

| Best Use Case | Abrasives, refractories, and ceramics | High-temperature applications, abrasive tools | Cutting tools, dental applications, and ceramics |

Silicon Carbide is a formidable alternative to fused alumina, particularly in high-temperature applications. Its superior thermal conductivity makes it ideal for environments where heat dissipation is critical. While it typically comes at a lower cost than fused alumina, silicon carbide requires specific processing tools, which may increase initial setup costs. Additionally, while it offers low maintenance, its brittleness can pose challenges in applications requiring high-impact resistance.

Zirconia, or zirconium dioxide, is another alternative that stands out for its exceptional toughness and wear resistance. It is commonly used in cutting tools and dental applications due to its ability to withstand high stress without fracturing. However, zirconia tends to be more expensive than fused alumina, primarily due to the complexity of its production. Maintenance requirements are moderate, as zirconia is sensitive to environmental factors, necessitating careful handling during processing and application.

Selecting the right material or method for your industrial applications requires a thorough understanding of your specific requirements, including performance expectations, budget constraints, and operational capabilities. While fused alumina is a robust choice for many applications due to its wear resistance and processing versatility, alternatives like silicon carbide and zirconia may offer specific advantages that could better align with your needs. By assessing the performance characteristics, costs, and maintenance demands of each option, B2B buyers can make informed decisions that enhance efficiency and effectiveness in their operations.

Fused alumina, a synthetic material derived from aluminum oxide, is widely utilized in various industrial applications. Understanding its technical properties is crucial for B2B buyers to ensure they select the right grade for their needs.

Material grades indicate the quality and purity of fused alumina. Common grades include white fused alumina (WFA) and brown fused alumina (BFA), with WFA being purer and more suitable for applications requiring high abrasion resistance. Selecting the appropriate material grade can significantly impact the performance of the final product, making this a vital consideration for manufacturers in sectors like automotive, aerospace, and construction.

The grain size of fused alumina affects its hardness and cutting efficiency. Grain sizes are typically classified into fine, medium, and coarse categories. For instance, finer grains are better for polishing and finishing applications, while coarser grains excel in grinding. Understanding grain size is essential for B2B buyers to match the material with their specific application requirements.

Fused alumina is known for its high hardness, rated at approximately 9 on the Mohs scale. This property makes it an excellent choice for abrasive applications, such as sandblasting and grinding. Buyers should prioritize hardness ratings to ensure longevity and performance in demanding environments.

Fused alumina exhibits excellent thermal stability, allowing it to withstand high temperatures without degrading. This property is particularly important for applications in furnaces and kilns. Buyers need to evaluate thermal stability to prevent material failure under extreme conditions.

Bulk density measures the mass of the material relative to its volume and influences its handling and processing characteristics. Higher bulk density typically indicates stronger and more durable products, which can be beneficial for manufacturing processes. Buyers should consider bulk density when assessing the overall strength and application suitability of fused alumina.

Understanding trade terminology is essential for effective communication and negotiation in the B2B space. Here are some common terms associated with fused alumina that buyers should be familiar with.

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of fused alumina, OEMs may require specific grades and specifications tailored to their equipment. Knowing the OEM requirements can help buyers make informed purchasing decisions.

MOQ is the minimum quantity that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cost calculations. Understanding the MOQ helps buyers plan their orders according to production needs and budget constraints.

An RFQ is a document sent by a buyer to suppliers requesting pricing information for specific products or services. B2B buyers should utilize RFQs to compare prices and terms effectively, ensuring they receive the best deal for fused alumina.

Incoterms define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to avoid misunderstandings and ensure smooth logistics when sourcing fused alumina globally.

Lead time refers to the duration between placing an order and receiving the product. This term is especially significant for B2B buyers in industries where timely delivery is critical. Knowing the lead times associated with different suppliers can help businesses plan their production schedules more effectively.

In summary, grasping the essential technical properties and trade terminology related to fused alumina empowers B2B buyers to make informed purchasing decisions, ensuring they meet their operational requirements efficiently.

The fused alumina market is experiencing significant growth driven by the increasing demand for high-performance materials in various industries such as automotive, aerospace, and electronics. Key trends include the rising adoption of advanced manufacturing technologies, such as additive manufacturing and automation, which require high-quality fused alumina for precision components. Additionally, the growing awareness of the benefits of fused alumina over traditional materials is prompting international B2B buyers to explore innovative applications, particularly in the Middle East and Africa where infrastructure projects are booming.

Emerging markets in South America and Europe are also witnessing a surge in demand, driven by the expansion of industries like construction and manufacturing. This increased demand is leading to more competitive pricing and supply chain efficiencies, making it essential for buyers to stay informed about market fluctuations. Additionally, international partnerships are becoming crucial as suppliers seek to establish a global presence, allowing buyers from regions like Argentina and Saudi Arabia to access high-quality products more reliably.

A stock image related to fused alumina meaning.

To navigate these market dynamics, B2B buyers should focus on building strong relationships with suppliers who have a proven track record of innovation and quality. Understanding local market conditions, including regulatory requirements and logistical challenges, will also be vital for successful sourcing strategies.

Sustainability is increasingly becoming a critical consideration for B2B buyers in the fused alumina sector. The environmental impact of production processes, particularly regarding energy consumption and waste management, is under scrutiny. Buyers are now looking for suppliers who prioritize sustainable practices, such as reducing carbon footprints and utilizing renewable energy sources in manufacturing.

Ethical sourcing is equally important, as consumers and companies alike demand transparency in supply chains. Buyers should seek partnerships with suppliers who adhere to international standards and certifications, ensuring that their materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and various green certifications for materials are becoming essential for suppliers looking to differentiate themselves in the market.

Investing in sustainable and ethical sourcing not only enhances a company's reputation but also aligns with global initiatives aimed at reducing environmental degradation. By prioritizing these factors, B2B buyers can ensure that their sourcing strategies contribute positively to both their business objectives and broader societal goals.

The fused alumina market has evolved significantly over the past few decades, transitioning from traditional methods of production to advanced techniques that enhance quality and efficiency. Initially used primarily in abrasive applications, the material's versatility has led to its adoption across various sectors, including electronics and ceramics.

The technological advancements in manufacturing processes, such as the development of fusion techniques, have allowed for the creation of specialized grades of fused alumina that meet specific industry requirements. This evolution has not only broadened the applications of fused alumina but has also increased its market value, making it a critical material for B2B buyers aiming for high performance and reliability in their products.

As the market continues to mature, staying abreast of historical trends can provide valuable insights into future developments, helping buyers make informed decisions about sourcing and partnerships. Understanding the evolution of fused alumina will enable buyers to leverage its full potential in their operations.

How do I identify high-quality suppliers of fused alumina?

To identify high-quality suppliers of fused alumina, start by researching industry certifications such as ISO 9001, which indicates a commitment to quality management systems. Additionally, consider suppliers with a proven track record and positive reviews from other B2B buyers in your region. Networking at industry trade shows and utilizing platforms like Alibaba or Global Sources can also help you find reputable suppliers. Finally, request samples to evaluate the product quality before making a larger commitment.

What are the best applications for fused alumina in industrial settings?

Fused alumina is widely used in various industrial applications including abrasives, ceramics, refractories, and as a filler in polymer composites. Its hardness and thermal stability make it ideal for grinding wheels and sandpapers. In the ceramics industry, it enhances strength and durability, while in refractories, it improves thermal resistance. Understanding your specific application will help you choose the right type of fused alumina for optimal performance.

What should I consider regarding minimum order quantities (MOQ) when sourcing fused alumina?

When sourcing fused alumina, minimum order quantities (MOQ) can vary significantly between suppliers. It’s crucial to clarify MOQs upfront, as some suppliers may have higher MOQs for specialized products. If you are a smaller buyer, look for suppliers that cater to smaller orders or consider group purchasing with other businesses to meet MOQs. Additionally, negotiate terms that allow for flexibility in your initial orders to test the product before committing to larger quantities.

What payment terms are standard for international B2B transactions involving fused alumina?

Standard payment terms for international transactions can vary, but many suppliers prefer options like letters of credit (LC), telegraphic transfers (T/T), or escrow services. A common practice is to require a deposit before production, with the balance due upon shipment or delivery. Always clarify payment terms before finalizing the order to avoid any misunderstandings. Additionally, consider the currency fluctuations and transaction fees that may apply in cross-border payments.

How can I ensure the quality of fused alumina during shipping and handling?

To ensure quality during shipping and handling, request suppliers to use appropriate packaging materials that protect the product from damage. Additionally, specify the use of quality assurance processes, such as pre-shipment inspections or third-party audits. Establish clear communication channels with logistics providers to monitor the shipment’s condition. Finally, upon receipt, conduct a thorough inspection of the product to verify compliance with the agreed specifications.

What are the common customs regulations for importing fused alumina into my region?

Customs regulations for importing fused alumina can vary by country. Generally, you will need to provide documentation such as a bill of lading, commercial invoice, and any relevant certificates of origin or quality. It is essential to familiarize yourself with the specific import duties and taxes applicable in your region, as well as any restrictions on hazardous materials. Engaging a customs broker can also streamline the import process and ensure compliance with local regulations.

How do I customize my order of fused alumina to meet specific requirements?

To customize your order of fused alumina, begin by discussing your specific needs with potential suppliers. Customizations can include variations in grain size, purity levels, and packaging options. Most manufacturers are willing to accommodate special requests, especially for bulk orders. Ensure to provide detailed specifications and, if possible, samples of the desired product characteristics. Keep in mind that custom orders may have longer lead times and potentially higher costs.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, strategic sourcing of fused alumina offers significant advantages for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Understanding the unique properties of fused alumina—such as its durability, high melting point, and versatility—enables buyers to select the right products for their specific applications. By engaging with reliable suppliers and leveraging long-term partnerships, buyers can ensure consistent quality and competitive pricing.

To optimize sourcing strategies, businesses should prioritize suppliers that adhere to international quality standards and offer transparent supply chain practices. Buyers are encouraged to conduct thorough market research to identify the best suppliers and negotiate favorable terms. Additionally, exploring local suppliers can reduce lead times and transportation costs, enhancing overall supply chain efficiency.

Looking ahead, the demand for fused alumina is expected to grow, driven by advancements in various industries such as construction, automotive, and electronics. Buyers should stay informed about market trends and emerging technologies that may impact the availability and pricing of fused alumina. By proactively adapting their sourcing strategies, international B2B buyers can seize new opportunities and drive sustainable growth in their operations.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina