In today's competitive landscape, sourcing high-quality lijas de carburo de silicio (silicon carbide abrasives) presents a significant challenge for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The diversity in applications—from automotive to aerospace—demands a comprehensive understanding of product specifications and supplier capabilities. This guide aims to demystify the global market for silicon carbide abrasives by providing an in-depth analysis of types, applications, and the critical factors to consider when vetting suppliers.

By leveraging this resource, buyers can navigate the complexities of sourcing silicon carbide abrasives with confidence. We delve into essential topics such as cost considerations, quality standards, and logistical challenges, enabling informed purchasing decisions that align with specific operational needs. The guide also highlights regional market trends and supplier networks relevant to diverse geographical contexts, including the unique requirements of buyers in the UAE and Saudi Arabia.

Ultimately, this guide serves as a strategic tool for B2B buyers looking to optimize their procurement processes, ensuring they select the right products from reliable suppliers while maximizing value and efficiency in their operations. Whether you are a seasoned buyer or new to the market, the insights provided will empower you to make decisions that enhance your competitive advantage.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wet/Dry Sandpaper | Coated with silicon carbide, suitable for both wet and dry use | Automotive refinishing, woodworking | Pros: Versatile, reduces dust; Cons: May wear out faster when used dry. |

| Hook and Loop Sandpaper | Designed with a hook-and-loop backing for easy attachment | Furniture manufacturing, cabinetry | Pros: Quick changes, reusable; Cons: Adhesive may wear out over time. |

| Screen Sandpaper | Consists of a mesh backing, allowing dust to escape | Metalworking, drywall finishing | Pros: Reduces clogging, longer-lasting; Cons: Less flexible than traditional types. |

| Aluminum Oxide Blended Sandpaper | Combines aluminum oxide with silicon carbide for added durability | Heavy-duty applications, flooring | Pros: High durability, effective on tough materials; Cons: More expensive than standard options. |

| Specialty Sandpaper | Tailored for specific tasks like polishing or shaping | Jewelry making, automotive detailing | Pros: Customizable for specific needs; Cons: Limited availability and higher costs. |

Wet/dry sandpaper is a versatile option that can be used with water or dry, making it suitable for a variety of applications. This type is particularly favored in automotive refinishing and woodworking, where a smooth finish is paramount. When purchasing, consider the grit size, as finer grits are ideal for finishing, while coarser grits are better for material removal. Buyers should also be aware that while wet use reduces dust, it may lead to faster wear if used dry.

Hook and loop sandpaper features a backing that allows for quick attachment and removal from sanding tools. This is especially beneficial in environments like furniture manufacturing or cabinetry, where efficiency is crucial. When sourcing this type, buyers should look for quality in the adhesive strength and backing material to ensure longevity. While it offers convenience, the adhesive can degrade over time, necessitating a balance between cost and quality.

Screen sandpaper is designed with a mesh backing that facilitates dust escape, minimizing clogging during use. This feature is particularly advantageous in metalworking and drywall finishing, where maintaining a clean surface is vital. B2B buyers should consider the mesh size and grit when selecting screen sandpaper, as these factors will impact performance. Its durability is a significant advantage, although it may lack the flexibility of traditional sandpaper types.

Aluminum oxide blended sandpaper combines the properties of aluminum oxide with silicon carbide, resulting in a highly durable product suitable for heavy-duty applications like flooring and industrial work. Buyers should assess the grit and blend ratio to ensure it meets their specific needs. While this type is more costly, its longevity and effectiveness on tough materials often justify the investment, making it a smart choice for businesses requiring reliability.

Specialty sandpaper is crafted for specific tasks, such as polishing or shaping, making it ideal for industries like jewelry making and automotive detailing. B2B buyers should evaluate the specific requirements of their projects to determine the most suitable specialty sandpaper. Although these products may come at a higher price point and limited availability, their tailored designs can significantly enhance the quality and efficiency of specialized tasks.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of lijas de carburo de silicio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Abrasive tools for machining and finishing parts | Enhances precision and surface quality | Look for suppliers with ISO certification and proven track record. |

| Electronics | Wafer fabrication for semiconductors | Improves efficiency and yields in production | Ensure sourcing from manufacturers with advanced quality control measures. |

| Construction Materials | Surface preparation for concrete and masonry | Provides better adhesion and durability | Consider local sourcing options to reduce shipping costs and time. |

| Aerospace | Component finishing for engines and airframes | Increases performance and reliability | Seek suppliers with expertise in aerospace-grade materials. |

| Metalworking | Grinding and polishing of metal parts | Achieves high precision and reduces waste | Verify the grit size and type suitable for specific applications. |

In the automotive sector, lijas de carburo de silicio are primarily utilized in the production of abrasive tools for machining and finishing various parts, such as engine components and body panels. These abrasives enhance the precision and surface quality of machined parts, which is crucial for performance and safety. International buyers should prioritize suppliers that offer a range of grit sizes and ensure adherence to ISO certifications to maintain quality standards.

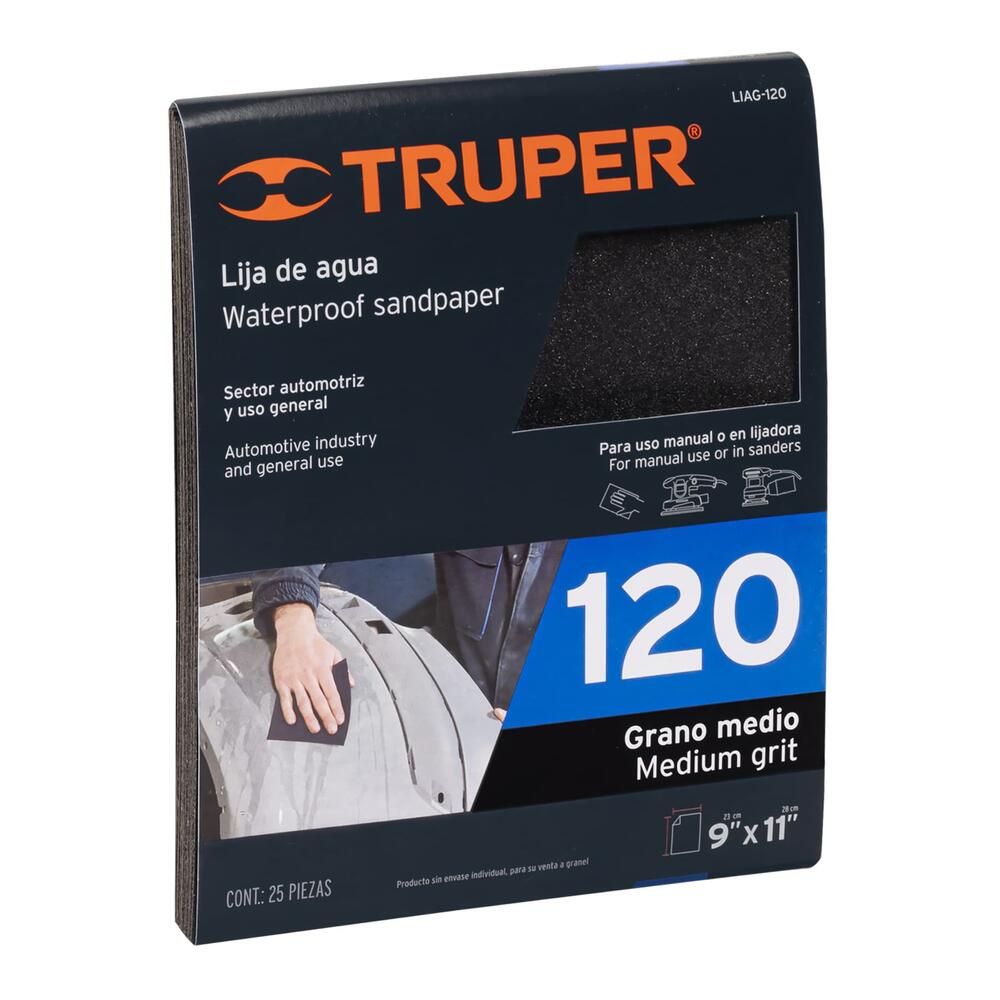

A stock image related to lijas de carburo de silicio.

In electronics, lijas de carburo de silicio are integral to the wafer fabrication process for semiconductors. These abrasives improve the efficiency and yield of production by ensuring a smooth surface finish on wafers. Buyers from regions like Africa and the Middle East should focus on sourcing from manufacturers that implement rigorous quality control measures to guarantee the reliability of their products, particularly as the demand for high-performance electronic components grows.

In the construction materials industry, lijas de carburo de silicio are used for surface preparation of concrete and masonry. This application enhances adhesion and durability when applying coatings or finishes. For international B2B buyers, local sourcing can be advantageous to minimize shipping costs and lead times, while also ensuring that the abrasives meet the specific requirements for various construction applications.

Lijas de carburo de silicio are critical in the aerospace industry for the finishing of components used in engines and airframes. The use of these abrasives increases the performance and reliability of aerospace parts, which is vital for safety and efficiency. Buyers should seek suppliers with specialized knowledge in aerospace-grade materials, as this ensures compliance with stringent industry standards and regulations.

In metalworking, lijas de carburo de silicio are employed for grinding and polishing metal parts, achieving high precision and minimizing waste during production. This application is essential for industries that require finely finished components, such as machinery and tooling. B2B buyers should verify the grit size and type of abrasives to ensure they are tailored for their specific metalworking needs, enhancing overall production efficiency.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem: One of the most pressing challenges faced by B2B buyers in industries such as manufacturing, automotive, and construction is sourcing high-quality 'lijas de carburo de silicio' (silicon carbide abrasives) that meet specific application needs. Many suppliers offer products with varying grit sizes and bonding agents, leading to confusion over which option is suitable for tasks like grinding, polishing, or sanding. This inconsistency can result in subpar performance, increased costs due to wastage, and project delays.

The Solution: To effectively source the right 'lijas de carburo de silicio', buyers should first conduct a thorough needs analysis. Determine the specific applications where the abrasives will be used, including the materials they will be applied to and the desired finish. Once the requirements are clear, engage with suppliers who specialize in silicon carbide abrasives and can provide product specifications, certifications, and performance data. It’s also beneficial to request samples for testing before committing to large orders. Consider forming partnerships with reputable manufacturers who can offer consistency in quality and performance across different product lines. Regularly reviewing supplier performance and maintaining open communication can help ensure ongoing satisfaction with product quality.

The Problem: Many B2B buyers are often caught in a dilemma between cost and quality when purchasing 'lijas de carburo de silicio'. Opting for lower-priced products can lead to issues such as faster wear rates, poor finish quality, and ultimately, higher long-term costs due to rework and replacement. Conversely, premium products may stretch budgets, especially for large-scale operations where multiple purchases are necessary.

The Solution: To navigate this challenge, buyers should adopt a value-based purchasing approach rather than simply looking for the lowest price. Evaluate the total cost of ownership by considering factors such as durability, performance, and the specific application requirements. Conduct a cost-benefit analysis that includes potential savings from reduced rework and longer product life. Collaborate with suppliers to negotiate bulk purchasing agreements or explore alternative products that offer a better cost-performance ratio. Additionally, consider investing in training for staff on the optimal use of 'lijas de carburo de silicio' to maximize their lifespan and effectiveness, which can significantly reduce overall costs.

The Problem: Safety is a critical concern for B2B buyers in industries that utilize 'lijas de carburo de silicio', especially when it comes to compliance with local regulations and standards. Improper handling and usage can lead to accidents, health risks from dust inhalation, and non-compliance with workplace safety laws. This can not only harm employees but also result in significant financial penalties for businesses.

The Solution: To mitigate these risks, companies must prioritize safety by implementing a comprehensive training program for all employees handling abrasives. This training should cover proper usage techniques, personal protective equipment (PPE) requirements, and the safe disposal of used materials. Additionally, buyers should ensure that the products they source come with safety data sheets (SDS) that outline hazards and safe handling procedures. Work with suppliers who prioritize safety and can provide documentation regarding compliance with international standards, such as ISO certifications. Regular safety audits and feedback sessions can help reinforce a culture of safety and ensure that all practices align with current regulations, thus protecting both employees and the company’s bottom line.

When selecting materials for lijas de carburo de silicio, it is crucial for B2B buyers to consider various factors that influence product performance, application suitability, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of these abrasive products.

Silicon carbide (SiC) is the primary material used in the production of lijas de carburo de silicio. It boasts exceptional hardness and thermal conductivity, making it suitable for high-performance applications. SiC can withstand high temperatures (up to 1600°C) and exhibits excellent resistance to corrosion and wear, which enhances its durability in various environments.

Pros & Cons: The main advantage of SiC is its longevity and effectiveness in grinding and polishing applications. However, its manufacturing process can be complex and costly, which may impact the overall pricing of the final product.

Impact on Application: SiC is compatible with a wide range of media, including metals, ceramics, and composites, making it a versatile choice for different industrial applications.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that their suppliers comply with relevant standards (e.g., ASTM, DIN) to guarantee product quality and performance.

Aluminum oxide is another common material used in abrasive products. It is less expensive than SiC and provides good performance for general-purpose applications. Aluminum oxide has a lower hardness compared to SiC but still offers decent durability and thermal stability.

Pros & Cons: The cost-effectiveness of aluminum oxide makes it attractive for budget-conscious buyers. However, its lower hardness means it may wear out faster than SiC, especially in demanding applications.

Impact on Application: This material is well-suited for softer materials and is often used in woodworking and metal finishing.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of the varying quality standards for aluminum oxide abrasives and should seek products that meet local compliance requirements.

Zirconia is utilized in high-performance applications where durability and resistance to wear are paramount. It can handle high pressures and temperatures, making it suitable for heavy-duty grinding tasks.

Pros & Cons: The key advantage of zirconia is its exceptional toughness, which allows it to maintain its cutting ability over time. However, it is one of the more expensive materials, which may limit its use in cost-sensitive applications.

Impact on Application: Zirconia is particularly effective for grinding metals and other hard materials, making it a preferred choice for industrial applications.

Considerations for International Buyers: Buyers from Europe and the UAE should consider the availability of zirconia products and their compliance with regional standards, as this material is often subject to stricter regulations.

Ceramic materials are increasingly being used in the production of lijas de carburo de silicio due to their hardness and thermal resistance. They can withstand high temperatures and are resistant to chemical corrosion.

Pros & Cons: The primary advantage of ceramic materials is their ability to maintain performance under extreme conditions. However, they can be brittle, which may lead to chipping during use.

Impact on Application: Ceramics are ideal for precision grinding applications where a fine finish is required, making them suitable for industries such as aerospace and automotive.

Considerations for International Buyers: B2B buyers in South America and Africa should evaluate the supply chain for ceramic abrasives, as sourcing can be more complex due to the specialized manufacturing processes involved.

| Material | Typical Use Case for lijas de carburo de silicio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | General industrial grinding and polishing | High durability and effectiveness | High manufacturing complexity | High |

| Aluminum Oxide | Woodworking and metal finishing | Cost-effective | Lower hardness and durability | Medium |

| Zirconia | Heavy-duty grinding applications | Exceptional toughness | Higher cost | High |

| Ceramic | Precision grinding in aerospace and automotive | Maintains performance under heat | Brittle, prone to chipping | Medium |

This comprehensive guide provides actionable insights for international B2B buyers, ensuring they make informed decisions when selecting materials for lijas de carburo de silicio.

The manufacturing process of lijas de carburo de silicio (silicon carbide abrasives) involves several critical stages, each ensuring that the final product meets the required specifications for performance and quality. Understanding these stages is crucial for B2B buyers looking to source high-quality abrasives.

The first step in manufacturing lijas de carburo de silicio is the preparation of raw materials. Silicon carbide is synthesized from silica sand and petroleum coke in an electric arc furnace. This process typically requires precise control over temperature and the ratio of raw materials to ensure that the resulting silicon carbide crystals are of high purity and consistency.

Once the silicon carbide is produced, it is crushed and screened to obtain the desired particle size. This step is essential as the particle size affects the abrasive properties of the lijas. The material is then mixed with a binding agent, often resin, which plays a vital role in enhancing the durability and performance of the final product.

After forming, the mixture is pressed into sheets or discs, depending on the type of abrasive product being manufactured. This pressing process must be performed under controlled conditions to ensure uniform density and strength. It is crucial for B2B buyers to understand that variations in this stage can lead to inconsistencies in performance.

The final stage involves curing the pressed product, which enhances its durability and performance. This curing process often involves heating the product in an oven to harden the resin binder. After curing, the lijas de carburo de silicio undergoes surface treatment, which may include sanding or coating to achieve the desired finish. Quality control checks are essential at this stage to ensure that the product meets all specified requirements.

Quality assurance is a critical aspect of manufacturing lijas de carburo de silicio. Adhering to international and industry-specific standards ensures that the products are safe, reliable, and effective for their intended applications.

ISO 9001 is a widely recognized standard for quality management systems (QMS). Manufacturers of lijas de carburo de silicio should be certified to this standard, demonstrating their commitment to quality and continuous improvement. B2B buyers should verify the supplier's ISO certification as part of their due diligence.

In addition to ISO 9001, lijas de carburo de silicio manufacturers may also comply with industry-specific certifications such as CE marking for products sold in Europe or API standards for oil and gas applications. These certifications indicate that the products meet specific safety and performance criteria.

Effective quality control (QC) is vital for ensuring the integrity and performance of lijas de carburo de silicio. Different checkpoints are established throughout the manufacturing process to monitor quality.

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This step ensures that only high-quality materials are used in production, reducing the risk of defects in the final product.

During the manufacturing process, IPQC is employed to monitor critical parameters such as temperature, pressure, and density. This real-time monitoring allows manufacturers to identify and address issues before they affect the final product.

FQC involves comprehensive testing of the finished products. This may include checking for dimensional accuracy, surface finish, and performance characteristics such as abrasiveness and durability. Testing methods can vary but often include standardized tests to ensure compliance with relevant standards.

Various testing methods are employed to evaluate the performance and quality of lijas de carburo de silicio. B2B buyers should be familiar with these methods to assess the reliability of their suppliers.

Performance testing evaluates the abrasive properties of the product, including its cutting efficiency and lifespan. This testing often involves comparison against industry benchmarks to ensure competitiveness.

Durability tests assess how well the lijas de carburo de silicio withstands wear and tear under operational conditions. This includes exposure to high temperatures, humidity, and mechanical stress.

Chemical analysis is conducted to verify the purity and composition of the silicon carbide. This analysis is crucial for ensuring that the product meets specific industry requirements and performs as expected.

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. This can be achieved through several methods:

A stock image related to lijas de carburo de silicio.

Conducting on-site audits of potential suppliers allows buyers to assess the manufacturing processes, quality control measures, and compliance with international standards. This firsthand evaluation can provide valuable insights into the supplier's capabilities.

Requesting detailed quality control reports from suppliers can help buyers understand the testing methods and results associated with their products. These reports should include data on IQC, IPQC, and FQC processes.

Engaging third-party inspection services can provide an unbiased evaluation of the supplier's quality control practices. These inspections can confirm compliance with industry standards and the effectiveness of the supplier's QC measures.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding quality control and certification:

Cultural and Regulatory Differences: Understanding local regulations and cultural expectations can impact procurement decisions. Buyers should ensure that suppliers are aware of and compliant with local laws regarding product safety and quality.

Logistical Challenges: The logistics of transporting lijas de carburo de silicio across international borders can introduce risks. Buyers should consider suppliers' ability to provide consistent quality across different shipping methods and conditions.

Language Barriers: Communication can be a challenge when verifying quality control processes. Buyers should ensure that they have clear channels of communication with suppliers to address any quality-related concerns promptly.

By considering these aspects, international B2B buyers can make informed decisions when sourcing lijas de carburo de silicio, ensuring that they obtain high-quality products that meet their specific needs.

Sourcing lijas de carburo de silicio (silicon carbide sandpaper) requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This guide provides a comprehensive checklist designed for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and make informed decisions.

Establishing clear technical specifications is essential before reaching out to suppliers. Consider factors such as grit size, backing material, and the intended application (e.g., metalworking, woodworking). This clarity will help you communicate effectively with suppliers and ensure the products meet your specific needs.

Conduct thorough research to identify potential suppliers of lijas de carburo de silicio. Utilize online directories, trade shows, and industry publications to compile a list of manufacturers and distributors. Pay attention to suppliers who specialize in your industry, as they are more likely to understand your requirements.

It’s crucial to verify that your chosen suppliers adhere to relevant industry standards and certifications. Look for ISO certifications, adherence to safety regulations, and compliance with environmental standards. This step not only ensures product quality but also reduces risks associated with non-compliance.

Before placing a bulk order, request samples of the lijas de carburo de silicio from shortlisted suppliers. Testing samples allows you to evaluate the product's performance, durability, and compatibility with your equipment. This step is critical to ensuring that the products meet your operational requirements.

Once you have evaluated the samples, compare pricing and payment terms from different suppliers. Consider not just the unit price but also shipping costs, discounts for bulk purchases, and payment flexibility. This assessment will help you find the best overall value, not just the lowest price.

Investigate the reliability and reputation of potential suppliers through online reviews, case studies, and references. Engaging with other businesses in your region or industry can provide valuable insights into a supplier's reliability and customer service. A reputable supplier is more likely to fulfill orders on time and address any issues that arise.

Before finalizing any order, ensure that all contract terms and conditions are clearly defined. This includes delivery timelines, return policies, and warranty information. A well-drafted contract protects both parties and minimizes misunderstandings during the procurement process.

By following this practical checklist, B2B buyers can effectively source lijas de carburo de silicio while ensuring quality, compliance, and cost-effectiveness, ultimately leading to successful procurement outcomes.

When sourcing lijas de carburo de silicio (silicon carbide sandpaper), understanding the cost structure is crucial for international B2B buyers. The primary components of the cost structure include:

Materials: The base material, silicon carbide, is a significant cost factor. Prices fluctuate based on global demand and supply conditions. Buyers should consider sourcing from regions with stable production to avoid volatility.

Labor: Labor costs vary by region, impacting the overall price. For instance, labor-intensive manufacturing in countries with higher wage standards, like those in Europe, may result in higher prices compared to regions with lower labor costs, such as parts of Asia.

Manufacturing Overhead: This encompasses utilities, rent, and equipment depreciation. Companies with advanced manufacturing processes may have lower overheads due to efficiency, which can be advantageous for buyers seeking cost-effective solutions.

Tooling: This refers to the costs associated with the machinery and tools necessary for production. Custom tooling can lead to increased initial costs but may be necessary for specialized products.

Quality Control (QC): Ensuring product quality incurs costs related to testing and inspections. Certifications such as ISO can further influence pricing, as they require additional compliance measures.

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping methods, and tariffs can significantly affect the total cost.

Margin: Suppliers typically mark up prices to cover risks and ensure profitability. Understanding the average margins in the industry can help buyers negotiate better deals.

Several factors influence the pricing of lijas de carburo de silicio, making it essential for buyers to be aware of these nuances:

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers maximize savings while ensuring they meet their own demand needs.

Specifications and Customization: Customized products generally come at a premium. Buyers must evaluate whether the benefits of customization justify the additional costs.

Material Quality and Certifications: Higher-quality materials and recognized certifications can raise prices but are often necessary for specific applications. Buyers should weigh the importance of quality against budget constraints.

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record and service quality.

Incoterms: The terms of shipping (e.g., FOB, CIF) significantly influence costs. Buyers should negotiate Incoterms that optimize shipping costs and risks.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

Negotiate Wisely: Leverage your purchasing power, especially if you represent a large organization. Establishing long-term relationships with suppliers can lead to better pricing and terms.

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost over the product's lifecycle, including maintenance, replacement, and disposal costs. This perspective can lead to more informed purchasing decisions.

Understand Pricing Nuances: Be aware of the impact of exchange rates, local taxes, and tariffs on overall costs. Engaging a local expert can provide insights into market conditions and pricing trends.

Request Samples: Before finalizing large orders, request samples to assess quality. This practice can prevent costly mistakes and ensure that the product meets your specifications.

Stay Informed About Market Trends: Keeping abreast of global market conditions can help buyers anticipate price changes and adjust their purchasing strategies accordingly.

Prices for lijas de carburo de silicio can vary significantly based on multiple factors mentioned above. It is advisable for buyers to conduct thorough market research and consult with suppliers for the most accurate and current pricing information tailored to their specific needs.

In the competitive landscape of industrial abrasives, lijas de carburo de silicio (silicon carbide sandpaper) stands out for its durability and efficiency. However, several alternatives exist that may better suit specific applications or budgetary constraints. This section explores viable alternatives, enabling international B2B buyers from regions such as Africa, South America, the Middle East, and Europe to make informed decisions.

| Comparison Aspect | Lijas De Carburo De Silicio | Aluminum Oxide Sandpaper | Ceramic Sandpaper |

|---|---|---|---|

| Performance | High cutting efficiency; ideal for hard materials | Good for wood and soft metals; less effective on hard surfaces | Excellent for high-pressure applications; very durable |

| Cost | Moderate to high | Low to moderate | High |

| Ease of Implementation | Easy to use; available in various grits | Widely available; familiar to most users | Requires specific handling; may not be as commonly found |

| Maintenance | Low; minimal care needed | Low; replace as needed | Moderate; can wear out quickly under heavy use |

| Best Use Case | Metalworking, glass, ceramics | Woodworking, soft metals | Heavy-duty grinding and finishing tasks |

Pros: Aluminum oxide sandpaper is widely recognized for its versatility and cost-effectiveness. It works well on softer materials like wood and is readily available in various grits, making it a common choice for woodworking projects. Its long-lasting nature reduces the frequency of replacements, resulting in lower operational costs.

Cons: While effective for softer substrates, aluminum oxide may struggle with harder materials compared to lijas de carburo de silicio. This limitation can lead to increased time spent on tasks that require finer finishes on tough surfaces, potentially impacting productivity in industrial applications.

Pros: Ceramic sandpaper excels in high-pressure environments, making it ideal for heavy-duty applications such as metalworking and grinding. Its durability allows for prolonged use without frequent changes, thus enhancing efficiency in manufacturing settings. Additionally, it provides a superior finish on tough materials.

Cons: The primary drawback of ceramic sandpaper is its cost, which can be significantly higher than both lijas de carburo de silicio and aluminum oxide. Furthermore, it may not be as widely available, particularly in regions with limited access to specialized abrasives. Handling requires some care due to its rigidity, which could deter users accustomed to more flexible options.

When selecting the best abrasive solution, B2B buyers should consider several factors, including the specific materials they work with, their budget, and the nature of their projects. Lijas de carburo de silicio is an excellent choice for those dealing with hard materials and requiring a fine finish. In contrast, aluminum oxide may be more suitable for cost-sensitive projects focused on softer substrates. For heavy-duty applications, ceramic sandpaper could be the best investment despite its higher upfront cost.

Ultimately, understanding the nuances of each option allows businesses to align their choice with operational needs, ensuring efficiency and cost-effectiveness in their processes. By analyzing these alternatives, international buyers can optimize their supply chain and enhance their product offerings in competitive markets.

When sourcing lijas de carburo de silicio (silicon carbide abrasives), understanding their technical properties is crucial for making informed purchasing decisions. Here are the essential specifications to consider:

Material Grade

- The material grade of silicon carbide determines its hardness and suitability for different applications. Common grades include F8 to F120, which indicate the coarseness of the abrasive. Higher grades (F100 and above) are finer and used for polishing and finishing, while lower grades are used for heavy grinding. Selecting the right grade ensures optimal performance for specific tasks, reducing costs and improving efficiency.

Tolerance

- Tolerance refers to the allowable variation in the dimensions of the abrasive sheets. Tighter tolerances can lead to better fit and finish in applications, which is particularly important in industries like automotive and aerospace. Ensuring that suppliers can meet your required tolerances can significantly impact the quality of the final product.

Bond Type

- The bond type indicates how the abrasive grains are held together. Common bond types include resin, ceramic, and metal. Each bond type offers different durability and performance characteristics, influencing the lifespan of the abrasive. Understanding the bond type can help buyers choose products that align with their operational needs.

Grain Size

- Grain size affects the aggressiveness of the abrasive action. Smaller grain sizes provide a smoother finish, while larger grains are more aggressive and suitable for material removal. Selecting the appropriate grain size is essential for achieving desired surface finishes and operational efficiency.

Durability

- The durability of lijas de carburo de silicio is influenced by factors like bond strength and grain retention. Durable abrasives reduce the frequency of replacements, leading to lower overall costs and less downtime in production. Buyers should inquire about the expected lifespan of products to ensure they are making a cost-effective investment.

Understanding industry jargon is vital for effective communication and negotiation in the B2B market. Here are some common trade terms relevant to lijas de carburo de silicio:

OEM (Original Equipment Manufacturer)

- OEM refers to companies that produce parts or equipment that are used in another company's products. In the context of abrasives, purchasing from an OEM may ensure that the products meet specific standards required for integration into larger systems.

MOQ (Minimum Order Quantity)

- MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for buyers, especially when budgeting for initial stock levels. Negotiating lower MOQs can help smaller businesses manage inventory costs effectively.

RFQ (Request for Quotation)

- An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For international buyers, providing detailed specifications in an RFQ ensures that suppliers can provide accurate quotes, reducing the risk of unexpected costs.

Incoterms (International Commercial Terms)

- Incoterms define the responsibilities of buyers and sellers regarding shipping and delivery. Understanding these terms is critical to avoiding misunderstandings about who bears the costs and risks at various stages of the shipping process. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight).

Lead Time

- Lead time refers to the time it takes for an order to be processed and delivered. Knowing the lead time is crucial for planning and inventory management, especially in industries with tight production schedules.

By familiarizing yourself with these technical properties and trade terms, you can enhance your decision-making process when sourcing lijas de carburo de silicio, ensuring that you select products that meet your operational needs while also navigating the complexities of international trade effectively.

The global market for lijas de carburo de silicio (silicon carbide abrasives) is experiencing notable growth, driven by several key factors. The surge in demand from industries such as automotive, aerospace, and construction is largely attributed to the material's superior hardness and thermal conductivity. Emerging technologies, including electric vehicles (EVs) and advanced manufacturing processes, are further propelling the need for silicon carbide products. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, staying abreast of these trends is crucial for strategic sourcing.

In addition to traditional applications, there is a marked shift towards more sustainable practices. Companies are increasingly looking for suppliers who can demonstrate a commitment to innovation and environmental responsibility. The rise of e-commerce platforms is also influencing sourcing dynamics, allowing international buyers to access a broader range of suppliers and pricing options. As competition intensifies, leveraging data analytics to optimize procurement processes is becoming essential for maintaining a competitive edge.

Environmental impact and ethical sourcing are paramount considerations for modern B2B buyers. The production of lijas de carburo de silicio can involve significant energy consumption and waste generation. Therefore, buyers are encouraged to partner with manufacturers who prioritize sustainable practices, such as utilizing recycled materials or implementing energy-efficient production methods.

Certifications like ISO 14001 (Environmental Management) and adherence to global sustainability standards are becoming increasingly relevant. These certifications not only demonstrate a supplier's commitment to reducing environmental impact but also enhance the buyer's brand reputation. Moreover, ethical sourcing practices ensure that suppliers uphold labor rights and community welfare, which is particularly important for companies looking to establish a positive corporate social responsibility profile.

The lijas de carburo de silicio industry has evolved significantly over the past few decades. Initially developed in the late 19th century for use in the production of abrasives, the material has since gained traction in various high-performance applications, including semiconductor manufacturing and power electronics. As industries have increasingly sought more efficient and durable materials, the demand for silicon carbide has surged.

This evolution has been marked by technological advancements that have improved the manufacturing processes and applications of silicon carbide. Today, B2B buyers can leverage this historical context to make informed decisions, understanding that the material's origins are deeply intertwined with innovation and industrial progress. The ongoing research and development efforts in this sector promise to unveil even more applications, making it a vital area for strategic sourcing.

How do I select the right lijas de carburo de silicio for my application?

Choosing the right silicon carbide sandpaper involves understanding the specific requirements of your project. Consider the grit size that corresponds to your surface finishing needs; finer grits are ideal for polishing, while coarser grits are suitable for heavy material removal. Additionally, evaluate the backing material and whether it’s suitable for wet or dry applications. Consulting with suppliers about your intended use can also provide insights into the most appropriate products for your needs.

What are the key factors to consider when sourcing lijas de carburo de silicio internationally?

When sourcing silicon carbide sandpaper internationally, consider factors such as supplier reputation, product certifications, and compliance with local regulations. Investigate the supplier's production capabilities and quality assurance processes to ensure they meet your standards. Additionally, assess logistics, including shipping times and costs, to ensure timely delivery. Engaging with suppliers through platforms like trade shows or online marketplaces can also facilitate better communication and negotiation.

What is the minimum order quantity (MOQ) for lijas de carburo de silicio?

Minimum order quantities for silicon carbide sandpaper can vary significantly between suppliers. Typically, MOQs may range from a few hundred to several thousand units, depending on the supplier's production capacity and your negotiation skills. If you're starting small or testing a new product line, discuss your needs with potential suppliers; some may offer flexibility on MOQs, especially for first-time buyers or strategic partnerships.

What payment terms should I expect when purchasing lijas de carburo de silicio?

Payment terms for silicon carbide sandpaper vary by supplier and the nature of the transaction. Common arrangements include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may also offer credit terms based on your business's creditworthiness. It's essential to clarify payment methods (e.g., wire transfer, letter of credit) and negotiate terms that work for both parties before finalizing the order.

How can I verify the quality of lijas de carburo de silicio before purchasing?

To ensure quality, request samples of the silicon carbide sandpaper prior to placing a large order. Evaluate the samples based on grit consistency, durability, and performance against your specific application. Additionally, ask for product certifications and compliance documents to verify that the materials meet industry standards. Establishing a quality assurance process with your supplier can also help maintain product standards over time.

What logistics considerations should I keep in mind when importing lijas de carburo de silicio?

Logistics for importing silicon carbide sandpaper include understanding shipping options, customs regulations, and potential tariffs. Choose reliable freight forwarders who are familiar with your destination country's import requirements. It’s crucial to factor in lead times for production and shipping to avoid delays. Also, ensure that you have the necessary documentation for customs clearance to prevent any disruptions.

Can lijas de carburo de silicio be customized for specific applications?

Yes, many suppliers offer customization options for silicon carbide sandpaper. This can include adjustments to grit size, backing materials, and even the formulation of the abrasive for specialized applications. When discussing customization, provide detailed specifications about your intended use, and ask about lead times and costs associated with custom orders. This can significantly enhance the product's effectiveness for your specific needs.

What are the common applications of lijas de carburo de silicio in various industries?

Silicon carbide sandpaper is widely used across industries for applications such as metalworking, woodworking, and automotive refinishing. Its hardness makes it suitable for grinding, polishing, and finishing hard materials like metals, glass, and ceramics. In the automotive industry, for example, it is used for bodywork preparation and paint finishing. Understanding your industry’s specific requirements can help you select the right type of lijas de carburo de silicio for optimal results.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, strategic sourcing of lijas de carburo de silicio offers significant advantages for international B2B buyers. Prioritizing quality, supplier reliability, and cost-effectiveness ensures that businesses can meet their operational needs while maximizing profitability. Establishing strong relationships with suppliers from diverse regions—including Africa, South America, the Middle East, and Europe—can enhance supply chain resilience and adaptability.

Buyers are encouraged to leverage technology and data analytics to identify trends and optimize purchasing decisions. Engaging in transparent negotiations and fostering long-term partnerships can yield better pricing and service terms. Additionally, understanding regional market dynamics is crucial for making informed sourcing choices that align with local demands and regulations.

Looking ahead, the demand for high-quality lijas de carburo de silicio is expected to grow as industries seek innovative solutions for their manufacturing processes. International buyers should stay proactive in exploring new suppliers and markets, ensuring they remain competitive in an evolving landscape. By adopting a forward-thinking approach to strategic sourcing, businesses can position themselves for success in the global marketplace.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina