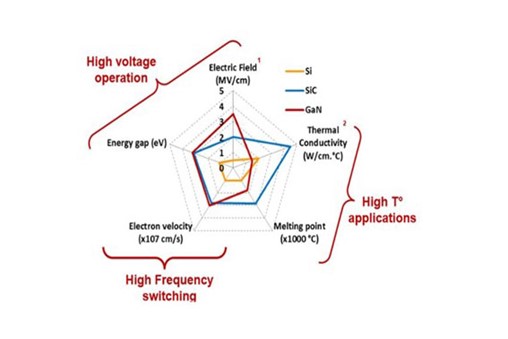

Understanding the critical role of melting point silicon carbide (SiC) in advanced industrial applications is essential for any international B2B buyer seeking to optimize their supply chain and product performance. As a high-performance ceramic material known for its exceptional thermal stability, hardness, and chemical resistance, melting point SiC is a cornerstone component across sectors such as electronics, aerospace, automotive, and energy. For buyers in diverse regions like Africa, South America, the Middle East, and Europe, navigating the complexities of sourcing this material requires a nuanced grasp of its variations, quality standards, and market dynamics.

This comprehensive guide is designed to empower procurement professionals and technical decision-makers with actionable insights into the global melting point SiC landscape. It covers an extensive range of topics including the different types and grades of SiC, key raw materials, manufacturing processes, and stringent quality control measures that ensure product reliability. Additionally, it offers a detailed overview of trusted suppliers worldwide, cost factors influencing pricing, and emerging market trends that impact availability and innovation.

By integrating these elements, the guide equips buyers from Argentina to Turkey—and beyond—with the knowledge needed to make informed sourcing decisions, mitigate risks, and establish strategic partnerships. Whether you are seeking to enhance product quality, reduce lead times, or optimize procurement costs, this resource serves as your authoritative roadmap for effectively engaging with the melting point SiC market on a global scale.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Melting Point SiC | High purity, consistent melting behavior | Electronics, high-temperature ceramics, abrasives | + Reliable quality; - Higher cost due to purity requirements |

| Sintered SiC | Formed by sintering powders, improved mechanical strength | Mechanical seals, automotive parts, wear-resistant coatings | + Enhanced durability; - Slightly lower thermal conductivity |

| Reaction-Bonded SiC | Created by infiltrating carbon with silicon | Industrial furnace components, chemical processing | + Cost-effective; - Porosity may affect strength |

| Nano-Structured SiC | Ultra-fine grain size for superior hardness and thermal properties | Advanced electronics, aerospace, defense | + Superior performance; - Higher production complexity |

| Doped SiC | SiC modified with additives to alter electrical/thermal properties | Power electronics, sensors, semiconductors | + Tailored properties; - Requires precise quality control |

Standard Melting Point SiC

This type features high purity silicon carbide with a well-defined melting point, making it ideal for applications requiring thermal stability and consistent performance. It is widely used in electronics and high-temperature ceramics. Buyers should prioritize suppliers who guarantee purity and uniformity, especially in regions like Europe and the Middle East where quality standards are stringent. While offering reliability, the cost can be higher, so buyers should balance budget and performance needs.

Sintered SiC

Produced by compacting and sintering SiC powders, this variation offers enhanced mechanical strength and resistance to wear. It suits demanding environments such as automotive parts and mechanical seals. B2B buyers from industrial sectors in South America and Africa will find sintered SiC beneficial due to its durability. However, slight compromises in thermal conductivity mean it’s less ideal for applications where heat transfer is critical.

Reaction-Bonded SiC

Reaction bonding involves infiltrating carbon preforms with molten silicon, resulting in components that are cost-effective and easier to manufacture. This type is preferred for industrial furnace linings and chemical processing equipment. Buyers in emerging markets should consider this option for its affordability, though the inherent porosity requires careful evaluation of mechanical strength for high-stress applications.

Nano-Structured SiC

Featuring ultra-fine grain sizes, nano-structured SiC exhibits superior hardness and enhanced thermal properties, making it suitable for cutting-edge aerospace and defense applications. This advanced material appeals to buyers in technologically advanced regions such as Europe and the Middle East. The complexity and cost of production are higher, so procurement decisions should factor in performance gains versus budget constraints.

Doped SiC

Doped silicon carbide incorporates additives to modify electrical or thermal characteristics, enabling use in power electronics, sensors, and semiconductor devices. This customization is critical for buyers focusing on innovation-driven markets, including Turkey and Argentina. Quality control is paramount since doping impacts material consistency. Buyers should collaborate closely with suppliers to ensure specifications meet exact application requirements.

Related Video: Explaining Melting Points (Simple/Giant Covalent, Ionic, Metallic) - GCSE Chemistry Revision

| Industry/Sector | Specific Application of melting point sic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics & Semiconductors | High-temperature substrates and heat sinks | Enhances device performance and longevity through thermal stability | Purity grade, particle size distribution, consistent melting point, reliable supplier certifications |

| Aerospace & Defense | Thermal barrier coatings and high-temp components | Improves durability and safety under extreme conditions | Compliance with aerospace standards, traceability, batch consistency, logistics reliability |

| Automotive | Engine components and brake systems | Increases wear resistance and thermal endurance | Material uniformity, quality assurance, supplier capacity to meet volume demands |

| Industrial Manufacturing | Abrasives and cutting tools | Extends tool life and improves precision in machining | Particle hardness, melting point consistency, supplier technical support |

| Energy & Power Generation | Insulation materials for high-temp environments | Reduces energy loss and enhances operational safety | Thermal properties verification, long-term stability, supplier experience in energy sector |

Electronics & Semiconductors

In electronics manufacturing, melting point SiC (silicon carbide) is crucial for producing substrates and heat sinks that operate reliably at high temperatures. Its superior thermal conductivity and stability prevent overheating in semiconductors, directly improving device performance and lifespan. International buyers, especially from regions like South America and Europe, should prioritize sourcing SiC with consistent melting points and high purity to meet stringent electronic component standards. Reliable certifications and supplier audits are essential to ensure quality and compliance.

Aerospace & Defense

SiC’s high melting point makes it ideal for thermal barrier coatings and components exposed to extreme heat in aerospace applications. It enhances durability and safety for engines and structural parts subjected to harsh environments. Buyers from the Middle East and Europe must ensure suppliers comply with aerospace industry standards such as AS9100, and provide full traceability and batch consistency to mitigate risks associated with component failure.

Automotive

In automotive manufacturing, melting point SiC is utilized in engine parts and brake systems where thermal resistance and wear resistance are critical. This improves vehicle safety and component longevity. For B2B buyers in Africa and Turkey, sourcing considerations include material uniformity and robust quality assurance processes, as well as supplier capacity to meet increasing demand driven by automotive sector growth in these regions.

Industrial Manufacturing

SiC is widely used in abrasives and cutting tools due to its hardness and ability to maintain structural integrity at elevated temperatures. This results in longer tool life and higher machining precision. Buyers should focus on particle hardness and melting point consistency, while also valuing suppliers who offer technical support to optimize application performance, particularly in manufacturing hubs across Europe and South America.

Energy & Power Generation

In the energy sector, SiC serves as an insulating material capable of withstanding high temperatures, reducing energy loss and improving safety in power plants and industrial furnaces. International buyers from regions with expanding energy infrastructure, such as Africa and the Middle East, need to verify thermal property specifications and ensure long-term material stability. Partnering with experienced suppliers familiar with energy sector demands is crucial for successful procurement.

Related Video: Uses and Gratifications Theory

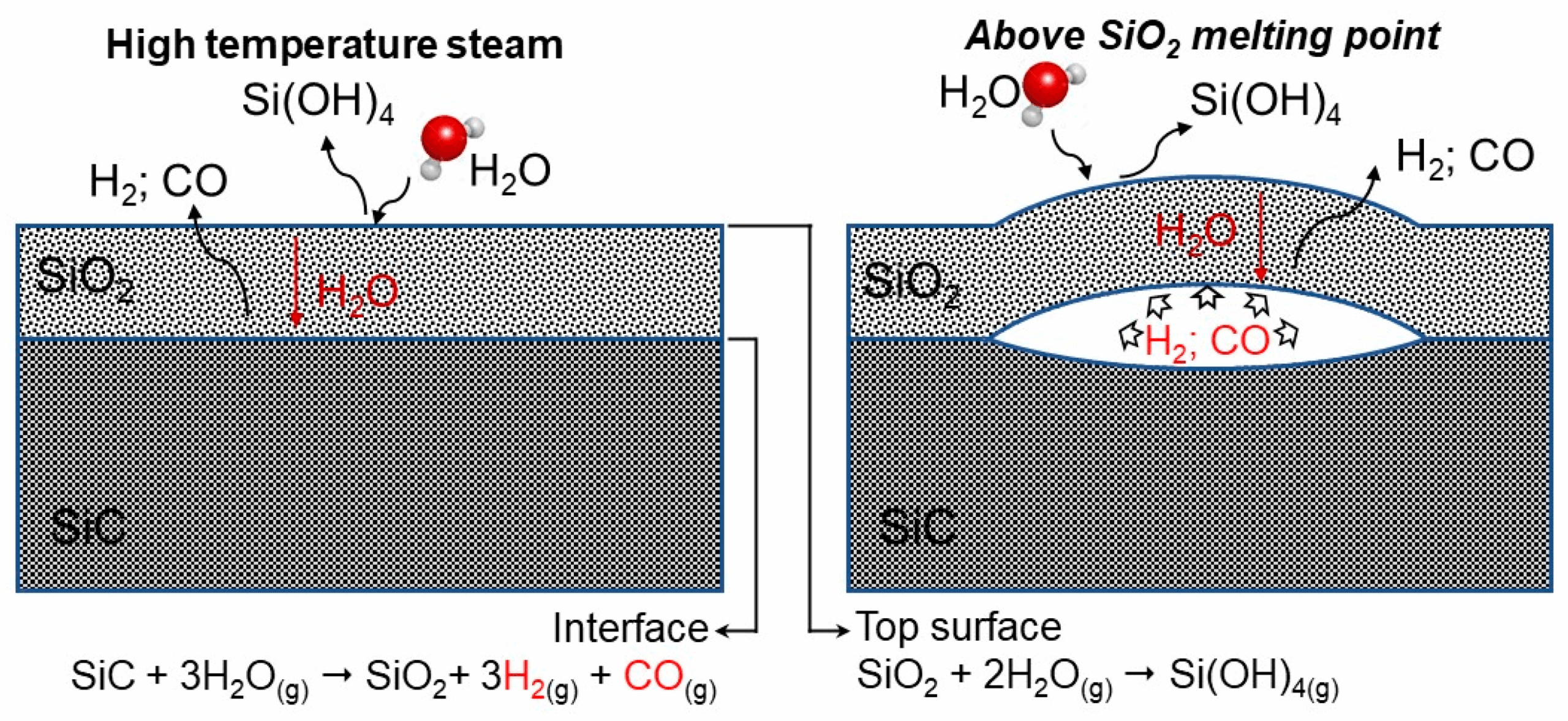

Key Properties: Silicon carbide ceramics exhibit an extremely high melting point (~2730°C), exceptional hardness, and excellent thermal conductivity. They offer outstanding corrosion resistance against acids, alkalis, and molten metals, alongside good wear resistance and mechanical strength at elevated temperatures.

Pros & Cons: SiC ceramics are highly durable and ideal for high-temperature and abrasive environments, but they are brittle and require precise manufacturing processes, which can increase costs. Their machining complexity demands advanced equipment, impacting lead times and pricing.

Impact on Application: SiC ceramics excel in applications involving aggressive chemical media, high thermal cycling, and abrasive slurries, such as in chemical reactors, heat exchangers, and semiconductor manufacturing. Their chemical inertness makes them suitable for handling corrosive fluids.

International Buyer Considerations: Buyers in Africa, South America, the Middle East, and Europe should verify compliance with ASTM C799 or DIN EN 60672 standards for ceramic materials. Regions like Turkey and Argentina often require conformity with both European and international standards. Import tariffs and local manufacturing capabilities may affect sourcing decisions, so partnering with suppliers who offer technical support and certification is critical.

Key Properties: These refractories maintain structural integrity up to 1600-1800°C and resist thermal shock and chemical attack. They have high compressive strength and moderate thermal conductivity, suitable for furnace linings and kiln furniture.

Pros & Cons: Sintered SiC refractories are denser and more durable but costlier, while reaction-bonded SiC offers lower cost and easier machining but reduced mechanical strength. Both types provide excellent corrosion resistance but require careful handling to avoid cracking.

Impact on Application: Ideal for metallurgical and glass industries where exposure to molten metals and slags occurs. Their thermal shock resistance makes them suitable for cyclic heating applications.

International Buyer Considerations: Compliance with ASTM C799 and ISO 9001 quality management systems is often required. Buyers from emerging markets should assess supplier capacity for consistent quality and availability, as well as logistics costs. Regional standards such as DIN EN 1094 in Europe may also apply.

Key Properties: SiC fibers have a melting point above 2700°C and provide excellent tensile strength, thermal stability, and chemical resistance. When used as reinforcement in composites, they enhance mechanical properties and thermal shock resistance.

Pros & Cons: These materials offer superior strength-to-weight ratios and durability in extreme environments but come with high production costs and complex fabrication processes. Their integration into composites requires specialized manufacturing expertise.

Impact on Application: Widely used in aerospace, defense, and high-performance industrial applications where lightweight and high-temperature resistance are critical. Also applicable in advanced heat exchangers and turbine components.

International Buyer Considerations: Buyers should ensure suppliers meet ASTM C1245 or equivalent standards for fiber properties. Due to high costs, strategic sourcing and volume negotiation are essential. Export controls and import regulations in regions like the Middle East may affect procurement timelines.

Key Properties: SiC powders have a melting point around 2730°C and are used as raw materials for sintering, coatings, and abrasives. They exhibit high purity, controlled particle size distribution, and excellent thermal and chemical stability.

Pros & Cons: Powders offer flexibility in manufacturing diverse SiC products but require precise handling and processing conditions. Lower upfront cost compared to finished ceramics but necessitate investment in downstream processing.

Impact on Application: Used in producing wear-resistant coatings, abrasive tools, and high-temperature composites. Their adaptability makes them essential in multiple industrial sectors.

International Buyer Considerations: Quality certification such as ISO 9001 and particle size standards (ASTM B214) are critical. Buyers in developing regions should consider supply chain reliability and potential customs delays. Bulk purchasing can reduce costs but requires robust storage and handling facilities.

| Material | Typical Use Case for melting point sic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide Ceramics | High-temperature chemical reactors, abrasive environments | Exceptional hardness and chemical resistance | Brittleness and complex machining | High |

| Silicon Carbide Refractories | Furnace linings, kiln furniture in metallurgical processes | Thermal shock resistance and corrosion resistance | Trade-off between density and cost | Medium |

| Silicon Carbide Fibers & Composites | Aerospace components, high-performance heat exchangers | Superior strength-to-weight ratio | High production cost and fabrication complexity | High |

| Silicon Carbide Powders | Raw material for sintering, coatings, abrasives | Flexibility in manufacturing diverse products | Requires precise processing and handling | Low |

The production of melting point silicon carbide (SiC) involves a series of precise and controlled manufacturing stages, each critical to achieving the material’s renowned thermal stability and mechanical strength. Understanding these stages helps B2B buyers evaluate suppliers' capabilities and ensure product consistency.

1. Raw Material Preparation

The initial phase starts with sourcing high-purity silicon and carbon powders. These raw materials are carefully measured and mixed to achieve the desired stoichiometric ratio. Purity levels directly impact the melting point and overall performance of SiC, so suppliers often conduct rigorous incoming quality control (IQC) to verify chemical composition and particle size distribution.

2. Forming and Shaping

Following material preparation, the mixture undergoes forming processes that shape the SiC into required forms such as powders, blocks, or custom components. Common techniques include:

These methods are selected based on end-use requirements, balancing cost, mechanical properties, and thermal resistance.

3. Assembly and Integration

For composite or multi-component products, the shaped SiC parts are assembled with other materials. This stage demands precision alignment and bonding, often using specialized adhesives or mechanical fastening. Proper assembly is crucial for maintaining the thermal expansion compatibility and mechanical stability of the final product.

4. Finishing Processes

Post-assembly, finishing operations such as grinding, polishing, and coating enhance surface quality and dimensional accuracy. These steps improve thermal conductivity and resistance to oxidation or corrosion, which are vital for high-temperature industrial applications.

Robust quality assurance (QA) frameworks ensure that melting point SiC products meet stringent international standards, providing reliability and performance assurances critical for B2B buyers globally.

Key International and Industry Standards

- ISO 9001: The foundational quality management system standard that ensures consistent processes and continuous improvement.

- CE Marking: Relevant for products sold within the European Economic Area, indicating compliance with EU safety and environmental requirements.

- API Standards: For SiC components used in oil and gas sectors, adherence to American Petroleum Institute specifications is often mandatory.

- ASTM and JIS Standards: Define test methods for material properties such as hardness, thermal conductivity, and purity, widely recognized in global trade.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verifies raw material quality before production starts, including chemical purity and particle size.

- In-Process Quality Control (IPQC): Monitors critical parameters during forming, sintering, and assembly stages. Checks include temperature control, density measurements, and defect detection.

- Final Quality Control (FQC): Conducted on finished products, focusing on dimensional accuracy, surface finish, and performance testing.

Common Testing Methods

- Differential Scanning Calorimetry (DSC): Measures melting point and thermal transitions to confirm thermal stability.

- X-Ray Diffraction (XRD): Identifies crystalline phases and purity levels.

- Scanning Electron Microscopy (SEM): Examines surface morphology and detects microstructural defects.

- Hardness Testing: Assesses mechanical robustness, typically via Vickers or Mohs scale.

- Chemical Analysis: Ensures elemental composition aligns with specifications.

For buyers in Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks and secure high-performance SiC materials.

1. Request Comprehensive QC Documentation

Ensure suppliers provide detailed QC reports, including raw material certificates, process control data, and final product test results. These documents should reference applicable standards and demonstrate traceability.

2. Conduct On-Site Audits

Arrange supplier audits focusing on their manufacturing processes and QA systems. Evaluate adherence to ISO 9001 and industry-specific standards, process controls, and staff qualifications. For buyers in regions like Turkey or Argentina, partnering with local inspection agencies can facilitate audits and overcome logistical barriers.

3. Utilize Third-Party Inspection and Testing

Engage independent laboratories for product verification, especially for critical applications. Third-party testing adds an unbiased layer of quality assurance and can be a contractual requirement in international procurement.

4. Understand Regulatory and Certification Nuances

Different regions may impose unique certification requirements. For example:

Buyers should clarify these requirements upfront and confirm supplier capabilities to comply.

By carefully analyzing manufacturing processes and establishing rigorous quality assurance protocols, international B2B buyers can confidently source melting point SiC products that meet their operational demands and regulatory obligations.

When sourcing melting point silicon carbide (SiC) for industrial applications, understanding the cost structure and pricing dynamics is crucial for making informed procurement decisions. This analysis breaks down the key cost components, price influencers, and practical buyer strategies to optimize investment and ensure supply chain efficiency, with a focus on international buyers from Africa, South America, the Middle East, and Europe.

Raw Materials: The primary cost driver is the quality and grade of silicon carbide powder, which depends on the purity level and particle size distribution. High-purity SiC with precise melting points commands premium pricing due to stricter production controls.

Labor: Skilled labor involved in the manufacturing process, especially in specialized sintering and quality control operations, adds to costs. Labor costs vary significantly by region, influencing final pricing.

Manufacturing Overhead: This includes energy consumption (high-temperature furnaces for melting point SiC), plant maintenance, and depreciation of specialized equipment. Overhead costs are typically embedded in unit prices but can vary with production scale.

Tooling and Equipment: Custom tooling for shaping or processing SiC components can incur upfront costs, particularly for bespoke orders or complex geometries.

Quality Control (QC): Rigorous testing to verify melting point accuracy, structural integrity, and certification compliance (e.g., ISO, ASTM) adds to the cost but is essential for critical industrial applications.

Logistics and Freight: International shipping, customs duties, and handling fees can significantly impact landed cost. Fragile or hazardous material classification may require special packaging and transport methods, increasing expenses.

Supplier Margin: Profit margins depend on supplier positioning, market demand, and competitive landscape. Established suppliers with robust certifications often price higher but offer reliability and after-sales support.

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically benefit from economies of scale, reducing per-unit costs. Conversely, small or sample orders might attract premium pricing.

Specifications and Customization: Tailored material properties, such as specific melting point ranges or composite formulations, increase complexity and cost. Off-the-shelf standard grades are more cost-effective.

Material Quality and Certifications: Certifications for quality assurance, environmental compliance, and safety standards (e.g., REACH, RoHS) add to the price but are often non-negotiable for regulated markets.

Supplier Reputation and Location: Suppliers based closer to the buyer or with strong regional presence (Europe for European buyers, Middle East hubs for Middle Eastern buyers) can reduce logistics costs and lead times.

Incoterms: The chosen Incoterm (e.g., FOB, CIF, DDP) shifts responsibility and cost burden between buyer and supplier, affecting total procurement cost and risk exposure.

Negotiation Levers: Emphasize order volume commitments, longer contract terms, and flexible payment terms to negotiate better pricing. Request breakdowns of cost components to identify negotiation opportunities.

Focus on Total Cost of Ownership (TCO): Evaluate not just the unit price but also logistics, customs duties, inventory holding costs, and potential rework expenses. For buyers in Argentina or Turkey, local import tariffs and currency fluctuations can significantly affect TCO.

Leverage Regional Suppliers: Where possible, source from regional suppliers to minimize freight costs and reduce lead times. For Africa and South America, identify suppliers with established distribution networks or local warehouses.

Understand Pricing Nuances: Be aware of seasonal demand fluctuations, raw material price volatility, and geopolitical factors that may influence supplier pricing. For example, energy-intensive manufacturing costs can spike due to regional energy price changes.

Quality vs. Cost Balance: Avoid compromising on quality certifications to save costs, as inferior melting point SiC can lead to process inefficiencies and higher downstream expenses.

Incoterms Clarity: Clearly define Incoterms in contracts to avoid unexpected charges. Buyers unfamiliar with international shipping should consider DDP terms for simplified logistics management, although this might increase initial costs.

Prices for melting point silicon carbide vary widely depending on grade, volume, and supplier. Indicative pricing typically ranges from $5 to $20 per kilogram, but buyers should request customized quotes reflecting their specific requirements and market conditions. Always verify pricing validity dates and factor in currency exchange risks when budgeting.

By thoroughly analyzing these cost and pricing factors, international B2B buyers can optimize procurement strategies for melting point SiC, ensuring cost efficiency without compromising material quality or supply reliability.

When sourcing silicon carbide (SiC) materials based on their melting point, understanding critical technical properties is essential to ensure product suitability and process efficiency. Here are the most important specifications buyers should consider:

Material Grade

SiC is available in various grades, such as α-SiC (alpha) and β-SiC (beta), with differences in crystal structure and purity. The grade affects melting behavior, thermal stability, and mechanical properties. Selecting the right grade ensures compatibility with your application, whether for refractory linings or semiconductor components.

Melting Point Range

The melting point of SiC typically lies around 2730°C to 2830°C. Precise knowledge of this range, including any deviations due to impurities or doping, is crucial for high-temperature processing. Buyers should request detailed melting point data to guarantee material performance under operational conditions.

Purity Level

High purity SiC (usually >99%) exhibits more consistent melting points and superior thermal conductivity. Lower purity may introduce impurities that lower the melting point and affect the material’s stability. Purity directly impacts product quality, especially in demanding industrial applications.

Particle Size and Distribution

The particle size influences melting characteristics and sintering behavior. Uniform particle size distribution allows for predictable melting and better control during manufacturing. This property is particularly important for powder-based processes and ceramic production.

Tolerance and Dimensional Stability

Tight tolerance specifications on dimensions and shape retention at high temperatures help ensure consistent melting point behavior and reliable integration into manufacturing lines. Buyers should verify tolerance limits to avoid costly mismatches or production delays.

Thermal Conductivity

While not directly a melting point, thermal conductivity affects how SiC materials absorb and dissipate heat during melting. Higher conductivity supports more efficient thermal management in furnaces and reactors, improving overall process control.

Understanding industry jargon facilitates smoother communication and negotiation between international buyers and suppliers. Here are key terms every buyer should know:

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or materials to be used in another company’s product. Many SiC suppliers cater to OEMs by providing materials tailored to specific equipment or processes. Buyers from industries like automotive or electronics often deal with OEM-grade SiC.

MOQ (Minimum Order Quantity)

The smallest amount of SiC material a supplier is willing to sell in one order. MOQs vary widely and can impact cost-efficiency for smaller buyers. Negotiating MOQ terms is critical, especially for startups or businesses with limited upfront capital.

RFQ (Request for Quotation)

A formal inquiry sent by a buyer to suppliers to obtain pricing, availability, and terms for SiC products. A well-prepared RFQ with clear specifications (grade, purity, particle size, etc.) accelerates supplier responses and ensures accurate quotes.

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs between buyer and seller. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect total landed cost and delivery risk.

Lead Time

The time interval between placing an order and receiving the product. Understanding lead times for SiC materials helps buyers plan production schedules and manage inventory efficiently, minimizing downtime.

Certificate of Analysis (CoA)

A document provided by the supplier detailing the chemical composition, melting point, purity, and other critical specifications of the SiC batch. Requesting a CoA ensures product traceability and quality assurance.

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, mastering these technical properties and trade terms empowers smarter purchasing decisions. Clear communication of specifications and terms with suppliers reduces risk, optimizes cost, and secures consistent supply of high-quality melting point SiC materials.

The global market for melting point silicon carbide (SiC) is characterized by robust growth driven by its expanding applications in high-performance electronics, automotive components, and industrial machinery. Key drivers include the increasing demand for energy-efficient power devices, electric vehicles (EVs), and renewable energy systems. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing and supply chain optimization.

Regional Demand Nuances:

- Africa and South America: Emerging manufacturing sectors and growing investments in renewable energy infrastructure are creating new demand for SiC materials, especially in power electronics and energy storage solutions. Buyers in countries like Argentina are increasingly seeking reliable SiC suppliers to support local industrialization and technology upgrades.

- Middle East: With its focus on diversifying economies and investing heavily in green technologies, the Middle East is a growing market for SiC, particularly for applications in solar power inverters and smart grid technologies.

- Europe: Europe leads in adopting SiC technology due to stringent energy efficiency regulations and a strong automotive industry pivoting towards EVs. Countries like Turkey, bridging Europe and Asia, serve as critical hubs for sourcing and distribution.

Sourcing Trends:

- Diversification of Supply Chains: Geopolitical uncertainties and trade disruptions have pushed B2B buyers to diversify their supplier base, incorporating manufacturers from Japan, China, and emerging producers in Southeast Asia.

- Technology Integration: Advanced analytics and AI-driven procurement tools are being deployed to forecast demand and optimize inventory management of SiC materials, reducing lead times and costs.

- Customization and Quality Assurance: Buyers increasingly demand tailored SiC products with precise melting points and purity levels, necessitating close collaboration with suppliers to meet specific industrial standards.

Sustainability is becoming a pivotal factor in the procurement of melting point SiC, driven by both regulatory pressure and corporate social responsibility initiatives. The production of silicon carbide involves energy-intensive processes and raw material extraction that can have significant environmental impacts, including greenhouse gas emissions and resource depletion.

Environmental Impact Mitigation:

- Leading suppliers are investing in cleaner production technologies, such as electric arc furnaces powered by renewable energy, to reduce carbon footprints.

- Waste management and recycling of SiC scrap are increasingly integrated into manufacturing cycles to enhance resource efficiency.

Ethical Supply Chain Importance:

- Buyers are prioritizing transparency and traceability in the SiC supply chain to avoid sourcing from regions with questionable labor practices or environmental negligence.

- Certifications such as ISO 14001 (Environmental Management) and Responsible Minerals Assurance Process (RMAP) are gaining traction among suppliers, providing buyers with assurance of ethical sourcing.

Green Certifications & Materials:

- The emergence of “green SiC” materials, produced with lower environmental impact, is a growing trend. Buyers should seek suppliers offering verifiable green certifications or those committed to sustainable practices to align with global ESG (Environmental, Social, and Governance) standards.

- Incorporating sustainability criteria into supplier evaluation not only mitigates risks but also enhances corporate reputation and compliance with international regulations.

Silicon carbide’s history dates back to the late 19th century, initially developed as an abrasive material due to its exceptional hardness and thermal stability. Over time, its unique properties—high melting point, thermal conductivity, and chemical inertness—have expanded its use into semiconductors and power electronics. The advent of electric vehicles and renewable energy technologies in the 21st century has further elevated SiC’s strategic importance.

For B2B buyers, understanding this evolution highlights the material’s transition from a niche industrial component to a critical enabler of modern energy-efficient technologies. This historical context underscores the need for sophisticated sourcing strategies that align with ongoing technological advancements and market shifts, particularly in regions investing heavily in industrial modernization and sustainable development.

Illustrative Image (Source: Google Search)

What customization options are typically available for melting point SiC, and how do these affect pricing and lead times?

Customization can include particle size distribution, purity grades, and packaging tailored to your production needs. Some suppliers offer bespoke formulations or coatings to optimize melting point or thermal stability. Custom orders often require longer lead times due to specialized processing and quality control steps. Pricing may increase with tighter specifications or smaller batch sizes. To manage costs and timelines, clearly define your requirements upfront and negotiate minimum order quantities (MOQs) that balance customization with economies of scale.

What are the standard minimum order quantities (MOQs) and lead times I should expect when sourcing melting point SiC internationally?

MOQs vary widely depending on supplier scale and product grade but typically range from 500 kg to several tons. Lead times generally span 3 to 8 weeks, influenced by factors like production schedules, customization needs, and shipping logistics. Buyers from Africa, South America, the Middle East, and Europe should factor in customs clearance and potential regional shipping delays. Early engagement with suppliers to understand their capacity and flexibility on MOQs can help optimize order planning and inventory management.

Which payment terms are common in international B2B transactions for melting point SiC, and how can I mitigate financial risks?

Common payment terms include letters of credit (LC), advance payments, or open account with net 30 to 60 days. For new suppliers or high-value orders, LCs provide security by ensuring payment only upon meeting shipment and quality conditions. Advance payments reduce supplier risk but increase buyer exposure. To mitigate risks, conduct thorough due diligence, use escrow services if possible, and clarify payment milestones aligned with production and delivery stages. Employ trade credit insurance to protect against non-payment, especially when dealing with emerging markets.

What quality assurance measures and certifications should I require from melting point SiC suppliers?

Insist on quality management certifications like ISO 9001 and, where applicable, ISO 14001 for environmental compliance. Suppliers should provide material safety data sheets (MSDS), batch-specific certificates of analysis (CoA), and traceability documentation. Third-party testing reports or compliance with ASTM or equivalent international standards for silicon carbide can add confidence. Regular audits and supplier scorecards help maintain standards. For critical applications, consider contractual clauses on quality disputes and replacement or compensation policies.

How can I optimize logistics and shipping for melting point SiC to reduce costs and avoid delays?

Work with freight forwarders experienced in handling chemical or abrasive materials and familiar with your target regions’ import regulations. Consolidate shipments to achieve better freight rates and reduce customs fees. Choose Incoterms that balance risk and cost effectively—FOB or CIF are common but clarify responsibilities for customs clearance and insurance. Ensure packaging meets international safety standards to prevent contamination or damage. Plan shipments well ahead of production schedules to accommodate potential port congestion or regulatory inspections.

What strategies should I adopt to handle disputes or quality issues with international melting point SiC suppliers?

Establish clear contractual terms detailing product specifications, inspection protocols, and dispute resolution mechanisms before ordering. Use third-party inspection services upon shipment to verify compliance. If issues arise, document all evidence and communicate promptly with the supplier to seek resolution. Mediation or arbitration clauses in contracts can facilitate amicable settlements without costly litigation. Maintain good supplier relationships but have contingency plans, including alternative suppliers, to minimize operational disruptions.

Are there specific regulatory or environmental considerations when importing melting point SiC into regions like Africa, South America, the Middle East, or Europe?

Yes, importers must comply with local chemical import regulations, which may include registration, labeling, and safety documentation. Environmental regulations can affect packaging, waste disposal, and permissible materials. The EU, for example, enforces REACH compliance for chemical substances, requiring detailed substance information. Some countries may impose import tariffs or restrictions based on trade agreements or safety concerns. Engage with customs brokers familiar with regional laws and stay updated on regulatory changes to ensure smooth clearance and compliance.

Illustrative Image (Source: Google Search)

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Key Takeaways for International B2B Buyers

Understanding the melting point of silicon carbide (SiC) is fundamental for industries requiring high-performance materials in extreme environments. For buyers across Africa, South America, the Middle East, and Europe, recognizing the thermal properties of SiC enables smarter procurement decisions, ensuring compatibility with end-use applications such as electronics, automotive, and aerospace manufacturing. Strategic sourcing of SiC with consistent melting point specifications guarantees product reliability and supports long-term supply chain stability.

The Value of Strategic Sourcing

Strategic sourcing goes beyond price negotiation—it involves partnering with suppliers who demonstrate technical expertise, quality assurance, and supply chain resilience. Prioritizing suppliers with transparent quality control and certifications can mitigate risks associated with material inconsistencies and delivery delays. This approach is especially critical for emerging markets and regions where logistical challenges may impact lead times. Leveraging regional supplier networks and understanding geopolitical factors can further enhance sourcing efficiency.

Looking Ahead

As demand for advanced materials grows globally, international buyers should proactively engage in supplier development and innovation collaborations. Embracing digital sourcing platforms and data-driven supplier evaluations will unlock new opportunities and optimize procurement cycles. Buyers from Argentina, Turkey, and other key markets are encouraged to deepen their technical knowledge and cultivate strategic partnerships to secure high-quality SiC supplies that meet evolving industry standards. Taking these steps will position your business at the forefront of material innovation and competitive advantage.

Illustrative Image (Source: Google Search)

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina