Guide to Que Significa Abrasivos

In today’s interconnected industrial landscape, understanding the true meaning of que significa abrasivos is essential for international B2B buyers aiming to optimize their sourcing strategies. Abrasives are fundamental components across manufacturing, construction, automotive, and metalworking sectors, making their quality, type, and supplier reliability critical to operational success. For buyers in Africa, South America, the Middle East, and Europe—such as Brazil or Australia—navigating this complex market can be challenging without comprehensive knowledge of product varieties, material compositions, and global supply dynamics.

This guide offers a strategic overview designed to empower you with actionable insights into the abrasive market. It covers key aspects including different types of abrasives, raw materials, manufacturing processes, quality control standards, and leading global suppliers. Additionally, it delves into cost considerations, market trends, and frequently asked questions to help you make informed procurement decisions.

By understanding these core elements, international buyers can mitigate risks, optimize costs, and establish reliable supply chains that meet rigorous industry standards. Whether you are sourcing for large-scale industrial projects or seeking high-performance abrasives for specialized applications, this guide aims to be your trusted resource in navigating the global marketplace. Ultimately, it enables smarter, more strategic purchasing decisions that align with your operational goals and regional market nuances.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Oxide | Hard, durable, and versatile with a relatively low cost | Metal grinding, woodworking, general abrasive tasks | Cost-effective and widely available; moderate lifespan, may produce more heat during use |

| Silicon Carbide | Extremely hard, sharper, and suitable for cutting and finishing | Ceramics, glass, non-metallic materials | Excellent for precision work; brittle and can wear quickly if not used properly |

| Zirconia Alumina | High toughness, resistant to wear, suitable for heavy-duty applications | Steel grinding, heavy metal removal | Long-lasting and effective for tough materials; higher cost but reduces downtime |

| Garnet | Natural abrasive with a coarse, angular grain structure | Woodworking, shipbuilding, surface preparation | Eco-friendly and affordable; less durable, requiring frequent replacement |

| Ceramic Alumina | Extremely high-performance, with self-sharpening properties | Aerospace, automotive, high-precision machining | Superior cutting performance; higher initial investment but lower overall operating costs |

Aluminum Oxide is one of the most common abrasives globally, valued for its versatility and affordability. Its moderate hardness makes it suitable for a wide range of applications, from metal grinding to woodworking. B2B buyers should consider its cost-effectiveness and availability, but also factor in its moderate lifespan, which can lead to increased consumption over time. When sourcing aluminum oxide, ensure consistent grain size and purity to maintain quality across batches.

Silicon Carbide stands out for its exceptional hardness and sharpness, making it ideal for precision cutting and finishing tasks involving non-metallic materials like ceramics and glass. Its brittle nature requires careful handling, especially for high-volume applications. Buyers should evaluate supplier consistency in grain size and sharpness, as well as the abrasive’s suitability for specific machinery. Its quick wear rate can be offset by its high cutting efficiency, but procurement strategies should include bulk purchasing for cost savings.

Zirconia Alumina is favored for heavy-duty, high-wear applications such as steel grinding and metal removal. Its toughness and resistance to fracture make it suitable for demanding industrial environments, reducing downtime and replacement frequency. While its higher cost might initially seem prohibitive, the long lifespan and efficiency gains often justify the investment. B2B buyers should prioritize suppliers offering consistent quality and consider bulk orders to optimize cost per unit.

Garnet is a natural abrasive with a coarse, angular grain structure, making it popular in eco-friendly and cost-sensitive projects like shipbuilding and surface preparation. Its natural origin appeals to environmentally conscious buyers, but its lower durability compared to synthetic abrasives necessitates frequent replacements. When purchasing garnet, verify the mineral purity and grain uniformity to ensure consistent performance across batches.

Ceramic Alumina represents the pinnacle of abrasive technology, offering self-sharpening properties and exceptional durability. It is especially suitable for high-precision, high-performance applications such as aerospace and automotive manufacturing. Despite its higher initial cost, ceramic alumina’s efficiency and longer lifespan can significantly reduce overall operational expenses. B2B buyers should assess supplier certifications and consistency in grain quality to maximize the return on investment.

By understanding these variations, international buyers can make more informed procurement decisions tailored to their specific industry needs, operational demands, and budget constraints.

| Industry/Sector | Specific Application of que significa abrasivos | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining & Mineral Processing | Material removal and surface preparation of ore and mineral deposits | Enhances extraction efficiency, reduces equipment wear, improves product quality | Abrasive hardness, grain size, durability, and compatibility with mineral types; supplier certifications and regional logistics |

| Aerospace & Automotive Manufacturing | Precision grinding and finishing of engine components, turbine blades, and structural parts | Achieves tight tolerances, superior surface finish, prolongs component lifespan | High-performance abrasives with consistent quality, specialized grain types (e.g., diamond, CBN), and supply reliability |

| Construction & Heavy Industry | Surface preparation, cutting, and polishing of concrete, stone, and metal structures | Faster processing, improved surface quality, reduced labor costs | Abrasive grit, bond type, and size tailored to specific materials; availability and cost-effectiveness for large-scale projects |

| Electronics & Precision Engineering | Fine grinding and polishing of delicate electronic components and circuit boards | Ensures high precision, minimal surface defects, and compliance with industry standards | Ultra-fine abrasives, contaminant-free materials, and strict quality controls for sensitive applications |

| Oil & Gas (Offshore & Onshore) | Cutting, cleaning, and surface treatment of pipelines, valves, and drilling equipment | Prevents corrosion, ensures integrity under high pressure, reduces downtime | Abrasive material resistance to harsh environments, certification for safety standards, and supply chain robustness |

Abrasivos are crucial in the mining industry for crushing, grinding, and mineral liberation. They are used in crushers, mills, and grinding circuits to efficiently break down rocks and ores. For international buyers from Africa, South America, and the Middle East, sourcing high-quality abrasives ensures reduced equipment wear and energy consumption, leading to cost savings. Buyers should prioritize suppliers offering abrasives with appropriate hardness and grain size, along with certifications that guarantee performance consistency in demanding mineral environments.

In these sectors, abrasivos enable precision finishing of engine parts, turbines, and structural components. The demand for high-performance abrasives such as diamond or cubic boron nitride (CBN) is critical to meet tight tolerances and surface quality standards. For European, Brazilian, or Australian manufacturers, reliable sourcing of abrasives that deliver consistent quality and specialized grain types is vital to maintain production efficiency and product integrity. Additionally, suppliers should offer traceability and adherence to industry standards like ISO or ASTM.

Abrasivos are extensively used for surface preparation, cutting, and polishing of concrete, stone, and metal surfaces. These applications require abrasives that can handle large volumes while maintaining consistent performance. International buyers involved in infrastructure projects across regions like South America or the Middle East should consider sourcing abrasives with high durability and grit versatility to ensure faster processing times and superior surface finishes. Cost-effective bulk sourcing and regional logistics are also key factors.

In the electronics sector, abrasivos are used for fine grinding and polishing of delicate components, circuit boards, and microelectromechanical systems (MEMS). The key challenge is avoiding surface defects while achieving ultra-smooth finishes. Buyers from Europe or South America should seek abrasives with contaminant-free properties, ultra-fine grit, and strict quality control measures. Sourcing from suppliers with proven certifications ensures compliance with industry standards and reduces the risk of defects affecting sensitive electronics.

Abrasivos play a vital role in cleaning, cutting, and surface treatment of pipelines, valves, and drilling equipment. These abrasives must withstand extreme conditions, including high pressure, corrosive environments, and abrasive wear. For international buyers from Africa or the Middle East, sourcing abrasives with proven resistance to harsh environments and relevant safety certifications is essential to prevent equipment failures and costly downtime. Reliable supply chains and regional logistics support are also critical to maintaining operational continuity.

When selecting materials for abrasives in the context of que significa abrasivos, understanding the properties and limitations of common abrasive materials is crucial for international B2B buyers. The choice impacts not only product performance but also compliance, cost-efficiency, and suitability for specific applications across diverse regions such as Africa, South America, the Middle East, and Europe.

Key Properties:

Aluminum oxide is a widely used abrasive due to its hardness (Mohs 9), high temperature resistance (up to 1,000°C), and good toughness. It exhibits excellent chemical stability, making it suitable for a variety of industrial applications. Its density and grain size can be tailored to specific needs, from coarse to fine finishes.

Pros & Cons:

Its durability and cost-effectiveness make it a popular choice globally. Aluminum oxide is relatively easy to manufacture, allowing for consistent quality. However, it can be brittle at very fine grain sizes, which may limit its use in applications requiring high flexibility.

Impact on Application:

It performs well in grinding, cutting, and polishing across metals, ceramics, and composites. Its chemical inertness ensures compatibility with most media, but it may not be suitable for softer materials where less aggressive abrasives are preferred.

International Buyer Considerations:

Aluminum oxide conforms to major standards such as ASTM and DIN, facilitating compliance across regions. Buyers in Africa and South America should verify supplier certifications for quality assurance, while European buyers often prefer EU-specific standards. Cost variation depends on grain size and purity, but generally, it offers a good balance of cost and performance.

Key Properties:

Silicon carbide is a very hard abrasive (Mohs 9-9.5) with excellent thermal conductivity and low thermal expansion. It withstands high temperatures (up to 2,500°C) and maintains its strength under extreme conditions. Its sharp, angular grains provide aggressive cutting action.

Pros & Cons:

Its high hardness and thermal stability make it ideal for precision grinding and cutting of hard materials like glass, ceramics, and hardened steels. However, silicon carbide is more brittle than aluminum oxide, leading to potential grain fracture and shorter lifespan in some applications. It is also generally more expensive.

Impact on Application:

Silicon carbide’s sharpness and low wear rate make it suitable for fine finishing and precision applications. Its chemical inertness allows it to be used in media that require resistance to corrosion or chemical attack.

International Buyer Considerations:

Buyers should ensure suppliers meet international standards such as JIS or ASTM. Due to its cost, buyers from regions with high import taxes or limited local manufacturing might prefer bulk purchasing or alternative materials. Compatibility with specific media and environmental conditions should be assessed to maximize lifespan.

Key Properties:

Garnet is a natural mineral with Mohs hardness around 6.5-7.5. It offers good toughness, high density, and excellent angular grain shape, which provides effective cutting action. It is resistant to moisture and chemical attack, making it suitable for wet and dry blasting.

Pros & Cons:

Garnet is environmentally friendly, non-toxic, and produces minimal dust, which is advantageous for health and safety regulations. Its availability varies geographically, affecting cost and supply stability. It is generally less durable than synthetic abrasives, leading to higher consumption rates.

Impact on Application:

Ideal for surface preparation, cleaning, and finishing in industries such as shipbuilding, construction, and automotive. Its natural origin makes it preferred in environmentally conscious markets, especially in Europe and Australia.

International Buyer Considerations:

Buyers should verify the origin and certification of garnet to ensure compliance with environmental standards like REACH in Europe. Regional availability influences price and supply chain reliability; African and South American buyers should consider local sourcing options or import logistics.

| Material | Typical Use Case for que significa abrasivos | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Grinding, polishing, cutting metals and ceramics | Cost-effective, durable, widely available | Brittle at fine grain sizes, may require frequent replacement | Med |

| Silicon Carbide | Precision grinding, cutting hard materials like glass and ceramics | Extremely hard, high thermal stability, sharp grains | More brittle, higher cost, shorter lifespan in some cases | High |

| Garnet | Surface preparation, blasting, cleaning | Eco-friendly, low dust, natural mineral | Less durable, higher consumption, supply variability | Low to Med |

This strategic understanding of abrasive materials enables B2B buyers to optimize their procurement based on application needs, regional standards, and cost considerations, ensuring efficient and compliant operations across global markets.

The production of abrasives involves a series of meticulously controlled stages to ensure product consistency, performance, and safety. For international B2B buyers, understanding these processes is crucial to evaluating supplier capabilities and product quality.

Material Preparation:

The manufacturing process begins with sourcing high-quality raw materials, such as aluminum oxide, silicon carbide, zirconia, or diamond grit. Raw materials must meet strict specifications to ensure abrasive durability and cutting efficiency. Suppliers often source these from certified producers, adhering to international standards like ISO 9001 for quality management.

Forming and Bonding:

Once raw materials are prepared, they are shaped into abrasive grains or products via methods such as crushing, milling, and classifying. For bonded abrasives (e.g., grinding wheels, cutting discs), abrasive grains are mixed with bonding agents—resins, vitrified materials, or metal binders—and then molded into specific shapes. These are then subjected to curing or sintering processes, depending on the abrasive type, to achieve the desired hardness and structural integrity.

Assembly and Finishing:

The formed abrasives undergo finishing processes, including trimming, grinding, and surface treatments, to meet dimensional and surface quality standards. For industrial applications, consistency in size and surface texture is vital for predictable performance. Manufacturers may also apply coatings or treatments to enhance wear resistance or reduce heat buildup during use.

Quality Control in Manufacturing:

Throughout these stages, strict process controls are maintained. Advanced techniques like laser sizing, optical inspection, and non-destructive testing are employed to ensure each batch meets specified standards. Automation and real-time monitoring help reduce variability and improve overall product reliability.

International B2B buyers must verify that suppliers adhere to rigorous quality assurance protocols. This involves understanding relevant standards, inspection points, testing methods, and supplier certifications.

International Standards & Industry Certifications:

- ISO 9001: The foundation for quality management systems, ensuring consistent process control and continuous improvement.

- CE Marking: Required for abrasives sold within the European Economic Area, confirming compliance with safety and environmental directives.

- API Standards: For abrasives used in oil and gas applications, adherence to API standards (e.g., API RP 7L) ensures suitability for demanding environments.

- Other Certifications: For specific markets, certifications such as ASTM, EN, or local regulatory approvals add layers of confidence.

QC Checkpoints and Testing Methods:

- Incoming Quality Control (IQC): Raw materials are inspected upon receipt using methods like particle size analysis, purity testing, and hardness verification.

- In-Process Quality Control (IPQC): During manufacturing, dimensional checks, surface inspections, and mechanical tests are performed to detect deviations early.

- Final Quality Control (FQC): Finished products undergo comprehensive testing, including grit size verification, friability testing, and performance simulations to ensure compliance before shipment.

Common Testing Techniques:

- Particle Size Analysis: Using sieving or laser diffraction to confirm grit specifications.

- Hardness Testing: Ensures abrasive grains meet specified hardness levels for cutting efficiency.

- Friability Testing: Measures the tendency of abrasives to break down during handling and use.

- Performance Testing: Simulating actual use conditions (e.g., cutting, grinding) to verify product behavior.

Verification for International B2B Buyers:

Buyers should request detailed certificates of analysis (CoA), test reports, and process documentation. Conducting audits—either directly or via third-party inspection agencies—is recommended, especially when establishing long-term partnerships. Many suppliers participate in quality management audits aligned with ISO 19011 guidelines.

Regulatory and Certification Nuances:

Buyers from Europe, especially those in Brazil and Australia, must ensure products comply with local safety standards (e.g., CE, AS/NZS standards). This often entails reviewing supplier certifications and testing documentation thoroughly.

Supplier Audits and Third-Party Inspection:

Due to varying manufacturing maturity levels across regions, engaging third-party inspection agencies (e.g., SGS, Bureau Veritas) is vital for verifying QC processes. These inspections include factory audits, sample testing, and review of quality management systems.

Documentation and Traceability:

International buyers should insist on detailed traceability records, including batch numbers, raw material certificates, and production logs. This transparency is critical for compliance, especially in sectors like aerospace, oil & gas, or heavy machinery.

Understanding Local Market Standards:

In regions like Africa and the Middle East, standards may be less prescriptive, but buyers should still enforce strict quality criteria. Establishing clear specifications and engaging with suppliers who have proven compliance records minimizes risks.

Building Long-term Relationships:

Consistent quality delivery hinges on a collaborative approach. Regular audits, performance reviews, and supplier development initiatives foster trust and ensure ongoing adherence to quality standards.

By understanding and rigorously evaluating manufacturing and quality assurance processes, B2B buyers from Africa, South America, the Middle East, and Europe can secure reliable, high-performance abrasives that meet their operational needs and compliance standards.

Understanding the detailed cost structure of abrasivos (abrasives) is crucial for international B2B buyers aiming to optimize procurement strategies. The primary cost components include:

Several factors influence the final pricing and should be carefully considered:

While prices vary widely based on specifications and market conditions, typical wholesale costs for standard abrasives range from $1 to $10 per kilogram. Premium or specialized abrasives may cost $10 to $30 per kilogram or more. Always consider that these figures are indicative; actual prices depend on order size, supplier negotiations, and logistical arrangements.

In conclusion, a comprehensive understanding of the cost structure and influencing factors enables international B2B buyers to negotiate effectively, optimize procurement, and achieve the best balance between price, quality, and delivery timelines.

Understanding the technical specifications of abrasives is essential for making informed purchasing decisions. Here are key properties that influence the performance, durability, and suitability of abrasive products in industrial applications:

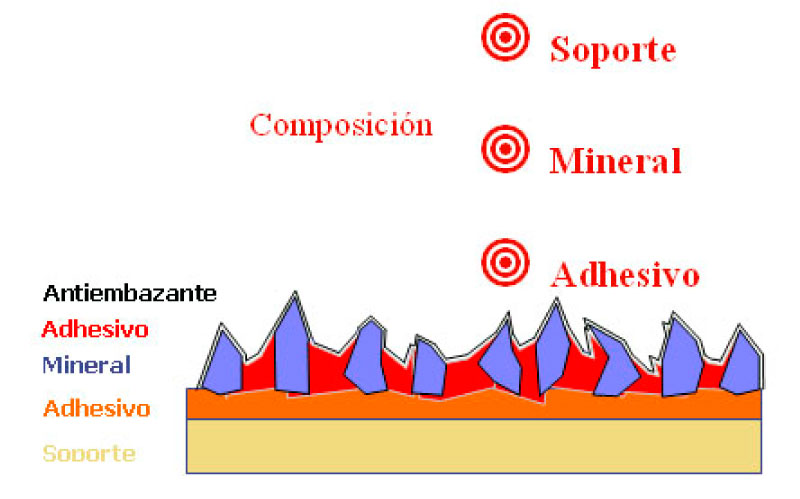

1. Material Grade and Composition

The raw material used—such as aluminum oxide, silicon carbide, or zirconia—determines the abrasive’s hardness, toughness, and application suitability. Higher-grade materials typically offer increased durability and cutting efficiency. For B2B buyers, selecting the appropriate material ensures process consistency and cost-effectiveness, especially in high-volume manufacturing.

2. Grain Size (Abrasive Grit)

Grain size, measured in micrometers or mesh size, affects the finish quality and removal rate. Coarser grits (e.g., 36-60) are ideal for rapid material removal, while finer grits (e.g., 150-320) provide a smoother finish. Understanding the required surface finish and production speed helps buyers choose the right grit for specific tasks.

3. Bonding Type

The bond holds abrasive grains together and influences the tool’s lifespan and performance. Common bond types include vitrified (ceramic), resin, and metal bonds. For example, vitrified bonds are suitable for precision grinding, while resin bonds are preferred for flexible applications. Selecting the correct bond type maximizes efficiency and reduces downtime.

4. Tolerance and Dimensional Accuracy

Dimensional tolerances specify the permissible variation in size and shape of abrasive products. Tight tolerances are critical in applications requiring high precision, such as aerospace or medical device manufacturing. B2B buyers should verify tolerance specifications to ensure compatibility with their equipment and quality standards.

5. Hardness and Toughness

The hardness of abrasive grains determines their cutting ability, while toughness influences resistance to fracture. Balancing these properties ensures the abrasive can withstand operational stresses without premature wear. Suppliers often specify these properties to help buyers assess durability for specific applications.

6. Density and Porosity

Density impacts the strength and heat dissipation of abrasive tools. Higher density generally correlates with longer tool life. Porosity, conversely, affects chip clearance and cooling. Buyers should consider these factors to optimize performance in high-speed or high-pressure environments.

Understanding common jargon accelerates communication and streamlines procurement processes. Here are key terms every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or products under their own brand or for other brands. In abrasives, OEM specifications often require strict adherence to proprietary standards, impacting choice of supplier and product customization.

2. MOQ (Minimum Order Quantity)

The smallest quantity of abrasive products a supplier is willing to sell. Recognizing MOQ helps buyers plan inventory levels and negotiate better terms, especially when entering new markets or testing new abrasive types.

3. RFQ (Request for Quotation)

A formal document sent to suppliers requesting price, lead time, and technical details for specific abrasive products. Efficient RFQs facilitate comparison shopping and ensure clarity in specifications, reducing procurement delays.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities of buyers and sellers regarding shipping, insurance, and customs. Familiarity with Incoterms (e.g., FOB, CIF) enables accurate cost estimation and risk management across international transactions.

5. Lead Time

The period between placing an order and receiving the products. Understanding lead times is vital for supply chain planning, especially for just-in-time production environments common in automotive, aerospace, and manufacturing sectors.

6. Certification and Standards

References to ISO, ASTM, or other industry standards ensure abrasives meet specific quality and safety benchmarks. Verifying these certifications provides confidence in product reliability and compliance with regulatory requirements.

By mastering these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make strategic decisions that optimize costs, ensure quality, and foster long-term supplier relationships. Proper understanding of these elements is fundamental to navigating the global abrasive market effectively.

The global abrasives market, integral to manufacturing, automotive, construction, and aerospace industries, is experiencing dynamic shifts driven by technological innovation, supply chain restructuring, and evolving demand patterns. Key drivers include rapid industrialization in emerging markets such as Africa, South America, and parts of the Middle East, which seek high-quality abrasives for infrastructure development and manufacturing expansion. Developed regions like Europe and Australia focus on advanced, precision abrasives suited for high-tech applications, emphasizing performance and environmental standards.

Emerging sourcing trends highlight the increasing adoption of synthetic and hybrid abrasives, such as cubic boron nitride (CBN) and synthetic diamond, which offer superior durability and efficiency. Additionally, digitalization in procurement processes—via e-sourcing platforms and supply chain analytics—enhances transparency and reduces lead times. For international B2B buyers, especially from regions like Brazil or Australia, understanding local market conditions—such as raw material availability and regional regulations—is critical for optimizing sourcing strategies.

Market dynamics are also influenced by geopolitical factors, tariffs, and trade agreements, which can affect cost structures and supply stability. Buyers should monitor these elements closely, leveraging regional suppliers and diversified sourcing to mitigate risks. Furthermore, technological advancements in automation and Industry 4.0 are transforming manufacturing processes, increasing demand for high-performance abrasives that meet strict quality standards.

In summary, the market is marked by innovation, regional growth disparities, and a shift toward sustainable and digitally integrated sourcing approaches. Navigating these trends requires strategic partnerships, local market insights, and agility to adapt to rapid technological and geopolitical changes.

Sustainability has become a pivotal factor in the abrasives sector, driven by environmental concerns, regulatory pressures, and consumer expectations. The extraction and processing of raw materials—such as garnet, silicon carbide, and industrial diamonds—can have significant ecological impacts, including habitat disruption and energy consumption. As a result, B2B buyers from Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers with robust environmental management practices.

Ethical sourcing is equally critical, involving transparent supply chains that prevent child labor, forced labor, and illegal mining activities. Certifications such as ISO 14001 (Environmental Management), ISO 45001 (Occupational Health and Safety), and Fair Trade labels serve as benchmarks for responsible sourcing. Many buyers now require suppliers to provide traceability documentation, verifying that raw materials are obtained sustainably and ethically.

Incorporating 'green' materials and technologies not only aligns with corporate social responsibility (CSR) goals but also offers competitive advantages—such as access to eco-conscious markets and compliance with stringent regulations. For example, using recycled abrasives or bio-based lubricants can significantly reduce environmental footprints. Additionally, suppliers investing in energy-efficient manufacturing processes and waste reduction demonstrate a commitment to sustainability, fostering long-term partnerships with conscientious buyers.

For international buyers, establishing clear sustainability criteria and conducting due diligence on supplier practices are essential steps. Collaborating with certified suppliers and participating in sustainability audits can help ensure responsible sourcing, ultimately contributing to a more resilient and ethically sound supply chain.

Illustrative Image (Source: Google Search)

The abrasives sector has evolved from traditional natural mineral extraction—such as garnet and emery—to highly engineered synthetic products designed for specific industrial needs. This shift, driven by technological advancements and environmental considerations, has expanded the range of available abrasives, improving efficiency and safety standards. Over time, the industry has increasingly embraced sustainability practices, integrating eco-friendly materials and responsible sourcing protocols to meet global environmental targets.

Illustrative Image (Source: Google Search)

This evolution reflects broader industrial trends emphasizing innovation, quality, and environmental stewardship. For B2B buyers, understanding this progression helps in assessing supplier reliability and in making informed procurement decisions aligned with both operational and sustainability goals.

To ensure supplier credibility, conduct comprehensive due diligence including requesting ISO, CE, or other relevant certifications. Review their export history and client references, especially from your region. Visiting suppliers or engaging third-party inspection services can provide insights into production standards. Additionally, request samples for testing in your application before committing to large orders. Establish clear communication channels and ask detailed questions about their manufacturing processes and quality control measures. Working with suppliers who have consistent quality audits reduces risks of defective products and ensures compliance with your industry standards.

Customization begins with clearly defining your application requirements—material type, grit size, bonding type, and desired finish. Share detailed specifications with potential suppliers and inquire about their ability to modify abrasives accordingly. Confirm their capacity for small batch or large volume customization, lead times, and costs. Consider testing prototypes before full production runs to validate performance. Establish agreements on quality assurance, and ensure the supplier can provide technical support or guidance for optimal customization. Effective communication and detailed specifications are critical to achieving a product that meets your precise operational needs.

MOQs for abrasives vary widely depending on supplier size and product complexity, often ranging from 500 to 5,000 units or equivalent weight. Lead times can range from 2 to 8 weeks, influenced by manufacturing location, customization requirements, and shipping logistics. For urgent needs, negotiate with suppliers who offer flexible MOQs or ready-stock options. Establish clear timelines upfront and consider suppliers with local warehouses or distribution centers in your region to reduce lead times. Building strong relationships and forecasting demand well in advance can help optimize inventory levels and minimize delays.

Common international payment options include wire transfers, letters of credit, and secure online escrow services. Letters of credit are often preferred for larger transactions, providing security for both parties. To mitigate risks, negotiate payment terms aligned with milestones—such as partial payments upon order confirmation and balance after inspection. Conduct thorough credit checks on new suppliers and consider using trade insurance or payment platforms with dispute resolution features. Always verify the supplier’s banking details and avoid upfront full payments without guarantees or references, especially when dealing with unfamiliar vendors.

Illustrative Image (Source: Google Search)

Ensure suppliers comply with internationally recognized standards such as ISO 9001 for quality management, and check for certifications relevant to your industry, like ANSI, CE, or ASTM. These certifications indicate adherence to strict manufacturing and safety protocols. Request test reports, batch certificates, and product datasheets for each shipment. For critical applications, consider suppliers with additional certifications like environmental management (ISO 14001) or specific industry standards (e.g., aerospace, automotive). Regular audits and third-party testing can further guarantee that the abrasives meet your quality and safety expectations.

Partner with experienced freight forwarders familiar with your region’s import regulations and customs procedures. Determine the most cost-effective shipping mode—sea, air, or land—based on urgency, volume, and product nature. Ensure all shipping documents, including invoices, packing lists, certificates of origin, and inspection certificates, are accurate and complete to avoid delays. Consider incoterms like FOB or CIF to clarify responsibilities and costs. To reduce risks, plan for customs clearance in advance and factor in potential delays. Establish strong communication with logistics providers to monitor shipments and address issues proactively.

Immediately document the issue with detailed photos, test results, and correspondence records. Review your contract and quality agreement to understand the resolution process. Engage the supplier directly to negotiate corrective actions such as replacements, refunds, or discounts. If the issue persists, escalate to higher management or involve third-party mediators or industry associations. Maintaining open communication and a professional approach often leads to quicker resolutions. To prevent future disputes, include clear quality clauses, inspection rights, and dispute resolution mechanisms in your contracts.

Regional considerations such as trade tariffs, import duties, and logistical infrastructure significantly impact cost and delivery timelines. For African, South American, Middle Eastern, and European buyers, selecting suppliers with local or nearby manufacturing facilities can reduce shipping costs and lead times. Be aware of regional standards and certifications to ensure compliance. Understanding local language, business customs, and payment preferences facilitates smoother negotiations. Additionally, assessing political stability and economic conditions in supplier regions helps mitigate risks of supply disruptions. Partnering with experienced local agents or distributors can also streamline your sourcing process in unfamiliar markets.

En un mercado globalizado, la adopción de un enfoque de sourcing estratégico para abrasivos es fundamental para optimizar costos, garantizar calidad y fortalecer la cadena de suministro. Los compradores internacionales, especialmente en regiones como África, Sudamérica, Oriente Medio y Europa, deben priorizar la diversificación de proveedores y evaluar cuidadosamente factores como la sostenibilidad, la innovación y la capacidad de respuesta.

La colaboración con fabricantes confiables y la implementación de análisis de riesgos permiten reducir vulnerabilidades y aprovechar oportunidades emergentes en mercados dinámicos. Además, mantenerse actualizado sobre tendencias tecnológicas y normativas internacionales facilitará decisiones más informadas y competitivas.

De cara al futuro, la clave será adoptar soluciones digitales y sostenibles que impulsen la eficiencia y el impacto ambiental positivo. Los compradores que inviertan en relaciones estratégicas y en una gestión proactiva del sourcing estarán mejor posicionados para afrontar desafíos y capitalizar oportunidades en un entorno global en constante cambio.

Este es el momento de fortalecer su estrategia de adquisición de abrasivos y consolidar alianzas que impulsen el crecimiento sostenible en sus mercados internacionales.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina