In the ever-evolving global market, sourcing accurate poissonzahl data is crucial for businesses aiming to enhance their operational efficiency and product quality. This guide addresses the challenges faced by international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, when navigating the complexities of poissonzahl procurement. By providing insights into various types, applications, and the critical importance of supplier vetting, we aim to empower decision-makers to make informed choices that align with their business objectives.

Understanding the nuances of poissonzahl is essential for industries ranging from manufacturing to construction, where material properties directly impact performance and safety. This comprehensive guide will explore essential factors such as cost considerations, supplier reliability, and market trends, ensuring that you have the tools necessary for effective sourcing.

Additionally, the guide will highlight best practices for evaluating suppliers, including certifications and past performance, to mitigate risks associated with international trade. With actionable insights tailored to the unique needs of B2B buyers across diverse regions, this resource equips you with the knowledge to secure quality poissonzahl products that meet your specific requirements. As you embark on this journey, you will gain the confidence to optimize your purchasing strategies and foster long-term supplier relationships.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Poisson | Basic model with constant rate of occurrence | Manufacturing, telecommunications | Pros: Simple to implement. Cons: Assumes constant rate, may not fit all scenarios. |

| Non-Homogeneous Poisson | Variable rate depending on time or space | Event management, traffic analysis | Pros: More accurate for fluctuating events. Cons: Complex to model and implement. |

| Compound Poisson | Sum of several Poisson processes with varying intensities | Insurance claims, financial modeling | Pros: Captures variability in claims. Cons: Requires extensive data for accuracy. |

| Marked Poisson | Includes additional information about events (marks) | Marketing analytics, customer behavior | Pros: Provides deeper insights. Cons: More data-intensive and complex analysis. |

| Spatial Poisson | Accounts for spatial distribution of events | Urban planning, environmental studies | Pros: Useful for geographic analysis. Cons: Requires spatial data, which may be hard to obtain. |

The Standard Poisson process is characterized by a constant average rate of occurrence for events over time or space. This model is widely utilized in various B2B sectors, particularly in manufacturing and telecommunications, where events such as machine failures or call arrivals can be anticipated. Buyers should consider its simplicity and ease of implementation, but they must also be cautious of its limitations, as it may not adequately represent scenarios with fluctuating event rates.

The Non-Homogeneous Poisson process allows for a varying rate of occurrence, which can change over time or across different locations. This flexibility makes it ideal for applications in event management and traffic analysis, where event rates can fluctuate significantly. B2B buyers should weigh the increased accuracy against the complexity of modeling, as this process requires more sophisticated data handling and analysis capabilities.

Compound Poisson processes combine multiple Poisson processes, each with its own intensity, to model scenarios like insurance claims or financial risks. This approach captures the variability and uncertainty inherent in claims, making it particularly useful for insurance companies and financial institutions. Buyers should be aware that while this model provides a more realistic representation of risk, it demands extensive historical data for effective implementation.

Marked Poisson processes extend the standard model by including additional attributes (marks) for each event, such as the value of a transaction or customer demographics. This capability is invaluable for marketing analytics and understanding customer behavior. B2B buyers should consider the benefits of gaining deeper insights into their data, although they must also prepare for the complexities of data collection and analysis.

Spatial Poisson processes are designed to analyze events distributed across geographic areas, making them essential for urban planning and environmental studies. This type of analysis helps businesses understand how spatial factors influence event occurrences. Buyers should recognize the advantages of using spatial data for targeted decision-making, but they also need to ensure they have access to high-quality spatial datasets to leverage this model effectively.

A stock image related to poissonzahl.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of poissonzahl | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Material selection for lightweight structures | Reduces weight, improving fuel efficiency and performance | Ensure compliance with international aerospace standards and testing |

| Civil Engineering | Design of structural components | Enhances durability and safety of constructions | Consider local building codes and environmental factors |

| Automotive | Analysis of vehicle components under stress | Improves safety and performance of vehicles | Source materials with proven reliability and durability |

| Manufacturing | Optimization of manufacturing processes | Increases efficiency and reduces waste | Evaluate suppliers for quality certifications and production capacity |

| Oil & Gas | Stress analysis in pipeline design | Ensures integrity and safety of transportation systems | Assess the supplier's experience in harsh environments and regulations |

In the aerospace industry, Poisson's ratio (poissonzahl) is crucial for selecting materials used in lightweight structures. A low Poisson's ratio indicates that the material will deform less laterally when stretched, which is vital for maintaining structural integrity under high stress. This application helps manufacturers reduce the overall weight of aircraft, leading to improved fuel efficiency and performance. International buyers should ensure that materials meet stringent aerospace standards and undergo rigorous testing to guarantee safety and compliance.

Civil engineering relies on Poisson's ratio to design structural components that can withstand various loads and stresses. By understanding how materials behave under different conditions, engineers can select the right materials that enhance durability and safety in constructions, such as bridges and buildings. Buyers in this sector must consider local building codes and environmental factors, ensuring that sourced materials are suitable for the specific conditions of their projects.

In the automotive industry, Poisson's ratio is applied to analyze vehicle components under stress, such as frames and suspension systems. This analysis helps engineers design safer and more efficient vehicles by predicting how components will behave during operation. For international B2B buyers, sourcing materials with a proven track record of reliability and durability is essential to meet safety standards and enhance vehicle performance.

Manufacturers utilize Poisson's ratio to optimize various processes, from material selection to production techniques. Understanding the deformation characteristics of materials allows companies to increase efficiency and reduce waste during manufacturing. B2B buyers should evaluate suppliers based on their quality certifications and production capacity to ensure they can meet the demands of optimized processes.

In the oil and gas sector, Poisson's ratio is critical for conducting stress analysis in pipeline design. It helps engineers assess the integrity and safety of transportation systems, particularly in harsh environments. International buyers should consider suppliers' experience in navigating complex regulations and their ability to provide materials that withstand extreme conditions, ensuring reliability in pipeline systems.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem: In the realm of materials science and engineering, accurate measurements of materials' properties are critical. A common pain point for B2B buyers, especially in industries like construction and manufacturing, is the challenge of obtaining precise values for Poisson's ratio. Variability in testing methods, material inconsistencies, and a lack of standardized procedures can lead to incorrect calculations, resulting in significant financial losses and project delays.

The Solution: To mitigate this issue, buyers should prioritize sourcing materials from reputable suppliers who provide detailed specifications, including verified Poisson's ratio values. Implementing a standardized testing protocol for their materials can also enhance accuracy. This may involve collaborating with accredited laboratories to conduct tensile tests under controlled conditions. Moreover, utilizing software that integrates material properties can streamline calculations and reduce human error. Regular training sessions for the technical team on the importance of Poisson's ratio and its implications can further ensure that everyone involved understands the critical nature of these measurements.

The Problem: B2B buyers often face conflicts during the material selection process, particularly when dealing with diverse applications that require specific material properties. For instance, selecting a material with an inappropriate Poisson's ratio can lead to structural failures or performance issues, especially in high-stress environments such as aerospace or automotive industries.

The Solution: To address this challenge, businesses should develop a comprehensive material database that includes not just Poisson's ratio but other relevant mechanical properties. When evaluating materials, it's crucial to use simulation tools that can predict how different materials will behave under various conditions. Encouraging collaboration between engineering, procurement, and quality assurance teams can also facilitate better decision-making. Regularly updating the database with the latest research and testing results will ensure that all teams have access to the most current data for informed material choices.

The Problem: Another significant pain point arises from inconsistent quality in materials supplied, which can directly affect the performance of products that rely on specific Poisson's ratio values. B2B buyers, particularly in industries such as construction and manufacturing, may struggle with suppliers who cannot guarantee the consistency of their materials, leading to unpredictable results in their projects.

The Solution: Establishing long-term relationships with a select group of suppliers can help mitigate this issue. Buyers should conduct thorough evaluations of potential suppliers, focusing on their quality control processes and the reliability of their material specifications. Implementing a supplier performance tracking system can help monitor consistency over time. Regular audits and site visits can further ensure that suppliers maintain the quality of their products. Additionally, integrating a feedback loop where end-users report back on material performance can provide suppliers with the insights needed to improve their offerings. By fostering a collaborative environment, buyers can encourage suppliers to maintain high standards and reliability in their products, particularly concerning Poisson's ratio.

When selecting materials for applications involving poissonzahl, it's crucial to consider properties such as temperature ratings, pressure resistance, and corrosion resistance. Here, we analyze four common materials used in these applications: stainless steel, aluminum, brass, and polymers.

Key Properties: Stainless steel is known for its high tensile strength and excellent corrosion resistance, making it suitable for high-pressure environments. It typically withstands temperatures up to 800°C and is compliant with various international standards, including ASTM and DIN.

Pros & Cons: The durability and strength of stainless steel make it ideal for demanding applications. However, it is more expensive than other materials and can be challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel's compatibility with aggressive media, such as acids and chlorides, makes it a preferred choice in industries like oil and gas, particularly in regions like the Middle East where such conditions are prevalent.

Considerations for International Buyers: Buyers from Africa and South America should ensure compliance with local standards and consider the availability of stainless steel grades that meet their specific environmental conditions.

Key Properties: Aluminum offers a favorable strength-to-weight ratio and good corrosion resistance, with temperature ratings typically up to 200°C. Its lightweight nature makes it suitable for applications where weight savings are critical.

Pros & Cons: The primary advantage of aluminum is its cost-effectiveness and ease of machining. However, it has lower strength compared to stainless steel and may not be suitable for high-pressure applications.

Impact on Application: Aluminum is often used in applications where weight is a concern, such as in automotive and aerospace sectors. Its compatibility with non-corrosive media makes it a viable option for various industries.

Considerations for International Buyers: Buyers in Europe may prefer aluminum for its recyclability and lower environmental impact, aligning with EU sustainability goals.

Key Properties: Brass is a copper-zinc alloy known for its excellent machinability and good corrosion resistance. It typically operates effectively at temperatures up to 150°C and is commonly used in plumbing and electrical applications.

Pros & Cons: Brass's machinability and aesthetic appeal make it a popular choice. However, it is susceptible to dezincification in certain environments, which can limit its use in specific applications.

Impact on Application: Due to its conductivity and resistance to corrosion, brass is often used in fittings and connectors, particularly in regions with high humidity, such as parts of Africa and South America.

Considerations for International Buyers: Compliance with local plumbing codes and standards is essential, especially in regions where water quality may impact material performance.

Key Properties: Polymers, such as PTFE and PVC, offer excellent chemical resistance and flexibility. They typically operate effectively at temperatures up to 100°C and are lightweight.

Pros & Cons: The primary advantage of polymers is their low cost and ease of fabrication. However, they may not withstand high pressures and temperatures as effectively as metals.

Impact on Application: Polymers are often used in applications involving corrosive chemicals, making them suitable for industries like pharmaceuticals and food processing.

Considerations for International Buyers: Buyers from the Middle East and Europe should consider the specific chemical compatibility of polymers with the media they will encounter in their applications.

| Material | Typical Use Case for poissonzahl | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure applications in oil & gas | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Lightweight components in automotive | Cost-effective and easy to machine | Lower strength, not for high-pressure use | Medium |

| Brass | Plumbing and electrical fittings | Good machinability and aesthetic appeal | Susceptible to dezincification | Medium |

| Polymers | Chemical processing applications | Low cost and flexible | Limited high-pressure and temperature use | Low |

This strategic material selection guide provides international B2B buyers with essential insights to make informed decisions when sourcing materials for poissonzahl applications. Each material has distinct advantages and limitations, which should be carefully evaluated in the context of specific application requirements and regional standards.

The manufacturing process for Poissonzahl typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets the required specifications and quality standards.

Material preparation is the foundational step where raw materials are selected and processed. For Poissonzahl, materials such as metals, polymers, or composites are commonly used, depending on the intended application. This stage often involves cutting, shaping, and treating materials to enhance their properties. Buyers should inquire about the sourcing and quality of raw materials, as these directly affect the performance of the final product.

Once materials are prepared, the next step is forming, which involves shaping the materials into the desired configuration. Common techniques include machining, casting, and molding. For instance, machining is frequently used to create precise dimensions, while casting may be employed for more complex shapes. Understanding the forming techniques used by suppliers can help buyers assess the capabilities and limitations of their manufacturing processes.

The assembly stage involves putting together various components to create the final product. This may include welding, soldering, or fastening parts together. Effective assembly processes are crucial for maintaining the integrity and functionality of Poissonzahl. B2B buyers should ensure that suppliers use standardized assembly practices to guarantee consistency and reduce the risk of defects.

Finally, finishing processes such as coating, polishing, or surface treatment are applied to enhance the aesthetic appeal and functional properties of the product. Finishing not only improves the appearance but also protects against corrosion and wear. Buyers should inquire about the finishing techniques used, as these can significantly impact the product's lifespan and performance.

Quality assurance (QA) is vital in the manufacturing of Poissonzahl to ensure that products meet international and industry-specific standards. Key elements of QA include adherence to international standards, quality checkpoints throughout the manufacturing process, and rigorous testing methods.

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 ensures that suppliers maintain consistent quality and continuous improvement. Additionally, industry-specific certifications like CE marking (for products sold in Europe) and API standards (for the oil and gas industry) are also crucial. Buyers should request proof of these certifications to validate their suppliers’ commitment to quality.

Quality control (QC) checkpoints are integrated into the manufacturing process to identify and mitigate defects early. These checkpoints typically include:

Understanding these checkpoints helps buyers gauge the thoroughness of their suppliers' QC processes.

Testing methods are critical in verifying the quality and performance of Poissonzahl. Common testing techniques include:

B2B buyers should inquire about the specific testing methods employed by suppliers and request test reports to verify compliance with quality standards.

To ensure a supplier's quality control is robust, B2B buyers should consider several verification methods:

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific nuances in quality assurance. Understanding local regulations, trade agreements, and cultural expectations can impact the sourcing process.

In conclusion, understanding the manufacturing processes and quality assurance practices for Poissonzahl is essential for international B2B buyers. By focusing on material preparation, forming techniques, assembly processes, and rigorous quality control, buyers can make informed decisions and ensure they source high-quality products that meet their specific needs.

In today's competitive global market, sourcing 'poissonzahl' effectively requires a structured approach. This checklist serves as a practical guide for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to navigate the procurement process with confidence.

Before initiating the sourcing process, it is essential to clearly articulate your technical requirements for 'poissonzahl'. This includes understanding the specific characteristics, dimensions, and performance standards necessary for your application. A well-defined specification not only streamlines the search for suppliers but also ensures that you receive products that meet your operational needs.

Conduct thorough research to identify potential suppliers who specialize in 'poissonzahl'. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. A diverse supplier base can provide options regarding quality, price, and delivery timelines.

It’s crucial to verify that potential suppliers comply with international quality standards and regulations relevant to 'poissonzahl'. This step helps mitigate risks associated with quality and safety.

Before finalizing a supplier, request samples of 'poissonzahl' for evaluation. Testing these samples will help you assess their quality and suitability for your specific application.

Once you have identified a suitable supplier, proceed to negotiate terms that align with your business objectives. This includes pricing, payment terms, delivery schedules, and warranty policies.

Effective communication is vital for a successful sourcing relationship. Establish a clear plan for regular updates and feedback throughout the procurement process.

Before placing an order, ensure that all terms are captured in a formal purchase agreement. This document should outline all negotiated terms, including delivery expectations and quality assurance measures.

By following these steps, B2B buyers can effectively navigate the sourcing process for 'poissonzahl', ensuring that they secure quality products that meet their business needs while fostering strong supplier relationships.

When sourcing poissonzahl, understanding the comprehensive cost structure is essential for B2B buyers. The primary cost components include:

Materials: The type and quality of materials used significantly impact the overall cost. High-grade materials may increase initial expenses but often enhance product durability and performance.

Labor: Labor costs encompass wages for skilled workers involved in manufacturing and assembly. Regions with lower labor costs, such as parts of Africa and South America, may offer a competitive edge.

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads.

Tooling: Custom tooling required for production can be a substantial upfront cost. However, investing in high-quality tooling can lead to better long-term efficiency and product quality.

Quality Control (QC): Implementing rigorous QC processes is crucial for maintaining product standards. While this adds to the cost, it reduces the risk of defects and returns, ultimately saving money.

Logistics: Shipping and handling costs vary based on distance, mode of transport, and Incoterms. Understanding the logistics involved can significantly influence total costs.

Margin: The supplier's profit margin is also a critical factor. It can vary widely based on market conditions, competition, and perceived value.

Several factors can influence the pricing of poissonzahl, impacting the final cost for international buyers:

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing for bulk orders. Understanding MOQ can help buyers negotiate more favorable terms.

Specifications and Customization: Customized products may incur additional costs due to unique tooling and material requirements. Clearly defined specifications can prevent misunderstandings and additional expenses.

Quality and Certifications: Higher quality products often come at a premium. Certifications (e.g., ISO) can also influence pricing but may be necessary for compliance and market acceptance.

Supplier Factors: The supplier's reputation, location, and production capabilities can significantly affect pricing. Established suppliers may offer reliability but at a higher cost.

Incoterms: The terms of delivery (e.g., FOB, CIF) can impact the total cost. Buyers should carefully evaluate these terms to understand what costs are covered and where additional expenses may arise.

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

Negotiate Terms: Don’t hesitate to negotiate pricing and terms. Suppliers often have flexibility, especially for larger orders or long-term contracts.

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, operational, and disposal costs. This perspective can justify higher upfront costs if they lead to savings in the long run.

Understand Pricing Nuances: Familiarize yourself with the pricing landscape in the supplier's region. This includes local economic factors, currency fluctuations, and import/export duties that could affect the final price.

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Trust and communication are key in B2B dealings.

Consider Local Suppliers: Sourcing from local suppliers may reduce logistics costs and lead times. It can also simplify compliance with regional regulations.

Navigating the cost and pricing landscape of poissonzahl sourcing requires a keen understanding of various components and influencers. By leveraging effective negotiation strategies and focusing on the total cost of ownership, international buyers can achieve better pricing and enhance their procurement processes. Always remember to conduct thorough research and maintain open lines of communication with suppliers to ensure the best outcomes.

Disclaimer: Prices mentioned are indicative and subject to change based on market conditions and supplier negotiations.

In the dynamic landscape of B2B solutions, evaluating alternatives to a product or method like Poissonzahl is crucial for informed decision-making. Understanding how Poissonzahl stacks up against other viable solutions can help international buyers from regions such as Africa, South America, the Middle East, and Europe make strategic choices that align with their specific business needs. This analysis will focus on comparing Poissonzahl with two alternative solutions, examining key aspects such as performance, cost, ease of implementation, maintenance, and the best use cases for each.

| Comparison Aspect | Poissonzahl | Alternative 1: Statistical Modeling | Alternative 2: Machine Learning |

|---|---|---|---|

| Performance | High accuracy in predictions | Moderate accuracy, dependent on data quality | High accuracy with large datasets |

| Cost | Medium cost | Low to medium cost | High initial investment |

| Ease of Implementation | Requires training | Relatively easy to implement | Requires significant expertise |

| Maintenance | Moderate maintenance needs | Low maintenance | High maintenance and retraining |

| Best Use Case | Predictive analytics in specialized fields | General statistical analysis | Complex data-driven decision-making |

Statistical modeling serves as a foundational alternative to Poissonzahl, offering a range of techniques for analyzing data. Its primary advantage lies in its accessibility; businesses can implement it without extensive training or specialized software. Statistical models often require lower costs, making them attractive for startups or smaller enterprises. However, the accuracy of statistical models can vary significantly based on data quality and the specific methods used, which may not always yield reliable predictions compared to Poissonzahl.

Machine learning represents a more advanced alternative, particularly beneficial for organizations dealing with vast amounts of data. Its strength lies in its ability to learn from data over time, providing high accuracy in predictions, especially when working with large datasets. However, the initial investment in machine learning can be considerable, requiring advanced tools and skilled personnel to implement effectively. Maintenance is also a challenge, as models need to be retrained regularly to remain accurate, which can be resource-intensive for businesses.

When selecting the right analytical solution, B2B buyers must consider their unique requirements, including budget, data complexity, and the expertise available within their teams. While Poissonzahl offers high accuracy and reliability, alternatives such as statistical modeling and machine learning may provide greater flexibility and accessibility, depending on the business context. Ultimately, assessing the specific needs and capabilities of your organization will guide you in making a choice that maximizes efficiency and enhances decision-making.

Understanding the critical technical properties of poissonzahl (Poisson's ratio) is vital for B2B buyers, particularly those involved in the engineering, materials science, and manufacturing sectors. Here are several key specifications to consider:

Material Grade

Material grade refers to the classification of materials based on their mechanical properties, including elasticity and strength. In the context of poissonzahl, it is essential to know how different materials behave under stress. For instance, metals typically have a lower Poisson's ratio compared to polymers, which can significantly impact product design and application.

Tolerance

Tolerance defines the allowable deviation from a specified dimension or property. In manufacturing processes, understanding the tolerance related to Poisson's ratio ensures that components fit and function correctly. High tolerance levels are crucial in industries such as aerospace and automotive, where precision is paramount.

Temperature Dependency

Poisson's ratio can vary with temperature, affecting a material's performance under different environmental conditions. For international buyers, especially those in regions with extreme climates, knowing how temperature affects the Poisson's ratio of materials can help in selecting the right products for their applications.

Elastic Modulus

This property is a measure of a material's ability to deform elastically when a force is applied. It is closely related to Poisson's ratio; materials with high elastic moduli tend to exhibit specific Poisson's ratios. Understanding elastic modulus is vital for engineers designing components that must withstand various loads.

Fatigue Limit

The fatigue limit is the maximum stress a material can withstand for an infinite number of cycles without failing. This property is essential for industries like construction and manufacturing, where materials are subjected to repeated loading. Knowing the fatigue limit in relation to Poisson's ratio helps buyers assess long-term performance.

Familiarizing yourself with industry jargon can streamline communication and facilitate smoother transactions. Here are some essential terms to know:

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding the OEM landscape is crucial, as it can affect quality and warranty considerations for products that utilize specific materials based on their Poisson's ratio.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for international buyers, as it can impact the cost-effectiveness of purchasing materials with specific Poisson's ratios, especially for small to medium-sized enterprises.

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. Including detailed specifications related to Poisson's ratio in your RFQ can help ensure that you receive accurate quotes tailored to your needs.

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in global trade transactions. Understanding these terms helps buyers from Africa, South America, the Middle East, and Europe navigate shipping and delivery logistics, which may be affected by the properties of the materials they are purchasing.

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. This is especially crucial for B2B buyers who need specific materials with defined poissonzahl properties for urgent projects. Knowing the lead time can help in project planning and resource allocation.

Certification

Certification ensures that materials meet specific standards or regulations. For products related to Poisson's ratio, certifications can include compliance with industry standards for safety and performance. Buyers should always check for relevant certifications to ensure the quality and reliability of the materials they are sourcing.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when procuring materials related to poissonzahl, ensuring optimal performance and compliance in their applications.

The poissonzahl sector is currently experiencing significant shifts driven by globalization, technological advancement, and the increasing demand for data-driven decision-making. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing strategies. One of the primary trends is the integration of Artificial Intelligence (AI) and machine learning into sourcing processes. These technologies enable suppliers to analyze vast datasets, providing insights that enhance procurement efficiency and reduce costs.

Additionally, there is a growing emphasis on digital platforms that facilitate transparent supply chain management. B2B buyers are increasingly looking for suppliers that offer robust digital interfaces, enabling seamless transactions and real-time updates on inventory levels. This trend is particularly pronounced in emerging markets where mobile technology is becoming ubiquitous, allowing buyers to access suppliers and market data more easily.

Furthermore, sustainability is becoming a critical factor in sourcing decisions. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, reflecting a broader shift toward corporate social responsibility (CSR). This trend is particularly relevant in regions where consumers are becoming more environmentally conscious, pressuring businesses to adopt greener practices.

Sustainability and ethical sourcing have emerged as pivotal considerations in the poissonzahl sector. Environmental impacts from production processes and resource extraction can be significant, leading to regulatory scrutiny and reputational risks for businesses. For international B2B buyers, especially those from regions like Europe and the Middle East, aligning with suppliers who practice sustainability can enhance brand reputation and customer loyalty.

Buyers should prioritize suppliers that have obtained 'green' certifications or utilize sustainable materials. These certifications often reflect adherence to international environmental standards, ensuring that suppliers are minimizing their ecological footprint. Moreover, ethical sourcing practices contribute to the overall integrity of the supply chain, enhancing transparency and fostering trust between buyers and suppliers.

For instance, many companies are now focusing on circular economy principles, which promote the reuse and recycling of materials. This not only reduces waste but also opens up new avenues for innovation and cost savings. By choosing suppliers committed to sustainable practices, B2B buyers can contribute to a more responsible supply chain while also meeting the demands of environmentally conscious consumers.

The evolution of the poissonzahl sector has been marked by significant technological advancements and changing market demands. Initially, sourcing in this sector was largely manual, relying on traditional methods of procurement and supplier management. However, as businesses began to recognize the importance of data analytics and real-time decision-making, the sector underwent a transformation.

The introduction of digital platforms and AI has streamlined sourcing processes, allowing for better data management and enhanced supplier relationships. This evolution has been driven by the need for efficiency and cost-effectiveness in an increasingly competitive global market. As a result, international B2B buyers are now equipped with tools that not only simplify procurement but also provide insights into market dynamics, enabling more informed decision-making.

Today, the poissonzahl sector is characterized by a strong focus on sustainability and ethical practices, reflecting broader societal trends. This shift underscores the importance of aligning business strategies with evolving consumer expectations and regulatory standards, ensuring that B2B buyers are well-prepared to navigate the complexities of this dynamic market landscape.

How do I determine the quality of poissonzahl for my business needs?

To assess the quality of poissonzahl, first, request product specifications and certifications from potential suppliers. Evaluate samples to ensure they meet your standards. Additionally, review third-party testing results, if available. Establish a quality assurance process that includes regular audits and feedback mechanisms to maintain consistent product quality. Engaging with suppliers who have a proven track record in quality management can further safeguard your interests.

What is the best poissonzahl supplier for international buyers?

Selecting the best supplier for poissonzahl involves evaluating their reputation, experience, and reliability in international markets. Research suppliers through industry forums, trade shows, and online directories. Request references from existing clients to gauge their satisfaction. Consider suppliers who offer comprehensive customer support and are responsive to inquiries, as this can indicate a commitment to service and quality.

How can I customize my poissonzahl order to suit specific requirements?

To customize your poissonzahl order, communicate your specific needs clearly to potential suppliers. Discuss options such as dimensions, materials, and finishes. Many suppliers are willing to accommodate custom requests, especially for larger orders. Be prepared to provide detailed specifications and possibly engage in a prototype phase to ensure the final product meets your expectations before full-scale production begins.

What are typical minimum order quantities (MOQs) for poissonzahl?

Minimum order quantities for poissonzahl can vary significantly based on the supplier and the type of product. Generally, MOQs can range from 100 to several thousand units. When negotiating with suppliers, inquire about flexible order options or tiered pricing that may apply if you commit to larger volumes. Understanding the MOQ can help you plan your inventory and cash flow effectively.

What payment terms should I expect when sourcing poissonzahl internationally?

Payment terms for international purchases of poissonzahl typically include options like advance payment, letter of credit, or payment upon delivery. Discuss payment methods upfront with suppliers to find mutually agreeable terms. Be cautious of upfront payments that exceed 30-50% of the total order value, as this may increase risk. Ensure that the terms are documented in your purchase agreement to prevent any misunderstandings.

How do I ensure compliance with international trade regulations when importing poissonzahl?

To ensure compliance with international trade regulations, familiarize yourself with the import laws of your country and the export regulations of the supplier's country. Consult with customs brokers or trade compliance specialists to understand tariffs, duties, and necessary documentation. Keeping abreast of changes in trade agreements can also help avoid penalties and facilitate smoother transactions.

What logistics considerations should I keep in mind when sourcing poissonzahl?

When sourcing poissonzahl, consider logistics aspects such as shipping methods, lead times, and costs. Determine whether air freight or sea freight is more suitable based on your urgency and budget. Ensure that the supplier can provide reliable shipping options and track your order. Additionally, factor in customs clearance processes and potential delays that could impact delivery timelines.

How can I build a long-term relationship with my poissonzahl supplier?

Building a long-term relationship with your poissonzahl supplier involves consistent communication, transparency, and mutual respect. Provide constructive feedback on product quality and service, and be open to discussing improvements. Regularly engage in business reviews to align goals and expectations. Establishing trust through timely payments and honoring agreements can also foster loyalty and encourage suppliers to prioritize your orders.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

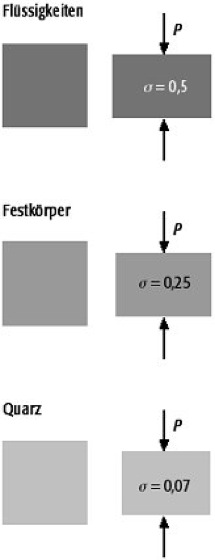

A stock image related to poissonzahl.

In summary, leveraging strategic sourcing for poissonzahl presents a multitude of advantages for B2B buyers across Africa, South America, the Middle East, and Europe. Understanding the poissonzahl, or Poisson's ratio, is critical for evaluating material performance and ensuring optimal procurement decisions. This knowledge not only enhances product quality but also streamlines supply chain efficiency, leading to cost savings and improved competitiveness.

Strategic sourcing empowers international buyers to identify reliable suppliers, negotiate better terms, and foster long-term relationships. By prioritizing quality and sustainability, companies can mitigate risks associated with fluctuating markets and ensure compliance with regional standards. As industries evolve, staying informed about advancements in poissonzahl applications will be vital for maintaining a competitive edge.

As you navigate the complexities of sourcing materials, consider integrating advanced data analytics and supplier performance assessments into your strategy. This proactive approach will enable you to anticipate market changes and make informed decisions. Engage with industry experts and participate in networking opportunities to expand your knowledge and capabilities in sourcing materials effectively. The future of strategic sourcing in the realm of poissonzahl is promising; seize the opportunity to elevate your procurement processes today.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina