In today's competitive global market, sourcing the right types of schleifpapier holz metall unterschied—or sanding paper for wood and metal—can be a daunting task for international B2B buyers. This guide is designed to address the unique challenges faced by companies in Africa, South America, the Middle East, and Europe, such as navigating varying quality standards, understanding specific applications, and vetting reliable suppliers. Whether you are looking to enhance your manufacturing processes or improve product finishes, having the right sanding materials is crucial for achieving high-quality results.

This comprehensive guide covers a wide range of topics, including the different types of sanding paper available, their specific applications, and practical tips for selecting the best options for your needs. Furthermore, it provides insights into cost considerations, supplier vetting processes, and key performance indicators to help you make informed purchasing decisions. By leveraging this information, B2B buyers can effectively streamline their sourcing processes and ensure they are investing in the most suitable products for their operations.

As you navigate the complexities of the global market for sanding paper, this guide empowers you with the knowledge and tools needed to make strategic decisions. It serves as an invaluable resource for international buyers seeking to enhance their procurement strategies and achieve operational excellence in their respective industries.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wood Sandpaper | Coarse to fine grits, flexible backing | Furniture manufacturing, carpentry | Pros: Excellent finish on wood; Cons: Not suitable for metal. |

| Metal Sandpaper | Durable, often aluminum oxide or silicon carbide | Metal fabrication, automotive repair | Pros: Long-lasting, effective on metal; Cons: Can clog with soft metals. |

| Multi-Purpose Sandpaper | Versatile grit options, suitable for various materials | General construction, DIY projects | Pros: Convenient for mixed-material tasks; Cons: May not perform as well on specific materials. |

| Wet/Dry Sandpaper | Waterproof backing, suitable for wet use | Automotive finishing, woodworking | Pros: Reduces dust, prevents clogging; Cons: More expensive than standard sandpaper. |

| Specialty Sandpaper | Specific formulations for unique applications | Aerospace, electronics manufacturing | Pros: Tailored for specific tasks; Cons: Higher costs, limited availability. |

Wood sandpaper is available in a range of grits, from coarse to fine, which allows for versatile applications in woodworking. Its flexible backing helps conform to the surface being sanded, making it ideal for achieving a smooth finish on furniture and cabinetry. When purchasing wood sandpaper, buyers should consider the grit size for their specific application, as well as the type of wood being worked on. This type of sandpaper is not suitable for metal surfaces, so clear demarcation of use is essential.

Metal sandpaper is specifically designed for use on metal surfaces and typically features a durable backing made from materials like aluminum oxide or silicon carbide. These materials provide longevity and effectiveness when sanding metals, especially in automotive repair and metal fabrication industries. Buyers should consider the grit and the type of metal they will be working with, as softer metals can cause clogging. Proper selection can enhance productivity and quality of finish.

Multi-purpose sandpaper offers versatility, making it suitable for a wide range of materials, including wood, metal, and plastic. This type is especially beneficial for contractors and DIY enthusiasts who often work with mixed materials. When purchasing, B2B buyers should evaluate the specific projects planned to ensure they select the right grit and type. While it is convenient, it may not perform as well as specialized sandpapers on specific materials, so understanding its limitations is crucial.

Wet/dry sandpaper features a waterproof backing that allows it to be used with water or other lubricants, which helps to reduce dust and prevent clogging during sanding. This makes it ideal for automotive finishing and woodworking applications where a clean, smooth finish is desired. B2B buyers should consider the increased cost compared to standard sandpaper but recognize the benefits in terms of reduced cleanup and improved results.

Specialty sandpaper is formulated for unique applications, such as aerospace or electronics manufacturing, where precision and performance are critical. These sandpapers can come in various grit sizes and compositions tailored to specific tasks. When purchasing specialty sandpaper, buyers should be prepared for higher costs and potentially limited availability. However, the investment can yield superior results and efficiency in specialized tasks, making it a worthwhile consideration for businesses in niche markets.

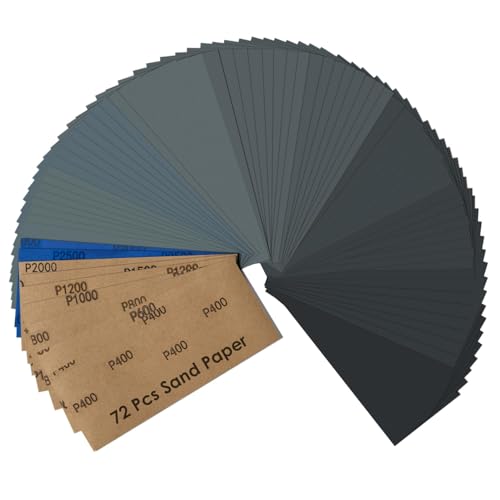

A stock image related to schleifpapier holz metall unterschied.

Related Video: Schleifmittel - Aufbau und Verwendung von Schleifpapier

| Industry/Sector | Specific Application of schleifpapier holz metall unterschied | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Surface preparation and finishing of wooden furniture | Enhances aesthetic appeal and durability of products | Quality of abrasives, grit size, and compatibility with finishing materials |

| Automotive Industry | Metal surface smoothing and finishing | Improves paint adhesion and corrosion resistance | Abrasive type (aluminum oxide vs. silicon carbide), availability of various grits |

| Construction | Surface leveling of wooden beams and metal structures | Ensures structural integrity and aesthetics | Sourcing from local suppliers to reduce shipping costs and time |

| Metal Fabrication | Deburring and polishing of metal components | Enhances product safety and performance | Consideration of the type of metal and required finish for specific applications |

| DIY and Crafting | Sanding and finishing for various small projects | Provides a smooth finish for customer satisfaction | Availability of assorted packs to cater to different project needs |

In the furniture manufacturing sector, 'schleifpapier holz metall unterschied' plays a critical role in both surface preparation and finishing processes. Different grades of sandpaper are utilized to smooth wooden surfaces before applying varnishes or paints, enhancing the aesthetic appeal and durability of the final product. For international buyers, especially in regions like Africa and South America, it's crucial to consider the quality of abrasives used, as lower-quality options can lead to uneven finishes and increased production costs.

In the automotive industry, this type of sandpaper is essential for preparing metal surfaces before painting. It ensures that the paint adheres properly and increases resistance to corrosion. Buyers from Europe and the Middle East should focus on sourcing sandpaper that is specifically formulated for metal surfaces, as the abrasive type (e.g., aluminum oxide) can significantly impact the quality of the finish. Additionally, availability of various grits is important to meet different surface preparation requirements.

In construction, 'schleifpapier holz metall unterschied' is used for surface leveling of wooden beams and metal structures. This application is crucial for ensuring that surfaces are smooth, which enhances both the aesthetic and structural integrity of buildings. For international buyers, sourcing sandpaper from local suppliers can reduce shipping costs and time, which is particularly beneficial in emerging markets where timely project completion is critical.

In the metal fabrication sector, this sandpaper is used primarily for deburring and polishing metal components. This process not only improves the safety of the products by removing sharp edges but also enhances their performance by providing a smoother finish. B2B buyers, especially those in regions with stringent safety regulations, should pay close attention to the type of metal being worked on and select sandpaper that meets specific finishing requirements.

For DIY enthusiasts and crafters, 'schleifpapier holz metall unterschied' is indispensable for sanding and finishing various small projects. A smooth finish is often crucial for customer satisfaction in handmade goods. Buyers should look for assorted packs that cater to different project needs, ensuring they have the right grit sizes on hand. This flexibility is especially advantageous for small businesses and artisans in diverse markets, including Italy and Indonesia, where customization is key.

Related Video: Uses of Metals - Science 9

The Problem:

B2B buyers often struggle with selecting the right type of sandpaper for their specific applications. The confusion arises primarily from the differences in abrasives, grit types, and backing materials used in sandpapers designed for wood versus those intended for metal. Buyers may purchase the wrong product, leading to inefficiencies, wasted materials, and increased costs in their manufacturing processes. This is particularly challenging for businesses that operate in diverse markets across Africa, South America, the Middle East, and Europe, where local suppliers may not provide clear product descriptions.

The Solution:

To overcome this issue, it is crucial to educate buyers on the specific characteristics of sandpapers for wood and metal. For wood, look for sandpapers with a softer abrasive like aluminum oxide or garnet, which is less likely to damage the surface. For metal, silicon carbide or ceramic abrasives are preferred as they can withstand the heat and pressure of metalworking. When sourcing, consider suppliers who provide detailed product specifications, including the type of abrasive, grit size, and intended use. Additionally, leveraging online resources or industry guides can help clarify these differences, ensuring buyers make informed decisions. Engaging in training sessions or workshops can also enhance understanding and application.

The Problem:

Buyers in international markets often face challenges in sourcing high-quality sandpaper that meets their specific needs. Variability in quality standards, especially in regions like Africa and South America, can lead to inconsistent product performance. This inconsistency can cause delays in production and damage to finished goods, negatively impacting customer satisfaction and brand reputation.

The Solution:

To address this sourcing challenge, B2B buyers should establish relationships with reputable suppliers who adhere to international quality standards. Conduct thorough research on potential suppliers, checking for certifications like ISO or EN standards. Request samples to evaluate the quality before making bulk purchases. Additionally, consider joining industry associations or networks that focus on material sourcing, as these can provide insights into reliable suppliers and best practices for procurement. By prioritizing quality and consistency, buyers can ensure that their operations run smoothly and maintain high product standards.

The Problem:

Many B2B buyers are unaware of the total cost of ownership associated with using different types of sandpaper. While a cheaper product might seem appealing upfront, it may wear out quickly or require more frequent replacements, ultimately leading to higher overall costs. This is especially true in industries where precision and finish quality are critical, such as metal fabrication or fine woodworking.

The Solution:

To manage costs effectively, buyers should conduct a cost-benefit analysis when selecting sandpaper. This includes assessing the longevity of the sandpaper, the time required for application, and the finish quality achieved. Investing in higher-quality sandpapers that might be more expensive initially can result in savings over time due to reduced replacement frequency and improved productivity. Additionally, consider bulk purchasing options or negotiating contracts with suppliers for better pricing on high-quality products. Implementing a tracking system to monitor sandpaper usage and costs can further aid in making informed purchasing decisions that align with budget constraints while maintaining product quality.

When selecting materials for schleifpapier holz metall unterschied, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of various materials used in sandpaper production. This knowledge not only impacts product performance but also influences cost, manufacturing complexity, and compliance with industry standards.

Aluminum oxide is one of the most widely used materials for sandpaper, particularly for wood and metal applications.

Silicon carbide is another common material, especially favored for its sharpness and efficiency.

Garnet sandpaper is often used for woodworking applications due to its natural abrasive properties.

Ceramic sandpaper is a newer entrant in the market, known for its durability and performance.

| Material | Typical Use Case for schleifpapier holz metall unterschied | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Heavy-duty sanding for wood and metal | High durability | Higher cost compared to garnet | Medium |

| Silicon Carbide | Wet or dry sanding of hard materials | Sharpness and efficiency | Wears out faster | Medium |

| Garnet | Fine finishing on soft woods | Eco-friendly and quality finish | Lower durability | Low |

| Ceramic | Industrial applications on metals | Exceptional durability | Higher cost | High |

This guide provides actionable insights for international B2B buyers to make informed decisions regarding material selection for schleifpapier holz metall unterschied, ensuring compliance with local standards and optimizing performance for their specific applications.

Manufacturing schleifpapier (sandpaper) designed for wood (holz) and metal (metall) involves several critical stages. Understanding these processes is essential for B2B buyers, particularly those sourcing from different global regions, as it directly impacts product quality and performance.

The manufacturing process begins with the selection of appropriate raw materials. For schleifpapier, the primary components include:

Properly sourcing and preparing these materials is crucial, as the quality of the abrasives and backing will significantly influence the performance of the final product.

After material preparation, the next step is forming. This involves several techniques:

These processes must be closely monitored to maintain uniformity and quality across all products.

After forming, the sheets are cut and assembled into their final configurations. This includes:

Quality assurance (QA) is a critical component in the manufacturing of schleifpapier, ensuring that the final products meet international standards and customer expectations.

International quality standards such as ISO 9001 are vital for manufacturers of schleifpapier. This standard emphasizes a quality management system that ensures consistent quality and continuous improvement. Additionally, industry-specific certifications like CE marking for products sold in the European Economic Area (EEA) or API standards for certain industrial applications may also apply.

To ensure quality throughout the manufacturing process, several quality control checkpoints are implemented:

Testing methods for schleifpapier vary based on the intended application but typically include:

B2B buyers must be diligent in verifying the quality control practices of their suppliers. Here are actionable steps:

For international buyers, understanding the nuances of quality control is crucial. Different regions may have varying standards and regulations that affect product quality. For instance, buyers from Africa and South America may encounter different import regulations compared to those in Europe or the Middle East.

A stock image related to schleifpapier holz metall unterschied.

Moreover, language barriers and cultural differences can complicate communication regarding quality expectations. Therefore, establishing clear channels of communication and understanding the local regulations of your supplier's country can help mitigate risks.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures for schleifpapier is essential. By focusing on material preparation, forming, assembly, and rigorous quality control, buyers can ensure they source high-quality products that meet their specific needs. Engaging in proactive verification of supplier practices will further enhance the reliability of your supply chain.

To successfully navigate the procurement of 'schleifpapier holz metall unterschied' (sandpaper for wood and metal differences), international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, need a structured approach. This checklist serves as a comprehensive guide to ensure informed decision-making and optimal sourcing outcomes.

Before reaching out to suppliers, clearly outline your technical requirements. This includes the grit size, material composition, and intended application of the sandpaper. By defining these parameters, you can ensure that the products meet your operational needs and avoid costly mistakes.

Conduct thorough research to identify suppliers who specialize in sandpaper products. Utilize trade directories, industry forums, and social media platforms to create a list of potential candidates.

Before committing to any supplier, verify their certifications and compliance with international standards. This step is crucial to ensure product quality and safety.

Once you have shortlisted potential suppliers, request samples to evaluate their products firsthand. This allows you to assess the quality and performance of the sandpaper before making a bulk purchase.

Engage in negotiations to secure the best possible terms. This includes pricing, payment terms, and delivery schedules.

Effective communication with your chosen supplier is vital for a successful partnership. Establish clear lines of communication to ensure all parties are aligned on expectations.

After making a purchase, assess the supplier's post-purchase support. This includes warranty, returns, and customer service quality.

By following this checklist, B2B buyers can streamline the sourcing process for 'schleifpapier holz metall unterschied', ensuring they obtain high-quality products that meet their specific needs while fostering strong supplier relationships.

When sourcing schleifpapier holz metall unterschied, understanding the cost structure is crucial for international B2B buyers. The main cost components include:

Materials: The type of abrasive material used significantly influences cost. For instance, aluminum oxide is generally less expensive than zirconia, which offers higher durability and performance. Buyers should evaluate the material based on the intended application to ensure cost-effectiveness.

Labor: Labor costs can vary significantly based on the region. In countries with higher wage standards, such as Western Europe, labor costs will be higher compared to regions in Africa or South America. Understanding local labor rates can aid in estimating total costs.

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. A factory's location can impact overhead costs, with urban facilities often incurring higher expenses compared to rural settings.

Tooling: The initial investment in tooling can be substantial, especially for custom products. Buyers should consider whether the tooling costs can be amortized over a larger order volume, reducing the per-unit cost.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can add to costs. Certifications (e.g., ISO) may also incur additional expenses but can enhance product credibility in international markets.

Logistics: Shipping costs depend on the mode of transport, distance, and any customs duties involved. Understanding Incoterms is essential for clarifying who bears these costs and risks during shipping.

Margin: Suppliers will typically add a profit margin to their costs. This margin can vary based on market conditions and the supplier's positioning.

Several factors can influence the pricing of schleifpapier holz metall unterschied:

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit prices due to economies of scale. Buyers should negotiate MOQs to optimize costs.

Specifications and Customization: Custom abrasives tailored to specific applications will generally cost more than standard products. Clear communication of requirements can help in obtaining accurate quotes.

Material Quality and Certifications: Higher-quality materials and certifications (e.g., environmental standards) can drive up costs. Buyers should weigh the benefits against their specific needs.

Supplier Factors: Reputation, reliability, and location of suppliers can impact pricing. Established suppliers with strong market positions may offer higher prices due to their brand value.

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, adopting strategic approaches can lead to better pricing outcomes:

Negotiate Wisely: Always negotiate prices based on detailed analysis of cost components. Presenting data on competitor pricing can strengthen your position.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs associated with maintenance, performance, and disposal. This holistic view can lead to better sourcing decisions.

Understand Pricing Nuances: Different regions may have varying pricing structures due to local market dynamics. Buyers should be aware of regional trends and cost factors to make informed choices.

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms. Suppliers may offer discounts or favorable terms to loyal customers.

It is important to note that prices for schleifpapier holz metall unterschied can fluctuate based on market conditions, material availability, and supplier negotiations. Therefore, buyers should seek updated quotes tailored to their specific needs before finalizing any procurement decisions.

In the quest for effective surface preparation solutions in various industries, it is essential for B2B buyers to consider viable alternatives to traditional options like 'schleifpapier holz metall unterschied' (sandpaper for wood and metal). This analysis provides a comparative overview of different solutions, enabling buyers to make informed decisions tailored to their specific requirements.

| Comparison Aspect | Schleifpapier Holz Metall Unterschied | Alternative 1: Diamond Abrasives | Alternative 2: Aluminum Oxide Discs |

|---|---|---|---|

| Performance | Good for fine finishing on both surfaces | Superior durability and longevity | Versatile for a range of materials |

| Cost | Economical and widely available | Higher initial investment | Moderate pricing |

| Ease of Implementation | Simple to use and apply | Requires specialized tools | Easy to use with standard tools |

| Maintenance | Low maintenance | Minimal maintenance required | Moderate maintenance required |

| Best Use Case | Ideal for DIY and light industrial applications | Heavy-duty industrial applications | General-purpose sanding |

Diamond Abrasives are known for their exceptional performance, particularly in demanding applications. They offer superior durability, making them ideal for heavy-duty industrial tasks where longevity is critical. The downside, however, is the higher initial cost, which may deter smaller businesses or those with limited budgets. Additionally, they require specialized tools for application, which could add to the overall investment.

Aluminum Oxide Discs are another alternative that provides a versatile solution suitable for various materials, including wood, metal, and plastics. They are priced moderately, making them accessible for businesses of all sizes. The ease of use with standard tools is a significant advantage, allowing for quick integration into existing workflows. However, they may not offer the same level of performance in heavy-duty applications as diamond abrasives, potentially necessitating more frequent replacements.

When selecting the right surface preparation solution, B2B buyers must evaluate their specific needs, including the materials being worked on, the required durability, and budget constraints. While 'schleifpapier holz metall unterschied' provides a cost-effective and versatile option for many applications, alternatives like diamond abrasives and aluminum oxide discs offer distinct advantages that may be more suitable for certain industrial contexts. By carefully considering performance, cost, ease of implementation, maintenance, and best use cases, businesses can make strategic purchasing decisions that enhance their operational efficiency and product quality.

When considering the purchase of schleifpapier (sandpaper) designed for wood and metal applications, it is crucial for B2B buyers to understand specific technical properties that dictate performance and suitability. Here are some key specifications:

Material Grade: Sandpaper can be made from various materials, including aluminum oxide, silicon carbide, and garnet. Each material has different applications; for instance, aluminum oxide is durable and ideal for metal, while garnet is more suited for woodworking. Understanding material grades helps buyers select the right product for their specific needs.

Grit Size: The grit size indicates the coarseness of the sandpaper. Grit numbers range from 40 (coarse) to 600 (fine). A lower grit is effective for removing material quickly, while higher grits are used for finishing surfaces. Selecting the correct grit size is essential to achieve the desired finish without damaging the workpiece.

Backing Material: The backing of sandpaper, often made from paper, cloth, or film, affects its flexibility and durability. For instance, cloth-backed sandpaper is more robust and suitable for sanding irregular surfaces. Buyers should assess the backing material to ensure it aligns with their project requirements.

Adhesive Type: The adhesive used to bond the abrasive material to the backing can significantly affect performance. Common types include resin and glue. Resin adhesives are more heat resistant and suitable for high-speed sanding, while glue might be used for lower-speed applications. Understanding adhesive types can help buyers choose products that will last longer in their specific applications.

Tolerance: This refers to the acceptable limits of variation in the dimensions of the sandpaper sheets. Tolerance is critical in industrial applications where precision is paramount. Buyers must ensure that the sandpaper they select meets the required tolerances for their operations.

Durability Rating: This property indicates how long the sandpaper will last under specific conditions. A higher durability rating means the sandpaper can withstand more wear and tear, making it more cost-effective in the long run. Buyers should consider this rating to avoid frequent replacements.

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to sandpaper procurement:

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of sandpaper, buyers may work directly with OEMs to ensure they receive products that meet specific quality standards and specifications.

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory levels and negotiate better terms. Suppliers may set MOQs based on production costs and logistics.

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers asking for pricing information on specific products. This process is crucial for comparing prices and terms among different suppliers, enabling informed purchasing decisions.

Incoterms (International Commercial Terms): Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for buyers importing sandpaper from overseas.

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for planning production schedules and managing supply chains effectively.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing schleifpapier for their operations, ensuring quality and efficiency in their projects.

The schleifpapier holz metall unterschied sector is experiencing significant transformations driven by technological advancements, evolving consumer preferences, and market globalization. Key trends shaping this market include the increasing demand for specialized abrasive products tailored for specific materials, such as wood and metal. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly influenced by the growing emphasis on efficiency and productivity in manufacturing processes. The rise of Industry 4.0 technologies, including automation and data analytics, is enabling suppliers to optimize their offerings, resulting in enhanced performance and cost-effectiveness.

Additionally, the shift towards e-commerce platforms is redefining how buyers source products. Online marketplaces are providing B2B buyers with easier access to diverse suppliers and products, fostering competitive pricing and faster procurement processes. As businesses increasingly seek to streamline their supply chains, partnerships with manufacturers who can provide just-in-time delivery and flexible order quantities are becoming essential.

Moreover, sustainability is emerging as a key driver in sourcing decisions. Buyers are prioritizing suppliers that not only meet quality standards but also adhere to environmentally friendly practices. This trend is particularly pronounced in Europe, where regulatory frameworks are pushing for more sustainable manufacturing practices.

The environmental impact of production processes in the schleifpapier holz metall unterschied sector cannot be overlooked. The use of non-renewable resources, energy-intensive manufacturing methods, and waste generation poses significant challenges. Consequently, ethical sourcing and sustainability have become paramount for international B2B buyers. Companies are now expected to demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that production processes minimize harm to the environment.

Buyers should look for suppliers who hold certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management systems. These certifications not only verify compliance with sustainability standards but also enhance the credibility of suppliers in the eyes of environmentally-conscious buyers.

Furthermore, integrating "green" materials into products, such as recycled abrasives or sustainably sourced substrates, is gaining traction. This not only reduces the carbon footprint but also appeals to a growing segment of consumers who prioritize eco-friendly products. As a result, international B2B buyers should actively seek out suppliers committed to sustainable practices to align with their corporate social responsibility goals.

The evolution of the schleifpapier holz metall unterschied sector has been marked by significant advancements in material science and manufacturing techniques. Initially, abrasive products were predominantly made from natural materials, such as garnet or emery. However, the mid-20th century saw the introduction of synthetic abrasives, which revolutionized the industry by offering greater durability and consistency in performance.

Over the years, innovations such as ceramic and diamond abrasives have emerged, catering to more demanding applications in both wood and metal processing. The increasing complexity of manufacturing processes has led to a diversification of product offerings, allowing for specialized abrasives that cater to specific materials and applications.

Today, the sector continues to evolve, driven by technological advancements and a growing focus on sustainability. This historical context provides international B2B buyers with a deeper understanding of the current landscape and the importance of sourcing from suppliers who are not only innovative but also committed to responsible practices.

How do I choose the right type of Schleifpapier for wood versus metal?

Choosing the right type of Schleifpapier (sandpaper) for wood or metal depends on the material's hardness and the desired finish. For wood, opt for sandpaper with a lower grit (60-120) for coarse sanding and higher grit (180-320) for finishing. For metal, use sandpaper with a higher grit (80-240) to remove rust or smooth surfaces without damaging the metal. Always consider the specific application, as different projects may require varying levels of abrasiveness.

What is the best grit for sanding wood and metal?

The best grit for sanding wood typically ranges from 80 to 220, depending on whether you are rough shaping or finishing. For metal, start with a coarser grit like 80 to remove any scale or rust, then progress to finer grits (120-240) for a smooth finish. Always test the sandpaper on a scrap piece to ensure compatibility with the material you are working on.

What are the key differences between Schleifpapier for wood and metal?

The primary differences between Schleifpapier for wood and metal lie in the materials used and the grit. Wood sandpaper often has a softer backing and is designed to avoid tearing the fibers, while metal sandpaper is typically more durable, featuring a stiffer backing to withstand higher pressure. Additionally, the abrasives used can differ, with metal sandpapers often employing aluminum oxide or silicon carbide for better efficacy on harder surfaces.

How do I vet suppliers for Schleifpapier in international markets?

When vetting suppliers for Schleifpapier, consider their reputation, certifications, and production capabilities. Look for suppliers with experience in your specific market, and request references or case studies. Verify their compliance with international standards and regulations, especially concerning safety and quality control. Conducting a factory visit or requesting samples can also help assess their product quality before placing large orders.

What minimum order quantities (MOQs) should I expect when sourcing Schleifpapier?

Minimum order quantities for Schleifpapier can vary widely depending on the supplier and the type of product. Generally, MOQs can range from 500 to 1,000 units for standard products, while custom products may have higher MOQs due to setup costs. Discuss your needs with potential suppliers to see if they can accommodate smaller orders, especially if you are testing the market or starting a new project.

What payment terms should I negotiate when sourcing Schleifpapier?

When negotiating payment terms, aim for conditions that provide a balance of security and flexibility. Common terms include a 30% upfront deposit with the remainder due upon shipment. Consider using a letter of credit for larger orders to mitigate risk. Ensure all terms are clearly documented in the contract, including currency, payment methods, and any penalties for late payment.

How do I ensure quality assurance (QA) for Schleifpapier purchases?

To ensure quality assurance for Schleifpapier, establish a clear set of specifications and standards with your supplier before production begins. Consider implementing regular quality checks during the manufacturing process, such as in-line inspections. Request samples for testing before full-scale production and consider third-party inspections to verify compliance with your quality standards, especially for international shipments.

What logistics considerations should I keep in mind when importing Schleifpapier?

When importing Schleifpapier, factor in shipping costs, delivery times, and customs regulations. Choose a reliable logistics partner familiar with international shipping to manage the complexities of customs clearance and documentation. Understand the tariffs and taxes applicable to your product in your destination country, and ensure that your supplier can provide the necessary paperwork for a smooth import process. Planning for potential delays due to customs can help mitigate disruptions in your supply chain.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In navigating the complexities of sourcing schleifpapier holz metall unterschied (sandpaper for wood and metal), it is crucial for international B2B buyers to understand the distinct characteristics and applications of each type. Buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must leverage strategic sourcing to optimize their procurement processes. This includes evaluating supplier capabilities, assessing product quality, and considering logistics costs to ensure competitive pricing and timely delivery.

Strategic sourcing not only improves cost efficiency but also enhances supplier relationships, leading to better negotiation outcomes and product innovation. By fostering collaborative partnerships with reliable manufacturers, buyers can ensure they receive the most suitable products tailored to their specific needs, whether for industrial, commercial, or artisanal applications.

As the global market evolves, staying informed about technological advancements and sustainability trends will be essential. International B2B buyers should prioritize suppliers who adopt eco-friendly practices and innovative materials, as these factors will increasingly influence purchasing decisions. Engage proactively with suppliers, attend industry trade shows, and utilize digital platforms to refine your sourcing strategy.

Embrace the opportunities that lie ahead by making informed sourcing decisions today, positioning your business for long-term success in the competitive landscape of sandpaper procurement.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina