In the ever-evolving landscape of industrial materials, sourcing high-quality fused zirconia alumina can present significant challenges for B2B buyers, particularly those operating across diverse markets in Africa, South America, the Middle East, and Europe. As industries increasingly demand materials that combine durability with performance, understanding the nuances of fused zirconia alumina becomes essential. This guide is designed to empower international buyers with the insights needed to navigate the complexities of sourcing this advanced material effectively.

Throughout this comprehensive resource, we will explore various types of fused zirconia alumina, their diverse applications, and the critical factors to consider when vetting suppliers. From understanding cost implications to identifying quality standards, this guide will equip you with the knowledge necessary to make informed purchasing decisions. Whether you are looking to enhance your manufacturing processes or improve product performance, the insights provided herein will serve as a valuable reference.

For buyers in regions like France and Saudi Arabia, where market dynamics differ significantly, recognizing local trends and supplier capabilities is crucial. By leveraging this guide, you will not only streamline your sourcing process but also foster partnerships that drive innovation and efficiency in your operations. Prepare to unlock the full potential of fused zirconia alumina as you enhance your competitive edge in the global market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Zirconia | High toughness and wear resistance; excellent thermal stability | Grinding wheels, refractory materials | Pros: Durable, versatile. Cons: Higher cost. |

| Fused Zirconia Alumina | Combines zirconia’s toughness with alumina’s hardness; better grinding efficiency | Abrasives, cutting tools | Pros: Balanced performance. Cons: Limited availability. |

| Zirconia Toughened Alumina (ZTA) | Enhanced toughness due to zirconia content; suitable for high-stress applications | Advanced ceramics, dental applications | Pros: Superior strength. Cons: More complex processing. |

| Alumina-Zirconia Composite | Tailored properties for specific applications; customizable formulations | Aerospace components, automotive parts | Pros: Tailored performance. Cons: Higher R&D costs. |

| Microcrystalline Zirconia | Fine-grained structure; high wear resistance and toughness | Precision grinding, specialized coatings | Pros: Excellent finish quality. Cons: Higher production costs. |

Fused Zirconia is known for its exceptional toughness and wear resistance, making it a preferred material for high-performance grinding wheels and refractory materials. Its ability to withstand high temperatures without losing structural integrity is critical for industries such as metallurgy and ceramics. Buyers should consider the cost-effectiveness of this material in relation to its longevity and performance in demanding applications.

Fused Zirconia Alumina offers a unique blend of the properties of both zirconia and alumina, providing enhanced grinding efficiency and durability. This type is particularly useful in the manufacturing of abrasives and cutting tools, where performance and longevity are paramount. B2B buyers should evaluate supplier offerings based on the consistency of quality and availability, as this can significantly impact production timelines.

Zirconia Toughened Alumina (ZTA) is engineered for high-stress applications, where additional toughness is required. This composite material is widely used in advanced ceramics and dental applications, providing superior strength and wear resistance. When purchasing ZTA, businesses should consider the complexity of the manufacturing process, as it may lead to increased costs but ultimately offers significant performance benefits.

Alumina-Zirconia Composites allow for the customization of material properties tailored to specific applications, making them ideal for aerospace components and automotive parts. These composites can be designed to meet precise performance criteria, but buyers should be aware that the initial R&D costs can be higher. Evaluating the long-term benefits against upfront costs is crucial for B2B buyers in these sectors.

Microcrystalline Zirconia features a fine-grained structure that contributes to its high wear resistance and toughness, making it suitable for precision grinding and specialized coatings. This material is particularly valued in industries requiring high-quality finishes. However, its production costs can be higher than conventional materials, so buyers must weigh the benefits of enhanced performance against the investment required.

Related Video: Common Abrasive Grain Types: Ceramic Alumina, Zirconia Alumina, Aluminum Oxide - Cascade Abrasives

| Industry/Sector | Specific Application of fused zirconia alumina | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metalworking | Production of high-performance grinding wheels | Enhanced grinding efficiency and tool longevity | Supplier reliability, material certifications, cost |

| Automotive Manufacturing | Abrasives for surface finishing and polishing of automotive parts | Improved surface quality and reduced rework costs | Availability of customized specifications, lead times |

| Aerospace | Coatings for turbine blades and other critical components | Increased operational lifespan and performance | Compliance with industry standards, sourcing location |

| Construction Materials | Additives in concrete and ceramics for enhanced durability | Improved strength and longevity of materials | Consistency in quality, bulk purchasing options |

| Electronics | Abrasives for semiconductor wafer processing | Higher precision and yield in semiconductor production | Technical support, compatibility with existing processes |

In the metalworking industry, fused zirconia alumina is primarily utilized in the manufacture of high-performance grinding wheels. These wheels are essential for precision machining processes, offering enhanced grinding efficiency and tool longevity. International B2B buyers, especially from Africa and South America, should consider the specific hardness and grit size required for their applications to ensure optimal performance. Reliability of suppliers is crucial, as consistent quality can significantly impact production efficiency.

In automotive manufacturing, fused zirconia alumina serves as a critical component in abrasives used for surface finishing and polishing automotive parts. This application is vital for achieving high surface quality, which reduces rework costs and enhances the overall durability of finished products. Buyers from Europe and the Middle East should focus on suppliers who can provide customized specifications to meet stringent industry standards, ensuring compatibility with various manufacturing processes.

Fused zirconia alumina is used in aerospace applications primarily for coatings on turbine blades and other critical components. These coatings provide enhanced durability and resistance to extreme temperatures and wear, significantly increasing the operational lifespan of aircraft parts. For international buyers, particularly in regions like Saudi Arabia and Europe, it is essential to ensure that suppliers comply with aerospace industry standards and can provide necessary certifications, as quality directly influences safety and performance.

In the construction sector, fused zirconia alumina is employed as an additive in concrete and ceramics to improve material durability and strength. This application is particularly beneficial in regions with challenging environmental conditions, where enhanced material performance is crucial. Buyers should prioritize sourcing from suppliers who guarantee consistency in quality and offer bulk purchasing options to manage costs effectively.

Fused zirconia alumina is utilized in the electronics industry for abrasives in semiconductor wafer processing. This application is critical for achieving higher precision and yield in semiconductor production, which is essential for meeting the demands of modern electronic devices. Buyers from South America and Africa should seek suppliers who provide technical support and ensure compatibility with existing processes to optimize production efficiency.

Related Video: Zirconia Production

The Problem:

International B2B buyers often face challenges when sourcing high-quality fused zirconia alumina, particularly due to varying standards across suppliers and regions. Buyers from Africa and South America may struggle with inconsistent product quality, leading to subpar performance in applications such as grinding and polishing. This inconsistency can result in higher operational costs, increased waste, and ultimately, a negative impact on profitability. Furthermore, navigating the supply chain complexities, including import duties and shipping delays, can complicate the purchasing process.

The Solution:

To ensure you source high-quality fused zirconia alumina, start by conducting thorough supplier research. Look for suppliers with established reputations in the industry and verify their certifications, such as ISO 9001, which indicates adherence to quality management systems. Engage in direct communication with potential suppliers to discuss their manufacturing processes and quality control measures. Request samples to evaluate the material's performance firsthand before making bulk purchases.

Additionally, consider establishing long-term relationships with suppliers who can provide consistent quality and support. This may involve negotiating contracts that include quality guarantees and performance benchmarks. Leverage technology to streamline your procurement process, using platforms that offer real-time tracking and updates on shipments to mitigate delays.

The Problem:

Another common pain point for B2B buyers is the challenge of ensuring that the fused zirconia alumina they purchase meets the specific performance requirements of their applications. For instance, users in the Middle East may require materials that withstand high temperatures for metalworking processes. If the wrong specifications are selected, it can lead to equipment failure, increased maintenance costs, and downtime in production.

The Solution:

To address application-specific performance issues, it is crucial to have a clear understanding of the requirements of your processes. Collaborate with your engineering or production teams to define the key characteristics needed from fused zirconia alumina, such as grain size, hardness, and thermal stability.

Consult with suppliers who have expertise in your industry to gain insights into which product formulations will best meet your needs. They can often provide technical data sheets and case studies showcasing how their products perform in similar applications. Furthermore, consider conducting trials with the selected materials under real production conditions to assess performance before full-scale implementation.

The Problem:

Cost management is a significant concern for B2B buyers, especially when purchasing fused zirconia alumina in bulk. Buyers from Europe, for example, may find that fluctuating prices due to market demand and raw material costs can strain budgets. This can be particularly problematic when trying to maintain competitive pricing for end customers while ensuring profitability.

The Solution:

To effectively manage costs, it is essential to adopt a strategic approach to purchasing. Start by analyzing historical price trends and forecasted demand for fused zirconia alumina to make informed purchasing decisions. Consider negotiating bulk purchase agreements with suppliers to lock in prices and minimize the impact of market fluctuations.

Additionally, explore alternative suppliers and materials that may offer better pricing without compromising quality. Conduct a total cost of ownership (TCO) analysis to understand the long-term costs associated with different suppliers, including shipping, handling, and potential downtime from lower-quality materials. This comprehensive approach will help ensure that your purchasing decisions align with both your operational goals and budget constraints.

When selecting materials for fused zirconia alumina in B2B applications, it is crucial to understand the properties, advantages, and limitations of various formulations. Below is a detailed analysis of three common materials used in the production of fused zirconia alumina, focusing on their relevance to international buyers, particularly from Africa, South America, the Middle East, and Europe.

Fused zirconia alumina is a composite material that combines the properties of zirconia and alumina. It exhibits excellent hardness and wear resistance, making it suitable for high-performance applications. Key properties include:

- Temperature Rating: Up to 1,600°C.

- Corrosion Resistance: High resistance to acidic and basic environments.

Pros & Cons:

- Pros: Exceptional durability and thermal stability, making it ideal for abrasive applications.

- Cons: Higher production costs compared to traditional alumina materials.

Impact on Application: FZA is particularly effective in applications requiring high abrasion resistance, such as grinding wheels and cutting tools.

Considerations for International Buyers: Compliance with ASTM and DIN standards is essential, especially for buyers in Europe and the Middle East. Buyers should also consider sourcing from manufacturers that adhere to international quality certifications.

This material blends alumina and zirconia in a specific ratio to enhance toughness and wear resistance. Key properties include:

- Temperature Rating: Up to 1,400°C.

- Corrosion Resistance: Moderate resistance to harsh chemicals.

Pros & Cons:

- Pros: Offers a balanced combination of toughness and hardness, making it versatile for various applications.

- Cons: May not perform as well as pure FZA in extreme conditions.

Impact on Application: Suitable for applications such as ceramic tiles and industrial components that require a combination of strength and wear resistance.

Considerations for International Buyers: Buyers from regions like Africa and South America should assess local supply chains for availability and cost-effectiveness, as well as compliance with local regulations.

ZTA is engineered to improve the toughness of alumina through the inclusion of zirconia. Key properties include:

- Temperature Rating: Up to 1,200°C.

- Corrosion Resistance: Good resistance to wear and thermal shock.

Pros & Cons:

- Pros: Enhanced toughness and thermal shock resistance, making it suitable for dynamic applications.

- Cons: Can be more expensive due to the additional zirconia content.

Impact on Application: Ideal for applications in the aerospace and automotive industries where materials must withstand high stress and temperature variations.

Considerations for International Buyers: European buyers, particularly in France, should ensure that suppliers meet stringent environmental and safety regulations.

| Material | Typical Use Case for fused zirconia alumina | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused Zirconia Alumina (FZA) | Grinding wheels, cutting tools | Exceptional durability and thermal stability | Higher production costs | High |

| Alumina-Zirconia Composite | Ceramic tiles, industrial components | Balanced toughness and hardness | Moderate performance in extreme conditions | Medium |

| Zirconia Toughened Alumina (ZTA) | Aerospace, automotive applications | Enhanced toughness and thermal shock resistance | Higher cost due to zirconia content | High |

This strategic material selection guide provides a comprehensive overview of the key materials used in fused zirconia alumina applications. By understanding these properties and considerations, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

The manufacturing of fused zirconia alumina involves several critical stages that ensure the final product meets the required specifications for various applications, particularly in the abrasive and refractory industries. Understanding these processes can help international B2B buyers from Africa, South America, the Middle East, and Europe make informed purchasing decisions.

The first step in the manufacturing process is the preparation of raw materials. Fused zirconia alumina is primarily produced from a mix of zirconium oxide (ZrO₂) and aluminum oxide (Al₂O₃). This blend is crucial for achieving the desired properties of the final product, such as hardness and thermal stability.

Material Sourcing: Reliable sourcing of high-quality raw materials is essential. Buyers should ensure that suppliers provide materials compliant with international standards to maintain product consistency.

Mixing: The raw materials are carefully weighed and mixed. The ratio of zirconia to alumina can significantly influence the performance characteristics of the fused product.

Granulation: The mixed material is granulated to enhance flow characteristics and ensure uniform particle size, which is vital for the subsequent melting process.

Once the materials are prepared, the next stage involves forming and melting:

Melting: The granulated mixture is subjected to high-temperature melting in electric arc furnaces. Temperatures can reach up to 2000°C, enabling the materials to fuse together. The melting process is crucial for achieving the desired microstructure and properties.

Casting: After melting, the molten material is poured into molds to form ingots or blocks. This step requires precise control to prevent defects such as air inclusions or uneven surfaces.

Cooling: The cast material is cooled gradually to prevent thermal shock, which could lead to cracking. Controlled cooling rates are essential to maintain the integrity of the material.

Finishing processes are crucial for achieving the desired surface quality and dimensions:

Grinding: The cooled ingots are ground to achieve specific sizes and surface finishes. This step may involve multiple stages of grinding, using different abrasive materials to achieve finer finishes.

Polishing: In some applications, additional polishing may be required to enhance the aesthetic quality of the product or to meet specific functional requirements.

Packaging: Finally, the finished product is packaged according to international shipping standards, ensuring protection during transit.

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final product meets industry standards and customer expectations. For international B2B buyers, understanding these measures is crucial for verifying the quality of their suppliers.

Fused zirconia alumina manufacturers must adhere to various international standards to ensure product quality:

ISO 9001: This standard outlines the requirements for a quality management system (QMS). Suppliers certified to ISO 9001 demonstrate their commitment to quality and continuous improvement.

CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

API Standards: In specific industries, such as oil and gas, compliance with API standards is necessary, particularly for products used in critical applications.

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure that defects are identified and rectified promptly:

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify compliance with specifications.

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the quality of the product at various stages, including melting and casting.

Final Quality Control (FQC): After finishing, a comprehensive inspection is conducted to ensure that the final product meets all specifications before it is shipped.

Several testing methods are utilized to verify the quality and performance of fused zirconia alumina:

Physical Testing: This includes hardness tests, density measurements, and thermal conductivity assessments to ensure the material meets performance criteria.

Chemical Analysis: X-ray fluorescence (XRF) and other analytical techniques are used to determine the chemical composition of the product, ensuring it meets the specified ratios of zirconia and alumina.

Microstructural Analysis: Scanning electron microscopy (SEM) may be employed to examine the microstructure of the material, identifying any potential defects or inconsistencies.

For international buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for minimizing risk:

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control systems, and adherence to international standards.

Requesting Quality Reports: Buyers should request comprehensive quality reports that detail the results of various tests and inspections conducted throughout the manufacturing process.

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of the supplier’s quality control practices and product quality.

Navigating the nuances of quality control and certification can be challenging for B2B buyers operating in different regions:

Understanding Regional Standards: Buyers must familiarize themselves with regional standards and regulations that may impact product specifications and certifications.

Building Relationships: Establishing strong relationships with suppliers can facilitate better communication regarding quality standards and expectations.

Leveraging Technology: Utilizing digital platforms for tracking and verifying compliance can streamline the quality assurance process and provide real-time insights into supplier performance.

By understanding the manufacturing processes and quality assurance measures associated with fused zirconia alumina, B2B buyers can make more informed decisions, ensuring they source high-quality products that meet their specific needs.

To effectively source fused zirconia alumina, international B2B buyers must follow a systematic approach that ensures quality, cost-effectiveness, and reliability. This practical sourcing guide serves as a checklist to help you navigate the complexities of procurement in this specialized market.

Clearly outlining your technical requirements is the first step in sourcing fused zirconia alumina. Consider factors such as grain size, purity levels, and intended applications, as these will directly impact performance in your specific use case. Having precise specifications helps suppliers understand your needs and reduces the risk of receiving subpar products.

Conduct thorough research to identify suppliers with a strong reputation in the fused zirconia alumina market. Utilize industry directories, trade shows, and online platforms to compile a list of potential candidates. Focus on suppliers who have experience serving your region, such as Africa, South America, the Middle East, or Europe, as they will be more familiar with local regulations and market conditions.

Before entering into agreements, it’s crucial to verify the certifications and compliance of potential suppliers. Look for industry-specific standards such as ISO certifications, which indicate a commitment to quality management systems. Additionally, inquire about any environmental or safety certifications that may be relevant to your industry, ensuring that your supplier aligns with your corporate social responsibility goals.

Once you have shortlisted suppliers, request samples of their fused zirconia alumina products. Testing samples allows you to evaluate the material's performance, consistency, and compatibility with your application. Pay attention to factors such as hardness, wear resistance, and thermal stability to ensure the product meets your specifications.

Evaluate the pricing structures of your shortlisted suppliers, keeping in mind that the lowest price may not always reflect the best value. Consider total cost of ownership, which includes shipping, customs duties, and potential delays. Additionally, negotiate payment terms that are favorable for your cash flow, such as net 30 or net 60 days.

Before finalizing your supplier choice, ask for references and case studies from previous clients. This information provides insights into the supplier’s reliability, customer service, and ability to meet deadlines. Engaging with other buyers can reveal potential red flags and confirm the supplier’s reputation in the market.

Once you select a supplier, establish clear communication protocols to facilitate ongoing discussions and feedback. Regular updates regarding production timelines, shipment schedules, and any potential issues will help maintain a strong working relationship. Consider utilizing digital tools for effective communication, especially when dealing with international suppliers across different time zones.

By following this checklist, B2B buyers can streamline their procurement process for fused zirconia alumina, ensuring they make informed decisions that lead to successful sourcing outcomes.

When sourcing fused zirconia alumina, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The cost of raw materials plays a significant role in pricing. Fused zirconia alumina is typically derived from high-purity zirconium oxide and alumina, and fluctuations in the price of these raw materials can directly impact overall costs.

Labor: Labor costs vary based on the region and the skill level required for processing. In regions like Europe and the Middle East, labor costs may be higher compared to some African and South American countries, affecting the final price.

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can help reduce these overheads, impacting pricing.

Tooling: If custom tooling is required for specific applications or specifications, this can add to the initial cost. It's important to factor in these expenses when negotiating contracts.

Quality Control (QC): Implementing rigorous quality control processes ensures product reliability but adds to the overall cost. Certifications like ISO can enhance product credibility but may also increase expenses.

Logistics: Transportation and warehousing costs are critical, especially for international shipments. Factors such as distance, shipping methods, and customs duties can significantly influence total costs.

Margin: Suppliers typically apply a profit margin on top of their costs, which can vary widely depending on the supplier’s market position and the competitive landscape.

Several factors influence the pricing of fused zirconia alumina, making it essential for buyers to understand these dynamics:

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Understanding the minimum order quantities (MOQ) can help in negotiating better prices.

Specifications and Customization: Customized products that meet specific client requirements may carry higher costs. Buyers should clearly define their specifications to avoid unexpected price hikes.

Quality and Certifications: Higher quality materials and certifications such as ASTM or ISO standards can result in increased costs. However, these often justify the investment through enhanced performance and reliability.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium but often provide better quality assurance and service.

Incoterms: Understanding Incoterms is vital for determining who bears the costs and risks during shipping. Different terms can significantly affect the total landed cost of the product.

To maximize value when sourcing fused zirconia alumina, consider the following strategies:

Conduct a Total Cost of Ownership Analysis: Assess not just the purchase price but all associated costs, including shipping, customs, and potential delays. This comprehensive view will help you make informed decisions.

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and negotiate bulk pricing. Suppliers are often more willing to provide discounts for larger orders.

Build Long-term Relationships: Establishing a good rapport with suppliers can lead to better terms and pricing over time. Loyalty can be rewarded with preferential pricing or faster turnaround times.

Stay Informed on Market Trends: Keeping abreast of changes in raw material prices and market conditions can provide leverage during negotiations. Knowledge is a powerful tool in securing favorable deals.

Consider Alternative Suppliers: Don’t hesitate to explore multiple suppliers. Comparing quotes can provide insights into market rates and help identify the best value.

Prices for fused zirconia alumina can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

When considering materials for industrial applications, particularly in abrasive and cutting tools, it's essential to evaluate the alternatives to fused zirconia alumina. This analysis provides insights into how fused zirconia alumina compares against other viable solutions, helping international B2B buyers make informed decisions.

| Comparison Aspect | Fused Zirconia Alumina | Alternative 1: Aluminum Oxide | Alternative 2: Silicon Carbide |

|---|---|---|---|

| Performance | High durability and toughness | Good hardness but lower toughness | Excellent hardness, moderate toughness |

| Cost | Moderate | Generally lower | Higher initial investment |

| Ease of Implementation | Requires specialized equipment | Widely available and easy to source | Requires specialized handling |

| Maintenance | Low maintenance needs | Moderate maintenance | Low maintenance but requires careful handling |

| Best Use Case | Heavy-duty applications | General-purpose applications | High-performance cutting tools |

Aluminum oxide, also known as alumina, is a widely used abrasive material that offers several advantages. It is typically lower in cost than fused zirconia alumina, making it an attractive option for general-purpose applications. Additionally, its availability makes it easy to source for various industrial needs. However, while aluminum oxide provides good hardness, it lacks the superior toughness and durability of fused zirconia alumina, which can lead to more frequent replacements in demanding applications. Therefore, aluminum oxide is best suited for less intensive tasks.

Silicon carbide is another alternative that boasts exceptional hardness and is often used in high-performance applications, such as cutting tools for metals and ceramics. It can withstand high temperatures and is particularly effective in applications that require aggressive cutting action. However, the initial investment for silicon carbide can be higher compared to fused zirconia alumina. Additionally, while it has low maintenance requirements, the handling of silicon carbide requires care due to its brittleness, making it less user-friendly in certain scenarios. Thus, silicon carbide is ideal for specialized applications demanding high performance.

When selecting the appropriate abrasive material, international B2B buyers should assess their specific application requirements, including performance expectations, budget constraints, and ease of sourcing. Fused zirconia alumina is an excellent choice for heavy-duty tasks where durability is paramount. In contrast, aluminum oxide may be more suitable for general-purpose use with lower cost implications, while silicon carbide should be considered for high-performance applications despite its higher initial investment. By carefully evaluating these factors, businesses from Africa, South America, the Middle East, and Europe can make informed decisions that align with their operational needs and cost structures.

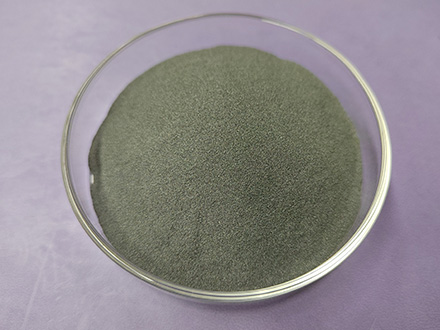

A stock image related to fused zirconia alumina.

Fused zirconia alumina is recognized for its exceptional performance in various industrial applications, particularly in grinding and abrasive processes. Understanding its technical properties is crucial for B2B buyers who need reliable materials for manufacturing.

Material Grade

The grade of fused zirconia alumina indicates its composition and quality. Higher-grade materials typically offer enhanced durability and performance, making them suitable for demanding applications. Buyers should assess the grade to ensure it meets their specific operational requirements.

Grain Size

The grain size of fused zirconia alumina directly affects its cutting performance and finish quality. Finer grains provide a smoother finish but may wear out faster, while coarser grains offer quicker material removal. Understanding the optimal grain size for your application can help improve efficiency and product quality.

Hardness

Hardness is a critical property that defines the material's resistance to wear and abrasion. Fused zirconia alumina is known for its high hardness, making it ideal for use in grinding wheels and cutting tools. B2B buyers should consider hardness ratings when selecting materials for high-wear environments.

Toughness

Toughness refers to the material's ability to withstand impact and stress without fracturing. This property is particularly important in applications involving heavy machinery or high-speed operations. Buyers should prioritize toughness to ensure the longevity and reliability of their products.

Thermal Stability

Fused zirconia alumina exhibits excellent thermal stability, maintaining its properties under high temperatures. This makes it suitable for applications in environments where heat resistance is critical. Understanding thermal stability can help buyers select appropriate materials for specialized applications.

Being familiar with industry terminology is essential for effective communication and negotiation in the B2B landscape.

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications can help buyers ensure compatibility and quality in their purchases.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for buyers to know, as it can affect purchasing decisions and inventory management. Buyers should negotiate MOQs based on their needs and market demand.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process helps buyers compare offers and make informed purchasing decisions. Knowing how to craft an effective RFQ can streamline procurement.

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and delivery responsibilities.

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is essential for effective inventory management and planning. Buyers should discuss lead times with suppliers to align their production schedules.

Certification

Certification refers to the process of verifying that a product meets specific industry standards. Many B2B buyers seek certified materials to ensure quality and compliance with regulations. Understanding certification requirements can help buyers avoid potential legal and operational issues.

By mastering the technical properties and trade terminology associated with fused zirconia alumina, international B2B buyers can make informed decisions that enhance their operational efficiency and product quality.

The global fused zirconia alumina market is witnessing significant growth, driven by increasing demand across various industries, including abrasives, ceramics, and refractories. Key market dynamics include technological advancements, rising investments in manufacturing capabilities, and a shift towards high-performance materials. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing decisions.

Emerging trends such as digital transformation in supply chains and the adoption of Industry 4.0 technologies are reshaping how businesses operate. Automation, data analytics, and the Internet of Things (IoT) are enhancing operational efficiencies and reducing costs. Buyers should focus on suppliers who leverage these technologies for better transparency and reliability in their sourcing processes. Furthermore, the increasing preference for customized solutions among manufacturers is leading to innovations in product offerings, which can provide competitive advantages for businesses willing to adapt quickly.

Sustainability is a significant concern for B2B buyers today, particularly in regions like Europe where environmental regulations are stringent. The production of fused zirconia alumina has environmental implications, including energy consumption and waste generation. Therefore, buyers are increasingly looking for suppliers that prioritize ethical sourcing and sustainable practices.

Ethical supply chains are essential not only for compliance but also for enhancing brand reputation and customer loyalty. Buyers should seek suppliers who possess certifications such as ISO 14001, which indicates a commitment to environmental management. Furthermore, the availability of 'green' materials that minimize environmental impact is becoming a decisive factor in the sourcing process. Suppliers offering recycled or eco-friendly alternatives can meet the growing demand for sustainable solutions, making them more attractive partners for international buyers.

Fused zirconia alumina has evolved significantly since its introduction in the mid-20th century. Initially developed for industrial applications, it has become essential in various sectors due to its exceptional properties, including high hardness and thermal stability. Over the years, advancements in production technologies have improved the material's performance and versatility, making it suitable for applications ranging from grinding wheels to advanced ceramics.

As markets continue to globalize, the significance of fused zirconia alumina as a high-performance material will only increase, reinforcing its position as a critical component in modern manufacturing and industrial processes. Understanding its evolution can help B2B buyers appreciate the value and potential of this material in their sourcing strategies.

How do I identify high-quality suppliers of fused zirconia alumina?

To identify high-quality suppliers, begin by researching manufacturers with a strong reputation in the industry. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Attend trade shows and exhibitions to meet suppliers face-to-face and evaluate their products. Additionally, request samples to assess the quality of the fused zirconia alumina. Online platforms like Alibaba and industry-specific directories can also provide insights and ratings from other buyers.

What is the best application for fused zirconia alumina in industrial processes?

Fused zirconia alumina is best suited for applications requiring high durability and resistance to wear, such as abrasive materials in grinding wheels and cutting tools. Its unique composition provides superior performance in harsh environments, making it ideal for industries like metalworking, aerospace, and automotive. When selecting a product, consider the specific requirements of your application, including the type of material being processed and the expected operational conditions.

What are the minimum order quantities (MOQ) for fused zirconia alumina?

Minimum order quantities (MOQ) for fused zirconia alumina can vary significantly depending on the supplier and the product specifications. Typically, MOQs range from 100 kg to several tons. It is advisable to negotiate with suppliers, especially if you are a smaller buyer or if you are testing new applications. Some suppliers may offer lower MOQs for trial orders or initial shipments to establish a business relationship.

What payment terms should I expect when sourcing fused zirconia alumina internationally?

Payment terms can vary widely among suppliers and regions. Common terms include a 30% deposit upfront with the balance due upon delivery or a letter of credit. For international transactions, consider using secure payment methods such as PayPal or escrow services to protect your interests. Always clarify payment terms in your contract to avoid disputes and ensure timely delivery of products.

How can I ensure quality assurance (QA) in my order of fused zirconia alumina?

To ensure quality assurance, work with suppliers who offer comprehensive QA processes, including material testing and certification. Request detailed product specifications and quality control reports before finalizing your order. Additionally, consider conducting third-party inspections or audits of the manufacturing facility. Establishing clear communication with the supplier about your quality expectations will also help ensure that the delivered products meet your standards.

A stock image related to fused zirconia alumina.

What logistics considerations should I be aware of when importing fused zirconia alumina?

When importing fused zirconia alumina, consider shipping methods, customs regulations, and potential tariffs specific to your region. Choose a logistics partner experienced in handling industrial materials to navigate these complexities effectively. Ensure that your supplier provides all necessary documentation, such as customs declarations and certificates of origin, to facilitate smooth clearance. Lastly, plan for potential delays in transit and factor these into your supply chain management.

How do I customize my order of fused zirconia alumina for specific applications?

Customizing your order typically involves discussing your specific requirements with the supplier. This may include adjusting the particle size, composition, or packaging of the fused zirconia alumina. Engage in detailed discussions about the performance characteristics you need, such as hardness or thermal stability. Some suppliers may offer tailored solutions or blends to meet your application needs, so be sure to explore these options during the sourcing process.

What are the common challenges faced by B2B buyers of fused zirconia alumina?

Common challenges include navigating supplier reliability, fluctuating prices, and quality inconsistencies. Buyers may also face difficulties in understanding technical specifications and ensuring compliance with local regulations. To mitigate these challenges, conduct thorough due diligence on suppliers, maintain open lines of communication, and establish clear contracts that outline expectations. Leveraging industry networks for recommendations can also help in finding trustworthy partners.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, strategic sourcing of fused zirconia alumina is essential for international B2B buyers seeking to enhance their operational efficiency and product quality. By understanding the unique properties and applications of fused zirconia alumina, businesses can make informed decisions that lead to improved performance in abrasive and refractory markets. Key takeaways include the importance of supplier reliability, the need for quality assurance, and the advantages of leveraging local and international market dynamics to optimize costs.

As the demand for high-performance materials continues to grow, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing will play a pivotal role in maintaining a competitive edge. Buyers should focus on building strong relationships with suppliers, investing in research and development, and staying abreast of technological advancements in material science.

Looking ahead, it is crucial for international B2B buyers to actively engage in market analysis and networking opportunities to identify emerging trends and technologies in the fused zirconia alumina space. By doing so, they can ensure they are well-positioned to capitalize on new opportunities and drive sustainable growth in their respective industries. Embrace strategic sourcing today to unlock the full potential of your operations.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina