The global demand for silicon carbide (SiC) grit continues to surge, driven by its unparalleled hardness, thermal stability, and versatility across industrial applications. For B2B buyers in sectors such as abrasives manufacturing, electronics, automotive, and refractory materials, sourcing high-quality SiC grit is critical to maintaining competitive advantage and product excellence. This guide is designed to equip international buyers—particularly those from Africa, South America, the Middle East, and Europe—with the insights needed to navigate the complex global supply landscape confidently.

Understanding the nuances of SiC grit—from its various types and raw materials to manufacturing processes and quality control standards—is essential for making informed procurement decisions. Additionally, evaluating suppliers across different regions requires a keen awareness of market dynamics, cost structures, and logistical considerations. This comprehensive guide covers all these dimensions, including detailed analyses of SiC grit classifications, production technologies, key global suppliers, pricing trends, and answers to frequently asked questions.

By leveraging this resource, international buyers will gain a strategic edge in selecting reliable partners, optimizing cost-efficiency, and ensuring consistent product quality. Whether you are sourcing for abrasive applications in the UK, refractory solutions in Egypt, or advanced electronics manufacturing in Brazil, this guide empowers you to make decisions grounded in data and industry expertise. Ultimately, it supports your goal of securing premium SiC grit that aligns with your operational needs and market demands, fostering sustainable growth and long-term success in a competitive global marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Silicon Carbide | Manufactured by fusing silica and carbon at high temperatures; angular, sharp-edged particles | High-performance grinding, cutting tools, abrasive blasting | Pros: High hardness and thermal conductivity; durable Cons: Higher cost; may be over-specified for light-duty tasks |

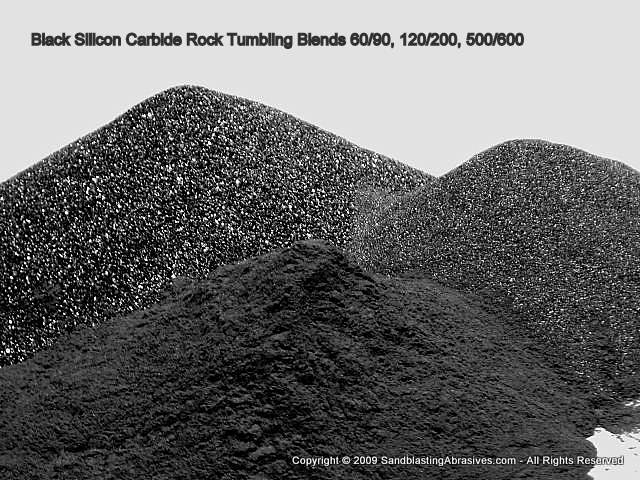

| Black Silicon Carbide | Dark, fine-grained with high purity and hardness | Precision grinding, polishing, and lapping | Pros: Excellent for fine finishing; cost-effective Cons: Brittle; less suited for heavy-duty grinding |

| Green Silicon Carbide | High purity, greenish tint, finer grain size | Polishing optical glass, semiconductors, ceramics | Pros: Superior polishing quality; suitable for delicate surfaces Cons: More expensive; limited bulk abrasive use |

| Coated Silicon Carbide | Silicon carbide grit bonded to substrates like paper or cloth | Sandpaper, abrasive belts, and discs | Pros: Versatile for surface preparation; easy to handle Cons: Limited lifespan; not suitable for high-temperature applications |

| Recycled Silicon Carbide | Produced from reclaimed silicon carbide waste | Cost-sensitive abrasive blasting, lower precision grinding | Pros: Cost-effective; eco-friendly Cons: Variable quality; inconsistent grit size distribution |

Fused Silicon Carbide is prized for its extreme hardness and thermal conductivity, making it ideal for heavy-duty grinding and cutting applications in industries such as metal fabrication and automotive manufacturing. Buyers should consider its higher price point relative to other types but balance this against its durability and performance in demanding environments. For businesses in regions with high industrial activity like South Africa or Germany, investing in fused SiC can enhance operational efficiency and tool lifespan.

Black Silicon Carbide is a versatile abrasive favored for precision grinding and polishing due to its fine grain and high purity. Its brittleness means it performs best in applications requiring fine finishes rather than aggressive material removal. This type is suitable for electronics manufacturing and fine metalworking sectors prevalent in markets like the UK and Brazil. Buyers should evaluate the trade-off between cost-effectiveness and application-specific suitability.

Green Silicon Carbide stands out for its superior polishing capabilities, especially on delicate materials such as optical glass, ceramics, and semiconductors. Its higher cost is justified by the quality of finish it delivers, making it essential for high-tech industries in Europe and the Middle East. When purchasing, businesses should verify the purity levels and grain size to ensure optimal results for sensitive surface treatments.

Coated Silicon Carbide abrasives are silicon carbide particles bonded to flexible substrates, widely used in surface preparation tasks like sanding and finishing. Their ease of use and adaptability make them popular in woodworking, automotive refinishing, and metal surface treatment. However, buyers should be aware of their limited lifespan and avoid using them in high-temperature environments common in heavy industry.

Recycled Silicon Carbide offers an environmentally friendly and cost-effective option by repurposing silicon carbide waste. While suitable for abrasive blasting and less precision-demanding grinding, its inconsistent grit size and quality can affect performance. This variation is attractive to cost-conscious buyers in emerging markets or sectors prioritizing sustainability, such as construction and basic manufacturing in Africa and South America. Proper quality control is essential to ensure consistent supply.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of sic grit | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives Manufacturing | Production of grinding wheels and sandpapers | High durability and precision in abrasive products | Consistent grit size, purity, and supply reliability |

| Metallurgy & Foundries | Surface preparation for metal casting molds | Enhances mold lifespan and improves metal surface finish | Thermal stability and grit hardness to withstand high-temperature use |

| Electronics & Semiconductors | Polishing silicon wafers and electronic components | Achieves ultra-smooth surfaces critical for device performance | Ultra-fine grit grades, contamination-free sourcing |

| Automotive & Aerospace | Component finishing and deburring | Improves part longevity and performance | Uniform grit distribution and compliance with industry standards |

| Construction & Ceramics | Cutting and grinding of tiles and refractory materials | High wear resistance and cost efficiency | Bulk availability and compatibility with local machinery |

In abrasives manufacturing, SiC grit is essential for producing high-performance grinding wheels and sandpapers. Its exceptional hardness and sharp edges enable manufacturers to create abrasive products that maintain cutting efficiency over extended use. For B2B buyers in Africa, South America, the Middle East, and Europe, ensuring consistent grit size and purity is crucial to maintain product quality. Reliable supply chains and certifications for material quality are also key, especially for businesses aiming to penetrate competitive markets like the UK or Egypt.

SiC grit plays a vital role in surface preparation of metal casting molds, where it is used for sandblasting and mold finishing. The grit’s thermal stability and hardness help extend mold life and improve the surface quality of cast metals, reducing defects and rework. Buyers in regions with heavy metal industries, such as South America and the Middle East, should prioritize suppliers offering high-grade SiC grit that can withstand extreme temperatures and abrasive conditions, ensuring consistent performance and cost-effectiveness.

In electronics manufacturing, SiC grit is used for polishing silicon wafers and delicate components to achieve ultra-smooth, defect-free surfaces. This is critical for device efficiency and reliability. International buyers, particularly in Europe and the Middle East, must source ultra-fine, contamination-free SiC grit to meet stringent industry standards. Attention to particle size distribution and trace impurities is essential to avoid damaging sensitive semiconductor materials.

The automotive and aerospace sectors utilize SiC grit for component finishing and deburring, which enhances part durability and operational performance. Uniform grit distribution ensures smooth surface finishes that meet rigorous quality standards. Buyers from these industries in Africa and Europe should focus on suppliers who provide SiC grit compliant with automotive and aerospace certifications, ensuring reliability and safety in critical applications.

SiC grit is widely used in cutting and grinding tiles, refractory bricks, and other construction materials due to its high wear resistance. It offers cost efficiency by reducing tool wear and improving cutting speed. For B2B buyers in regions with growing construction sectors such as Africa and South America, sourcing bulk quantities of SiC grit compatible with local cutting machinery is important to optimize operational costs and maintain steady project timelines.

Related Video: Grit Blasting process Vs Sand Blasting process, Types of Grit Blasting abrasive materials

Key Properties: Black SiC is characterized by high hardness (Mohs scale ~9-9.5), excellent thermal conductivity, and good chemical inertness. It withstands temperatures up to 1600°C and exhibits strong resistance to oxidation and corrosion under normal industrial conditions.

Pros & Cons:

- Pros: Exceptional durability and sharpness make it ideal for aggressive grinding and cutting applications. It is cost-effective compared to other high-performance abrasives.

- Cons: Manufacturing complexity is moderate; however, it is less suitable for machining ferrous metals due to chemical reactivity that can cause premature wear.

Impact on Application: Black SiC grit is preferred in abrasive blasting, grinding of non-ferrous metals, ceramics, and glass. Its thermal stability supports high-speed operations without degradation.

International B2B Considerations: Buyers in Africa and South America often prioritize cost-efficiency, making Black SiC a popular choice. Compliance with ASTM B74 and DIN 66146 standards ensures quality consistency. European markets, including the UK, demand adherence to stringent purity and grain size distribution specifications, while Middle Eastern buyers focus on supply chain reliability and certification for industrial safety standards.

Key Properties: Green SiC is purer and harder than black SiC, with a higher melting point (~2700°C) and superior abrasion resistance. It offers excellent thermal shock resistance and chemical stability, particularly in acidic and alkaline environments.

Pros & Cons:

- Pros: Ideal for precision grinding and polishing of hard materials such as tungsten carbide and ceramics. Its sharpness and durability extend tool life.

- Cons: Higher production costs and limited availability can affect pricing. It is more brittle, requiring careful handling during manufacturing.

Impact on Application: Green SiC is favored in high-precision industries like aerospace and electronics, where surface finish quality is critical. It performs well in chemical-mechanical polishing and high-temperature environments.

International B2B Considerations: In Europe and the UK, green SiC meets JIS and ISO standards, which are often prerequisites for aerospace and automotive sectors. Buyers in the Middle East and Africa should verify supplier certifications and consider logistics for timely delivery due to its specialized nature. South American industries may face import tariffs that influence cost-effectiveness.

Key Properties: Produced by reclaiming SiC from industrial waste, recycled SiC offers moderate hardness and thermal resistance. Its properties can vary based on the source material and recycling process.

Pros & Cons:

- Pros: Environmentally sustainable and significantly lower cost. Suitable for less demanding abrasive applications.

- Cons: Variability in grit size and purity may affect performance consistency. Not recommended for high-precision or critical applications.

Impact on Application: Commonly used in construction, sandblasting, and surface preparation where high precision is not mandatory. It supports green manufacturing initiatives.

International B2B Considerations: African and South American buyers increasingly seek recycled materials to align with sustainability goals and reduce costs. Compliance with environmental regulations such as REACH (Europe) and local standards is essential. Buyers must ensure suppliers provide detailed quality assurance reports to mitigate risks associated with variability.

Key Properties: This variant involves SiC grit embedded in ceramic matrices, enhancing mechanical strength and thermal resistance beyond standalone SiC particles.

Pros & Cons:

- Pros: Superior durability and resistance to wear in extreme conditions. Suitable for high-pressure and high-temperature applications.

- Cons: Higher manufacturing complexity and cost. Less versatile for general-purpose use.

Impact on Application: Ideal for heavy-duty grinding wheels, cutting tools, and abrasive belts used in metalworking and stone processing industries.

International B2B Considerations: European and Middle Eastern buyers often require compliance with DIN and ISO standards for bonded abrasives. The UK market demands traceability and certifications for industrial safety. African and South American buyers should evaluate total cost of ownership, considering longer tool life versus upfront investment.

| Material | Typical Use Case for sic grit | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Black Silicon Carbide (B-SiC) | Abrasive blasting, grinding non-ferrous metals | High durability and cost-effective | Less suitable for ferrous metals | Low |

| Green Silicon Carbide (G-SiC) | Precision grinding, polishing hard materials | Superior hardness and thermal stability | Higher cost and brittleness | High |

| Recycled Silicon Carbide | Construction, sandblasting, surface prep | Environmentally sustainable and low cost | Variable quality and less precision | Low |

| Ceramic-Bonded SiC Grit | Heavy-duty grinding wheels, cutting tools | Enhanced strength and wear resistance | Complex manufacturing and higher price | Medium |

Silicon Carbide (SiC) grit is a critical abrasive material used across various industrial applications, including grinding, polishing, and cutting. For international B2B buyers, understanding the manufacturing process is essential to assess product quality and supplier reliability. The production of SiC grit involves several key stages, each impacting the final grit properties such as particle size, hardness, and purity.

The manufacturing begins with sourcing raw materials, primarily high-purity silica sand and carbonaceous materials like petroleum coke or coal tar pitch. These materials are carefully weighed and mixed in precise ratios to ensure consistent chemical composition. The mixture is then formed into green bodies or briquettes, which act as the feedstock for the high-temperature synthesis process.

The core manufacturing step is the Acheson process, where the prepared mixture is placed in an electric resistance furnace. Temperatures reach approximately 2,500°C, facilitating a chemical reaction between silica and carbon to produce silicon carbide crystals. This step largely determines the grit’s crystalline structure and abrasive properties.

Once cooled, the solid SiC blocks are mechanically crushed and milled into smaller particles. This stage includes classification by size using sieves or air classifiers to produce various grit sizes suited for different industrial applications. Precise control during this phase ensures uniform particle size distribution, which is crucial for consistent abrasive performance.

The final stage involves surface treatments such as washing to remove impurities and drying to achieve optimal moisture content. The grit may also undergo additional grading and blending to meet specific customer requirements. Proper packaging ensures protection against contamination and moisture during transport and storage.

Quality assurance (QA) and quality control (QC) are paramount in manufacturing SiC grit due to its critical role in high-precision industrial processes. International buyers must evaluate supplier QC rigor to mitigate risks related to product inconsistency or non-compliance with industry standards.

For international B2B buyers sourcing SiC grit, a comprehensive understanding of the manufacturing stages—from raw material preparation to final packaging—is vital. Equally important is the supplier’s adherence to stringent quality control practices governed by international and regional standards. Buyers should actively engage in verifying QC measures through documentation review, audits, and third-party testing. Tailoring these approaches to regional regulatory landscapes ensures procurement of high-quality SiC grit that meets application-specific demands and compliance requirements.

Illustrative Image (Source: Google Search)

Understanding the cost structure behind silicon carbide (SiC) grit is crucial for B2B buyers seeking competitive pricing without compromising quality. The main cost components include:

Several factors directly influence SiC grit pricing, and understanding these can empower buyers to negotiate better deals:

For buyers in Africa, South America, the Middle East, and Europe, navigating the complexities of SiC grit pricing requires a strategic approach:

Prices for silicon carbide grit vary widely depending on grade, quantity, supplier, and global market conditions. The information provided here is indicative and should be used as a guide rather than an exact quotation. Buyers are encouraged to request detailed quotes and conduct supplier audits to ensure competitive and transparent pricing aligned with their specific needs.

Understanding the critical technical properties and trade terminology associated with silicon carbide (SiC) grit is essential for international B2B buyers to make informed purchasing decisions. This knowledge helps ensure product suitability, optimizes supply chain communication, and mitigates risks in cross-border transactions.

Illustrative Image (Source: Google Search)

1. Material Grade

SiC grit is available in different grades, typically distinguished by purity levels and crystalline structure (e.g., alpha and beta phases). Higher-grade SiC offers greater hardness and thermal stability, which is crucial for applications such as abrasive blasting, grinding, and polishing. Buyers should specify the grade to match their performance requirements and avoid product mismatches.

2. Particle Size and Distribution (Mesh Size)

Particle size is commonly expressed in mesh numbers, indicating the grit’s fineness or coarseness. For instance, a 60 mesh grit is coarser than a 220 mesh grit. Uniform particle size distribution ensures consistent abrasion and surface finish. Specifying the correct mesh size is vital for processes like sandblasting or precision grinding, directly impacting product quality and operational efficiency.

3. Hardness

Measured on the Mohs scale, SiC grit hardness typically ranges around 9-9.5, making it one of the hardest abrasive materials. Hardness affects cutting speed and durability. For buyers, understanding hardness helps in selecting grit that balances performance with equipment wear and energy consumption.

4. Tolerance and Purity

Tolerance refers to the allowable variation in particle size or composition. Purity indicates the percentage of silicon carbide versus impurities or binders. Tight tolerances and high purity are critical for industries such as electronics or automotive manufacturing, where consistency and material integrity affect end-product reliability.

5. Bulk Density

This property describes the mass of grit per unit volume, influencing packaging, shipping costs, and handling. Buyers should consider bulk density to optimize logistics and storage, especially for large-scale orders.

1. OEM (Original Equipment Manufacturer)

In B2B contexts, OEM refers to companies that produce parts or products that may incorporate SiC grit as a component. Understanding OEM requirements helps buyers tailor specifications and certifications, ensuring compatibility with client manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity a supplier is willing to sell. For international buyers, negotiating MOQ is critical to balance inventory costs with demand forecasts, especially when testing new suppliers or entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers to obtain detailed pricing and terms for specific quantities and specifications of SiC grit. Crafting precise RFQs with clear technical details reduces misunderstandings and accelerates procurement cycles.

4. Incoterms (International Commercial Terms)

Incoterms specify the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) directly affect total landed cost and risk exposure. Buyers must understand Incoterms to negotiate favorable delivery terms and avoid hidden expenses.

5. Certification and Compliance Terms

Terms such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) or RoHS (Restriction of Hazardous Substances) indicate regulatory compliance. For buyers in Europe and other regulated markets, ensuring suppliers meet these certifications is mandatory to avoid legal penalties and maintain market access.

6. Lead Time

Lead time denotes the period between order placement and delivery. Accurate lead time estimates are vital for production planning and inventory management, especially in just-in-time manufacturing environments.

By mastering these technical properties and trade terms, B2B buyers across Africa, South America, the Middle East, and Europe can confidently source SiC grit that meets precise application needs while navigating complex international trade dynamics effectively. This knowledge supports strategic supplier selection, cost optimization, and risk mitigation in global supply chains.

The silicon carbide (sic) grit market is experiencing robust growth globally, driven by increasing demand across diverse industrial applications such as abrasives, refractories, electronics, and automotive sectors. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding regional supply dynamics and emerging sourcing trends is critical. The surge in electric vehicle (EV) manufacturing and renewable energy projects, particularly in Europe and the Middle East, is elevating demand for high-purity sic grit used in semiconductors and power electronics. Similarly, infrastructure development in Africa and South America is boosting requirements for durable abrasives and refractory materials.

Technological advances in production methods, such as improved carbothermal reduction processes and enhanced particle size control, are improving product consistency and performance. This shift allows B2B buyers to access higher quality sic grit tailored to specific industrial needs. Additionally, digital procurement platforms and supply chain transparency tools are gaining traction, enabling buyers to streamline sourcing, track shipments in real time, and assess supplier reliability.

Illustrative Image (Source: Google Search)

Market dynamics also reflect geopolitical influences, including trade policies and raw material availability. For instance, silicon metal, a key raw input, is subject to export restrictions in some countries, impacting global supply chains. Buyers in the UK and Egypt must navigate these complexities by diversifying suppliers and leveraging regional trade agreements to mitigate risks. Furthermore, growing demand for customized grit grades and shapes is prompting suppliers to offer more flexible production runs, enhancing value for B2B customers focused on application-specific performance.

Sustainability is becoming a decisive factor in the sic grit supply chain, as international buyers increasingly prioritize environmentally responsible sourcing to meet corporate social responsibility (CSR) mandates and regulatory requirements. The production of sic grit is energy-intensive, often relying on high-temperature furnaces powered by fossil fuels, which contributes to a significant carbon footprint. Buyers from Europe and the Middle East are particularly attuned to these environmental impacts due to stringent emissions regulations and evolving green procurement policies.

Ethical sourcing in this sector encompasses not only environmental considerations but also labor practices and community impact, especially in regions where raw materials are mined or processed. Transparent supply chains supported by third-party certifications—such as ISO 14001 for environmental management and Responsible Minerals Initiative (RMI) compliance—are becoming essential for B2B buyers aiming to ensure ethical standards.

The market is witnessing a growing adoption of “green” sic grit products, produced using renewable energy sources or through processes that minimize waste and emissions. Some suppliers are innovating with recycled silicon carbide or using bio-based binders in abrasive products to reduce environmental impact. For international buyers, engaging with suppliers who demonstrate sustainability credentials can enhance brand reputation and reduce exposure to regulatory risks. Collaborative initiatives between buyers and suppliers to improve energy efficiency and waste management in production are also emerging as best practices.

Silicon carbide grit’s journey began in the late 19th century when it was first synthesized as an abrasive alternative to natural materials like emery and corundum. Initially produced using the Acheson process, which involves heating silica sand and carbon in an electric furnace, sic grit quickly gained favor due to its hardness and thermal stability. Over the decades, advancements in manufacturing technology have refined particle purity, size uniformity, and production scale.

For B2B buyers today, understanding this evolution highlights the sector’s ongoing innovation and the increasing specialization of products tailored to modern industrial demands. This historical perspective underscores the importance of partnering with suppliers who invest in research and development to deliver cutting-edge, high-performance sic grit solutions.

How can I effectively vet suppliers of SiC grit to ensure quality and reliability?

To vet SiC grit suppliers, start by requesting detailed product specifications, including purity, grain size distribution, and certifications such as ISO 9001 or REACH compliance. Verify their manufacturing capabilities through factory audits or virtual tours. Check customer references and reviews, especially from companies in similar markets or regions. Confirm their experience in exporting to your country, understanding local regulations and logistics. Lastly, request samples for in-house testing to validate product performance before committing to large orders.

Is customization of SiC grit available, and what parameters can typically be tailored?

Many suppliers offer customization to meet specific industrial needs. Common customizable parameters include grit size (mesh size), purity level, grain shape (angular or blocky), and packaging formats. For specialized applications, suppliers may adjust chemical composition or provide coated SiC grit. Discuss your technical requirements upfront to ensure the supplier can accommodate them. Customization may affect lead times and minimum order quantities (MOQs), so clarify these factors early in the negotiation.

What are typical minimum order quantities (MOQs) and lead times for international orders of SiC grit?

MOQs for SiC grit vary widely depending on supplier capacity and customization levels, but generally range from 1 to 10 metric tons per shipment. Bulk orders often benefit from price breaks. Lead times can span 2 to 6 weeks, influenced by order size, customization, and supplier location. For buyers in Africa, South America, or the Middle East, factor in additional transit time and potential customs clearance delays. Establish clear delivery timelines with your supplier to align expectations and mitigate supply chain risks.

Which payment terms are commonly accepted for international B2B transactions involving SiC grit?

Suppliers typically accept Letters of Credit (L/C), Telegraphic Transfers (T/T), or open account terms depending on buyer history and order size. New buyers often start with 30% advance payment and 70% upon shipment or via L/C to reduce risk. Established buyers with proven credit may negotiate more flexible terms. Always ensure payment methods comply with your country’s foreign exchange regulations and protect your transaction through escrow or verified banking channels.

What quality assurance measures and certifications should I look for when sourcing SiC grit?

Look for suppliers with documented quality management systems, such as ISO 9001 certification, ensuring consistent production standards. Additional certifications like REACH or RoHS compliance indicate adherence to environmental and safety regulations, especially critical for buyers in Europe. Request batch test reports that include chemical composition, grain size distribution, and impurity levels. Third-party lab testing can be arranged for independent verification. A robust QA process minimizes variability and protects downstream manufacturing quality.

How can I optimize logistics and shipping for importing SiC grit into regions like Africa or South America?

Choose suppliers with experience shipping to your region who understand local customs and import regulations. Opt for consolidated shipments or full container loads (FCL) to reduce per-unit freight costs. Use reputable freight forwarders familiar with your port to expedite customs clearance. Consider incoterms carefully; CFR or CIF terms can shift logistics responsibility to the supplier, easing your coordination burden. Plan for potential delays during peak seasons or geopolitical disruptions, and maintain buffer stock to avoid production stoppages.

What strategies can help resolve disputes or quality issues with SiC grit suppliers?

Establish clear contractual terms detailing product specifications, inspection protocols, and dispute resolution mechanisms before ordering. Use third-party inspection services to verify shipment quality prior to dispatch. If issues arise, document all discrepancies with photos and test results, and communicate promptly with the supplier to seek amicable solutions such as replacement shipments or refunds. In complex cases, mediation or arbitration clauses can provide structured resolution paths without resorting to litigation.

Are there regional considerations for sourcing SiC grit that B2B buyers should be aware of?

Yes, regional factors such as local regulations, import duties, and currency volatility impact sourcing decisions. For example, European buyers must comply with stringent environmental standards, while African and Middle Eastern buyers should consider infrastructure limitations affecting delivery reliability. Language barriers and cultural differences may influence negotiation and relationship-building. Engaging local agents or consultants can facilitate smoother transactions and help navigate regulatory landscapes, ensuring compliance and reducing risks.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, sourcing silicon carbide (SiC) grit demands a strategic approach that balances quality, cost-efficiency, and supply reliability. For B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing suppliers with strong certifications, consistent product performance, and transparent logistics is essential. Leveraging partnerships with manufacturers who emphasize sustainable production and innovation can further enhance supply chain resilience and product competitiveness.

Key takeaways for international buyers include:

- Thorough supplier vetting to ensure compliance with industry standards and regional regulations.

- Diversified sourcing strategies to mitigate geopolitical and logistical risks.

- Investment in long-term relationships that foster collaboration on product customization and volume flexibility.

- Attention to total cost of ownership, including freight, duties, and inventory management.

Looking ahead, the demand for high-quality SiC grit is expected to grow, driven by expanding industrial applications such as electronics, automotive, and advanced manufacturing sectors. Buyers who adopt a proactive sourcing mindset—embracing digital procurement tools and sustainability criteria—will be best positioned to capitalize on market opportunities.

International B2B buyers are encouraged to engage early with trusted suppliers, explore innovative sourcing models, and continuously monitor market trends to secure a competitive edge in the evolving SiC grit landscape.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina