As international B2B buyers seek to source silicio aplicaciones for diverse industrial uses, one of the primary challenges they face is identifying reliable suppliers who meet specific quality standards while offering competitive pricing. The global market for silicon applications is vast and varied, encompassing everything from semiconductors to solar panels, and navigating this landscape requires a comprehensive understanding of the available options. This guide aims to equip you with the knowledge necessary to make informed purchasing decisions by exploring different types of silicon applications, their applications across various industries, and effective strategies for supplier vetting.

In this comprehensive resource, you will find insights into the latest trends in silicon technology, key factors influencing cost structures, and essential criteria for selecting suppliers that align with your business needs. Whether you are operating in Africa, South America, the Middle East, or Europe—countries like Italy and Poland—this guide is tailored to address the unique challenges and opportunities present in your region. By empowering you with actionable insights and best practices, we aim to facilitate a smoother procurement process, ensuring that you can confidently secure high-quality silicon applications that drive your business forward.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicio Cristalino | High purity, excellent electrical conductivity | Electronics, Solar Cells | Pros: High efficiency and performance. Cons: Higher cost. |

| Silicio Amorfoso | Non-crystalline form, flexible and lightweight | Thin-film solar panels, Displays | Pros: Cost-effective and versatile. Cons: Lower efficiency. |

| Silicio Doped | Impurities added to enhance electrical properties | Semiconductor devices | Pros: Tailored electrical properties. Cons: More complex supply chain. |

| Silicio Microestructurado | Nanostructured for enhanced properties | Advanced electronics, Sensors | Pros: Superior performance in specific applications. Cons: Requires specialized manufacturing. |

| Silicio Polimérico | Polymer-based silicon for flexible applications | Wearable technology, Medical devices | Pros: Lightweight and adaptable. Cons: Limited durability. |

Silicio Cristalino, or crystalline silicon, is characterized by its high purity and excellent electrical conductivity. This type of silicon is primarily used in electronics and solar cells, where performance and efficiency are paramount. B2B buyers should consider the upfront investment versus long-term gains in efficiency, as this type often comes at a higher cost but offers superior performance and longevity in applications.

Silicio Amorfoso, or amorphous silicon, is a non-crystalline form that is flexible and lightweight, making it ideal for thin-film solar panels and display technologies. This type of silicon is cost-effective and versatile, allowing for various applications. However, B2B buyers should be aware that while it offers lower production costs, it typically has a lower efficiency compared to crystalline forms, which may affect long-term performance.

Silicio Doped refers to silicon that has had specific impurities added to enhance its electrical properties. This type is crucial for semiconductor devices, as it allows for tailored performance based on the needs of the application. Buyers need to consider the complexity of the supply chain and the potential for increased costs associated with sourcing and processing doped silicon. However, the benefits often outweigh these challenges, especially in high-tech applications.

Silicio Microestructurado features nanostructured silicon that is engineered for enhanced properties, making it suitable for advanced electronics and sensor applications. This type offers superior performance, particularly in specialized environments. B2B buyers should evaluate the need for specialized manufacturing processes, as this can lead to higher costs and longer lead times, but the performance benefits can justify the investment.

Silicio Polimérico is a polymer-based silicon that is particularly advantageous for flexible applications such as wearable technology and medical devices. It is lightweight and adaptable, which is essential for innovative product design. However, B2B buyers must consider the limited durability of this type compared to traditional silicon forms. Understanding the application requirements will help in determining if the trade-off between flexibility and durability aligns with business needs.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of silicio aplicaciones | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | Semiconductor manufacturing | Enhanced performance and energy efficiency in devices | Quality of silicio, purity levels, and supplier certifications |

| Renewable Energy | Solar panel production | Increased energy conversion rates and durability | Compliance with international standards, sourcing local materials |

| Automotive | Electric vehicle (EV) battery components | Improved battery life and charging efficiency | Technical specifications, compatibility with existing systems |

| Construction | Concrete additives for enhanced durability | Longer lifespan of structures, reduced maintenance | Local regulations, environmental impact assessments |

| Chemical Processing | Silica gel for moisture control | Extended shelf life of products, reduced spoilage | Purity and granule size specifications, supplier reliability |

In the electronics industry, silicio aplicaciones are primarily utilized in semiconductor manufacturing. This application is crucial for enhancing the performance and energy efficiency of electronic devices such as smartphones, computers, and home appliances. B2B buyers should ensure that the silicio sourced meets high purity standards to avoid defects in semiconductor fabrication. Additionally, certifications from suppliers regarding the quality and reliability of silicio are essential to mitigate risks in production.

Silicio aplicaciones are vital in the production of solar panels, where they are used to create high-efficiency photovoltaic cells. The incorporation of silicio significantly boosts energy conversion rates, making solar energy more viable and sustainable. International buyers, especially in regions like Africa and South America, should focus on sourcing silicio that complies with international standards to ensure compatibility with existing solar technologies and to enhance the durability of solar panels against environmental factors.

In the automotive sector, silicio aplicaciones are increasingly employed in the manufacturing of electric vehicle (EV) battery components. The use of high-quality silicio improves battery life and charging efficiency, addressing the growing demand for sustainable transportation solutions. B2B buyers must consider technical specifications and compatibility with existing systems when sourcing silicio, as the automotive industry is moving towards more integrated and efficient technologies.

In construction, silicio aplicaciones are used as additives in concrete to enhance its durability. This application helps in extending the lifespan of structures and reducing maintenance costs, which is particularly valuable in regions with harsh weather conditions. Buyers from Africa and the Middle East should be aware of local regulations and environmental impact assessments when sourcing silicio for construction applications, ensuring that the materials used contribute to sustainable building practices.

Silicio aplicaciones are also utilized in chemical processing, particularly as silica gel for moisture control. This application is critical for extending the shelf life of various products, including food and pharmaceuticals, by preventing spoilage due to moisture. B2B buyers should focus on the purity and granule size of the silica gel sourced, as these factors directly influence its effectiveness. Reliability of suppliers is also a key consideration, especially for businesses operating in highly regulated markets.

Related Video: What are all the Laboratory Apparatus and their uses?

The Problem: B2B buyers in regions such as Africa and South America often face challenges in sourcing high-quality silicio aplicaciones. This can stem from a lack of local suppliers, leading to reliance on international vendors. Buyers may encounter issues such as inconsistent product quality, lengthy lead times, and inflated shipping costs. Furthermore, the difficulty in verifying the credentials and reputation of suppliers can result in significant risks, including receiving substandard materials that could compromise their projects.

The Solution: To effectively source high-quality silicio aplicaciones, buyers should establish relationships with reputable international suppliers known for their quality assurance processes. This can be achieved by leveraging platforms like Alibaba or global trade shows focused on semiconductor materials, where they can meet suppliers face-to-face and assess product samples. Additionally, conducting thorough due diligence on potential suppliers is crucial. This includes checking for certifications such as ISO or industry-specific standards, reading customer reviews, and requesting references. Buyers should also negotiate clear terms regarding quality guarantees and delivery timelines to mitigate risks associated with sourcing.

The Problem: B2B buyers in Europe and the Middle East often struggle with navigating the complex regulatory landscape surrounding the use of silicio aplicaciones. Each region may have different compliance requirements regarding safety, environmental impact, and product specifications. This can lead to confusion and potential legal issues, especially for companies looking to expand into new markets without a solid understanding of local laws.

The Solution: To navigate compliance effectively, buyers should invest in regulatory consulting services that specialize in the semiconductor industry. These experts can provide insights into the specific requirements for silicio aplicaciones in their target markets, ensuring that buyers are fully compliant with local regulations. Additionally, buyers should consider joining industry associations that offer resources and training on compliance matters. Staying updated on changes in legislation and participating in webinars or workshops can further enhance their understanding of compliance issues. Creating a compliance checklist specific to their operations can also help streamline the process and ensure all necessary regulations are met before product deployment.

The Problem: Many B2B buyers face integration challenges when trying to incorporate new silicio aplicaciones into their existing manufacturing or technological systems. This can lead to operational disruptions, inefficiencies, and increased costs if the new materials do not align well with current processes or machinery. Buyers may find themselves investing time and resources into retraining staff or modifying equipment to accommodate the new applications.

The Solution: To ease the integration of silicio aplicaciones, buyers should conduct a comprehensive assessment of their current systems before making any purchasing decisions. Engaging with suppliers who offer technical support and integration services can facilitate a smoother transition. Buyers should ask for detailed product specifications and compatibility information from suppliers to ensure that the silicio aplicaciones are suitable for their existing systems. Additionally, considering pilot projects or small-scale implementations before full-scale adoption can help identify potential integration issues early on. Collaborating with engineers or consultants during the planning phase can also yield valuable insights and recommendations on optimizing the integration process, ultimately reducing costs and minimizing disruptions.

When selecting materials for silicio aplicaciones, it is essential to consider their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. This guide analyzes four common materials used in silicio aplicaciones, providing insights that can help buyers make informed decisions.

Key Properties: Silicon carbide exhibits exceptional thermal conductivity, high-temperature resistance (up to 1600°C), and excellent chemical stability. It is also known for its hardness and mechanical strength.

Pros & Cons: The durability of SiC makes it suitable for high-stress applications, but its high manufacturing complexity can lead to increased costs. While it offers superior performance in extreme conditions, the initial investment may be a barrier for smaller companies.

Impact on Application: SiC is particularly effective in high-power and high-frequency applications, making it ideal for devices in the automotive and aerospace sectors.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should consider compliance with standards such as IEC and ASTM for semiconductor applications, ensuring that the material meets local regulations.

Key Properties: Silicon dioxide is known for its excellent dielectric properties, thermal stability, and chemical inertness. It can withstand temperatures up to 1200°C.

Pros & Cons: SiO2 is relatively cost-effective and widely available, making it a popular choice for various applications. However, it is less durable compared to SiC and may not perform well under high mechanical stress.

Impact on Application: SiO2 is commonly used in the manufacturing of insulators and substrates in electronic devices, providing essential support for circuit integrity.

Considerations for International Buyers: Buyers should ensure that the SiO2 used complies with JIS standards, particularly in electronics manufacturing, to maintain product quality and safety.

Key Properties: Amorphous silicon has a lower density and is flexible, allowing it to be used in thin-film applications. It has moderate thermal stability and good optical properties.

Pros & Cons: The flexibility and lightweight nature of amorphous silicon make it suitable for solar cells and displays. However, its lower efficiency compared to crystalline silicon can limit its use in high-performance applications.

Impact on Application: Amorphous silicon is ideal for applications requiring lightweight and flexible materials, such as portable electronics and solar panels.

Considerations for International Buyers: Compliance with EU regulations on energy efficiency is crucial for buyers in Europe, especially for solar applications, to ensure market acceptance.

Key Properties: Crystalline silicon is characterized by its high efficiency in converting solar energy, with a thermal stability of up to 200°C. It has excellent electrical conductivity.

Pros & Cons: This material is widely used in photovoltaic cells due to its high efficiency and durability. However, the manufacturing process is energy-intensive, leading to higher costs.

Impact on Application: Crystalline silicon is the preferred choice for solar panels, ensuring maximum energy output and reliability.

Considerations for International Buyers: Buyers from Africa and South America should consider local incentives for renewable energy technologies, which may influence their choice of material based on cost and efficiency.

| Material | Typical Use Case for silicio aplicaciones | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | High-power electronics | Exceptional thermal conductivity | High manufacturing complexity | High |

| Silicon Dioxide (SiO2) | Insulators and substrates | Cost-effective and widely available | Less durable under mechanical stress | Low |

| Amorphous Silicon | Solar cells and flexible displays | Lightweight and flexible | Lower efficiency compared to crystalline silicon | Medium |

| Crystalline Silicon | Photovoltaic cells | High energy conversion efficiency | Energy-intensive manufacturing process | High |

This guide provides international B2B buyers with a clear understanding of the materials available for silicio aplicaciones, allowing for informed decision-making based on specific application needs and regional compliance requirements.

The manufacturing of silicio aplicaciones involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these processes is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to ensure they make informed purchasing decisions.

Material Preparation

- The first step in the manufacturing process is the preparation of raw materials. High-purity silicon is sourced, often from quartz sand or metallurgical-grade silicon. This phase may also involve the purification of silicon to remove impurities that could affect the end product's quality.

- For buyers, it is crucial to verify the source of these materials and the supplier’s purification processes to ensure compliance with industry standards.

Forming

- In this stage, the prepared silicon is shaped into the desired form. This can involve methods such as:

Assembly

- Once formed, the silicon components are assembled into final products. This could involve integrating silicon chips into electronic devices or combining silicon with other materials for specific applications.

- An effective assembly process ensures minimal defects and high functionality. Buyers should inquire about the assembly methods and the experience of the workforce involved.

Finishing

- The finishing stage includes processes like polishing, etching, and coating to enhance the silicon's properties and prepare it for market.

- Surface treatments can significantly affect the electrical and thermal properties of silicon applications, making this a critical phase for quality assurance.

Quality assurance (QA) is paramount in the manufacturing of silicio aplicaciones to meet international standards and customer expectations. Various QA practices are employed throughout the manufacturing stages to ensure product reliability and compliance.

ISO 9001 Certification

- This is a widely recognized quality management standard that ensures organizations meet customer and regulatory requirements consistently. Buyers should prioritize suppliers with ISO 9001 certification, as it indicates a commitment to quality management practices.

Industry-Specific Standards

- Depending on the application, other certifications may be relevant:

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and rectify defects early. These checkpoints typically include:

Incoming Quality Control (IQC)

- This involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers should request IQC reports to verify the quality of materials used in production.

In-Process Quality Control (IPQC)

- Conducted during the manufacturing process, IPQC ensures that each stage meets quality benchmarks. Common methods include statistical process control (SPC) and regular inspections.

Final Quality Control (FQC)

- This is the last line of defense before products are shipped. FQC involves comprehensive testing of finished products against specifications. Buyers should obtain FQC reports to confirm that the end products meet their requirements.

Verification of a supplier's quality control processes is essential for B2B buyers to ensure reliability and compliance. Here are effective strategies:

Conduct Supplier Audits

- Regular audits help assess the supplier's adherence to quality standards. Buyers should develop a checklist based on ISO standards and industry-specific requirements for a thorough evaluation.

Request Quality Assurance Reports

- Suppliers should provide detailed reports on their quality assurance processes, including IQC, IPQC, and FQC data. Analyzing these reports can help buyers gauge the effectiveness of the supplier's QC measures.

Third-Party Inspections

- Engaging third-party inspection services can provide an unbiased assessment of the supplier's quality control practices. This is especially important for international transactions where buyers may not have direct oversight.

International B2B buyers face unique challenges in ensuring quality control, particularly in regions like Africa, South America, the Middle East, and Europe. Here are some nuances to consider:

Cultural and Regulatory Differences

- Different regions may have varying regulatory requirements and cultural practices that influence manufacturing standards. Buyers should familiarize themselves with local regulations and ensure that suppliers comply with them.

Communication Barriers

- Clear communication is vital to avoid misunderstandings regarding quality expectations. Buyers should establish direct lines of communication with suppliers and consider language differences when discussing technical specifications.

Logistical Considerations

- The logistics of transporting silicon products can affect quality. Buyers should discuss packaging and shipping methods with suppliers to ensure that products remain intact and meet quality standards upon arrival.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing silicio aplicaciones, ensuring they partner with reliable suppliers who meet their quality expectations.

In the competitive landscape of B2B procurement, sourcing silicio aplicaciones effectively is essential for ensuring quality and reliability. This guide provides a structured checklist that international buyers, especially from Africa, South America, the Middle East, and Europe, can follow to streamline their sourcing process.

Before initiating the sourcing process, it's crucial to outline your specific technical requirements for silicio aplicaciones. This includes understanding the application type, purity levels, and any industry standards that must be met. Clear specifications will not only help in identifying suitable suppliers but will also serve as a benchmark during the evaluation process.

Conduct thorough research to identify suppliers who specialize in silicio aplicaciones. Utilize industry directories, trade shows, and online platforms to gather a list of potential vendors. Pay attention to their market reputation, experience in the industry, and geographical location, which can impact shipping times and costs.

Ensure that potential suppliers have the necessary certifications, such as ISO 9001, which indicates a commitment to quality management. Compliance with local and international regulations is also critical, especially when sourcing from different regions. Verify these certifications through direct communication with the supplier or third-party verification services.

Before making large orders, request samples of the silicio aplicaciones to evaluate their quality firsthand. This step is vital for assessing whether the product meets your technical specifications and performance requirements. Ensure that the samples are representative of the product you intend to procure.

Gather detailed pricing information from shortlisted suppliers, including any additional costs such as shipping, tariffs, and taxes. Compare the quotes to ensure they align with your budget without compromising on quality. Additionally, discuss payment terms to ensure they are favorable and secure for your business.

If feasible, conduct audits or site visits to potential suppliers. This hands-on approach allows you to assess their production capabilities, quality control processes, and working conditions. A personal visit can also strengthen your relationship with the supplier, providing a deeper understanding of their operations.

Once you select a supplier, establish clear communication protocols to facilitate ongoing dialogue. Regular updates on production timelines, shipping schedules, and any potential issues can prevent misunderstandings and ensure a smooth procurement process. Utilize tools like project management software or dedicated communication platforms for efficiency.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing silicio aplicaciones more effectively, ensuring they secure the right products from reliable suppliers.

When sourcing silicio aplicaciones, understanding the cost structure is crucial for effective budgeting and decision-making. The primary components that contribute to the overall cost include:

Materials: The cost of raw materials, particularly silicon, is a significant factor. Prices can fluctuate based on market demand, availability, and quality. Buyers should consider sourcing materials from reliable suppliers to ensure consistency and quality.

Labor: Labor costs vary by region and can significantly impact pricing. In countries with higher labor costs, such as many European nations, the overall price may be elevated. Conversely, sourcing from regions with lower labor costs, like parts of Africa and South America, can offer cost advantages.

Manufacturing Overhead: This includes utilities, facility maintenance, and other indirect costs associated with production. Understanding these costs can help buyers identify suppliers with efficient operations that may offer better pricing.

Tooling and Equipment: Custom tooling may be required for specific applications, which can add to initial costs. Buyers should assess whether suppliers can leverage existing tools or require new investments, affecting overall pricing.

Quality Control (QC): Ensuring the quality of silicio aplicaciones is essential. QC processes can add costs, but they also prevent defects and long-term losses. Buyers should inquire about the supplier's QC measures and certifications.

Logistics: Shipping and handling costs can vary significantly depending on the distance and mode of transport. Buyers should factor in these costs, especially when sourcing from international suppliers.

Margin: Suppliers will build in their profit margin, which can vary based on their operational efficiency and market conditions. Understanding this can aid in negotiation.

Several key factors influence the pricing of silicio aplicaciones, which international B2B buyers should consider:

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs. Buyers should negotiate MOQs that align with their demand forecasts to optimize pricing.

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

Material Quality and Certifications: Higher-quality materials often come at a premium. Buyers should assess the importance of certifications (e.g., ISO) in their purchasing decisions, as these can impact both cost and product reliability.

Supplier Factors: The supplier's reputation, reliability, and financial stability can affect pricing. Established suppliers may charge more but offer better quality assurance and service.

Incoterms: The chosen Incoterms (e.g., FOB, CIF) will influence the total landed cost. Buyers should understand how these terms impact shipping responsibilities and costs.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

Negotiation Strategies: Engage in open discussions with suppliers about pricing structures. Highlight your potential for repeat business to secure better terms.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, logistics, and potential risks. This holistic approach can lead to more informed purchasing decisions.

Pricing Nuances: Be aware of regional price variations due to local economic conditions, tariffs, and taxes. Understanding these nuances can help buyers make more strategic sourcing decisions.

Build Relationships: Developing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions over time.

Pricing for silicio aplicaciones can vary widely based on the factors mentioned above. It is crucial for buyers to obtain quotes directly from suppliers and conduct thorough market research to ensure they are making informed purchasing decisions.

In the rapidly evolving landscape of technology solutions, B2B buyers are often faced with a multitude of options. When considering 'silicio aplicaciones', it is crucial to understand how it stacks up against other viable solutions. This analysis will provide a comprehensive comparison, enabling international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed decisions.

| Comparison Aspect | Silicio Aplicaciones | Alternative 1: Silicon Carbide (SiC) | Alternative 2: Gallium Nitride (GaN) |

|---|---|---|---|

| Performance | High efficiency in energy conversion, suitable for a range of applications | Superior thermal conductivity, ideal for high-temperature environments | Excellent frequency response, suitable for RF applications |

| Cost | Moderate initial investment with lower long-term operational costs | Higher initial cost but lower thermal management costs | Generally higher upfront costs; cost-effective in high-performance applications |

| Ease of Implementation | Relatively easy integration into existing systems | Requires careful consideration of thermal management | Can be complex due to the need for specialized equipment |

| Maintenance | Low maintenance needs; robust and durable | Requires regular monitoring of thermal performance | Low maintenance but may require more frequent checks on power devices |

| Best Use Case | General-purpose applications in electronics and power systems | High-power applications like electric vehicles and industrial motors | RF applications, wireless communications, and power amplifiers |

Silicon Carbide (SiC) offers significant advantages, particularly in high-power applications. Its superior thermal conductivity allows for efficient heat dissipation, making it ideal for environments with elevated temperatures. However, the higher initial investment can be a barrier for some businesses. Companies must also consider the need for enhanced thermal management systems, which can complicate the implementation process. Overall, SiC excels in applications such as electric vehicles and industrial motors, where performance is critical.

Gallium Nitride (GaN) stands out for its exceptional frequency response and efficiency in RF applications. This material is particularly useful in wireless communications and power amplifiers, where high efficiency and compact size are paramount. However, GaN technology typically requires a higher upfront investment, and its complexity in implementation may necessitate specialized training and equipment. Despite these challenges, its effectiveness in high-performance applications can justify the costs for businesses aiming for cutting-edge technology.

Choosing between 'silicio aplicaciones' and its alternatives—Silicon Carbide and Gallium Nitride—depends largely on your specific business requirements. If your focus is on general-purpose applications with moderate costs and ease of implementation, 'silicio aplicaciones' may be the ideal choice. Conversely, if your applications require high-temperature performance or exceptional frequency response, investing in SiC or GaN could yield better results in the long run. As a B2B buyer, carefully evaluate your operational needs, budget constraints, and the technical requirements of your projects to select the most suitable solution.

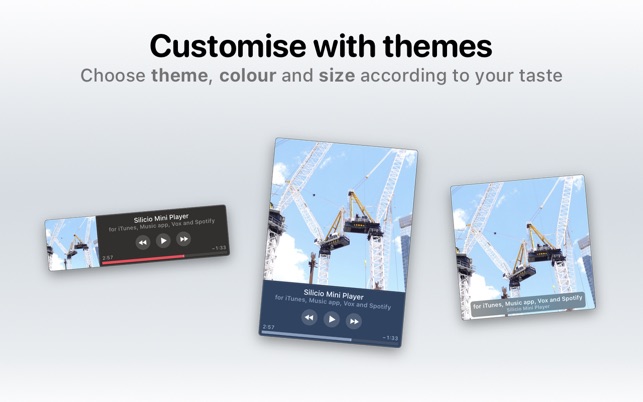

A stock image related to silicio aplicaciones.

When considering silicio aplicaciones, understanding its technical properties is crucial for B2B buyers, especially those involved in industries such as electronics, renewable energy, and manufacturing. Here are some essential specifications:

Material grade refers to the quality and purity of silicon used in applications. Higher grades of silicon often have fewer impurities, leading to better performance in electrical conductivity and thermal resistance. For buyers, selecting the right material grade is vital for ensuring product reliability and efficiency, particularly in semiconductor manufacturing.

Tolerance levels indicate the allowable deviation from specified dimensions. In silicio aplicaciones, maintaining tight tolerances is essential for components that require precision, such as microprocessors and solar cells. Understanding tolerance levels helps buyers ensure compatibility with other components and optimize the manufacturing process, reducing waste and costs.

Thermal conductivity measures how well silicon can conduct heat. This property is especially important in applications like power electronics and photovoltaic cells, where heat management is critical for performance and longevity. Buyers should prioritize materials with high thermal conductivity to enhance efficiency and prevent overheating in their products.

Electrical resistivity is a measure of how strongly a material opposes the flow of electric current. In silicio aplicaciones, lower resistivity is preferred for semiconductor applications, as it allows for efficient electron flow. Buyers need to consider resistivity when selecting silicon for specific applications, as it directly impacts the performance of electronic devices.

Mechanical strength refers to the ability of silicon to withstand applied forces without deforming or breaking. This property is crucial for applications where silicon components must endure physical stress, such as in automotive or industrial settings. Buyers should assess mechanical strength to ensure that products can withstand operational demands.

Understanding trade terminology is essential for effective communication and negotiation in the B2B landscape. Here are some key terms related to silicio aplicaciones:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the silicon industry, OEMs often provide components for larger electronic systems. Buyers should be aware of OEM relationships to understand sourcing options and ensure compatibility with their products.

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory management and cost-effectiveness. Understanding the MOQ can help buyers plan their procurement strategies and avoid excess stock or shortages.

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. For silicio aplicaciones, issuing an RFQ allows buyers to compare prices and terms from multiple vendors, ensuring they get the best deal. It’s an essential step in the procurement process.

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. For B2B buyers in silicio aplicaciones, understanding Incoterms is vital for clarifying shipping responsibilities, risk management, and cost allocation. This knowledge can prevent disputes and enhance trade efficiency.

Lead time refers to the amount of time it takes for an order to be fulfilled. In the silicon supply chain, lead times can vary based on production capacity and logistics. Buyers should be mindful of lead times to manage project timelines effectively and ensure timely delivery of products.

Supply chain transparency involves the clear visibility of the supply chain processes and the origin of materials. For B2B buyers, this is increasingly important for compliance and ethical sourcing. Understanding supply chain transparency can help buyers make informed decisions and build sustainable partnerships.

A stock image related to silicio aplicaciones.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing silicio aplicaciones, ultimately leading to enhanced product performance and market competitiveness.

The silicio aplicaciones sector is experiencing significant growth driven by advancements in technology and increasing demand for silicon-based applications across various industries, including electronics, renewable energy, and automotive. Key trends include the integration of artificial intelligence (AI) in manufacturing processes, which enhances efficiency and reduces production costs. Additionally, the rise of electric vehicles (EVs) is propelling the demand for high-purity silicon used in battery production. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe (such as Italy and Poland), understanding these dynamics is crucial for effective sourcing strategies.

Emerging B2B tech trends include the adoption of digital platforms for procurement and supplier management, enabling buyers to streamline their supply chains and access a broader range of suppliers. Blockchain technology is also gaining traction, providing transparency and traceability in sourcing, which is particularly important for ensuring quality and compliance with industry standards. As buyers navigate these trends, they should focus on building relationships with suppliers who can provide innovative solutions and demonstrate agility in responding to market changes.

Sustainability has become a pivotal consideration in the silicio aplicaciones sector, with increasing pressure from consumers and regulatory bodies to minimize environmental impacts. The extraction and processing of silicon can have significant ecological consequences, making it essential for businesses to prioritize ethical sourcing practices. This includes ensuring that suppliers adhere to environmental regulations and implement sustainable practices throughout the supply chain.

International B2B buyers should look for suppliers who possess 'green' certifications, such as ISO 14001, which indicates a commitment to environmental management systems. Furthermore, sourcing materials that are recycled or derived from sustainable processes can enhance a company's reputation and appeal to environmentally conscious consumers. By integrating sustainability into their sourcing strategies, buyers can not only mitigate risks associated with regulatory compliance but also contribute to a more sustainable future for the industry.

The evolution of the silicio aplicaciones sector has been marked by rapid technological advancements and a shift towards digitalization. Initially, the focus was primarily on traditional silicon applications; however, the advent of new technologies has led to a diversification of applications, including the development of silicon photonics and advanced semiconductor materials. This evolution has prompted B2B buyers to adapt their sourcing strategies, seeking suppliers who can offer cutting-edge materials and technologies that meet the demands of a fast-evolving market.

The historical context of the sector highlights the importance of innovation and adaptability in sourcing practices. As the industry continues to evolve, buyers must stay informed about emerging technologies and trends to ensure they are sourcing the most relevant and effective solutions for their needs. This ongoing evolution not only shapes the competitive landscape but also creates opportunities for businesses willing to embrace change and invest in future-oriented sourcing strategies.

How do I solve supply chain challenges when sourcing silicio aplicaciones?

To address supply chain challenges, start by mapping out your supply chain to identify potential bottlenecks. Engage with multiple suppliers to diversify your sources and reduce risk. Utilize technology, such as supply chain management software, to monitor and analyze logistics. Establish clear communication channels with suppliers to facilitate quick responses to disruptions. Finally, consider local sourcing options within your region to mitigate international shipping delays, particularly relevant for buyers from Africa and South America.

What is the best way to evaluate suppliers for silicio aplicaciones?

The best way to evaluate suppliers involves a multi-faceted approach. Begin with a thorough background check, including financial stability and market reputation. Request samples to assess product quality and compliance with your specifications. Review their manufacturing processes and certifications to ensure they meet international standards. Finally, consider visiting their facilities if possible, as firsthand observation can provide insights into their operational capabilities and commitment to quality.

What customization options are available for silicio aplicaciones?

Many suppliers offer customization options to meet specific industry needs. Customization may include variations in size, composition, or performance specifications based on your application. Discuss your requirements directly with suppliers to understand their capabilities and limitations. It's also beneficial to inquire about lead times and any additional costs associated with customized orders to ensure they align with your project timelines and budget.

What are the minimum order quantities (MOQ) for silicio aplicaciones?

MOQs for silicio aplicaciones can vary significantly between suppliers, often influenced by production costs and inventory management practices. Generally, larger orders can lead to better pricing, but smaller businesses should look for suppliers willing to accommodate lower MOQs. Negotiate with suppliers to find a balance that meets your needs while ensuring cost-effectiveness. Always clarify MOQs upfront to avoid surprises during the ordering process.

What payment terms should I expect when sourcing silicio aplicaciones?

Payment terms can vary widely depending on the supplier and your relationship with them. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. For new suppliers, consider negotiating favorable terms, such as net 30 or net 60 days, to improve cash flow. Always ensure that payment methods are secure, and consider using escrow services for large transactions to mitigate risks associated with international trade.

How can I ensure quality assurance for silicio aplicaciones?

To ensure quality assurance, establish clear quality standards and specifications before placing an order. Request documentation of the supplier's quality control processes and certifications, such as ISO standards. Consider implementing third-party quality inspections during production and prior to shipment. Building a strong partnership with your supplier can also enhance accountability and ensure that they prioritize your quality requirements throughout the manufacturing process.

What logistics considerations should I keep in mind when importing silicio aplicaciones?

When importing silicio aplicaciones, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a logistics provider experienced in handling similar products and familiar with the regulations in your destination country. Prepare all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance. Additionally, factor in lead times and possible delays to ensure timely delivery to your operations.

How do geopolitical factors affect sourcing silicio aplicaciones internationally?

Geopolitical factors can significantly impact international sourcing, including trade policies, tariffs, and political stability. Monitor developments in trade agreements that may influence costs and availability of silicio aplicaciones. Additionally, consider the political climate in supplier countries, as instability can disrupt supply chains. Building relationships with suppliers in politically stable regions can help mitigate risks associated with geopolitical changes and ensure continuity in your sourcing strategy.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing in the silicio aplicaciones sector is not just a cost-saving measure; it is a pathway to enhancing operational efficiency and fostering innovation. By prioritizing strong supplier relationships and leveraging data analytics, businesses can make informed decisions that align with market demands. This approach allows for greater flexibility and responsiveness to changing consumer needs, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

As we look toward the future, B2B buyers should embrace a proactive mindset. Consider diversifying supplier bases to mitigate risks associated with geopolitical tensions and supply chain disruptions. Additionally, investing in sustainable practices within sourcing strategies can not only enhance brand reputation but also attract environmentally conscious consumers.

Engage with suppliers who prioritize innovation and sustainability, and leverage technology to streamline procurement processes. By taking these steps, international buyers can position themselves at the forefront of the silicio aplicaciones market. The time is now to act strategically—empower your sourcing strategy to unlock new growth opportunities and ensure resilience in an ever-evolving global landscape.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina