Silicon carbide (SiC) material stands at the forefront of advanced industrial applications, offering unparalleled performance in sectors ranging from electronics and automotive to energy and manufacturing. For international B2B buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe, understanding the nuances of SiC is essential to unlocking competitive advantages and ensuring supply chain resilience.

This guide delivers a comprehensive roadmap to the global SiC market, addressing critical factors that influence sourcing decisions. From exploring various types of SiC materials—such as powders, wafers, and ceramics—to detailing the intricacies of manufacturing processes and stringent quality control standards, it equips buyers with the knowledge needed to evaluate product suitability and reliability. Additionally, the guide provides insights into leading global suppliers, cost considerations, and prevailing market trends that impact pricing and availability.

For B2B buyers in regions like Kenya and Turkey, where industrial growth and technological adoption are accelerating, this resource emphasizes tailored strategies to navigate logistical challenges, regulatory environments, and supplier vetting. By integrating practical information with market intelligence, the guide empowers procurement teams to make informed, strategic sourcing decisions that optimize operational efficiency and foster long-term partnerships.

Whether you are establishing new supplier relationships or expanding existing ones, this guide is designed to be your authoritative reference for mastering the complexities of SiC material procurement in an increasingly interconnected global marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alpha Silicon Carbide | Hexagonal crystal structure, high purity | Abrasives, high-performance ceramics, refractories | Pros: Excellent thermal conductivity, high hardness; Cons: Higher cost, limited machinability |

| Beta Silicon Carbide | Cubic crystal structure, lower purity | Grinding wheels, cutting tools, wear-resistant parts | Pros: Cost-effective, good toughness; Cons: Lower thermal stability, less hardness than Alpha |

| Sintered Silicon Carbide | Manufactured via sintering process, dense and strong | Mechanical seals, pump components, heat exchangers | Pros: Superior strength and corrosion resistance; Cons: Higher production cost, complex manufacturing |

| Reaction Bonded Silicon Carbide | Formed by silicon infiltration, porous but machinable | Semiconductor industry, furnace components | Pros: Good machinability, cost-efficient; Cons: Porosity affects strength and thermal shock resistance |

| Silicon Carbide Fibers | Fine fibrous form, high tensile strength | Composite reinforcement, aerospace, automotive | Pros: Enhances composite durability, lightweight; Cons: Specialty product, higher price point |

Alpha Silicon Carbide

Alpha SiC is recognized for its hexagonal crystal structure and high purity, making it ideal for applications demanding exceptional thermal conductivity and hardness. B2B buyers in industries such as abrasives, high-performance ceramics, and refractories will find this type advantageous for its durability and performance under extreme conditions. However, its higher cost and limited machinability require buyers to balance performance needs against budget constraints and manufacturing capabilities.

Beta Silicon Carbide

Beta SiC features a cubic crystal structure and is generally of lower purity than Alpha SiC, which translates to a more cost-effective option for abrasive tools and wear-resistant parts. This type is commonly used in grinding wheels and cutting tools due to its toughness. Buyers targeting medium-duty applications where cost efficiency is critical will appreciate Beta SiC, though they should consider its lower thermal stability and hardness relative to Alpha SiC.

Sintered Silicon Carbide

Produced through a sintering process, this dense and strong variant offers superior mechanical strength and corrosion resistance. It is widely employed in demanding environments such as mechanical seals, pump components, and heat exchangers. For international B2B buyers, especially those in sectors like petrochemical processing or water treatment, sintered SiC offers reliability and longevity, albeit at a higher upfront cost and with complex manufacturing lead times.

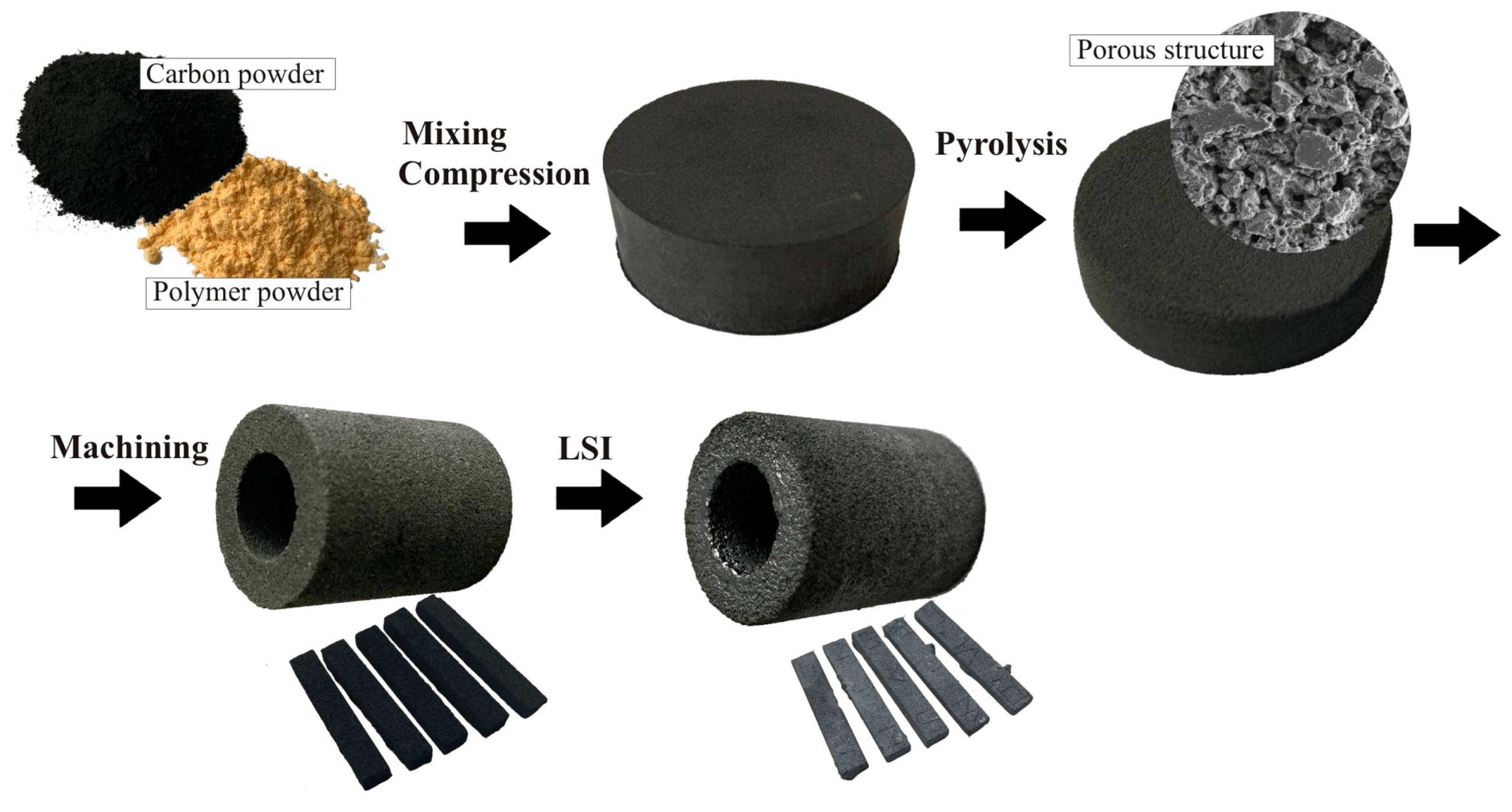

Reaction Bonded Silicon Carbide

This type is created by infiltrating porous carbon or silicon carbide preforms with molten silicon, resulting in a material that is more machinable but also more porous. It is well-suited for furnace components and semiconductor industry parts where precise machining is necessary. Buyers should weigh its cost efficiency and machinability against the reduced strength and thermal shock resistance caused by its porosity.

Silicon Carbide Fibers

SiC fibers are fine, high-tensile-strength materials primarily used to reinforce composites in aerospace, automotive, and other high-performance industries. They improve the durability and reduce the weight of composite materials. While these fibers offer significant performance advantages, they come at a premium price and require specialized handling and processing knowledge, making them suitable for buyers with advanced technical capabilities and specific performance requirements.

Related Video: Silicon Carbide Explained - SiC Basics

| Industry/Sector | Specific Application of sic material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Electronics | High-performance power semiconductors | Enhances energy efficiency and thermal management, reducing losses and downtime | Ensure supplier compliance with international quality standards and availability of customization for voltage/current ratings |

| Automotive & Transportation | Electric vehicle (EV) power modules and braking systems | Improves durability and heat resistance, extending component lifespan and reliability | Verify material purity and supplier ability to meet automotive-grade certifications |

| Industrial Manufacturing | Abrasive and cutting tools | Offers superior hardness and wear resistance, increasing tool life and reducing replacement costs | Confirm consistent particle size and supplier capacity for bulk orders |

| Renewable Energy | Components for solar inverters and wind turbines | Enables efficient power conversion and withstands harsh environmental conditions | Assess supplier track record in renewable energy sector and logistics capabilities for remote regions |

| Aerospace & Defense | High-temperature structural components | Provides lightweight, heat-resistant materials critical for performance and safety | Prioritize suppliers with certifications for aerospace standards and ability to supply traceability documentation |

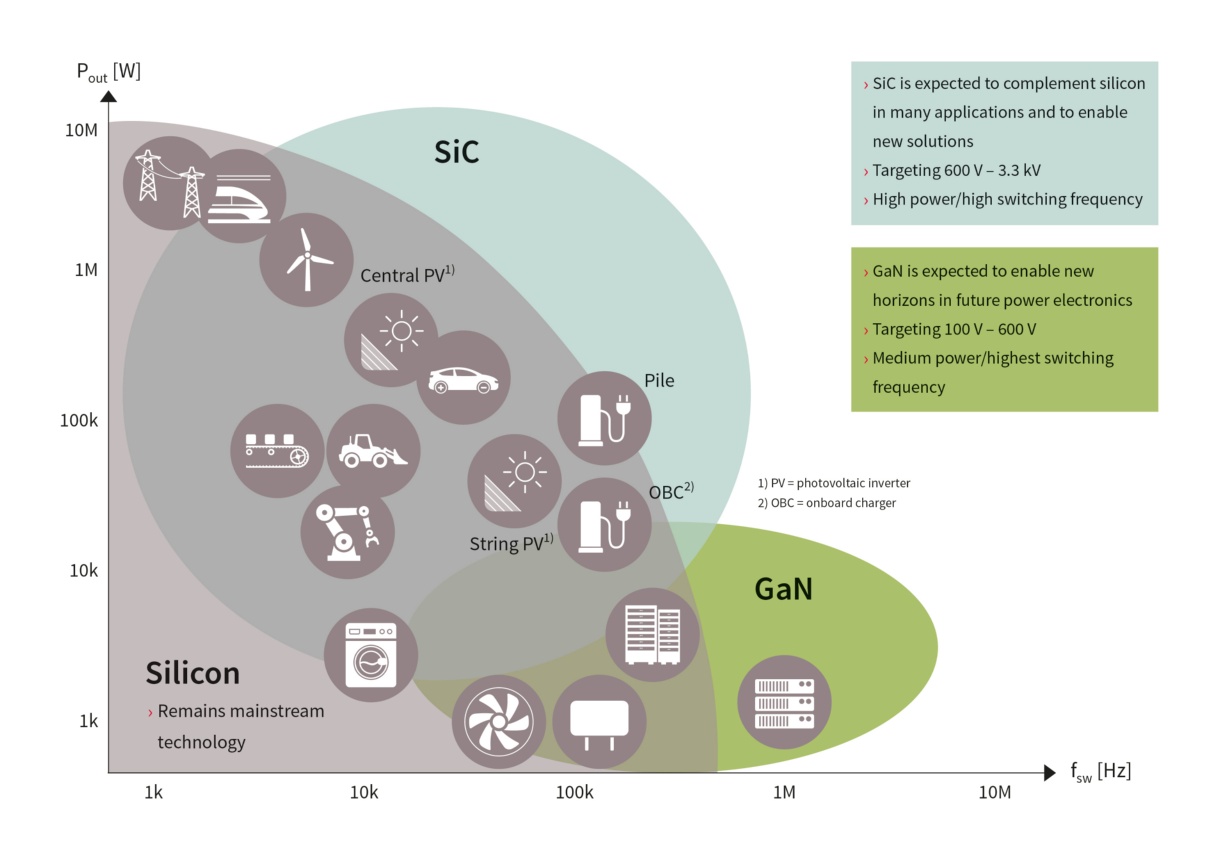

Silicon carbide (SiC) is widely used in power semiconductors such as MOSFETs and diodes, critical for energy-efficient power conversion systems. SiC devices operate at higher voltages, frequencies, and temperatures than traditional silicon, resulting in reduced energy losses and improved thermal management. For international buyers in Africa, South America, the Middle East, and Europe, sourcing SiC components requires careful evaluation of supplier quality standards and the ability to customize devices to specific voltage and current requirements, ensuring compatibility with local power infrastructure and industrial needs.

In the automotive sector, SiC materials are pivotal in electric vehicle (EV) power electronics, including inverters and braking systems. Their superior thermal conductivity and durability extend component life and improve vehicle efficiency. Buyers from emerging automotive markets such as Kenya or Turkey should focus on suppliers who provide automotive-grade certifications and demonstrate consistent material purity. This ensures compliance with stringent safety and performance standards essential for both OEMs and aftermarket suppliers.

Illustrative Image (Source: Google Search)

SiC’s exceptional hardness and wear resistance make it ideal for abrasive and cutting tools used in metalworking and machining industries. These tools deliver longer service life and reduce operational costs by minimizing downtime for replacements. For international buyers, especially in industrial hubs across South America and Europe, it is crucial to source SiC with consistent particle size and quality. Suppliers must also have the capacity to fulfill large, recurring orders to support continuous manufacturing operations.

SiC components play a critical role in renewable energy systems, including solar inverters and wind turbine power electronics. Their ability to operate efficiently under high temperatures and harsh environmental conditions enhances overall system reliability and energy yield. Buyers from regions investing heavily in renewable infrastructure, such as the Middle East and Europe, should prioritize suppliers with proven experience in the renewable sector and strong logistics networks capable of delivering to remote or challenging locations.

Illustrative Image (Source: Google Search)

The aerospace and defense industries leverage SiC for high-temperature structural components due to its lightweight nature and resistance to thermal stress. These properties are essential for improving fuel efficiency and ensuring safety in extreme operating environments. International buyers should focus on suppliers that comply with aerospace quality certifications and provide comprehensive traceability documentation, which is critical for regulatory compliance and quality assurance in these highly regulated sectors.

Silicon carbide (SiC) materials are pivotal in industries demanding high durability, thermal stability, and chemical resistance. When selecting SiC materials for B2B applications, especially across diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of each variant is essential for optimizing performance and cost-efficiency.

Key Properties:

RB-SiC features high thermal conductivity, excellent corrosion resistance, and moderate mechanical strength. It can withstand temperatures up to 1400°C and exhibits good resistance to acidic and alkaline environments.

Pros & Cons:

RB-SiC is relatively cost-effective compared to other SiC types and offers good machinability, which reduces manufacturing complexity. However, it has a slightly lower density and mechanical strength than sintered SiC, which may limit its use in extremely high-stress applications.

Impact on Application:

Ideal for components exposed to corrosive media such as chemical pumps, valves, and heat exchangers. Its resistance to thermal shock makes it suitable for industries like chemical processing and power generation.

Considerations for International B2B Buyers:

Buyers in regions like Kenya and Turkey should verify compliance with ASTM C799 or DIN EN 60672 standards, commonly referenced for RB-SiC. Given regional variations in manufacturing capabilities, sourcing from suppliers with ISO 9001 certification ensures consistent quality. RB-SiC’s moderate cost and adaptability make it attractive for emerging markets focusing on industrial infrastructure upgrades.

Key Properties:

SSiC exhibits superior hardness, high mechanical strength, and excellent wear resistance. It withstands temperatures exceeding 1600°C and has outstanding resistance to oxidation and corrosion.

Pros & Cons:

This material offers the highest performance for abrasive and high-temperature environments but comes with higher costs and more complex manufacturing processes. Machining SSiC requires specialized equipment, increasing lead times and expenses.

Impact on Application:

SSiC is preferred for high-performance seals, bearings, and semiconductor manufacturing components where extreme durability and precision are critical.

Considerations for International B2B Buyers:

European and Middle Eastern buyers often require adherence to stringent standards such as JIS G 5513 or DIN EN 60672-3 for sintered ceramics. Given the elevated cost, buyers should assess total cost of ownership, including longevity and maintenance savings. For South American markets, partnering with suppliers offering technical support and customization can mitigate challenges related to manufacturing complexity.

Key Properties:

PSSiC is characterized by fine grain size, excellent mechanical strength, and good thermal shock resistance. It can operate reliably at temperatures up to 1500°C and resists chemical attack from strong acids and alkalis.

Pros & Cons:

While PSSiC offers a balance between performance and cost, it is less dense than hot-pressed SiC and may have slightly reduced fracture toughness. Its manufacturing process is less complex than hot-pressed variants, making it more accessible.

Impact on Application:

Commonly used in components like kiln furniture, wear parts, and mechanical seals where moderate to high thermal and chemical resistance is required.

Considerations for International B2B Buyers:

Buyers in Africa and South America should focus on suppliers who provide materials compliant with ASTM C1245 or ISO 9001 standards to ensure reliability. The moderate cost and good performance make PSSiC suitable for industries expanding their manufacturing capabilities with budget constraints.

Key Properties:

HPSiC offers exceptional density, hardness, and fracture toughness. It performs excellently at temperatures above 1600°C and exhibits superior resistance to oxidation and chemical corrosion.

Pros & Cons:

This material delivers the best mechanical properties among SiC variants but at the highest cost and manufacturing complexity. The hot-pressing process limits the size and shape of components, potentially restricting design flexibility.

Impact on Application:

Ideal for aerospace, defense, and high-end semiconductor industries requiring maximum strength and thermal stability.

Considerations for International B2B Buyers:

European and Middle Eastern buyers often demand compliance with DIN EN 60672-3 and may require additional certifications for aerospace or defense applications. For buyers in Kenya and Turkey, establishing long-term partnerships with manufacturers who can provide technical validation and after-sales support is critical to justify the investment in HPSiC.

| Material | Typical Use Case for sic material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Reaction Bonded Silicon Carbide (RB-SiC) | Chemical pumps, valves, heat exchangers | Good corrosion resistance and machinability | Lower mechanical strength than sintered SiC | Low |

| Sintered Silicon Carbide (SSiC) | High-performance seals, bearings, semiconductor parts | Superior hardness and wear resistance | High cost and complex manufacturing | High |

| Pressureless Sintered Silicon Carbide (PSSiC) | Kiln furniture, wear parts, mechanical seals | Balanced performance with moderate cost | Slightly reduced fracture toughness | Medium |

| Hot-Pressed Silicon Carbide (HPSiC) | Aerospace, defense, high-end semiconductor components | Exceptional density and fracture toughness | Highest cost and limited design flexibility | High |

This guide empowers international B2B buyers to strategically select the appropriate SiC material variant based on application demands, regional compliance requirements, and cost considerations. Tailoring procurement to these factors ensures optimized performance and competitive advantage in global markets.

Silicon Carbide (SiC) is a highly durable and heat-resistant ceramic material widely used in industries such as automotive, electronics, and abrasives. Understanding its manufacturing process is crucial for B2B buyers aiming to source high-quality SiC components.

The initial stage involves sourcing high-purity raw materials, primarily silicon and carbon sources such as petroleum coke or charcoal. These materials undergo precise chemical reactions in electric resistance furnaces at temperatures exceeding 2,000°C, producing SiC crystals. The raw SiC then goes through crushing and sieving to achieve the required particle size distribution tailored for different applications.

Forming SiC into usable shapes requires advanced techniques due to its hardness and brittleness. Common forming methods include:

Selecting the appropriate forming technique depends on the end-use requirements, production volume, and cost considerations.

Post-forming, SiC components often require precise machining to meet dimensional tolerances. Techniques such as diamond grinding and laser machining are employed due to SiC’s extreme hardness. In some cases, components are assembled using high-temperature adhesives or mechanical fastening depending on the application.

Finishing steps enhance surface quality and performance characteristics. These include:

Each finishing process is selected to optimize the performance and longevity of the SiC product.

For B2B buyers, especially in diverse international markets such as Africa, South America, the Middle East, and Europe, rigorous quality assurance is paramount to ensure reliability and regulatory compliance.

Buyers should verify suppliers’ certifications and ensure their products meet the specific standards required by their industry and region.

Quality control is systematically integrated throughout the manufacturing cycle:

These checkpoints help maintain consistency and catch defects early, reducing waste and ensuring product reliability.

B2B buyers should request detailed test reports and understand the testing protocols to assess product suitability accurately.

For international B2B buyers sourcing SiC material, a thorough understanding of the manufacturing processes and quality assurance mechanisms is essential. Evaluating suppliers based on their adherence to international standards, robust QC checkpoints, and transparent documentation significantly reduces procurement risks. Tailoring these evaluations to regional regulatory and market conditions enhances sourcing success across Africa, South America, the Middle East, and Europe. This strategic approach ensures buyers receive high-performance SiC materials that meet their application-specific demands reliably and compliantly.

When sourcing silicon carbide (SiC) material for industrial applications, understanding the detailed cost structure and pricing dynamics is crucial for international B2B buyers. This knowledge enables strategic negotiation, cost optimization, and informed supplier selection—especially important for buyers in regions such as Africa, South America, the Middle East, and Europe.

Raw Materials

The primary input cost is the raw silicon carbide powder or crystals, which vary based on purity grade and particle size. High-purity SiC commands a premium, directly influencing the base material cost.

Labor Costs

Labor expenses depend on the manufacturing location and the complexity of processing. Regions with advanced manufacturing capabilities may have higher labor costs but offer superior quality control.

Manufacturing Overhead

Overhead includes energy consumption (SiC production is energy-intensive), equipment maintenance, and factory utilities. These fixed and variable costs impact the final price, especially for smaller production runs.

Tooling and Equipment Usage

Specialized tooling for shaping or sintering SiC components can be costly. Amortizing tooling expenses across production volumes affects unit costs, making low MOQ orders more expensive per unit.

Illustrative Image (Source: Google Search)

Quality Control and Certification

Rigorous QC processes and certifications (e.g., ISO, REACH, RoHS compliance) add to the cost but are essential for applications requiring high reliability and regulatory adherence.

Logistics and Freight

Shipping SiC material internationally involves freight charges, customs duties, and insurance. Costs vary significantly depending on shipment size, origin/destination countries, and chosen Incoterms.

Supplier Margin

Suppliers factor in profit margins based on market demand, competition, and service level, influencing final pricing.

Order Volume and Minimum Order Quantity (MOQ)

Larger orders generally yield volume discounts, reducing per-unit costs. Buyers with smaller requirements should negotiate MOQ terms or consider consolidating orders.

Specifications and Customization

Custom particle sizes, doping elements, or specific physical forms increase complexity and cost. Standardized products are usually more affordable.

Material Grade and Purity

Higher purity grades for electronic or semiconductor applications command higher prices compared to lower-grade abrasive SiC.

Quality Certifications and Traceability

Certified materials with documented traceability assure quality but come at a premium.

Supplier Location and Capabilities

Proximity to the supplier and their technological expertise can affect cost and lead times. Suppliers in established industrial hubs may charge more but offer reliability.

Incoterms and Payment Terms

Terms like FOB, CIF, or DDP shift cost responsibilities between buyer and seller, influencing total landed cost. Understanding these terms helps buyers avoid unexpected expenses.

Negotiate Based on Total Cost of Ownership (TCO)

Beyond unit price, consider quality, yield rates, delivery reliability, and after-sales support. A cheaper price can lead to higher indirect costs.

Leverage Volume Consolidation

Collaborate with other buyers or plan bulk purchases to reduce per-unit cost and shipping fees.

Assess Supplier Certifications Carefully

Prioritize suppliers with internationally recognized quality certifications to reduce risk, especially for critical applications.

Understand Regional Logistics Nuances

For buyers in Africa, South America, the Middle East, and Europe, factor in port efficiency, customs clearance times, and local transport infrastructure when estimating delivery timelines and costs.

Clarify Incoterms Upfront

Ensure clear agreements on who bears freight, insurance, and customs duties to avoid cost surprises.

Consider Local Regulations and Import Duties

Investigate any import tariffs or compliance requirements specific to your country to accurately budget total costs.

Build Relationships with Suppliers

Strong partnerships can lead to better pricing, flexible MOQs, and priority service.

Prices for silicon carbide materials vary widely depending on grade, volume, supplier, and market conditions. The figures discussed herein are indicative and should be verified with suppliers through direct quotations tailored to your specific sourcing requirements.

By thoroughly analyzing these cost components and pricing influencers, international B2B buyers can better strategize their SiC material procurement, ensuring competitive pricing without compromising on quality or supply chain reliability.

When sourcing silicon carbide (SiC) material, understanding its critical technical properties is essential to ensure optimal performance and compatibility with your industrial applications. Here are the most important specifications international buyers should consider:

Material Grade

SiC is available in several grades based on purity and particle size, such as green, black, and fused SiC. Higher purity grades offer better thermal conductivity and wear resistance, which are crucial for applications like abrasives or semiconductors. Choosing the right grade impacts product quality and lifecycle.

Particle Size and Distribution

The fineness or coarseness of SiC particles affects surface finish and machining efficiency. Uniform particle size distribution ensures consistent performance, especially in refractory and grinding applications. Buyers should specify particle size tolerances to avoid production inconsistencies.

Density and Porosity

Density reflects the compactness of the SiC material, influencing mechanical strength and thermal shock resistance. Lower porosity means fewer voids, leading to enhanced durability. This property is vital for manufacturers in automotive and aerospace sectors where material reliability is paramount.

Hardness (Mohs Scale)

SiC ranks about 9-9.5 on the Mohs hardness scale, making it extremely abrasive. This property determines its suitability for cutting, grinding, and wear-resistant components. Understanding hardness helps buyers select SiC variants that match their tool or component requirements.

Thermal Conductivity

SiC’s ability to conduct heat efficiently is critical in high-temperature applications such as power electronics and heat exchangers. High thermal conductivity ensures stable operation and prevents overheating, reducing downtime and maintenance costs.

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions or properties. Tight tolerances are necessary for precision engineering applications, while looser tolerances may be acceptable for bulk industrial use. Confirming tolerance specifications upfront avoids costly rejections or rework.

For international buyers navigating SiC procurement, familiarity with key trade and industry terminology streamlines communication and negotiation:

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or equipment which are then marketed by another company. When sourcing SiC, knowing if the supplier caters to OEMs can indicate product quality and compliance with industry standards.

MOQ (Minimum Order Quantity)

The smallest amount of SiC material a supplier is willing to sell in a single order. MOQs affect inventory planning and cash flow, so buyers from emerging markets like Kenya or Turkey should negotiate MOQs that align with their demand and storage capacity.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for SiC materials. A well-prepared RFQ with clear specifications helps buyers receive accurate and comparable bids, facilitating better purchasing decisions.

Incoterms (International Commercial Terms)

Standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) impact total landed cost and risk allocation.

Lead Time

The period between placing an order and receiving the shipment. Understanding lead times is critical for production scheduling and inventory management, especially for buyers in regions with longer shipping durations.

Certification and Compliance

Documents such as ISO certification or REACH compliance demonstrate a supplier’s adherence to quality and safety standards. Buyers should request these certifications to ensure the SiC material meets regulatory requirements and industry benchmarks.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement processes, and build stronger supplier relationships when dealing with silicon carbide materials. This knowledge helps mitigate risks, control costs, and enhance product quality across diverse markets.

The silicon carbide (SiC) material market is experiencing robust growth driven by its critical applications in high-performance electronics, automotive, and renewable energy sectors. Globally, the demand for SiC is fueled by the rapid adoption of electric vehicles (EVs), energy-efficient power devices, and industrial automation. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these macro trends is vital for strategic sourcing and supply chain resilience.

Key market drivers include the shift toward decarbonization and energy efficiency, which has intensified the need for SiC semiconductors and substrates known for superior thermal conductivity, high voltage tolerance, and durability. Buyers from emerging markets like Kenya and Turkey should note the increasing integration of SiC components in power electronics, especially in solar inverters and EV charging infrastructure, signaling expanding local and regional demand.

Technological advancements are shaping sourcing trends, with manufacturers focusing on improving crystal growth techniques and wafer quality to enhance performance and reduce costs. B2B buyers must prioritize suppliers investing in cutting-edge fabrication technologies to secure high-purity SiC materials. Additionally, digital procurement platforms and blockchain-enabled supply chain transparency are gaining traction, enabling buyers to track product origin and quality in real time, which is crucial for markets with complex logistics and regulatory frameworks.

Market dynamics also reflect geopolitical shifts and trade policies impacting raw material availability and pricing. Diversification of supplier bases across Asia, Europe, and North America is recommended to mitigate risks associated with supply disruptions. For buyers in the Middle East and Africa, establishing partnerships with regional distributors and leveraging free trade agreements can optimize sourcing efficiency and reduce lead times.

Sustainability is becoming a cornerstone in the SiC material sector, as environmental impacts from raw material extraction and manufacturing processes come under scrutiny. The production of SiC involves energy-intensive processes and the use of chemicals that can generate hazardous waste. B2B buyers must therefore evaluate suppliers based on their environmental management practices, including waste reduction, energy consumption, and emissions control.

Ethical sourcing is equally critical, particularly for buyers in regions with evolving regulatory landscapes and growing consumer awareness. Ensuring that SiC materials are procured from suppliers adhering to responsible labor practices and transparent supply chains helps mitigate reputational risks and aligns with global ESG (Environmental, Social, and Governance) standards.

Several certifications and standards are emerging as benchmarks for ‘green’ SiC materials. These include ISO 14001 for environmental management, RoHS compliance to restrict hazardous substances, and initiatives promoting circular economy principles such as material recycling and reuse. Buyers should prioritize partners who demonstrate certification compliance and active participation in sustainability programs.

Moreover, the rise of “green SiC” production methods — leveraging renewable energy sources and cleaner chemical processes — presents an opportunity for buyers to support innovation while meeting corporate sustainability goals. Collaborating with suppliers focused on lifecycle assessments and carbon footprint reduction can enhance supply chain transparency and contribute to broader climate commitments.

Silicon carbide’s journey began in the late 19th century as an abrasive material, prized for its hardness and thermal stability. Over decades, advances in crystal growth and semiconductor technology transformed SiC into a critical material for power electronics by the late 20th century. This evolution was driven by the need for devices that operate at higher voltages, temperatures, and frequencies than traditional silicon-based components.

For B2B buyers, understanding this history underscores the material’s proven reliability and continuous innovation. The transition from bulk abrasive applications to high-value semiconductor substrates highlights opportunities for buyers to capitalize on expanding industrial use cases, particularly in rapidly developing markets where infrastructure modernization and energy transition are priorities.

Today, SiC stands at the forefront of next-generation electronics, with ongoing research pushing the boundaries of performance and cost-efficiency. This trajectory suggests a growing role for SiC materials in global supply chains, reinforcing the importance of strategic sourcing, sustainable practices, and technological collaboration.

1. How can I effectively vet suppliers of SiC material in international markets?

Begin by verifying the supplier’s business licenses and certifications relevant to SiC production, such as ISO 9001 for quality management. Request samples and technical datasheets to assess product consistency. Check references or client testimonials, especially from companies in your region or industry. Use third-party inspection or audit services to validate manufacturing capabilities and compliance. Additionally, consider suppliers with local or regional offices for easier communication and support. Establishing clear communication channels and trial orders can further mitigate risks associated with new international suppliers.

2. What customization options are typically available for SiC materials, and how can I ensure they meet my specifications?

SiC materials can often be tailored in terms of purity levels, particle size, shape, and form (powder, grit, wafers). Discuss your application requirements upfront with suppliers to confirm their ability to deliver customized grades. Request detailed technical documentation and samples for testing before placing bulk orders. Clarify any additional costs or lead times associated with customization. Collaborating closely with your supplier’s technical team ensures the product meets your performance criteria, which is critical for industries like electronics, abrasives, and automotive components.

3. What are common minimum order quantities (MOQs) and lead times for SiC material shipments to regions like Africa or South America?

MOQs vary widely depending on the supplier and product grade but generally range from a few hundred kilograms to several tons. Lead times typically span 4 to 12 weeks, influenced by production schedules, customization, and shipping logistics. Buyers from Africa and South America should factor in additional transit times and customs clearance delays. Establishing a clear timeline with your supplier and considering buffer stock can prevent production downtime. Negotiating flexible MOQs or phased deliveries is advisable for businesses testing new suppliers or markets.

4. Which payment terms and methods are most secure and commonly accepted for international SiC transactions?

Secure payment methods include Letters of Credit (LC), Telegraphic Transfers (T/T), and Escrow services, with LC offering the highest security by ensuring payment only upon compliance with contract terms. Payment terms typically range from 30% upfront deposit to 70% upon shipment or delivery. For buyers in emerging markets, negotiating partial payments linked to production milestones can reduce risk. Always verify the supplier’s bank details independently to avoid fraud. Using international trade platforms or trusted financial intermediaries can further safeguard transactions.

5. What quality assurance certifications should I look for when sourcing SiC material internationally?

Key certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and industry-specific standards like REACH compliance for chemical safety in Europe. Certifications from recognized bodies such as SGS or TÜV can provide third-party validation of material purity and performance. Request batch-specific certificates of analysis (CoA) with each shipment to verify consistency. Regular audits and factory inspections help maintain quality over time. Ensuring your supplier complies with both international and local regulatory standards is crucial for smooth market entry.

6. How can I optimize logistics and shipping for importing SiC material into countries like Kenya or Turkey?

Partner with freight forwarders experienced in handling chemical and abrasive materials to navigate customs and hazardous goods regulations efficiently. Choose shipping routes and modes (sea, air, rail) balancing cost, speed, and product sensitivity. Consolidate shipments where possible to reduce freight costs but avoid excessive delays. Understand import duties, taxes, and documentation requirements specific to your country to prevent clearance issues. Establish clear Incoterms with your supplier to define responsibilities and risks during transit. Proactive communication with logistics partners ensures timely delivery and inventory planning.

7. What steps should I take if there is a dispute regarding SiC material quality or delivery?

Immediately document all discrepancies with photos, test results, and communication records. Notify the supplier promptly and request their investigation or replacement. Review the contract terms related to dispute resolution, including arbitration clauses or jurisdiction. Engaging third-party inspection or testing labs can provide impartial evidence. Maintain professional and clear communication to facilitate amicable solutions. If unresolved, escalate through industry trade bodies or legal counsel familiar with international trade laws. Preventive measures like detailed contracts and quality agreements reduce the likelihood of disputes.

8. Are there specific regulatory or environmental considerations when importing SiC material into my region?

Yes, SiC materials may be subject to chemical safety regulations such as REACH in Europe, OSHA standards in the US, or local environmental laws in Africa and the Middle East. Ensure your supplier provides material safety data sheets (MSDS) compliant with these regulations. Some countries require import permits or environmental impact assessments for abrasive or chemical products. Staying informed about waste disposal and handling protocols protects your company from legal penalties. Collaborate with local regulatory consultants or trade associations to navigate compliance efficiently and sustainably.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of SiC (silicon carbide) material stands as a critical enabler for businesses seeking to enhance product performance, durability, and efficiency across multiple industries. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of supplier reliability, quality certifications, and supply chain resilience is paramount. Prioritizing partnerships with established, transparent suppliers who offer traceability and consistent quality can mitigate risks associated with geopolitical volatility and fluctuating raw material costs.

Key takeaways include the importance of aligning sourcing strategies with long-term market trends such as the rising demand for electric vehicles, renewable energy systems, and advanced electronics. Buyers should leverage regional trade agreements, optimize logistics routes, and invest in supplier relationship management to ensure competitive pricing and timely delivery.

Looking ahead, the SiC material market is poised for significant growth driven by technological advancements and sustainability imperatives. International buyers are encouraged to adopt a proactive, informed approach—engaging in collaborative innovation with suppliers and exploring emerging markets to secure strategic advantages. By doing so, businesses will not only optimize their supply chains but also position themselves at the forefront of industrial transformation.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina