The global market for SiC (silicon carbide) presents a unique set of challenges for B2B buyers, particularly in sourcing high-quality materials that meet specific performance and cost requirements. As industries increasingly rely on SiC for its superior thermal conductivity, hardness, and electrical efficiency, understanding the diverse applications—from power electronics to automotive components—becomes crucial. This guide aims to equip international B2B buyers, especially those from Africa, South America, the Middle East, and Europe (including Poland and Turkey), with the insights needed to navigate this complex landscape effectively.

In this comprehensive guide, you will discover the various types of SiC, their applications across different sectors, and strategies for vetting suppliers to ensure quality and reliability. We will also delve into cost considerations, helping you assess the total cost of ownership and potential return on investment. By arming yourself with this knowledge, you can make informed purchasing decisions that align with your organization's operational goals.

This guide not only simplifies the procurement process but also empowers you to build strategic partnerships with suppliers, ensuring that you stay ahead in a competitive market. Whether you are looking to innovate or streamline your supply chain, understanding the nuances of SiC sourcing is essential for driving growth and achieving long-term success.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SIC Powder | Fine granules, high purity, customizable particle size | Abrasives, ceramics, and composite materials | Pros: Versatile; Cons: Handling can be hazardous. |

| SIC Wafer | Thin, flat silicon carbide layers, high thermal conductivity | Semiconductor devices, power electronics | Pros: High performance; Cons: Costly to produce. |

| SIC Substrate | Thick, sturdy base for electronic components | High-power and high-frequency devices | Pros: Excellent thermal management; Cons: Limited supply options. |

| SIC Coating | Thin layer applied to surfaces, enhances durability | Aerospace, automotive, and industrial tools | Pros: Improves wear resistance; Cons: Application complexity. |

| SIC Ceramics | Dense, hard materials with excellent thermal properties | High-temperature applications, cutting tools | Pros: High strength; Cons: Brittle nature can lead to failure. |

SIC Powder is characterized by its fine granules and high purity, often tailored to specific particle sizes to meet various industry needs. This type of silicon carbide is predominantly used in abrasives and ceramic applications, where its hardness and thermal stability are crucial. When considering B2B purchasing, buyers should evaluate the supplier's ability to provide consistent quality and the potential hazards associated with handling fine powders.

SIC Wafer is noted for its thin, flat structure, which is essential for semiconductor applications. Its high thermal conductivity makes it ideal for power electronics and devices requiring efficient heat dissipation. For B2B buyers, the main consideration is the wafer's quality and the manufacturer's reputation, as defects can significantly impact device performance. The higher production costs may also be a concern for budget-sensitive projects.

SIC Substrate offers a robust base for electronic components, especially in high-power and high-frequency applications. Its excellent thermal management capabilities make it suitable for advanced electronic devices. B2B buyers should consider the availability of these substrates and the supplier's ability to meet specific size and quality requirements, as sourcing can sometimes be limited compared to more common materials.

SIC Coating provides a thin layer that enhances the durability of various surfaces, making it particularly valuable in aerospace, automotive, and industrial tool applications. This coating significantly improves wear resistance, extending the life of tools and components. Buyers should assess the complexity of the application process and the coating's compatibility with existing materials, as these factors can influence overall effectiveness.

SIC Ceramics are recognized for their density, hardness, and exceptional thermal properties, making them ideal for high-temperature environments and cutting tools. However, their brittle nature can pose risks of failure under certain conditions. When purchasing, B2B buyers should weigh the benefits of high strength against the potential for brittleness, ensuring that the application aligns with the material's characteristics.

| Industry/Sector | Specific Application of sic siliziumcarbid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric Vehicle (EV) Power Electronics | Enhanced efficiency and performance in EV systems | Reliability of suppliers, certification standards, and material sourcing from reputable manufacturers. |

| Aerospace | High-Temperature Components | Increased durability and reduced weight of components | Compliance with aerospace regulations and testing for thermal stability. |

| Renewable Energy | Solar Inverter Systems | Improved energy conversion and lower operational costs | Availability of high-quality materials and support for integration with existing systems. |

| Semiconductor Manufacturing | High-Performance Transistors | Superior thermal conductivity and reduced energy loss | Assurance of purity and quality in raw materials, along with long-term supply agreements. |

| Industrial Equipment | Abrasives and Cutting Tools | Longer tool life and reduced downtime in production | Specification of grit size and performance metrics, alongside supplier reliability. |

In the automotive sector, Sic siliziumcarbid is primarily utilized in the power electronics of electric vehicles (EVs). Its exceptional thermal conductivity and high breakdown voltage enable the production of smaller, more efficient components. This leads to reduced energy losses and improved performance in EV systems. International buyers should focus on sourcing from manufacturers that adhere to strict reliability standards, ensuring that components can withstand the rigors of automotive applications.

Sic siliziumcarbid is vital in aerospace for high-temperature components, such as turbine blades and heat exchangers. Its ability to operate under extreme conditions while maintaining structural integrity makes it ideal for enhancing the performance and safety of aircraft. Buyers in this sector must ensure that suppliers meet aerospace industry regulations and provide materials that have been rigorously tested for thermal stability and durability.

In the renewable energy sector, particularly in solar power, Sic siliziumcarbid is employed in solar inverter systems. Its superior efficiency leads to better energy conversion rates, which can significantly reduce operational costs. For businesses sourcing these materials, it is crucial to evaluate the quality and performance of Sic siliziumcarbid, as well as the supplier's ability to support integration with existing renewable energy systems.

Sic siliziumcarbid is increasingly used in the semiconductor industry for high-performance transistors. Its unique properties allow for lower energy losses and better thermal management, which are essential for modern electronic devices. International B2B buyers should prioritize suppliers who can guarantee the purity of their Sic siliziumcarbid materials, as well as those who offer long-term supply agreements to ensure continuity in production processes.

In industrial applications, Sic siliziumcarbid is often used in abrasives and cutting tools. The material's hardness and durability lead to longer tool life, minimizing downtime and increasing productivity. Buyers should specify their requirements regarding grit size and performance metrics when sourcing Sic siliziumcarbid, and they should seek out suppliers with a proven track record in the manufacturing of high-performance industrial equipment.

Related Video: Thin Silicon Carbide Explained - SiC Basics

The Problem:

International B2B buyers often encounter challenges in sourcing high-quality Sic siliziumcarbid, especially when dealing with suppliers from different regions such as Africa, South America, and the Middle East. Buyers may face issues such as inconsistent product specifications, subpar material quality, and lack of transparency in the supply chain. This can lead to production delays, increased costs, and ultimately affect product reliability and performance in applications like semiconductors and power devices.

The Solution:

To mitigate these challenges, buyers should implement a rigorous supplier evaluation process. Start by requesting samples from multiple suppliers and conducting thorough quality assessments based on industry standards such as ISO 9001. Establish clear specifications for Sic siliziumcarbid that align with your application requirements, including purity levels, particle size, and thermal conductivity. Additionally, consider leveraging local partnerships with suppliers who have established reputations in the industry. This not only helps in ensuring quality but also facilitates easier communication and quicker response times. For buyers in Europe and the Middle East, attending regional trade shows can also provide opportunities to connect directly with manufacturers and verify their capabilities firsthand.

The Problem:

Many B2B buyers struggle to grasp the technical applications and benefits of Sic siliziumcarbid in their specific industries, which can hinder informed decision-making. For example, buyers from the automotive or renewable energy sectors may not fully understand how Sic siliziumcarbid can enhance the efficiency of electric vehicle batteries or improve the performance of photovoltaic systems. This lack of knowledge can lead to poor investment choices and missed opportunities for innovation.

The Solution:

Investing in educational resources is key to overcoming this knowledge gap. Buyers should seek out technical workshops, webinars, and online courses that focus on the applications of Sic siliziumcarbid in their industries. Collaborating with engineering teams or consulting with experts can also provide insights into how to best utilize this material to achieve desired outcomes. Furthermore, developing a clear understanding of the lifecycle and performance metrics of Sic siliziumcarbid will enable buyers to make better predictions about its long-term benefits. Engaging with case studies and peer-reviewed research can also offer concrete examples of successful implementations, helping buyers to envision how Sic siliziumcarbid could fit into their operations.

The Problem:

Cost management is a critical concern for international B2B buyers of Sic siliziumcarbid. Fluctuating prices due to market demand, geopolitical factors, and transportation costs can create unpredictability in budgeting. Buyers often find themselves in a position where they need to justify the investment in Sic siliziumcarbid against cheaper alternatives, which may not offer the same performance benefits, leading to internal conflicts and potential project delays.

The Solution:

To effectively manage costs, buyers should consider adopting a strategic sourcing approach. This involves conducting a total cost of ownership analysis that evaluates not only the upfront costs but also the long-term savings associated with using Sic siliziumcarbid. Engage in long-term contracts with suppliers to lock in favorable pricing and stabilize supply chains. Additionally, buyers can explore bulk purchasing agreements or cooperative buying groups to leverage collective bargaining power. Educating internal stakeholders on the value proposition of Sic siliziumcarbid, including its superior thermal and electrical properties, can help in gaining support for procurement decisions. Regularly reviewing market trends and establishing relationships with multiple suppliers can also provide leverage during negotiations, ensuring that cost concerns are effectively addressed without compromising on quality.

When selecting materials for sic siliziumcarbid (silicon carbide), it is essential to consider various options based on their properties, manufacturing complexities, and application suitability. Below, we analyze four common materials used in conjunction with sic siliziumcarbid, focusing on their key properties, pros and cons, and implications for international B2B buyers.

Key Properties: Silicon carbide itself is known for its high thermal conductivity, excellent thermal shock resistance, and high hardness. It can operate effectively at temperatures exceeding 1600°C and withstand significant mechanical stress.

Pros & Cons: The primary advantage of SiC is its durability and ability to maintain performance under extreme conditions. However, the manufacturing process can be complex and costly, which might limit its use in low-budget applications.

Impact on Application: SiC is highly compatible with high-temperature and high-pressure environments, making it ideal for applications in aerospace, automotive, and semiconductor industries.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, while European buyers may prefer materials that meet ASTM or DIN specifications.

Key Properties: Alumina is known for its excellent wear resistance, high melting point (over 2000°C), and good electrical insulation properties. It also exhibits moderate corrosion resistance.

Pros & Cons: The key advantage of alumina is its cost-effectiveness and availability. However, it is less durable than SiC, particularly under thermal shock, and may not perform well in high-pressure applications.

Impact on Application: Alumina is suitable for applications requiring electrical insulation and wear resistance, such as in grinding wheels and cutting tools.

Considerations for International Buyers: Buyers in Europe may find alumina compliant with various industry standards, while those in the Middle East should verify local regulations regarding material specifications.

Key Properties: Graphite has excellent thermal conductivity, chemical resistance, and a high melting point. It is also lightweight and has a low coefficient of thermal expansion.

Pros & Cons: The primary advantage of graphite is its ability to withstand extreme temperatures and chemical environments. However, it is relatively brittle and can be prone to oxidation at high temperatures.

Impact on Application: Graphite is often used in high-temperature applications, such as in furnaces and as a lubricant in high-stress environments.

Considerations for International Buyers: Buyers from South America should consider the availability of high-quality graphite, while European buyers may need to ensure compliance with environmental regulations regarding the sourcing of graphite.

Key Properties: Zirconia is known for its high fracture toughness, thermal stability, and resistance to corrosion. It can operate effectively at temperatures up to 2000°C.

Pros & Cons: The key advantage of zirconia is its ability to maintain structural integrity under high stress and temperature. However, it is more expensive than other materials and can be challenging to manufacture.

Impact on Application: Zirconia is ideal for applications in the dental and biomedical fields, as well as in high-performance ceramics.

Considerations for International Buyers: Buyers in Africa and the Middle East should assess the availability of zirconia and its compliance with local standards, while European buyers may prioritize suppliers with certifications in quality management systems.

| Material | Typical Use Case for sic siliziumcarbid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Aerospace components, semiconductors | High durability and thermal resistance | High manufacturing complexity | High |

| Alumina | Grinding wheels, electrical insulators | Cost-effective and widely available | Less durable under thermal shock | Medium |

| Graphite | High-temperature furnaces, lubricants | Excellent thermal conductivity | Brittle and prone to oxidation | Medium |

| Zirconia | Dental applications, high-performance ceramics | High fracture toughness | Expensive and complex to manufacture | High |

This strategic material selection guide aims to provide international B2B buyers with essential insights into the materials used for sic siliziumcarbid, enabling informed decisions that align with their operational needs and regional standards.

The manufacturing process for silicon carbide (SiC), known as Sic siliziumcarbid, involves several critical stages that ensure the production of high-quality materials. Each phase requires precision and adherence to best practices to meet industry standards.

The first step in SiC manufacturing is the preparation of raw materials. Silicon and carbon are the primary constituents, and their quality significantly impacts the final product. Suppliers often use high-purity silicon and carbon sources to minimize impurities that can affect the performance of the SiC. For international buyers, it is crucial to verify the quality of these materials through supplier certifications and chemical analysis reports.

Following material preparation, the next phase is forming. This stage typically involves techniques such as:

B2B buyers should inquire about the specific forming techniques used by suppliers, as this can influence the material's final properties and suitability for particular applications.

In some cases, especially for complex components, assembly is necessary. This phase may involve bonding SiC with other materials, which requires a thorough understanding of material compatibility and bonding techniques. Buyers should consider suppliers that provide clear documentation of their assembly processes to ensure reliability and performance.

The finishing stage includes surface treatments and precision machining to achieve the desired dimensions and surface quality. Techniques such as grinding, polishing, and coating may be employed to enhance the material's characteristics. For international buyers, understanding the finishing processes can help assess whether the components will meet specific performance criteria in their applications.

Quality assurance (QA) is a critical aspect of SiC manufacturing, ensuring that the products meet international standards and customer specifications. Various international and industry-specific standards govern the QA processes.

B2B buyers should confirm that suppliers adhere to these standards, as they reflect a commitment to quality and reliability.

Quality control (QC) in SiC manufacturing typically involves several checkpoints:

Buyers should ask suppliers about their QC procedures and the frequency of these inspections to gauge the reliability of their products.

Several testing methods are employed to validate the quality of SiC materials:

International buyers should request detailed testing reports from suppliers to verify compliance with relevant standards.

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier's quality control processes is essential to mitigate risks. Here are actionable steps:

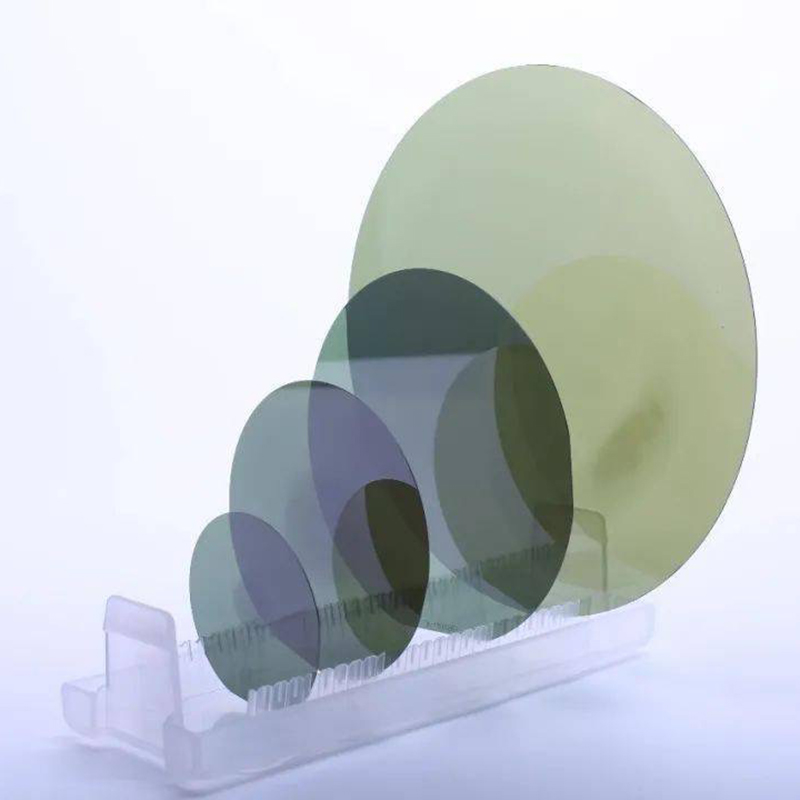

A stock image related to sic siliziumcarbid.

International buyers need to be aware of specific nuances when it comes to quality control in SiC manufacturing. These include:

By following these guidelines and understanding the manufacturing processes and quality assurance methods for Sic siliziumcarbid, international B2B buyers can make informed decisions and establish reliable supply chains.

The procurement of silicon carbide (SiC) is a critical process for B2B buyers looking to enhance their supply chain with high-performance materials. This guide outlines essential steps to ensure that your sourcing process is efficient, effective, and tailored to your specific needs.

Establishing clear technical specifications is the foundation of a successful procurement process. Determine the grade, size, and purity levels of SiC that are necessary for your application.

- Consider the end-use: Different applications, such as semiconductor devices or abrasives, may require varying specifications.

- Consult with your engineering team to ensure that all necessary parameters are included.

Understanding the market landscape is vital for identifying potential suppliers. Research the current market trends, pricing, and availability of SiC in your target regions, such as Europe or South America.

- Utilize industry reports and publications to gain insights into market dynamics.

- Explore online platforms that specialize in industrial materials to gauge competitive pricing and supplier options.

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request detailed company profiles, case studies, and references from buyers in similar industries.

- Assess their experience in supplying SiC and their reputation in the market.

- Verify their production capabilities to ensure they can meet your volume requirements.

Supplier certifications are critical indicators of quality and reliability. Ensure that potential suppliers have relevant certifications such as ISO 9001 or industry-specific quality standards.

- Check for compliance with international regulations that may apply to your industry.

- Request copies of their quality management systems to understand their commitment to maintaining high standards.

Before making a large order, requesting samples is essential to verify the quality of SiC. Testing samples in your application can reveal how well they perform under real-world conditions.

- Conduct performance tests to assess durability, thermal stability, and other relevant factors.

- Engage your R&D team to analyze the samples and provide feedback on their suitability.

Once you have shortlisted suppliers, it’s time to negotiate the terms of purchase. Discuss pricing, delivery schedules, payment terms, and warranties to ensure mutual agreement.

- Be clear about your expectations regarding delivery timelines and quality checks.

- Consider long-term contracts if you find a reliable supplier to secure better pricing and consistent supply.

Effective communication is key to a successful supplier relationship. Establish a clear communication plan that outlines how and when you will interact with your supplier.

- Set regular check-ins to discuss order status, quality issues, or any changes in demand.

- Utilize digital tools for efficient communication, especially if you are sourcing from suppliers in different regions.

Following this step-by-step checklist will help international B2B buyers streamline the procurement of silicon carbide, ensuring that the materials meet both technical specifications and business requirements.

When sourcing sic siliziumcarbid, understanding the cost structure is vital for international B2B buyers. The major cost components include:

Materials: The primary raw material, silicon carbide, is influenced by global market prices, availability, and quality. Prices can fluctuate based on supply chain disruptions or increased demand in sectors like automotive or electronics.

Labor: Labor costs vary significantly by region. Countries with lower wage standards may offer competitive pricing, but it's essential to consider the skill level and expertise required for manufacturing high-quality sic siliziumcarbid.

Manufacturing Overhead: This includes utilities, rent, and other operational costs. Buyers should assess whether suppliers operate in high-cost regions, as this can impact the overall pricing.

Tooling: Initial tooling costs can be significant, especially for customized solutions. Buyers need to factor in whether they require specialized tools that may increase upfront costs.

Quality Control (QC): Ensuring product quality often involves additional testing and certification costs. Buyers should prioritize suppliers with robust QC processes, as this can prevent costly issues later.

A stock image related to sic siliziumcarbid.

Logistics: Transportation and shipping costs, influenced by the Incoterms used in the contract, can vary widely. Buyers should consider the total logistics cost, including potential tariffs or duties.

Margin: Suppliers typically build their profit margins into the final pricing. Understanding the market rates and competitive landscape can help buyers negotiate better deals.

Several factors can influence the pricing of sic siliziumcarbid, including:

Volume/MOQ: Suppliers often have minimum order quantities (MOQ) that can affect pricing. Larger orders may lead to discounts, but buyers should evaluate their actual needs to avoid excess inventory.

Specifications and Customization: Custom solutions tailored to specific applications may incur additional costs. Buyers should clearly define their requirements to avoid misunderstandings and unexpected expenses.

Materials and Quality Certifications: The quality of raw materials and certifications (like ISO or RoHS) can affect pricing. Buyers should weigh the importance of quality against cost, as cheaper materials may result in higher total costs due to failure or inefficiency.

Supplier Factors: The reputation and reliability of suppliers can influence price. Established suppliers may charge more but offer better service, reliability, and quality assurance.

Incoterms: The choice of Incoterms affects the distribution of costs and risks between buyers and sellers. Understanding which Incoterm to use can help buyers manage expenses effectively.

To maximize cost-efficiency, international B2B buyers should consider the following strategies:

Negotiation: Engage suppliers in discussions about pricing and terms. Building a good relationship can lead to better deals and flexibility in pricing.

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. This includes maintenance, operational costs, and potential downtime, which can greatly affect the overall budget.

Pricing Nuances for International Markets: Be aware of currency fluctuations, import duties, and local taxes that can significantly impact costs. Buyers from Africa, South America, the Middle East, and Europe (e.g., Poland, Turkey) should stay informed about their specific market conditions.

Supplier Audits: Conduct regular assessments of suppliers to ensure they meet quality and pricing expectations. This can help avoid issues that may arise from sourcing from unreliable suppliers.

Leveraging Technology: Utilize digital tools and platforms for sourcing to gain insights into market trends, supplier performance, and pricing structures.

While sourcing sic siliziumcarbid, international B2B buyers must navigate a complex landscape of costs and pricing influences. By understanding the components involved and employing strategic sourcing practices, buyers can optimize their procurement processes, ensuring they achieve the best value for their investments.

Disclaimer: The prices and strategies discussed are indicative and may vary based on market conditions and specific supplier negotiations. Always conduct thorough market research and consult with industry experts before making purchasing decisions.

When considering sic siliziumcarbid (silicon carbide), it's essential to evaluate various alternative solutions available in the market. This analysis helps B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understand the unique benefits and drawbacks of each option. By comparing performance, cost, ease of implementation, maintenance, and best use cases, businesses can make informed purchasing decisions aligned with their operational needs.

| Comparison Aspect | Sic Siliziumcarbid | Alternative 1: Silicon (Si) | Alternative 2: Gallium Nitride (GaN) |

|---|---|---|---|

| Performance | High thermal conductivity; superior electrical performance | Moderate thermal conductivity; lower efficiency | Excellent thermal conductivity; high efficiency |

| Cost | Higher initial investment | Lower cost; widely available | Higher than Si but lower than SiC |

| Ease of Implementation | Requires specialized tools and training | Easy to implement; standard tools | Moderate complexity; requires specific design considerations |

| Maintenance | Low maintenance; durable | Moderate; depends on application | Low maintenance; robust reliability |

| Best Use Case | High-power applications, automotive, and aerospace sectors | General electronics, consumer products | Power amplifiers, RF applications, and electric vehicles |

Silicon is the most widely used semiconductor material due to its affordability and availability. It is suitable for various applications, particularly in consumer electronics. However, its performance can be limited in high-temperature and high-voltage scenarios. B2B buyers focusing on cost-sensitive projects may find silicon to be a viable option, but they should be aware that it may not meet the efficiency needs of advanced applications.

Gallium Nitride offers excellent performance in terms of efficiency and thermal conductivity, making it ideal for high-frequency and high-power applications. Its use is growing in sectors like telecommunications and electric vehicles. However, GaN can be more expensive than silicon and requires specific design considerations, which may complicate its implementation. Businesses looking to innovate in high-performance areas should consider GaN despite the higher upfront costs.

Selecting the right material or technology, such as sic siliziumcarbid, silicon, or gallium nitride, depends on the specific needs of your business. B2B buyers should assess their performance requirements, budget constraints, and the technical complexity of implementation. For high-performance applications where efficiency is paramount, sic siliziumcarbid or gallium nitride may be the best choices. Conversely, for more general applications with tighter budgets, silicon could suffice. By carefully analyzing these factors, buyers can ensure they make the most suitable choice for their operational objectives.

Silicon carbide (SiC) is a compound semiconductor known for its exceptional performance in high-temperature, high-voltage, and high-frequency applications. Understanding its critical technical properties is crucial for international B2B buyers looking to procure SiC materials for various industrial applications.

Material grades of SiC indicate the purity and crystalline structure of the silicon carbide being used. Common grades include 4H, 6H, and 3C, each differing in properties like thermal conductivity and electrical characteristics. For B2B buyers, selecting the appropriate material grade is essential as it directly impacts the performance of devices in applications such as power electronics and high-frequency devices.

Tolerance levels refer to the permissible limits of variation in dimensions and physical properties. For SiC wafers, this can include thickness, diameter, and surface roughness. High-precision tolerances are crucial for manufacturers in sectors like automotive and aerospace, where any deviation can lead to significant performance issues or failures.

SiC boasts high thermal conductivity, which makes it suitable for high-temperature applications. This property allows for efficient heat dissipation, critical in electronic devices that generate substantial heat during operation. B2B buyers should prioritize thermal conductivity specifications, especially when sourcing materials for power devices in energy and automotive industries.

The bandgap energy of SiC is approximately 3.26 eV, which is significantly larger than that of silicon. This characteristic enables SiC devices to operate at higher voltages and temperatures without compromising performance. Understanding bandgap energy is vital for buyers seeking to develop next-generation electronic devices that require higher efficiency and reliability.

The breakdown voltage of SiC is significantly higher than that of traditional silicon. This allows SiC devices to withstand higher electrical stress, making them suitable for applications in power conversion and high-voltage systems. Buyers should evaluate breakdown voltage ratings to ensure the selected materials meet the operational demands of their applications.

Navigating the procurement of silicon carbide requires familiarity with specific trade terminology. Here are some essential terms that every B2B buyer should know.

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the SiC market, OEMs are crucial as they often dictate specifications and quality standards for SiC components used in their products.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it can significantly impact inventory management and procurement costs. Buyers should negotiate MOQs to align with their production needs.

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. For SiC materials, issuing an RFQ allows buyers to compare pricing, delivery times, and terms from multiple suppliers, ultimately aiding in informed decision-making.

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping of goods. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and logistics involved in acquiring SiC materials from international suppliers.

Lead time refers to the time taken from placing an order to its delivery. In the SiC industry, lead times can vary significantly based on material availability and production schedules. Understanding lead times is crucial for buyers to plan their production schedules and ensure timely project execution.

For international B2B buyers, grasping the essential technical properties and trade terminology related to silicon carbide is vital for making informed purchasing decisions. A comprehensive understanding of these aspects not only enhances procurement strategies but also supports the development of high-performance applications across various industries.

The sic siliziumcarbid sector is experiencing significant growth driven by the increasing demand for high-performance materials in various applications, including power electronics, automotive, and renewable energy technologies. As global economies shift towards sustainable practices, the need for efficient and durable materials like silicon carbide (SiC) is paramount. Key trends influencing the market include the rapid adoption of electric vehicles (EVs), advancements in power semiconductor technology, and an emphasis on energy efficiency.

International B2B buyers, particularly in Africa, South America, the Middle East, and Europe (notably Poland and Turkey), should be aware of the growing competition from local manufacturers and the need to adapt to changing regulations regarding material sourcing and environmental impact. The rise of digital procurement platforms is also transforming how buyers interact with suppliers, facilitating faster decision-making and access to a wider range of products. Additionally, as industries seek to reduce operational costs, there is a notable trend towards sourcing materials that offer greater longevity and performance, thus reducing lifecycle costs.

Sustainability has become a critical component in the sourcing strategies of international B2B buyers. The environmental impact of sourcing silicon carbide, including mining and processing, necessitates a focus on ethical supply chains. Buyers should prioritize suppliers who demonstrate a commitment to reducing their carbon footprint and adhering to responsible mining practices.

Investing in 'green' certifications and materials can enhance a company's brand reputation and align with global sustainability goals. For instance, sourcing SiC from suppliers that use eco-friendly production methods or recycled materials can significantly reduce environmental harm. Furthermore, transparency in the supply chain is essential; buyers should seek partners who provide clear information on their sourcing practices and sustainability initiatives. By aligning with ethical sourcing practices, B2B buyers can not only contribute to environmental conservation but also meet the growing consumer demand for sustainable products.

The history of silicon carbide dates back to its discovery in the late 19th century, where it was primarily used as an abrasive material. Over the decades, advancements in manufacturing techniques and a deeper understanding of its semiconductor properties have propelled SiC into the forefront of electronic applications. Today, it is recognized for its ability to withstand high temperatures and voltages, making it essential for modern technologies such as electric vehicles, solar inverters, and power electronics.

Understanding the evolution of silicon carbide is crucial for B2B buyers as it highlights the material's growing importance in advanced applications and its role in driving innovation in various sectors. As industries continue to evolve, staying informed about the historical advancements in SiC technology can provide buyers with insights into future trends and opportunities in the market.

How do I choose the right supplier for sic siliziumcarbid?

Selecting the right supplier for sic siliziumcarbid involves evaluating several factors. Start by assessing the supplier's experience in the industry and their track record of reliability. Request samples to evaluate product quality and ensure they meet your specifications. It is also important to verify certifications and compliance with international standards. Additionally, consider logistical capabilities, such as shipping times and costs, especially if you are sourcing from regions like Africa, South America, or the Middle East.

What are the typical payment terms for international transactions involving sic siliziumcarbid?

Payment terms can vary significantly by supplier and region. Common methods include letters of credit, advance payments, or net terms (e.g., net 30 or 60 days). For international transactions, it’s advisable to negotiate terms that mitigate risk, such as partial upfront payments followed by the remainder upon delivery. Always ensure that payment terms are clearly stated in the contract to avoid misunderstandings, especially when dealing with suppliers from different cultural backgrounds.

What is the minimum order quantity (MOQ) for sic siliziumcarbid?

The minimum order quantity (MOQ) for sic siliziumcarbid can differ based on the supplier and the specific product. Many suppliers set MOQs to cover production costs and ensure profitability. Typically, MOQs can range from a few kilograms to several tons. When negotiating with suppliers, inquire about the possibility of lower MOQs for first-time orders or samples, which can help you test the market without committing to large quantities.

How can I ensure quality assurance when sourcing sic siliziumcarbid?

To ensure quality assurance, request detailed specifications and standards from your supplier. Conduct factory audits and inspections, if possible, to verify their production processes. Additionally, request third-party test reports or certifications that demonstrate compliance with international quality standards. Establishing a clear quality control agreement in your contract can help maintain product consistency and safeguard against defects.

What customization options are available for sic siliziumcarbid products?

Customization options for sic siliziumcarbid products may include variations in size, purity levels, and specific formulations tailored to your application. When discussing customization with suppliers, clearly outline your requirements and ask about their capabilities to meet these needs. Some suppliers may offer bespoke solutions or modifications to existing products, allowing you to optimize performance for your specific industrial applications.

What logistical considerations should I keep in mind when importing sic siliziumcarbid?

Logistical considerations include shipping methods, customs regulations, and delivery times. Choose a shipping method that balances cost and speed, such as air freight for urgent orders or sea freight for larger shipments. Familiarize yourself with the customs regulations of your country to avoid delays and ensure compliance. Collaborating with a freight forwarder experienced in handling industrial materials can simplify the process and provide valuable insights.

How do I handle disputes with suppliers of sic siliziumcarbid?

Handling disputes effectively requires clear communication and documentation. Start by addressing the issue directly with your supplier, providing evidence and details of the problem. If resolution is not achieved, refer to the contract's dispute resolution clause, which may include mediation or arbitration processes. Maintaining a professional demeanor throughout the process can help preserve the relationship, which is crucial for future collaborations.

What are the key market trends influencing the demand for sic siliziumcarbid?

Market trends impacting the demand for sic siliziumcarbid include the growing emphasis on energy efficiency and the expansion of electric vehicle (EV) technologies. As industries seek to reduce carbon footprints, materials like sic siliziumcarbid are increasingly favored for their superior thermal and electrical properties. Additionally, advancements in semiconductor technology and renewable energy applications are driving demand, particularly in regions focused on sustainable development, such as Europe and parts of Africa.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the evolving landscape of sic siliziumcarbid sourcing, strategic partnerships and localized supply chains are critical for maximizing operational efficiency and cost-effectiveness. International B2B buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who not only provide quality materials but also demonstrate adaptability to market fluctuations and regulatory changes. Understanding regional market dynamics and leveraging technology for sourcing decisions can enhance procurement strategies and mitigate risks.

Investing in strategic sourcing for sic siliziumcarbid allows companies to optimize their supply chains, ensuring they remain competitive in a rapidly changing global market. By focusing on long-term relationships with suppliers, businesses can benefit from improved pricing structures, consistent quality, and innovative solutions tailored to their specific needs. This approach not only leads to substantial cost savings but also drives value creation across the organization.

Looking ahead, the demand for sic siliziumcarbid is poised to grow, fueled by advancements in technology and increasing applications in various industries. Buyers should stay informed about emerging trends and invest in building resilient supply chains. By proactively engaging with suppliers and exploring collaborative opportunities, businesses can position themselves for success in this dynamic market. Now is the time to take action—evaluate your sourcing strategies and consider how you can leverage sic siliziumcarbid to achieve your business objectives.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina