In an increasingly competitive landscape, sourcing silicon carbide (SiC) mirrors can pose significant challenges for international B2B buyers, particularly those operating in diverse regions like Africa, South America, the Middle East, and Europe, including markets such as Poland and the UAE. With the growing demand for advanced optical components in sectors such as aerospace, defense, and telecommunications, understanding the nuances of SiC mirrors is vital for making informed purchasing decisions. This guide aims to illuminate various aspects of SiC mirrors, including types, applications, supplier vetting, and cost considerations, providing a comprehensive resource for businesses seeking to leverage the advantages of these high-performance optical components.

By navigating through this guide, buyers will gain insights into the latest technological advancements, enabling them to identify the right suppliers and products that meet their specific needs. Whether you are looking to enhance the precision of laser systems or improve the efficiency of optical instruments, this resource will empower you to make strategic choices that align with your business objectives. Furthermore, the guide addresses regional considerations and supplier dynamics, ensuring that you can effectively source SiC mirrors tailored to your operational context. Equip yourself with the knowledge to excel in the global market and make impactful purchasing decisions that drive your business forward.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SiC Mirrors | High thermal conductivity, lightweight, and durable | Aerospace, defense, and optical systems | Pros: Excellent thermal stability; Cons: Higher cost than traditional materials. |

| Galvanometer Mirrors | Fast response time, precision alignment capabilities | Laser scanning, imaging applications | Pros: High-speed operation; Cons: May require complex control systems. |

| Coated SiC Mirrors | Enhanced reflectivity with specialized coatings | High-power laser applications | Pros: Improved performance; Cons: Coating can degrade over time. |

| Custom SiC Mirrors | Tailored designs for specific applications | Research and development, custom optics | Pros: Fit specific needs; Cons: Longer lead times for production. |

| Multilayer SiC Mirrors | Multiple layers to enhance optical performance | Advanced optical systems and sensors | Pros: Superior optical properties; Cons: More complex manufacturing process. |

Standard silicon carbide (SiC) mirrors are renowned for their remarkable thermal conductivity and lightweight design, making them ideal for demanding environments such as aerospace and defense. Their durability ensures longevity and reliability in various optical systems. B2B buyers should consider the higher upfront cost compared to traditional materials, weighing it against the long-term benefits of reduced maintenance and operational efficiency.

Galvanometer mirrors are specifically designed for applications requiring rapid movement and precision alignment, such as laser scanning and imaging systems. Their fast response times enable high-speed operation, which is crucial in time-sensitive applications. Buyers should evaluate the complexity of the control systems needed for these mirrors, as this can influence overall system costs and integration challenges.

Coated SiC mirrors are engineered with specialized coatings that enhance reflectivity, making them suitable for high-power laser applications. These mirrors not only improve performance but also extend the lifespan of optical systems. However, buyers must be aware of potential coating degradation over time, which may necessitate regular maintenance or replacement, impacting long-term cost considerations.

Custom SiC mirrors provide tailored solutions for specific applications, making them invaluable in research and development settings. These mirrors can be designed to meet unique optical requirements, ensuring optimal performance in specialized environments. While the flexibility of custom designs is a significant advantage, buyers should factor in longer lead times for production and potential increases in costs.

Multilayer SiC mirrors are constructed with multiple layers to enhance optical performance, making them ideal for advanced optical systems and sensors. These mirrors offer superior optical properties, which can significantly improve system efficiency and effectiveness. However, the complex manufacturing process involved may lead to higher costs and longer production times, which buyers should consider when evaluating their options.

Related Video: Images Formed on Mirrors and Lenses | Grade 10 Science DepEd MELC Quarter 2 Module 4

| Industry/Sector | Specific Application of SiC Mirrors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision optical systems for satellite communication | Enhanced signal clarity and reliability | Certifications for aerospace-grade materials; performance testing |

| Laser Processing | Fast steering mirrors for laser machining | Improved accuracy and efficiency in manufacturing | Compatibility with existing laser systems; thermal stability |

| Defense and Security | Surveillance and reconnaissance imaging systems | High-resolution imaging in challenging environments | Robustness against environmental factors; custom design options |

| Medical Equipment | Optical components in surgical imaging devices | Increased precision in diagnostic procedures | Compliance with medical standards; biocompatibility |

| Renewable Energy | Solar concentrators utilizing SiC mirrors | Higher energy conversion efficiency | Durability under harsh weather conditions; scalability of supply |

In the aerospace sector, silicon carbide (SiC) mirrors are critical for precision optical systems used in satellite communication. These mirrors enhance signal clarity and reliability, which is paramount in ensuring uninterrupted communication. International buyers, particularly from regions like Europe and the Middle East, must consider sourcing materials that meet aerospace-grade certifications and undergo rigorous performance testing to ensure they can withstand the extreme conditions of space.

SiC mirrors are essential in laser processing applications, particularly as fast steering mirrors that direct laser beams with high precision. This capability significantly improves the accuracy and efficiency of manufacturing processes, such as cutting and engraving. Buyers should focus on compatibility with existing laser systems and the thermal stability of the mirrors, as these factors directly impact operational performance and longevity.

In defense and security, SiC mirrors are utilized in surveillance and reconnaissance imaging systems. Their ability to provide high-resolution imaging in challenging environments is invaluable for intelligence gathering. Buyers in this sector, especially from Africa and South America, should prioritize sourcing mirrors that are robust against environmental factors, ensuring reliability in diverse operational conditions, along with options for custom designs to fit specific equipment.

SiC mirrors find applications in medical equipment, particularly in surgical imaging devices. Their role in increasing precision during diagnostic procedures can significantly enhance patient outcomes. International buyers in the medical field must ensure that the sourced mirrors comply with medical standards and exhibit biocompatibility, as these factors are critical for patient safety and regulatory compliance.

In the renewable energy sector, SiC mirrors are used in solar concentrators to enhance energy conversion efficiency. By focusing sunlight onto a small area, these mirrors can significantly boost the performance of solar panels. Buyers should consider the durability of SiC mirrors under harsh weather conditions and the scalability of supply to meet increasing energy demands, particularly in developing regions in Africa and South America.

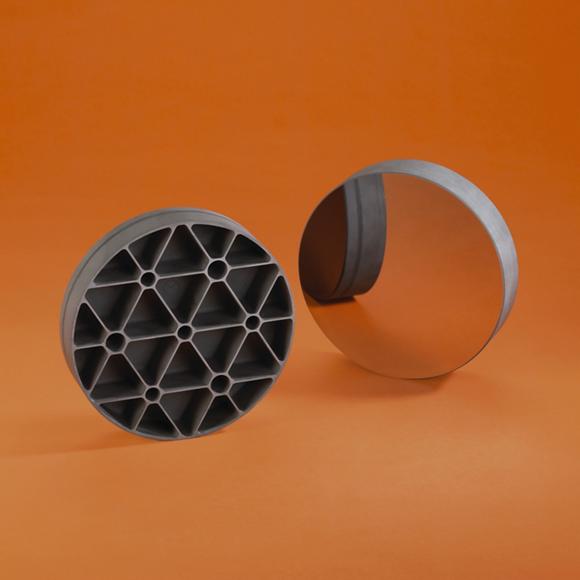

A stock image related to sic mirrors.

Related Video: Uses of Mirrors and Lenses in Optical Devices | Grade 10 Science DepEd MELC Quarter 2 Module 5

The Problem: B2B buyers often face difficulties when trying to customize silicon carbide (SiC) mirrors for specific applications. The challenge lies in balancing the technical specifications, such as surface roughness and optical flatness, with the intended performance criteria of their systems. Additionally, understanding the manufacturing capabilities of suppliers can lead to confusion, especially when buyers are not equipped with in-depth optical engineering knowledge. This complexity can result in delays, increased costs, and ultimately, dissatisfaction with the final product.

The Solution: To effectively navigate this challenge, buyers should engage with suppliers that offer comprehensive consultation services. This can include technical workshops and detailed product specifications. It's crucial to provide suppliers with precise requirements, including the intended application (e.g., laser processing or imaging systems), environmental conditions, and performance metrics. Buyers should also seek suppliers that can demonstrate their expertise through case studies or previous projects. Collaborating early in the design phase allows for iterative feedback, ensuring that the final product meets all specifications. Lastly, consider requesting prototypes or samples to validate the mirror's performance before committing to a large order.

The Problem: Buyers in regions like Africa and South America may encounter significant supply chain disruptions when sourcing SiC mirrors, particularly due to logistical challenges or geopolitical factors. These disruptions can lead to extended lead times, increased shipping costs, and the risk of receiving subpar quality products. For many businesses, this unpredictability can hinder project timelines and lead to financial losses.

The Solution: To mitigate supply chain risks, it is advisable for buyers to diversify their supplier base. Establishing relationships with multiple manufacturers across different regions can provide backup options in case of disruptions. Additionally, buyers should assess suppliers based on their logistics capabilities and production flexibility. Look for vendors that have robust inventory management systems and are capable of rapid prototyping and volume production. Implementing a just-in-time (JIT) inventory strategy can also help minimize the impact of delays, allowing businesses to maintain operational flow without overcommitting resources. Regular communication with suppliers regarding market conditions and potential delays can further enhance transparency and foster a collaborative approach to problem-solving.

The Problem: B2B buyers often struggle with ensuring the quality and performance consistency of SiC mirrors over time. Variations in manufacturing processes, material sourcing, and environmental conditions can lead to discrepancies in optical performance, which can significantly affect end applications such as laser cutting or imaging. This inconsistency can lead to increased operational costs and reliability issues, making it difficult for businesses to maintain high standards.

The Solution: Buyers should prioritize sourcing from manufacturers that adhere to strict quality assurance protocols and industry certifications, such as ISO 9001. It is beneficial to request detailed quality control documentation, including test results for surface quality, reflectivity, and durability. Implementing a supplier audit process can also help ensure that the chosen vendor maintains consistent production standards. Additionally, establishing a feedback loop with suppliers regarding the performance of mirrors in real-world applications allows for continuous improvement. Buyers should also consider long-term contracts with performance guarantees to ensure stability in quality and pricing, which can further mitigate risks associated with variability.

Silicon carbide (SiC) mirrors are increasingly popular in various applications due to their exceptional properties. When selecting materials for SiC mirrors, it is crucial for international B2B buyers to understand the key properties, advantages, disadvantages, and application impacts of different materials. Below, we analyze four common materials used in SiC mirror production.

Key Properties:

Silicon carbide is renowned for its high thermal conductivity, exceptional hardness, and resistance to thermal shock. It can withstand high temperatures (up to 1600°C) and pressures, making it suitable for demanding environments.

Pros & Cons:

The primary advantage of SiC is its durability and performance under extreme conditions. However, the manufacturing process can be complex and costly, which may lead to higher prices for end products.

Impact on Application:

SiC mirrors are ideal for applications in high-power laser systems and aerospace technologies, where reliability and precision are paramount.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure compliance with international standards like ASTM and DIN, especially for aerospace applications. Understanding local regulations can also help in selecting the right suppliers.

Key Properties:

Aluminum is lightweight and offers good thermal conductivity. It is also relatively resistant to corrosion, especially when anodized.

Pros & Cons:

While aluminum is cost-effective and easy to machine, it is less durable than SiC. Its lower melting point (around 660°C) limits its use in high-temperature applications.

Impact on Application:

Aluminum mirrors are commonly used in applications requiring lightweight components, such as in automotive and consumer electronics.

Considerations for International Buyers:

Buyers in Europe, particularly in countries like Poland, should consider the EU's regulations on aluminum production and recycling. Ensuring suppliers adhere to these standards can enhance sustainability efforts.

Key Properties:

Glass is transparent and can be manufactured to various specifications, including high optical quality. It is also resistant to chemical corrosion.

Pros & Cons:

The main advantage of glass is its optical clarity, making it suitable for imaging applications. However, it is less robust than SiC and can shatter under impact or thermal stress.

Impact on Application:

Glass mirrors are often used in optical systems, such as telescopes and cameras, where image quality is critical.

Considerations for International Buyers:

Buyers should be aware of the varying quality standards for glass in different regions. Compliance with ISO standards can ensure that the glass mirrors meet the required optical specifications.

Key Properties:

Coated metals, such as aluminum with a reflective coating, offer a balance between weight and reflectivity. The coating can enhance durability and corrosion resistance.

Pros & Cons:

While coated metals can be less expensive than pure SiC mirrors, their performance may degrade over time due to wear on the coating.

Impact on Application:

These mirrors are suitable for applications where cost is a significant factor, such as in educational settings or low-budget projects.

Considerations for International Buyers:

For buyers in South America, understanding local manufacturing capabilities and coating technologies can help in selecting the right products. Ensuring that coatings meet local environmental regulations is also essential.

| Material | Typical Use Case for SiC Mirrors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | High-power laser systems | Exceptional durability and performance | High manufacturing complexity | High |

| Aluminum | Automotive and consumer electronics | Cost-effective and lightweight | Limited high-temperature use | Medium |

| Glass | Optical systems like telescopes | High optical clarity | Fragile and less durable | Medium |

| Coated Metals | Educational and low-budget applications | Cost-effective and lightweight | Coating wear over time | Low |

This comprehensive analysis provides international B2B buyers with actionable insights into the strategic material selection for SiC mirrors, enabling informed decisions tailored to their specific needs and regional considerations.

The manufacturing of silicon carbide (SiC) mirrors involves several critical stages that ensure high precision and quality. Understanding these processes is essential for B2B buyers looking to procure these components for applications in optics, laser technologies, and more.

A stock image related to sic mirrors.

The first stage in the manufacturing process is the preparation of silicon carbide material. SiC is known for its exceptional hardness and thermal stability, making it suitable for high-performance applications. The raw material undergoes a purification process to eliminate impurities, followed by sintering, where SiC powder is compacted and heated to form a solid mass. This stage is crucial as the purity and homogeneity of the material directly influence the mirror's optical properties.

Once the material is prepared, the next step is forming. This typically involves precision machining techniques such as grinding, lapping, and polishing. CNC (Computer Numerical Control) machines are commonly used to achieve the desired shape and dimensions. The goal during this stage is to attain high geometric accuracy and surface quality, which is vital for the mirror's performance. Advanced techniques like diamond turning can also be employed for specific applications that require ultra-smooth surfaces.

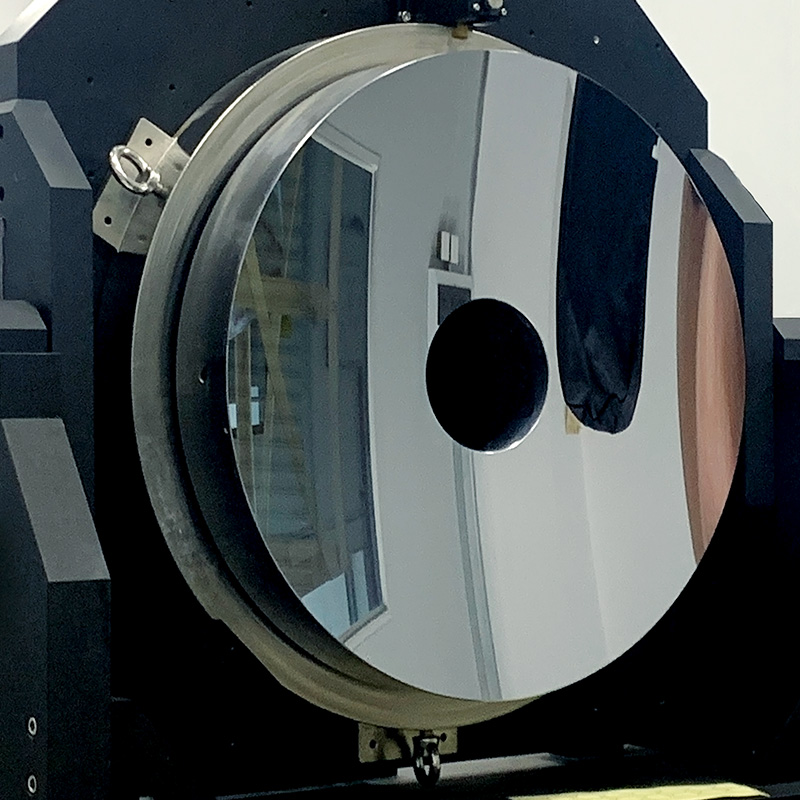

After the forming stage, the mirrors may undergo an assembly process if they are part of a larger optical system. This may involve integrating coatings, mounts, and other optical components. Careful alignment is essential to ensure that the optical path is accurate, which can significantly affect the system's overall performance. Manufacturers often employ precision alignment tools and techniques to achieve this.

The finishing stage includes additional polishing and coating to enhance the mirror's reflectivity and durability. Anti-reflective coatings may be applied to reduce losses, while protective coatings can enhance resistance to environmental factors. This stage is crucial for ensuring that the mirrors meet the specific requirements of their intended applications.

Quality assurance (QA) is a vital aspect of the manufacturing process for silicon carbide mirrors. B2B buyers should be well-informed about the QA standards and practices to ensure they are sourcing high-quality products.

International standards such as ISO 9001 play a significant role in establishing quality management systems within manufacturing processes. This standard ensures that manufacturers consistently produce products that meet customer and regulatory requirements. Other relevant certifications may include CE marking for compliance with European safety standards and industry-specific standards like API for certain applications.

Quality control (QC) checkpoints are essential for maintaining high standards throughout the manufacturing process. Common checkpoints include:

Several testing methods are employed to verify the quality of silicon carbide mirrors, including:

Ensuring that suppliers adhere to stringent quality control measures is essential for B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe.

Supplier Audits: Conducting regular audits of suppliers can help verify their adherence to quality standards. Buyers should assess documentation, processes, and product quality during these audits.

Requesting Quality Reports: Suppliers should provide quality assurance documentation, including reports from IQC, IPQC, and FQC stages. This transparency allows buyers to understand the supplier's quality management practices better.

Third-Party Inspections: Engaging third-party inspection services can provide an independent assessment of the supplier's quality control processes and product quality. This is particularly important for international transactions, where buyers may face challenges in verifying supplier capabilities.

For international B2B buyers, navigating the nuances of quality control can be challenging. It is crucial to understand the specific requirements of each market, including compliance with local regulations and standards.

Different regions may have varying standards that affect the quality assurance processes. For example, EU regulations may impose stricter environmental and safety standards compared to those in other regions. Buyers should ensure that their suppliers are compliant with the relevant standards in their target markets, which can also influence product acceptance and performance.

When sourcing SiC mirrors from international suppliers, buyers should consider factors such as:

By understanding the manufacturing processes and quality assurance measures for silicon carbide mirrors, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

In the realm of B2B procurement, sourcing silicon carbide (SiC) mirrors requires a strategic approach that ensures quality, compatibility, and value for your investment. This guide provides a clear checklist to help international buyers navigate the complexities of sourcing SiC mirrors effectively.

Establishing precise technical specifications is the foundation of any successful procurement process. Consider factors such as size, shape, surface quality, and reflective coatings required for your specific application. Clearly defined specifications help suppliers understand your needs and minimize the risk of receiving products that do not meet your expectations.

Understanding the market landscape is essential for identifying potential suppliers and gauging the availability of SiC mirrors. Conduct market research to discover leading manufacturers and distributors, especially those with experience in your specific industry or region. This knowledge will empower you to make informed decisions and spot competitive pricing.

Before committing, it is crucial to vet suppliers thoroughly. Request detailed company profiles, product catalogs, and case studies that highlight their experience with SiC mirrors. Additionally, seek references from other buyers in similar industries or regions to assess the supplier's reliability and service quality.

Ensuring that your suppliers hold relevant certifications is a critical step in safeguarding quality and compliance. Certifications such as ISO 9001 or industry-specific standards indicate that the supplier adheres to best practices in manufacturing and quality control. This can significantly reduce the risks associated with procurement.

Before placing a bulk order, request samples of the SiC mirrors to evaluate their quality and performance. This step allows you to verify that the products meet your technical specifications and perform as expected in real-world applications. Testing samples can also help avoid costly mistakes down the line.

Once you've identified a suitable supplier, it’s time to negotiate the terms and conditions of your purchase. Discuss pricing, delivery timelines, payment terms, and warranty policies to ensure that both parties have a clear understanding of the agreement. Effective negotiation can lead to favorable terms that benefit your organization.

After finalizing the deal, set up a communication plan with your supplier. Regular communication is vital for addressing any concerns that may arise during production and delivery. Establishing a clear point of contact will facilitate smoother transactions and help build a long-term relationship.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for silicon carbide mirrors, ensuring they acquire high-quality products that meet their specific requirements while fostering strong supplier relationships.

When sourcing silicon carbide mirrors, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

Materials: Silicon carbide is a high-performance material known for its durability and thermal stability. The price of SiC can fluctuate based on market demand and availability, impacting the overall cost of the mirrors.

Labor: Skilled labor is required for the precision manufacturing of SiC mirrors. Labor costs can vary significantly by region, influenced by local wage standards and the availability of skilled workers.

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help minimize these expenses.

Tooling: Specialized tools and machinery are essential for producing high-quality SiC mirrors. The initial investment in tooling can be substantial, but it is often amortized over large production runs.

Quality Control (QC): Rigorous QC processes ensure that the mirrors meet specified performance standards. The costs associated with QC can vary based on the complexity of the specifications and the required certifications.

Logistics: Shipping and handling costs can add to the total expense. Factors such as distance, shipping mode, and customs duties play a critical role in logistics costs.

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary based on market competition and the supplier's business strategy.

Several factors can influence the pricing of silicon carbide mirrors, particularly for international B2B buyers:

Volume/MOQ: Suppliers often have minimum order quantities (MOQs). Larger orders typically result in lower per-unit costs due to economies of scale. Negotiating MOQs can be beneficial for budget-conscious buyers.

Specifications and Customization: Custom designs or specific performance criteria can significantly impact pricing. Buyers should clearly outline their specifications to obtain accurate quotes.

Materials and Quality Certifications: Higher-grade materials and certifications (e.g., ISO, ASTM) can increase costs but may be necessary for certain applications. Buyers should assess the need for these certifications based on their end-use requirements.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge a premium, but they often provide better quality assurance and support.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can affect total costs.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance negotiation outcomes:

Conduct a Total Cost of Ownership (TCO) Analysis: Consider not only the purchase price but also logistics, maintenance, and potential downtime. A lower upfront cost might lead to higher long-term expenses.

Leverage Multiple Quotes: Request quotes from several suppliers to create a competitive environment. This can provide leverage during negotiations and help identify the best value.

Focus on Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and improved communication, which are essential for ongoing projects.

Understand Pricing Nuances: Be aware of regional pricing differences, particularly between suppliers in different countries. Factors such as import tariffs and currency fluctuations can significantly affect final costs.

Negotiate Terms: Don't hesitate to negotiate payment terms, lead times, and delivery schedules. Flexible terms can sometimes lead to more favorable pricing arrangements.

It is important to note that prices for silicon carbide mirrors can vary widely based on specific requirements, market conditions, and supplier negotiations. The figures presented here are indicative and should not be considered definitive. Buyers are encouraged to conduct thorough market research and engage directly with suppliers to obtain accurate pricing tailored to their needs.

When considering the procurement of optical solutions, it is crucial for B2B buyers to explore various alternatives to silicon carbide (SiC) mirrors. These alternatives can provide different performance characteristics, costs, and usability that may better align with specific project requirements. This analysis aims to compare SiC mirrors with other viable solutions, offering insights to help buyers make informed decisions.

| Comparison Aspect | Sic Mirrors | Alternative 1: Glass Mirrors | Alternative 2: Aluminum Mirrors |

|---|---|---|---|

| Performance | High thermal stability, excellent reflectivity across a wide range of wavelengths | Good reflectivity, but less stable at high temperatures | Moderate reflectivity, suitable for less demanding applications |

| Cost | Higher initial investment due to material and manufacturing complexity | Generally lower cost, widely available | Low-cost option, but may require additional coatings for performance |

| Ease of Implementation | Can be customized, but may require specialized handling | Easier to handle and install | Lightweight and easy to install, but may require post-processing |

| Maintenance | Low maintenance due to durability and resistance to environmental factors | May require regular cleaning and maintenance | Prone to oxidation, necessitating protective coatings |

| Best Use Case | Ideal for high-precision applications in aerospace, defense, and high-energy lasers | Suitable for general optics and imaging systems | Good for low-budget projects where high precision is not critical |

Glass mirrors are a common alternative, especially in applications where extreme conditions are not a concern. They offer good optical performance at a lower cost, making them accessible for a wide range of industries. However, their thermal stability is inferior to SiC mirrors, which can lead to distortion or damage in high-temperature environments. Additionally, glass mirrors require regular maintenance to keep them clean and free of scratches.

Aluminum mirrors provide a cost-effective solution, particularly for projects with tight budgets. They are lightweight and easy to install, which can reduce labor costs. However, their performance is generally lower than that of SiC mirrors. Aluminum mirrors can oxidize over time, necessitating protective coatings to maintain their reflective properties. This makes them less suitable for high-precision applications where durability and reliability are paramount.

Selecting the right optical solution requires careful consideration of specific application needs, budget constraints, and performance requirements. SiC mirrors excel in high-stress environments, offering superior thermal stability and durability, but come at a higher price point. Conversely, glass and aluminum mirrors provide more affordable options with varying performance levels suitable for less demanding applications. B2B buyers should evaluate their project requirements, including temperature ranges, precision needs, and maintenance capabilities, to determine the most suitable mirror technology for their operations. By aligning these factors with their operational goals, buyers can make strategic decisions that enhance their overall project outcomes.

Silicon Carbide (SiC) mirrors are renowned for their exceptional performance in high-precision optical applications. Understanding their technical specifications is crucial for B2B buyers, particularly in sectors like aerospace, defense, and high-tech manufacturing. Here are some key properties to consider:

Silicon carbide is available in various grades, each tailored for specific applications. High-purity SiC mirrors typically exhibit superior thermal stability and durability. This is vital for industries requiring high precision under extreme conditions, such as space exploration or laser applications.

Surface flatness is a critical specification, typically measured in wavelengths (λ). A flatness of λ/10 or better is desirable for high-performance optics. This property directly influences the mirror's ability to reflect light accurately, which is essential for applications like telescopes or high-resolution imaging systems.

Tolerances refer to the allowable variations in dimensions and surface quality. In SiC mirrors, tight tolerances (often within ±0.1 mm) ensure that the mirrors fit precisely into their optical systems. This precision reduces alignment issues, which can lead to performance degradation in sensitive applications.

Silicon carbide mirrors can be coated with various materials to enhance reflectivity and protect against environmental factors. Common coatings include aluminum and dielectric layers. Selecting the right coating is critical for optimizing performance in specific wavelengths, making it an essential consideration for buyers.

SiC boasts excellent thermal conductivity, which is crucial in high-power laser applications where heat management is paramount. High thermal conductivity helps to dissipate heat quickly, ensuring stable performance and longevity of the optical system.

The lightweight nature of SiC mirrors can be advantageous in aerospace and defense applications, where minimizing weight while maintaining strength is critical. Understanding the density helps in calculating the overall weight of the optical assembly, which can impact transportation and installation costs.

Navigating the B2B landscape involves understanding specific trade terminology that can affect procurement processes and negotiations. Here are some key terms related to silicon carbide mirrors:

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of SiC mirrors, working with OEMs can ensure high-quality components that meet specific industry standards, which is crucial for buyers in sectors like aerospace and telecommunications.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For silicon carbide mirrors, understanding the MOQ can help buyers manage inventory and budget effectively. It’s essential for international buyers to negotiate MOQs that align with their project needs and cash flow.

An RFQ is a standard business process where a buyer requests pricing and terms from suppliers. In the context of SiC mirrors, issuing an RFQ allows buyers to compare multiple suppliers, ensuring they secure the best deal while meeting their technical requirements.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for international B2B buyers, as they dictate shipping costs, insurance, and risk management during the transport of silicon carbide mirrors.

Lead time refers to the amount of time taken from placing an order to delivery. For silicon carbide mirrors, understanding lead times is vital for project planning, especially in industries where timing is critical. Buyers should inquire about lead times during negotiations to align with their project schedules.

Certification standards indicate that a product meets specific quality benchmarks. For silicon carbide mirrors, certifications such as ISO or industry-specific standards can assure buyers of product quality and reliability, which is particularly important in regulated industries.

Understanding these properties and trade terms can empower international B2B buyers to make informed decisions regarding silicon carbide mirrors, ensuring they select the right products for their specific applications.

The silicon carbide (SiC) mirrors market is experiencing robust growth driven by advancements in optical technology and the increasing demand for high-performance materials in various applications such as aerospace, defense, and semiconductor industries. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are now more focused on sourcing materials that offer enhanced thermal stability and lightweight properties, which are critical in high-temperature and high-precision environments.

One of the key trends is the shift towards customization and rapid prototyping. Suppliers are increasingly offering bespoke solutions tailored to specific industry needs, allowing buyers to optimize their applications while reducing lead times. Additionally, the integration of smart manufacturing technologies and Industry 4.0 principles is reshaping the supply chain dynamics, enabling real-time monitoring and improved quality assurance. Companies are leveraging data analytics to make informed sourcing decisions, ensuring that they can respond swiftly to market fluctuations.

Emerging markets in Africa and South America are also witnessing a surge in investment in advanced manufacturing capabilities, which is expected to boost local production of SiC mirrors. This trend creates opportunities for international buyers to engage with local suppliers, fostering partnerships that can lead to reduced shipping costs and shorter delivery times.

Sustainability has become a critical consideration for B2B buyers in the silicon carbide mirrors market. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny as companies strive to meet regulatory standards and consumer expectations for greener products. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and utilizing recyclable materials.

Ethical sourcing is also paramount, as supply chains are expected to be transparent and responsible. This involves ensuring that raw materials are sourced from suppliers who adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for suppliers aiming to build trust and credibility with international buyers.

Moreover, the adoption of 'green' materials in the production of SiC mirrors is gaining traction. Buyers should look for suppliers who utilize eco-friendly production methods and materials that minimize environmental impact. By aligning with sustainable and ethical suppliers, businesses can enhance their brand reputation while contributing positively to the global sustainability agenda.

The evolution of silicon carbide mirrors can be traced back to the early developments in optical materials during the mid-20th century. Initially, the use of SiC was limited due to its manufacturing challenges and high costs. However, with advancements in technology and increased research into its properties, SiC gained recognition for its superior thermal and mechanical performance.

In the 1990s, the aerospace and defense sectors began to adopt SiC mirrors for their applications, particularly in high-performance optics where precision is paramount. Over the years, as manufacturing processes improved and costs decreased, the adoption of SiC mirrors expanded into other industries, including telecommunications and medical devices. Today, the market is characterized by rapid innovation and a growing emphasis on customized solutions, reflecting the dynamic needs of international B2B buyers across various sectors.

How do I solve issues with the performance of silicon carbide mirrors?

To address performance issues with silicon carbide mirrors, first, ensure that they are properly installed and aligned according to the manufacturer's specifications. Regular maintenance checks, including cleaning and inspection for surface damage, can help identify problems early. Additionally, consider the operational environment; factors such as temperature and humidity can affect performance. If issues persist, consult with the supplier for technical support or warranty services, as they can provide insights based on their expertise and experience.

What is the best application for silicon carbide mirrors in industrial settings?

Silicon carbide mirrors are ideal for high-power laser applications, including laser machining and cutting, due to their excellent thermal conductivity and resistance to thermal distortion. They are also widely used in optical systems requiring high precision, such as in aerospace, defense, and medical imaging. When selecting a mirror for a specific application, consider the wavelength of light used, the required reflectivity, and the operational conditions to ensure optimal performance.

What are the key factors to consider when selecting a supplier for silicon carbide mirrors?

When choosing a supplier for silicon carbide mirrors, evaluate their manufacturing capabilities, quality certifications (such as ISO), and industry experience. Investigate their track record in delivering custom solutions and their ability to meet specific technical requirements. Additionally, consider their customer service responsiveness, warranty policies, and the availability of technical support for troubleshooting and maintenance.

What are the minimum order quantities (MOQs) for silicon carbide mirrors?

Minimum order quantities for silicon carbide mirrors can vary significantly by supplier and specific product specifications. Typically, MOQs may range from a single unit for standard products to larger quantities for custom designs. When negotiating with suppliers, clarify your needs and explore options for smaller initial orders or trial runs to assess product performance before committing to larger purchases.

What payment terms should I expect when purchasing silicon carbide mirrors internationally?

Payment terms for international purchases of silicon carbide mirrors often include options like advance payment, letter of credit, or net 30/60 days after delivery. It is essential to discuss payment methods upfront to ensure they align with your cash flow management practices. Be aware of additional costs such as customs duties and taxes that may apply when importing goods into your region.

How can I ensure quality assurance when sourcing silicon carbide mirrors?

To ensure quality assurance, request detailed product specifications and quality control processes from your supplier. Look for suppliers that provide inspection reports and certifications for their products. Additionally, consider conducting independent testing or sourcing mirrors from suppliers who offer a satisfaction guarantee or warranty, which can provide an extra layer of confidence in the quality of their products.

What logistics considerations should I keep in mind when importing silicon carbide mirrors?

When importing silicon carbide mirrors, consider logistics factors such as shipping methods, lead times, and customs regulations. Work with a logistics provider experienced in handling optical components to navigate potential challenges. It's also vital to ensure that the packaging is robust to prevent damage during transit, and that you have the necessary documentation for customs clearance to avoid delays.

Can silicon carbide mirrors be customized for specific applications?

Yes, many suppliers offer customization options for silicon carbide mirrors to meet specific application requirements. Customizations may include variations in size, shape, surface finish, and coating types. When discussing your needs with potential suppliers, provide detailed specifications about your application to receive tailored solutions that maximize performance and efficiency in your operations.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, strategic sourcing of silicon carbide (SiC) mirrors presents a significant opportunity for international B2B buyers, especially in dynamic markets such as Africa, South America, the Middle East, and Europe. The unique properties of SiC mirrors—such as thermal stability, lightweight, and high resistance to thermal shock—make them ideal for various applications ranging from aerospace to laser processing. By understanding the specific needs of their operations, buyers can leverage these advantages to enhance their product offerings.

Investing in strategic sourcing not only helps in optimizing costs but also fosters partnerships with reliable suppliers who can provide high-quality materials and customization options. Establishing strong relationships with manufacturers ensures access to the latest technological advancements and innovations in SiC mirror production. This is particularly crucial for companies looking to remain competitive in fast-evolving sectors.

Looking ahead, it is imperative for B2B buyers to stay informed about emerging trends in material science and manufacturing processes related to SiC mirrors. Engaging in continuous market analysis and nurturing supplier relationships will be essential for capitalizing on new opportunities. As global demand for high-performance materials continues to rise, proactive sourcing strategies will position companies to thrive in the future. Embrace this potential and start exploring your options today to secure a competitive edge in your industry.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina