In the competitive landscape of industrial materials, sourcing high-quality siliziumkarbid schleifscheibe (silicon carbide grinding wheels) can pose significant challenges for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. With diverse applications ranging from metalworking to ceramics, the need for reliable suppliers who can meet specific technical requirements is paramount. This guide offers a comprehensive overview of the types of silicon carbide grinding wheels available, their various applications, and crucial insights into supplier vetting processes.

By delving into the intricacies of cost factors, quality standards, and performance metrics, this resource equips B2B buyers with the knowledge necessary to make informed purchasing decisions. Whether you're a procurement manager in Poland seeking to enhance production efficiency or a manufacturer in Saudi Arabia aiming to improve product quality, understanding the nuances of silicon carbide grinding wheels is essential for optimizing operational outcomes.

Furthermore, this guide addresses common concerns, such as supplier reliability, logistics, and compliance with international standards, helping you navigate the complexities of global sourcing. Empowered with actionable insights and strategic guidance, you can confidently engage with suppliers and enhance your competitive edge in the market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Silicon Carbide Wheel | High hardness, excellent wear resistance | General grinding applications | Pros: Cost-effective, versatile. Cons: Limited performance on tough materials. |

| Resin-Bonded Silicon Carbide Wheel | Flexible bonding, good for fine finishing | Precision machining, ceramics | Pros: Smooth finish, adaptable. Cons: Less durable than metal-bonded wheels. |

| Metal-Bonded Silicon Carbide Wheel | High strength, suited for heavy-duty tasks | Heavy grinding, industrial applications | Pros: Long lifespan, stability. Cons: Higher cost, less flexibility. |

| Diamond-Embedded Silicon Carbide Wheel | Exceptional cutting ability, premium quality | Specialized materials, advanced ceramics | Pros: Superior performance, precision. Cons: Expensive, requires skilled handling. |

| Cup Silicon Carbide Wheel | Cup shape for edge grinding, high surface area | Edge grinding, deburring | Pros: Efficient material removal. Cons: Limited application scope. |

Standard silicon carbide wheels are known for their high hardness and wear resistance, making them ideal for general grinding applications. They are commonly used in the manufacturing of metal, wood, and other materials. When purchasing, buyers should consider their specific grinding needs, as these wheels may not perform optimally on extremely tough materials. Their cost-effectiveness and versatility make them a popular choice for many businesses.

Resin-bonded silicon carbide wheels are designed for fine finishing and precision machining. The flexible bonding allows for smoother finishes, making them suitable for ceramics and other delicate materials. Buyers should evaluate the balance between finish quality and durability when selecting these wheels, as they may wear out faster than their metal-bonded counterparts. Their adaptability in various applications is a significant advantage for B2B buyers.

Metal-bonded silicon carbide wheels are engineered for heavy-duty tasks, providing high strength and stability. They are ideal for industrial applications where longevity and performance are critical. While they come at a higher cost, their extended lifespan and ability to handle tough materials make them a worthwhile investment for businesses focused on productivity. Buyers should weigh the initial investment against the long-term benefits.

Diamond-embedded silicon carbide wheels are designed for exceptional cutting ability and precision, making them suitable for specialized materials and advanced ceramics. These premium-quality wheels are ideal for applications requiring high accuracy. However, they come with a higher price tag and necessitate skilled handling. Businesses should consider their specific needs and the potential return on investment when opting for these high-performance tools.

Cup silicon carbide wheels are specifically shaped for edge grinding and offer a high surface area for efficient material removal. They are commonly used in deburring applications. While they excel in their specific use case, their application scope is somewhat limited compared to other types. Buyers should assess their grinding requirements to determine if this specialized wheel is the right fit for their operations.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of siliziumkarbid schleifscheibe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision grinding of brake pads and rotors | Enhanced performance and safety of vehicles | Supplier certifications, material quality, and delivery times |

| Aerospace | Surface finishing of turbine blades | Improved fuel efficiency and reduced operational costs | Compliance with aerospace standards, lead times, and cost |

| Electronics | Dicing of semiconductor wafers | Higher yield rates and reduced material waste | Precision specifications, supplier reliability, and technology compatibility |

| Metalworking | Grinding of hard metals and alloys | Increased productivity and tool lifespan | Abrasive grade, hardness, and availability of custom sizes |

| Construction and Stone Fabrication | Shaping and polishing of stone surfaces | Enhanced aesthetic appeal and durability of products | Availability of specialized sizes, grit types, and pricing |

In the automotive industry, siliziumkarbid schleifscheibe is employed for precision grinding of brake pads and rotors. This application is critical for ensuring optimal performance and safety in vehicles. The high hardness and thermal resistance of silicon carbide allow for efficient material removal while maintaining dimensional accuracy. For international buyers, particularly from regions like Africa and South America, it’s essential to source these grinding wheels from suppliers that comply with industry standards and offer reliable delivery schedules to keep production lines running smoothly.

In aerospace manufacturing, siliziumkarbid schleifscheibe is utilized for the surface finishing of turbine blades, which are essential components in jet engines. This application enhances fuel efficiency and reduces operational costs by ensuring that blades are aerodynamically optimized. Buyers from the Middle East and Europe should prioritize suppliers who meet stringent aerospace quality certifications and can provide consistent quality assurance, as any defects can lead to significant safety and financial repercussions.

In the electronics sector, siliziumkarbid schleifscheibe is crucial for dicing semiconductor wafers, a process that requires high precision to maximize yield rates and minimize material waste. The use of these grinding wheels allows for clean cuts, reducing the risk of chipping or damage to the delicate wafers. B2B buyers in this field, particularly in Europe, should focus on sourcing from manufacturers that offer advanced technology solutions and can customize products to meet specific requirements, ensuring compatibility with existing manufacturing processes.

In metalworking, siliziumkarbid schleifscheibe is used for grinding hard metals and alloys, which are often challenging to machine. The abrasive properties of silicon carbide allow for increased productivity and extended tool lifespan, leading to lower operational costs. Buyers, especially from regions like South America and Africa, need to consider the abrasive grade and hardness of the wheels to ensure they meet their specific processing needs, as well as the availability of custom sizes for unique applications.

In the construction and stone fabrication industries, siliziumkarbid schleifscheibe is applied for shaping and polishing stone surfaces, which enhances both aesthetic appeal and durability. The ability of these grinding wheels to achieve a high-quality finish is crucial for meeting client expectations in design and functionality. International buyers should look for suppliers who can provide a variety of grit types and specialized sizes, ensuring that they can cater to diverse projects while also being mindful of pricing and lead times to maintain competitive advantage.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem:

B2B buyers often face the challenge of sourcing high-quality siliziumkarbid schleifscheibe (silicon carbide grinding wheels) that meet specific application requirements. Different industries, such as automotive and aerospace, have varying standards for precision and material performance. This can lead to difficulties in finding suppliers who can provide the right specifications, resulting in delays, increased costs, and subpar product quality. Additionally, the lack of transparency in product descriptions and performance data from suppliers can further complicate the sourcing process.

The Solution:

To overcome this challenge, B2B buyers should engage in thorough market research to identify reputable suppliers with a proven track record in their specific industry. Utilize platforms that offer comprehensive product catalogs, including detailed specifications and performance data. When communicating with suppliers, be explicit about your application requirements, such as the type of materials being processed and the expected durability of the grinding wheel. Request samples to test performance before committing to larger orders. Moreover, establishing long-term relationships with suppliers can lead to better customization options and more competitive pricing.

The Problem:

In high-volume production environments, maintaining the performance of siliziumkarbid schleifscheibe can be a significant concern. Users often experience rapid wear and tear, leading to increased downtime and higher operational costs. This not only affects productivity but also impacts the quality of finished products, which can harm customer satisfaction and brand reputation. The challenge lies in balancing the use of these grinding wheels with the need for efficiency and cost-effectiveness.

The Solution:

To effectively manage the performance of silicon carbide grinding wheels, B2B buyers should implement a structured maintenance and monitoring program. This includes regular inspections to assess the condition of the wheels and timely replacements to prevent performance degradation. Utilizing monitoring technology, such as vibration analysis or thermal imaging, can provide real-time insights into wheel performance, allowing for predictive maintenance. Additionally, buyers should consider investing in specialized training for their operators to ensure proper handling and usage of the grinding wheels, which can extend their lifespan and enhance overall productivity.

The Problem:

As industries evolve, B2B buyers often need to adapt their grinding solutions to accommodate a wider range of materials. For instance, when transitioning from traditional metals to advanced composites or ceramics, the existing siliziumkarbid schleifscheibe may not deliver the desired results. This can lead to challenges in maintaining production quality and efficiency, as well as potential safety risks due to inadequate grinding performance.

The Solution:

To successfully adapt to diverse material requirements, buyers should consider investing in advanced silicon carbide grinding wheels specifically designed for new materials. Collaborating with suppliers who specialize in engineered solutions can help in identifying the right products tailored for specific applications. It is also beneficial to conduct trials with different grinding wheels to evaluate their effectiveness on new materials. Providing feedback to manufacturers can lead to the development of customized solutions that better meet evolving industry standards. Additionally, keeping abreast of technological advancements in grinding technology can empower buyers to make informed decisions that enhance both safety and performance.

When selecting materials for siliziumkarbid schleifscheibe (silicon carbide grinding wheels), international B2B buyers must consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in the production of these grinding wheels, focusing on their properties, advantages, and limitations, along with specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Silicon carbide (SiC) is the primary material used in manufacturing grinding wheels due to its exceptional hardness and thermal conductivity. It can withstand high temperatures and is resistant to wear, making it ideal for grinding hard materials like metals and ceramics. SiC grinding wheels are also known for their ability to maintain sharp cutting edges, enhancing efficiency in machining operations.

Aluminum oxide is another common material used in grinding wheels, particularly for softer materials.

Pros:

- Cost-Effective: Aluminum oxide is generally less expensive than silicon carbide.

- Versatile: Suitable for a wide range of applications, including wood and metal grinding.

Cons:

- Lower Hardness: Compared to SiC, aluminum oxide is less hard, which may result in quicker wear when used on harder materials.

- Heat Sensitivity: It can lose its cutting ability at elevated temperatures, limiting its use in high-speed applications.

Impact on Application: Aluminum oxide is often used for general-purpose grinding but may not be suitable for high-precision applications requiring durability.

Ceramic materials are increasingly being used in grinding wheels due to their unique properties.

Pros:

- High Durability: Ceramic wheels maintain their form longer than traditional materials.

- Excellent Finish: They provide a superior surface finish on workpieces.

Cons:

- Higher Cost: The manufacturing process for ceramic wheels is more complex, leading to higher prices.

- Brittleness: While durable, ceramic can be more brittle than other materials, making it susceptible to chipping.

Impact on Application: Ceramic grinding wheels are ideal for precision grinding applications, particularly in industries requiring high-quality finishes, such as aerospace and automotive.

When sourcing grinding wheels, international buyers must be aware of compliance with local standards such as ASTM, DIN, or JIS. For instance, buyers in Saudi Arabia may need to ensure that products meet specific local regulations, while Polish buyers might prioritize adherence to European Union standards. Additionally, understanding the specific media compatibility of the grinding wheels with the materials being processed is crucial for optimizing performance.

| Material | Typical Use Case for siliziumkarbid schleifscheibe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Grinding hard metals and ceramics | Exceptional hardness and thermal conductivity | Higher cost compared to aluminum oxide | High |

| Aluminum Oxide | General-purpose grinding for softer materials | Cost-effective and versatile | Lower hardness, quicker wear | Low |

| Ceramic | Precision grinding in aerospace and automotive | High durability and excellent surface finish | Higher cost and brittleness | High |

| Diamond | Specialized grinding for ultra-hard materials | Long lifespan and superior cutting ability | Very high cost and limited availability | Very High |

By considering these materials and their respective properties, advantages, and limitations, international B2B buyers can make informed decisions that align with their specific operational needs and compliance requirements.

The manufacturing of siliziumkarbid schleifscheibe (silicon carbide grinding wheels) is a meticulous process that involves several critical stages. Understanding these stages is essential for B2B buyers to assess the quality and performance of the products they are sourcing.

Material Preparation

- Raw Material Selection: The process begins with the selection of high-purity silicon carbide grains, which are essential for achieving superior hardness and thermal conductivity.

- Sourcing: Suppliers should ensure that raw materials are sourced from reputable vendors to avoid inconsistencies in quality. It is advisable for buyers to request certificates of analysis from suppliers to confirm material purity.

Forming

- Mixing: The silicon carbide grains are mixed with a bonding agent, typically a resin or vitrified binder. The choice of binder can significantly influence the wheel's performance and application.

- Molding: The mixture is then placed into molds, where it is subjected to high pressure to form the desired shape of the grinding wheel. Advanced techniques like cold pressing are commonly employed to ensure uniform density.

Assembly

- Curing: After molding, the wheels are cured in an oven at controlled temperatures. This process solidifies the bond between the silicon carbide grains and the binder, enhancing the wheel's strength.

- Trimming and Shaping: Following curing, wheels are trimmed and shaped to meet specific dimensions and tolerances. This may involve grinding or machining to achieve precise specifications.

Finishing

- Surface Treatment: The final stage involves surface treatments, such as polishing or coating, to improve the grinding wheel's performance and longevity.

- Quality Inspection: Each wheel undergoes a series of inspections to ensure it meets the required standards before it is packed and shipped.

Quality assurance (QA) is a vital component of the manufacturing process for siliziumkarbid schleifscheibe. Implementing robust QA measures ensures that the products meet international standards and customer expectations.

Adherence to International Standards

- Manufacturers should comply with ISO 9001, which outlines the criteria for an effective quality management system. This certification ensures that the manufacturing process is consistent and meets customer and regulatory requirements.

- Industry-specific standards such as CE marking in Europe and API specifications in the Middle East may also apply, depending on the intended application of the grinding wheels.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This involves checking raw materials upon arrival to ensure they meet specified standards before production begins. Buyers should inquire about the IQC processes of potential suppliers.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are conducted to monitor critical parameters, ensuring that any deviations from the norm are addressed promptly.

- Final Quality Control (FQC): After manufacturing, grinding wheels undergo rigorous testing, including visual inspections, dimensional checks, and performance evaluations, to ensure they meet quality standards.

Testing Methods for Quality Assurance

- Common testing methods include hardness testing, wear resistance testing, and thermal shock resistance testing. These tests help verify that the wheels can withstand their intended applications.

- Buyers should request detailed reports of testing results to assess the quality of the grinding wheels before making a purchase.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is crucial for ensuring product reliability.

Supplier Audits

- Conducting on-site audits of suppliers can provide insight into their manufacturing processes and quality control measures. This step allows buyers to assess compliance with international standards firsthand.

- Buyers may consider employing third-party auditing services to ensure an unbiased evaluation of the supplier's capabilities.

Documentation and Reporting

- Requesting documentation such as quality control reports, certifications, and material test reports is essential. This documentation provides evidence of the supplier's commitment to quality assurance and adherence to international standards.

- Suppliers should be able to provide traceability for their materials and processes, which is crucial for accountability.

Third-Party Inspection Services

- Engaging third-party inspection services can be beneficial for buyers who wish to ensure that the products meet their quality requirements before shipment. These services can conduct inspections at various stages of the manufacturing process and provide detailed reports.

When sourcing siliziumkarbid schleifscheibe, international B2B buyers must navigate various quality control considerations to ensure they receive products that meet their expectations.

Regulatory Compliance

- Different regions have specific regulations governing the manufacturing and sale of industrial products. Buyers should familiarize themselves with these regulations to ensure compliance and avoid potential legal issues.

- For example, CE marking is mandatory for products sold in the European Union, while other regions may have their own certification requirements.

Cultural and Regional Differences

- Understanding cultural and regional differences in manufacturing practices can help buyers identify potential risks. For instance, some regions may have less stringent quality control measures, which can affect product quality.

- Engaging with local experts or consultants can help navigate these complexities and identify reliable suppliers.

Building Long-term Relationships

- Establishing long-term relationships with suppliers can lead to better quality assurance. Regular communication and collaboration can help ensure that suppliers remain committed to maintaining high-quality standards.

By understanding the manufacturing processes and quality assurance measures associated with siliziumkarbid schleifscheibe, international B2B buyers can make informed decisions, mitigate risks, and ensure they procure high-quality products that meet their operational needs.

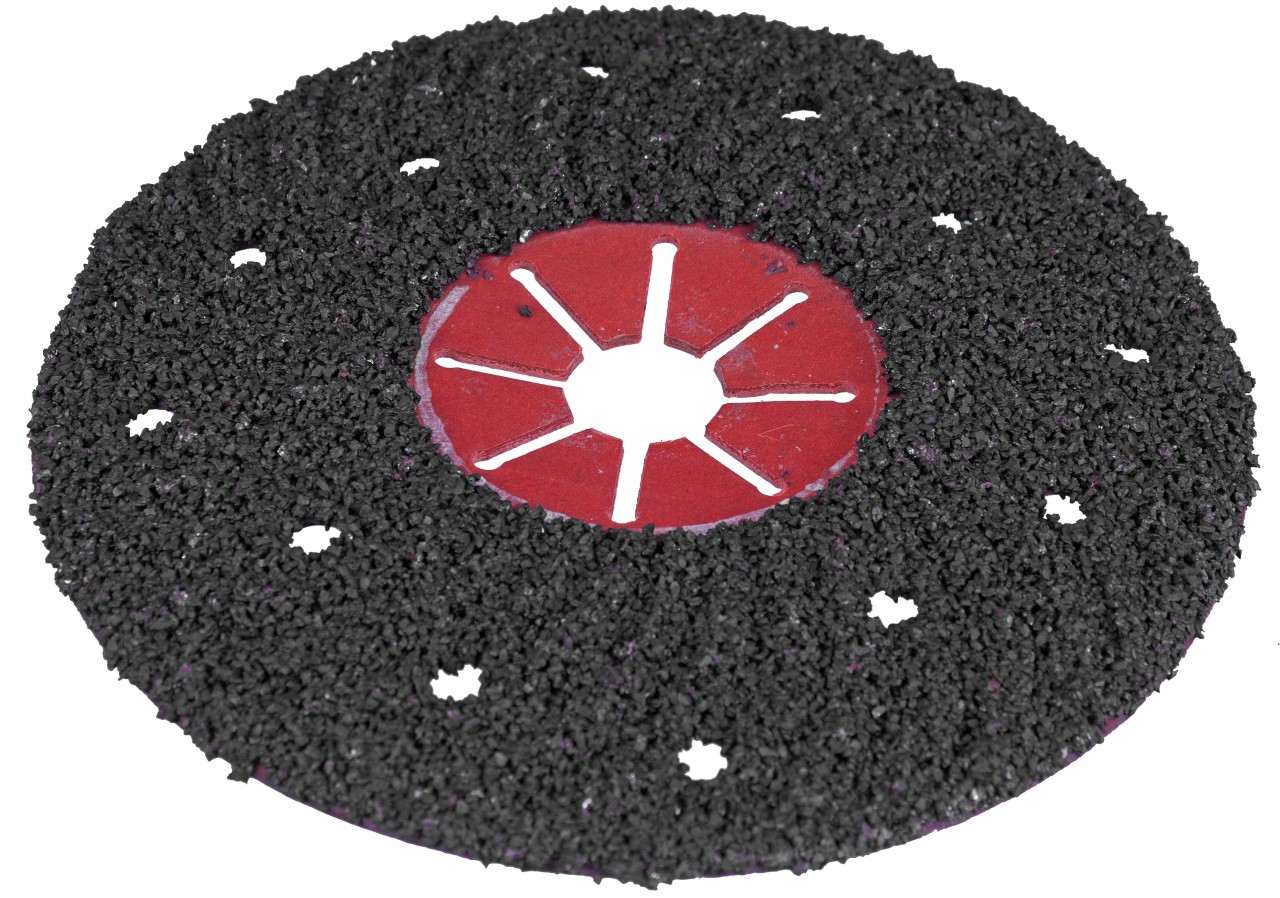

A stock image related to siliziumkarbid schleifscheibe.

In the competitive landscape of international B2B procurement, sourcing the right products can significantly impact your business operations. This practical sourcing checklist for siliziumkarbid schleifscheibe (silicon carbide grinding wheels) is designed to guide you through the essential steps to ensure you make informed purchasing decisions.

Before initiating the sourcing process, it’s crucial to clearly define your technical requirements. Identify the specific applications for which the silicon carbide grinding wheels will be used, including grit size, bond type, and dimensions.

- What to consider: The hardness of the material being processed, the required finish quality, and the machine compatibility.

Engage in thorough market research to understand the current trends and pricing of silicon carbide grinding wheels. This helps in establishing a baseline for negotiations and understanding the competitive landscape.

- Where to look: Industry reports, trade shows, and online marketplaces can provide valuable insights into supplier offerings and pricing strategies.

Before committing, vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from buyers in similar industries or regions.

- Key questions: What are the suppliers’ production capacities? How do they handle quality assurance?

Ensure that your chosen suppliers hold relevant certifications such as ISO 9001 or other industry-specific standards. These certifications are indicators of a supplier's commitment to quality and reliability.

- Why it matters: Certifications can also facilitate smoother customs clearance and compliance with local regulations, especially in international trade.

Always ask for product samples before making a bulk purchase. Testing samples allows you to assess the quality and performance of the silicon carbide grinding wheels in real-world conditions.

- What to evaluate: Durability, efficiency, and compatibility with your existing equipment.

Once you have shortlisted suppliers, engage in negotiations to secure the best terms. Discuss pricing, payment terms, delivery schedules, and after-sales support.

- Important aspects: Understand the warranty and return policies, as well as any potential penalties for late delivery.

Finally, set up a clear communication plan with your supplier. This should include regular updates on order status and a point of contact for any issues that arise.

- Why this is critical: Effective communication can help prevent misunderstandings and ensure timely resolution of any challenges during the procurement process.

By following these steps, B2B buyers can navigate the complexities of sourcing silicon carbide grinding wheels, ensuring a successful procurement process that aligns with their operational needs and quality expectations.

Understanding the cost structure of siliziumkarbid schleifscheibe (silicon carbide grinding wheels) is crucial for international B2B buyers. The primary cost components include:

Materials: The cost of silicon carbide itself is significant, influenced by global supply chain conditions. Prices can fluctuate based on purity and grain size, which directly affect the performance of the grinding wheel.

Labor: Labor costs vary widely by region. In countries with higher wages, labor costs can take up a larger share of the overall price. This is particularly relevant for manufacturers in Europe compared to those in Africa or South America.

Manufacturing Overhead: This includes expenses related to the factory's operation, such as utilities, maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these costs.

Tooling: The initial investment in tooling for the production of custom grinding wheels can be substantial. This cost is often amortized over the production run, influencing the price per unit.

Quality Control (QC): Ensuring the quality of siliziumkarbid schleifscheibe is essential, particularly for industries with strict regulatory requirements. QC processes add to the overall cost but are necessary to maintain product standards.

Logistics: Transportation and storage costs can vary depending on the supplier's location and the buyer's destination. International shipping, customs duties, and insurance should be factored into the total cost.

Margin: Suppliers will typically apply a profit margin to cover their costs and risks. This margin can vary significantly based on market competition and demand.

Several factors influence the pricing of siliziumkarbid schleifscheibe, which B2B buyers need to consider:

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from economies of scale, resulting in lower per-unit prices. Understanding a supplier's MOQ can help buyers negotiate better rates.

Specifications and Customization: Custom specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected price increases.

Material Quality and Certifications: Higher quality materials and certifications (such as ISO or industry-specific standards) often command higher prices. Buyers should assess whether these certifications are necessary for their application.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their perceived reliability and quality assurance.

Incoterms: The choice of Incoterms (International Commercial Terms) affects the cost structure. Understanding who is responsible for shipping, insurance, and customs can help buyers calculate the total cost accurately.

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

Conduct a Total Cost of Ownership (TCO) Analysis: This approach considers all costs associated with the purchase, including maintenance and operational costs, not just the upfront price. It helps in making informed decisions.

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and negotiate better pricing. Suppliers are often willing to offer discounts for larger, consistent orders.

Explore Multiple Suppliers: Engage with several suppliers to understand market prices and options. This competitive landscape can empower buyers during negotiations.

Communicate Clearly: Be explicit about requirements and expectations to avoid misunderstandings that could lead to increased costs.

Consider Long-Term Partnerships: Establishing ongoing relationships with suppliers can lead to better pricing structures and more favorable terms over time.

The cost and pricing analysis for siliziumkarbid schleifscheibe sourcing involves multiple layers, from material costs to logistical considerations. International B2B buyers must approach sourcing strategically, leveraging negotiation tactics and understanding the nuances of pricing influences to secure the best deals. Always remember that the prices can vary widely due to market conditions, and it’s essential to stay informed and adaptable in your sourcing strategy.

When exploring options for industrial grinding solutions, it’s essential to consider various alternatives to the siliziumkarbid schleifscheibe (silicon carbide grinding wheel). Each option presents unique advantages and disadvantages, making it crucial for international B2B buyers to analyze these alternatives based on their specific needs, operational context, and budget.

| Comparison Aspect | Siliziumkarbid Schleifscheibe | Alternative 1: Aluminum Oxide Wheel | Alternative 2: Diamond Wheel |

|---|---|---|---|

| Performance | High hardness and thermal stability, suitable for hard materials | Good for general-purpose grinding, effective on soft to medium materials | Superior cutting efficiency, ideal for hard materials |

| Cost | Moderate to high | Low to moderate | High |

| Ease of Implementation | Requires specific machinery and expertise | Widely compatible with various machines | Specialized equipment needed |

| Maintenance | Low, but requires proper handling | Low, easy to maintain | Moderate, diamond wheels can wear down |

| Best Use Case | Precision grinding of ceramics, glass, and metals | Versatile for many materials, including metals | Ideal for precision and fine finishing of hard materials |

Aluminum oxide wheels are a popular choice in many industrial settings due to their versatility and cost-effectiveness. They are particularly effective for grinding softer materials like aluminum, brass, and bronze. The primary advantage of aluminum oxide wheels is their affordability, making them a practical choice for operations with budget constraints. However, they may not perform as well on harder materials compared to silicon carbide wheels, leading to faster wear rates and the need for more frequent replacements.

Diamond wheels are renowned for their exceptional cutting ability and longevity, especially when working with hard materials such as ceramics, composites, and hardened steels. Their performance outstrips both siliziumkarbid schleifscheibe and aluminum oxide wheels when precision and finish quality are paramount. However, diamond wheels come with a high initial cost and may require specialized machinery, which can be a significant investment for smaller operations. Additionally, while they offer longer service life, the maintenance and handling can be more complex compared to the other options.

Selecting the right grinding solution depends on various factors, including material types, budget constraints, and operational requirements. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the specific applications and environments where these grinding wheels will be used is crucial. If precision and durability are top priorities and budget allows, diamond wheels may be the best choice. Conversely, for more general applications or when working with softer materials, aluminum oxide wheels could provide a more economical solution. Ultimately, the choice should align with the operational goals, taking into account both performance needs and cost considerations.

When evaluating siliziumkarbid schleifscheibe (silicon carbide grinding wheels), understanding the critical technical properties is essential for making informed purchasing decisions. Here are some of the most important specifications:

Definition: The material grade indicates the quality and composition of the silicon carbide used in the grinding wheel. Common grades include green and black silicon carbide, with green being harder and more suitable for grinding harder materials.

Importance for B2B Buyers: Selecting the right material grade is crucial for ensuring the grinding wheel's performance in specific applications. Buyers must align the material grade with the type of materials they are processing to achieve optimal results.

Definition: Grit size refers to the size of the abrasive particles on the grinding wheel surface. It is typically measured in mesh sizes, with lower numbers indicating coarser grit and higher numbers indicating finer grit.

Importance for B2B Buyers: Choosing the correct grit size affects the finish quality and removal rate. For instance, finer grits are ideal for polishing and finishing, while coarser grits are better for material removal.

Definition: The bond type is the material that holds the abrasive particles together. Common bond types include vitrified, resin, and metal bonds, each offering different performance characteristics.

Importance for B2B Buyers: The bond type influences the durability and cutting efficiency of the grinding wheel. Understanding the specific bonding requirements for different applications can help buyers select a wheel that meets their operational needs.

Definition: Tolerance refers to the allowable variation in the dimensions of the grinding wheel, including diameter and thickness.

Importance for B2B Buyers: Maintaining precise tolerances is vital for ensuring the grinding wheel fits correctly in the machine and performs as expected. This is particularly important in high-precision applications where deviations can lead to significant production errors.

Definition: Operating speed is the maximum rotational speed at which the grinding wheel can safely operate, usually expressed in revolutions per minute (RPM).

Importance for B2B Buyers: Selecting a grinding wheel with the appropriate operating speed is crucial for safety and performance. Exceeding the recommended speed can lead to wheel failure and potential hazards.

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms:

Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

Importance for B2B Buyers: Understanding whether a supplier is an OEM can help buyers assess the quality and reliability of the products being sourced, as OEMs often adhere to stringent manufacturing standards.

Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

Importance for B2B Buyers: Knowing the MOQ helps buyers plan their purchasing strategy and manage inventory costs effectively, especially when dealing with specialized products like grinding wheels.

Definition: An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific products or services.

Importance for B2B Buyers: Issuing an RFQ allows buyers to compare prices, terms, and conditions from multiple suppliers, facilitating better decision-making and negotiation.

Definition: Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions.

Importance for B2B Buyers: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks associated with the delivery of grinding wheels, which is crucial for effective logistics management.

Definition: Lead time is the time taken from placing an order to the delivery of the product.

Importance for B2B Buyers: Understanding lead times is essential for planning production schedules and inventory management, especially when sourcing grinding wheels from international suppliers.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement processes and ensure they are making informed decisions regarding siliziumkarbid schleifscheibe.

A stock image related to siliziumkarbid schleifscheibe.

The siliziumkarbid schleifscheibe (silicon carbide grinding wheel) sector is witnessing significant growth driven by advancements in manufacturing technologies and an increasing demand for efficient grinding solutions. Global factors such as the automotive, aerospace, and electronics industries are pushing for materials that enhance precision and reduce wear. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging trends include the integration of smart technology and automation within the production processes. This not only optimizes the performance of grinding wheels but also offers real-time monitoring and data analytics capabilities, which can significantly reduce operational costs. Additionally, the rise of e-commerce platforms for industrial products is transforming the way buyers source silicon carbide grinding wheels, allowing for greater transparency and accessibility to diverse suppliers.

In response to fluctuating market demands, manufacturers are also focusing on customizable solutions to meet specific application requirements. For instance, variations in grain sizes and bond types cater to different grinding needs, making it essential for buyers to clearly define their specifications when sourcing these products.

Sustainability has become a paramount concern in the siliziumkarbid schleifscheibe sector, with buyers increasingly prioritizing environmentally friendly practices. The production of silicon carbide, while efficient, poses environmental challenges, including energy-intensive manufacturing processes. Therefore, buyers are encouraged to seek suppliers that demonstrate a commitment to reducing their carbon footprint through energy-efficient technologies and responsible sourcing practices.

Ethical sourcing is equally important. B2B buyers should assess their suppliers' adherence to ethical labor practices and their impact on local communities. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier's commitment to sustainability. By choosing partners who prioritize ethical practices, buyers not only enhance their corporate social responsibility but also align with the growing consumer demand for sustainable products.

Incorporating green materials and processes into the production of silicon carbide grinding wheels can also provide a competitive edge. Buyers should explore innovations such as recycled materials and eco-friendly bonding agents that meet both performance and sustainability standards.

The evolution of the siliziumkarbid schleifscheibe sector traces back to the early 20th century when silicon carbide was first synthesized. Initially used as an abrasive material, its unique properties—such as high thermal conductivity and hardness—made it a preferred choice in various industrial applications. Over the decades, technological advancements have refined the manufacturing processes, leading to improved product quality and consistency.

By the late 20th century, the introduction of advanced bonding techniques and custom formulations allowed for specialized grinding wheels tailored to specific applications. Today, the sector is at the forefront of innovation, with an increasing focus on automation, smart manufacturing, and sustainable practices, reflecting the changing landscape of industrial sourcing. For B2B buyers, understanding this historical context is essential for recognizing the value and potential of silicon carbide grinding wheels in contemporary manufacturing environments.

How do I choose the right siliziumkarbid schleifscheibe for my application?

Selecting the appropriate siliziumkarbid schleifscheibe involves assessing your specific grinding needs, including the material being processed, the required finish, and the machining conditions. Consider factors such as grit size, bond type, and wheel hardness. It's essential to consult with suppliers who can provide technical data and recommendations based on your production parameters. Testing samples before making a bulk purchase can also help ensure the wheel meets your operational requirements.

What are the advantages of using siliziumkarbid schleifscheibe compared to other materials?

Siliziumkarbid (silicon carbide) schleifscheibe offers superior hardness and sharpness, making it ideal for grinding hard materials like ceramics, glass, and metals. Its high thermal conductivity helps dissipate heat during grinding, reducing the risk of workpiece damage. Additionally, silicon carbide wheels provide excellent surface finishes and can be used in both wet and dry applications, enhancing their versatility in industrial settings.

What should I consider when vetting suppliers for siliziumkarbid schleifscheibe?

When evaluating suppliers, consider their industry experience, production capabilities, and quality certifications (such as ISO). Requesting samples for testing can provide insight into product quality. Additionally, inquire about their ability to provide customized solutions and their responsiveness to inquiries. It's also beneficial to check customer reviews and testimonials to gauge their reliability and service standards.

What is the minimum order quantity (MOQ) for siliziumkarbid schleifscheibe?

The MOQ for siliziumkarbid schleifscheibe can vary significantly by supplier, typically ranging from a few pieces to several hundred, depending on the manufacturer’s policies and production setup. For international buyers, it's advisable to discuss MOQs upfront to avoid unexpected costs and delays. Some suppliers may offer lower MOQs for trial orders or long-term partnerships, so negotiating terms can be advantageous.

What payment terms should I expect when purchasing siliziumkarbid schleifscheibe internationally?

Payment terms for international purchases can vary, but common options include upfront payment, partial payment before shipping, or payment upon delivery. It's crucial to clarify terms in advance and ensure they align with your cash flow management. Some suppliers may offer letters of credit or escrow services for added security, especially for high-value transactions, so inquire about these options if needed.

How can I ensure quality assurance (QA) for my siliziumkarbid schleifscheibe orders?

To ensure quality assurance, request documentation such as certificates of conformity, material test reports, and quality control protocols from your supplier. Establishing a clear QA process before placing orders is crucial. This may include periodic inspections, third-party testing, or setting up a return policy for defective products. Regular communication with your supplier about quality expectations can also enhance product consistency.

What logistics considerations should I keep in mind when importing siliziumkarbid schleifscheibe?

When importing, consider shipping methods, customs regulations, and potential tariffs that may affect overall costs. Choose reliable logistics partners familiar with international shipping processes to avoid delays. It's also important to track shipments and confirm delivery timelines, especially for critical production schedules. Discussing packaging and handling requirements with your supplier can further mitigate risks during transit.

Can siliziumkarbid schleifscheibe be customized for specific applications?

Yes, many suppliers offer customization options for siliziumkarbid schleifscheibe to meet specific application needs. Customizations may include altering grit size, bond type, wheel shape, or dimensions based on your grinding requirements. Engaging in a dialogue with your supplier about your specific needs can lead to tailored solutions that enhance efficiency and product performance in your operations.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of siliziumkarbid schleifscheibe presents significant opportunities for international B2B buyers. By focusing on quality, supplier reliability, and cost-effectiveness, businesses can enhance their operational efficiency and product performance. Establishing strong relationships with suppliers can lead to improved negotiation outcomes and better service delivery.

Investing time in understanding the market dynamics specific to regions such as Africa, South America, the Middle East, and Europe will empower buyers to make informed decisions that align with their strategic goals.

Looking ahead, the demand for siliziumkarbid schleifscheibe is expected to grow, driven by advancements in technology and manufacturing processes. Buyers should remain proactive by staying updated on industry trends, emerging suppliers, and technological innovations.

To capitalize on these developments, consider engaging in collaborative partnerships, attending industry conferences, and leveraging digital platforms for sourcing. By doing so, you position your business at the forefront of the market, ensuring sustained competitive advantage.

In this ever-evolving landscape, let strategic sourcing be your pathway to success in the procurement of siliziumkarbid schleifscheibe. Take the next step today to explore new opportunities and forge valuable connections in the global marketplace.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina