Siliziumkarbid (SiC) ist ein bahnbrechendes Material, das in der heutigen globalen Industrie eine zentrale Rolle spielt. B2B-Käufer stehen jedoch oft vor der Herausforderung, geeignete Lieferanten zu finden, die qualitativ hochwertige SiC-Produkte anbieten. In diesem umfassenden Leitfaden für internationale B2B-Käufer, insbesondere aus Afrika, Südamerika, dem Nahen Osten und Europa (wie Argentinien und Spanien), werden wir die verschiedenen Aspekte von Siliziumkarbid beleuchten. Dazu gehören die Arten von SiC, seine Anwendungen in der Elektronik und Industrie, sowie wichtige Informationen zur Lieferantenauswahl und Preisgestaltung.

Dieser Leitfaden ist darauf ausgelegt, Ihnen das notwendige Wissen zu vermitteln, um fundierte Entscheidungen beim Einkauf von Siliziumkarbid zu treffen. Wir behandeln die neuesten Trends in der SiC-Technologie, die ökologischen Vorteile des Materials und die prognostizierte Marktentwicklung, um Ihnen eine solide Grundlage für strategische Investitionen zu bieten. Egal, ob Sie in der Energieerzeugung, der Automobilindustrie oder der Halbleitertechnik tätig sind, die Informationen in diesem Leitfaden werden Ihnen helfen, die besten Lieferanten auszuwählen und die richtigen Produkte für Ihre spezifischen Anforderungen zu identifizieren. So können Sie die Effizienz Ihrer Produktionsprozesse steigern und gleichzeitig nachhaltige Lösungen fördern.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Black Silicon Carbide | High hardness, low thermal conductivity | Abrasives, cutting tools | Pros: Cost-effective; Cons: Lower thermal performance. |

| Green Silicon Carbide | Higher purity, better thermal conductivity | Semiconductor devices, high-power electronics | Pros: Superior performance; Cons: Higher cost. |

| Silicon Carbide Wafers | Single-crystal form, used in high-frequency devices | Power electronics, RF applications | Pros: Excellent efficiency; Cons: Fragile handling. |

| Silicon Carbide Ceramics | High strength, excellent thermal stability | Aerospace, automotive components | Pros: Durable and lightweight; Cons: Expensive to manufacture. |

| Silicon Carbide Powder | Fine grain size, versatile for various applications | Polishing, abrasives, and composites | Pros: Versatile usage; Cons: Requires careful handling. |

Black Silicon Carbide (SiC) is recognized for its high hardness and low thermal conductivity, making it an ideal choice for applications requiring abrasive materials. It is commonly utilized in the manufacturing of cutting tools and abrasives. For B2B buyers, its cost-effectiveness is a significant advantage; however, its lower thermal performance may limit its use in high-temperature applications. Buyers should consider the specific requirements of their operations when opting for this type.

Green Silicon Carbide offers higher purity and superior thermal conductivity compared to its black counterpart. This type is particularly suitable for semiconductor devices and high-power electronics, making it a preferred choice for industries focused on efficiency and performance. While its enhanced capabilities come with a higher price tag, the long-term benefits in energy savings and device longevity often justify the investment. B2B buyers should evaluate their performance needs against budget constraints when considering this variant.

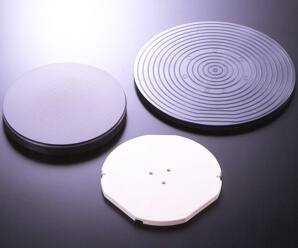

A stock image related to siliziumkarbid.

Silicon Carbide Wafers are essential for applications in power electronics and RF (radio frequency) devices due to their single-crystal structure, which allows for excellent efficiency and performance under high-frequency conditions. While these wafers provide significant advantages in terms of energy efficiency and heat resistance, they can be fragile and require careful handling during manufacturing and installation. B2B buyers must assess their production capabilities and handling processes to avoid damage and ensure optimal performance.

Silicon Carbide Ceramics are known for their high strength and exceptional thermal stability, making them suitable for demanding environments such as aerospace and automotive components. These materials are lightweight yet durable, which is a critical factor in industries where weight reduction is paramount. However, the manufacturing process can be costly, which may deter some buyers. Companies should weigh the benefits of enhanced performance against the investment required for these advanced materials.

Silicon Carbide Powder is characterized by its fine grain size and versatility across various applications, including polishing, abrasives, and composites. This type is widely used in industries that require precise finishing and surface preparation. While it offers broad applicability, careful handling is essential to prevent contamination and maintain quality. B2B buyers should consider their specific application needs and the handling capabilities of their operations when integrating silicon carbide powder into their processes.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of siliziumkarbid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Electronics | High-performance power devices (e.g., MOSFETs, IGBTs) | Enhanced efficiency and thermal performance in energy systems | Supplier reliability and technical support for integration |

| Automotive | Electric vehicle (EV) components | Improved energy efficiency and range for EVs | Compliance with international standards and certifications |

| Aerospace | High-temperature components in engines | Weight reduction and improved fuel efficiency | Proven track record in high-stress applications |

| Renewable Energy | Solar inverters and wind turbine converters | Increased energy conversion efficiency | Availability of customized solutions for specific projects |

| Industrial Manufacturing | Abrasives for cutting and grinding applications | Longer tool life and reduced downtime | Material quality and consistency for production processes |

In the power electronics sector, siliziumkarbid is utilized in high-performance devices such as MOSFETs and IGBTs. These components are crucial for managing electrical power efficiently, particularly in renewable energy systems and electric vehicles. The use of SiC allows for higher voltage and temperature operations, significantly enhancing the efficiency of power conversion. For international B2B buyers, sourcing from reliable suppliers who offer technical support is essential to ensure seamless integration into existing systems.

Siliziumkarbid is increasingly important in the automotive industry, especially in electric vehicle (EV) applications. Its high thermal conductivity and efficiency help improve the overall energy consumption and range of EVs, making them more competitive against traditional vehicles. Buyers should consider suppliers that comply with international automotive standards, as this ensures product reliability and performance in various climates, particularly in regions like Africa and South America.

In the aerospace sector, siliziumkarbid is employed in high-temperature components for engines and other critical systems. Its ability to withstand extreme conditions while reducing weight contributes to improved fuel efficiency and performance. B2B buyers in this industry must prioritize suppliers with a proven track record in high-stress applications, ensuring that materials meet stringent aerospace standards.

Siliziumkarbid is a key material in renewable energy systems, particularly in solar inverters and wind turbine converters. Its properties allow for increased energy conversion efficiency, which is vital for maximizing output from renewable sources. Buyers should focus on sourcing customized solutions that cater to specific project requirements, ensuring compatibility with existing systems and enhancing overall project viability.

A stock image related to siliziumkarbid.

In industrial manufacturing, siliziumkarbid serves as a superior abrasive material for cutting and grinding applications. Its hardness and durability lead to longer tool life and reduced downtime, which translates into cost savings for manufacturers. When sourcing SiC abrasives, businesses should emphasize material quality and consistency to maintain efficient production processes and minimize operational disruptions.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem:

B2B buyers often encounter challenges when sourcing high-quality siliziumkarbid (SiC) for demanding industrial applications, such as power electronics or abrasive materials. The primary concern lies in the variability of quality among suppliers, which can lead to inconsistent performance and reliability in end products. Buyers may find themselves overwhelmed by the number of suppliers, each claiming to provide superior quality, but without clear standards or certifications to verify their claims. This uncertainty can result in costly production delays or failures, as subpar materials may not withstand the required operational conditions.

The Solution:

To effectively source quality siliziumkarbid, it is crucial for buyers to establish a robust supplier evaluation process. Start by identifying suppliers that hold internationally recognized certifications, such as ISO 9001, which signifies adherence to quality management principles. Additionally, request detailed technical data sheets that specify the material's properties, such as purity, thermal conductivity, and grain size, which are critical for your specific application.

Engaging in a thorough due diligence process is essential. This includes visiting suppliers' manufacturing facilities, if feasible, to observe their production processes and quality control measures firsthand. Building relationships with suppliers can also lead to better transparency regarding the sourcing of raw materials and manufacturing practices. Consider forming partnerships with suppliers who are committed to continuous improvement and innovation, as they are likely to invest in research and development, ensuring that you have access to the latest advancements in siliziumkarbid technology.

The Problem:

As the demand for energy-efficient electronic devices increases, many manufacturers struggle with integrating siliziumkarbid components into existing systems. Compatibility issues often arise due to differences in thermal expansion coefficients between SiC and traditional silicon components. These discrepancies can lead to mechanical stress, premature failures, and overall system inefficiency. Buyers may also face challenges in finding suitable circuit designs that can accommodate the unique properties of SiC, further complicating the integration process.

The Solution:

To address compatibility issues when using siliziumkarbid in electronic applications, it is essential to collaborate closely with design engineers and component manufacturers. Begin by conducting a thorough analysis of the existing system to identify areas where SiC can be integrated without compromising performance. This may involve redesigning heat sinks or modifying circuit layouts to better accommodate the thermal characteristics of SiC.

Investing in simulation tools can also provide valuable insights into how SiC components will perform within the system. These tools can help predict thermal behavior and mechanical stresses, allowing for proactive design adjustments. Moreover, engaging with suppliers who offer technical support and design assistance can streamline the integration process. They may provide reference designs or case studies that demonstrate successful implementations of SiC in similar applications, serving as a guide for your own projects.

The Problem:

With increasing regulatory scrutiny on environmental impact and sustainability, B2B buyers are often confronted with the challenge of ensuring that their siliziumkarbid materials comply with local and international environmental regulations. Non-compliance can lead to hefty fines, reputational damage, and disruptions in supply chains. Buyers may also struggle to find reliable information regarding the environmental footprint of SiC production and its end-of-life disposal processes, making it difficult to make informed purchasing decisions.

The Solution:

To navigate the complexities of environmental compliance, buyers should prioritize sourcing siliziumkarbid from suppliers who demonstrate a commitment to sustainable practices. Look for suppliers that provide transparent information about their manufacturing processes, including energy consumption and waste management strategies. Certifications such as the Environmental Management System (EMS) ISO 14001 can indicate a supplier's dedication to minimizing their environmental impact.

Additionally, staying informed about the evolving regulatory landscape is crucial. Engage with industry groups and attend seminars focused on sustainability in materials sourcing. This knowledge can empower buyers to advocate for environmentally friendly practices within their organizations and make strategic decisions that align with both regulatory requirements and corporate sustainability goals. Implementing a life cycle assessment (LCA) approach can also help in evaluating the environmental impact of siliziumkarbid throughout its lifecycle, from production to disposal, ensuring compliance and fostering sustainability.

Siliziumkarbid (SiC) ist ein hochmodernes Material, das in verschiedenen Industrien aufgrund seiner einzigartigen Eigenschaften und Anwendungen an Bedeutung gewinnt. Bei der Auswahl von Materialien für spezifische Anwendungen ist es entscheidend, die verschiedenen Optionen zu analysieren. Hier sind einige gängige Materialien, die im Zusammenhang mit Siliziumkarbid häufig verwendet werden, sowie deren Eigenschaften, Vor- und Nachteile und spezifische Überlegungen für internationale B2B-Käufer.

Key Properties: Siliziumkarbid ist extrem hart und hat eine hohe thermische Leitfähigkeit. Es kann Temperaturen bis zu 1600 °C standhalten und ist chemisch sehr stabil, was es ideal für Anwendungen in rauen Umgebungen macht.

Pros & Cons: Die hohe Härte und Abriebfestigkeit sind große Vorteile, jedoch kann die Herstellungskosten von SiC hoch sein, was die Gesamtkosten für Endprodukte erhöht. Die Komplexität der Verarbeitung kann ebenfalls eine Herausforderung darstellen.

Impact on Application: SiC eignet sich hervorragend für Hochleistungsanwendungen, wie z.B. in der Leistungselektronik, wo hohe Temperaturen und Effizienz gefordert sind.

Considerations for International Buyers: Käufer aus Afrika, Südamerika, dem Nahen Osten und Europa sollten sich über die Einhaltung von Standards wie ASTM und DIN informieren, um sicherzustellen, dass die Materialien den lokalen Vorschriften entsprechen.

Key Properties: Aluminiumoxid ist ein weiteres häufig verwendetes Material, das hervorragende chemische Beständigkeit und eine hohe Temperaturbeständigkeit aufweist, jedoch nicht die gleiche elektrische Leitfähigkeit wie SiC besitzt.

Pros & Cons: Es ist kostengünstiger und leichter zu verarbeiten als SiC, hat jedoch eine geringere Härte und kann bei hohen Temperaturen weniger effizient sein.

Impact on Application: Aluminiumoxid wird oft in Anwendungen verwendet, wo die elektrische Isolation wichtig ist, aber die extremen Bedingungen von SiC nicht erforderlich sind.

Considerations for International Buyers: Käufer sollten die Verfügbarkeit und die lokalen Lieferketten für Aluminiumoxid in ihren Märkten prüfen, da dies die Produktionskosten erheblich beeinflussen kann.

Key Properties: Silizium ist ein weit verbreitetes Halbleitermaterial mit guter elektrischer Leitfähigkeit und relativ niedrigen Herstellungskosten.

Pros & Cons: Während Silizium kostengünstig ist, hat es eine geringere thermische Stabilität und kann in extremen Umgebungen versagen. Es ist weniger langlebig als SiC.

Impact on Application: Silizium wird häufig in der Elektronik verwendet, wo die Kosten eine größere Rolle spielen als die extremen Leistungsanforderungen.

Considerations for International Buyers: Käufer sollten die Marktpreise für Silizium und die Verfügbarkeit in ihren Regionen berücksichtigen, insbesondere in Ländern mit begrenztem Zugang zu Rohstoffen.

Key Properties: Borcarbid ist bekannt für seine hohe Härte und chemische Stabilität, was es zu einem hervorragenden Material für abrasive Anwendungen macht.

Pros & Cons: Es bietet eine hohe Abriebfestigkeit, ist jedoch teurer und kann in der Verarbeitung komplex sein.

Impact on Application: Borcarbid wird häufig in Anwendungen eingesetzt, die eine hohe Verschleißfestigkeit erfordern, wie z.B. in der Rüstungsindustrie.

Considerations for International Buyers: Käufer sollten sich über die spezifischen Anforderungen ihrer Branche informieren und sicherstellen, dass Borcarbid den lokalen Standards entspricht.

| Material | Typische Anwendung für Siliziumkarbid | Hauptvorteil | Hauptnachteil/Limitierung | Relativer Kosten (Niedrig/Mittel/Hoch) |

|---|---|---|---|---|

| Siliziumkarbid | Leistungselektronik | Hohe thermische Stabilität | Hohe Herstellungskosten | Hoch |

| Aluminiumoxid | Elektrische Isolierung | Kostengünstig | Geringere Härte | Mittel |

| Silizium | Allgemeine Elektronik | Niedrige Kosten | Geringere thermische Stabilität | Niedrig |

| Borcarbid | Abrasive Anwendungen | Hohe Abriebfestigkeit | Hohe Kosten | Hoch |

Diese Analyse bietet internationalen B2B-Käufern wertvolle Einblicke in die strategische Materialauswahl für Siliziumkarbid. Bei der Entscheidung sollten Käufer die spezifischen Anforderungen ihrer Anwendungen sowie die lokalen Marktbedingungen und Vorschriften berücksichtigen.

Siliziumkarbid (SiC) ist ein Schlüsselmaterial in der modernen Industrie, insbesondere in der Elektronik und Energietechnologie. Um die Qualität und Effizienz von SiC-Produkten sicherzustellen, ist es entscheidend, die Herstellungsprozesse und die Qualitätssicherungsmaßnahmen zu verstehen. Dieser Abschnitt bietet einen detaillierten Einblick in die typischen Herstellungsverfahren und die Qualitätssicherung für Siliziumkarbid, um internationalen B2B-Käufern, insbesondere aus Afrika, Südamerika, dem Nahen Osten und Europa, wertvolle Informationen zu bieten.

Die Herstellung von Siliziumkarbid beginnt mit der sorgfältigen Auswahl und Vorbereitung der Rohmaterialien. Die Hauptbestandteile sind Quarzsand und Kohlenstoff, die in spezifischen Verhältnissen gemischt werden. Diese Mischung wird dann in einem Elektroofen bei extrem hohen Temperaturen (über 2000 °C) erhitzt, was zur Bildung von SiC führt. Der Acheson-Prozess ist die am häufigsten verwendete Methode zur Herstellung von SiC und spielt eine entscheidende Rolle bei der Gewährleistung der Materialreinheit und -konsistenz.

Nach der Synthese erfolgt die Formung des SiC. Dies kann durch verschiedene Techniken wie Pressen, Spritzgießen oder Gießen erfolgen, abhängig von der gewünschten Endform und Anwendung. Die Formung muss präzise sein, um die strukturelle Integrität und die gewünschten mechanischen Eigenschaften zu gewährleisten. Ein weiterer wichtiger Schritt in diesem Prozess ist die Kristallisation, bei der das SiC in spezifische Kristallstrukturen umgewandelt wird, die für die elektrischen und thermischen Eigenschaften entscheidend sind.

In der Montagephase werden die geformten SiC-Komponenten zusammengefügt, um funktionale Einheiten zu bilden. Diese Phase kann das Zusammenfügen von Halbleiterbauelementen, wie Dioden und Transistoren, umfassen. Die Präzision in der Montage ist entscheidend, da sie die Leistung und Zuverlässigkeit der Endprodukte direkt beeinflusst. Techniken wie Laserbonding und Sinterung werden häufig verwendet, um eine zuverlässige Verbindung zwischen den Materialien herzustellen.

Die Endbearbeitung umfasst mehrere Schritte, darunter Schleifen, Polieren und Beschichten, um die Oberflächenqualität zu verbessern und spezifische Eigenschaften zu erreichen. Diese Prozesse sind entscheidend, um die Leistung in Anwendungen wie Leistungselektronik oder abrasiven Werkzeugen zu optimieren. Eine gründliche Endbearbeitung sorgt dafür, dass die Produkte den strengen Anforderungen der Branche entsprechen.

Die Qualitätssicherung in der SiC-Produktion erfolgt gemäß internationalen Standards wie ISO 9001, die die Anforderungen an ein effektives Qualitätsmanagementsystem definieren. Zudem sind branchenspezifische Normen wie die CE-Kennzeichnung für den europäischen Markt und API-Standards für die Öl- und Gasindustrie wichtig. Diese Standards helfen dabei, die Sicherheit und Zuverlässigkeit der Produkte zu gewährleisten und die Marktakzeptanz zu erhöhen.

Die Qualitätssicherung erfolgt typischerweise in mehreren Phasen des Produktionsprozesses:

Incoming Quality Control (IQC): Hierbei wird die Qualität der Rohmaterialien überprüft, bevor sie in die Produktion eingehen. Dies umfasst chemische Analysen und physikalische Tests, um sicherzustellen, dass die Materialien den festgelegten Standards entsprechen.

In-Process Quality Control (IPQC): Während der Produktion werden regelmäßige Stichproben durchgeführt, um sicherzustellen, dass die Prozesse den Qualitätsanforderungen entsprechen. Dies kann durch visuelle Inspektionen und Tests der physikalischen Eigenschaften geschehen.

Final Quality Control (FQC): Nach der Fertigstellung der Produkte erfolgt eine umfassende Endkontrolle. Hierbei werden die Produkte auf ihre Spezifikationen, Funktionalität und Sicherheitsstandards getestet.

Zu den gängigen Testmethoden gehören:

Internationale B2B-Käufer sollten folgende Maßnahmen ergreifen, um die Qualitätssicherung ihrer SiC-Lieferanten zu überprüfen:

Audits: Regelmäßige Audits vor Ort sind entscheidend, um die Einhaltung der Qualitätsstandards zu überprüfen. Käufer sollten sicherstellen, dass die Lieferanten über die erforderlichen Zertifizierungen verfügen und die Produktionsprozesse transparent sind.

Berichte: Anfordern von Qualitätsberichten und Testergebnissen von den Lieferanten ist wichtig, um die Qualität der Produkte zu gewährleisten. Diese Berichte sollten detaillierte Informationen über die durchgeführten Tests und deren Ergebnisse enthalten.

Drittanbieterinspektionen: Die Beauftragung unabhängiger Drittfirmen zur Inspektion der Produkte kann zusätzliche Sicherheit bieten. Diese Inspektoren können objektive Bewertungen der Qualität und der Einhaltung von Standards liefern.

B2B-Käufer aus Afrika, Südamerika, dem Nahen Osten und Europa sollten sich bewusst sein, dass unterschiedliche Märkte unterschiedliche Anforderungen an Qualität und Zertifizierung stellen. Es ist wichtig, sich über lokale Vorschriften und internationale Standards zu informieren, um sicherzustellen, dass die Produkte den regionalen Anforderungen entsprechen. Zudem sollten Käufer die kulturellen Unterschiede in den Geschäftsprozessen berücksichtigen, um effektive und nachhaltige Geschäftsbeziehungen aufzubauen.

Durch ein tiefes Verständnis der Herstellungsprozesse und der Qualitätssicherungsmaßnahmen für Siliziumkarbid können internationale B2B-Käufer fundierte Entscheidungen treffen und sicherstellen, dass sie qualitativ hochwertige Produkte von zuverlässigen Lieferanten erhalten.

The following practical sourcing guide aims to assist international B2B buyers in procuring siliziumkarbid (silicon carbide) effectively. This checklist is designed to ensure that buyers from regions such as Africa, South America, the Middle East, and Europe can make informed decisions while navigating the complexities of sourcing this advanced material.

Clearly outline the technical requirements for the siliziumkarbid you need. This includes defining the grade, purity level, and specific applications (e.g., electronics, abrasives). Establishing these specifications early on is crucial for ensuring that the material meets your operational needs and industry standards.

Stay informed about the latest market trends and pricing for siliziumkarbid. Understanding current demand, supply chain dynamics, and technological advancements can help you make strategic purchasing decisions.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assessing supplier credibility helps mitigate risks associated with quality and delivery.

Always request samples of siliziumkarbid before making a bulk purchase. Analyzing samples allows you to evaluate the material's quality and suitability for your specific applications.

Once you identify a suitable supplier, negotiate terms that align with your budget and operational needs. Discuss pricing, payment terms, and delivery schedules to ensure clarity.

Draft and finalize contracts that detail all agreed-upon terms. Make sure to include clauses that protect both parties, such as warranties, return policies, and dispute resolution processes.

After procurement, implement a quality control process to monitor the received siliziumkarbid. This will help ensure that the material consistently meets your specifications over time.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing siliziumkarbid effectively, ensuring they procure high-quality materials that meet their specific needs.

When sourcing siliziumkarbid (SiC), understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The raw materials for SiC production are high-purity quartz sand and carbon. Prices for these materials can fluctuate based on global supply and demand dynamics, impacting the overall cost.

Labor: Skilled labor is essential for the manufacturing process, particularly in handling high-temperature equipment and ensuring quality control. Labor costs may vary significantly by region, especially when comparing developed markets like Europe to emerging markets in Africa or South America.

Manufacturing Overhead: This encompasses all indirect costs associated with the production process, such as utilities, maintenance of equipment, and facility costs. Efficient manufacturing processes can help mitigate these costs.

Tooling: Investment in specialized tooling and machinery for SiC production can be substantial. The complexity of the tooling required for high-precision SiC applications can lead to increased upfront costs.

Quality Control (QC): Given the critical applications of SiC in electronics and energy sectors, rigorous quality control processes are mandatory. This includes testing for purity, thermal conductivity, and electrical performance, which can add to the overall cost.

Logistics: Transportation and warehousing costs are significant, especially for international shipments. The choice of Incoterms can also influence logistics expenses and responsibilities.

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on market conditions and competition.

Several factors can influence the pricing of siliziumkarbid, and understanding these can help buyers negotiate better deals:

Volume/MOQ: Suppliers often have minimum order quantities (MOQ) that can significantly affect pricing. Purchasing in larger volumes may lead to discounts, but buyers must balance this against their inventory management practices.

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized processes or materials. Buyers should assess whether the added value justifies the increased price.

Materials Quality and Certifications: The quality of raw materials and any certifications (e.g., ISO standards) can impact pricing. Higher-quality SiC with certifications may command a premium but often results in better performance and reliability.

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

Incoterms: The choice of Incoterms affects not only pricing but also risk management and responsibilities for shipping costs. Familiarity with Incoterms can help buyers avoid unexpected expenses.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

Conduct a Total Cost of Ownership Analysis: Evaluate all costs associated with sourcing SiC, including logistics, handling, and potential tariffs. This holistic approach can reveal the true cost of a supplier beyond just the purchase price.

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Frequent communication and understanding their business challenges can result in mutually beneficial agreements.

Be Transparent About Your Needs: Clearly communicate your specifications, expected volumes, and budget constraints. This transparency can help suppliers tailor their proposals to meet your needs more effectively.

Explore Multiple Suppliers: Diversifying your supplier base can provide leverage in negotiations and help you identify the best pricing options. Comparing multiple quotes allows for informed decision-making.

Stay Informed About Market Trends: Keeping abreast of global market trends in SiC pricing, such as demand fluctuations and technological advancements, can provide negotiation advantages.

Understanding the comprehensive cost structure and pricing dynamics of siliziumkarbid sourcing is vital for B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic negotiation techniques, buyers can optimize their sourcing decisions. Always remember that prices can vary widely, and it is advisable to consult with multiple suppliers to achieve the best possible deal.

As the demand for advanced materials grows, international B2B buyers are increasingly exploring alternatives to Siliziumkarbid (SiC). This section provides a comparative analysis of SiC against two prominent alternatives: Gallium Nitride (GaN) and Silicon (Si). Each of these materials offers unique advantages and disadvantages, making them suitable for different applications in electronics, power systems, and various industrial processes.

| Comparison Aspect | Siliziumkarbid (SiC) | Gallium Nitride (GaN) | Silicon (Si) |

|---|---|---|---|

| Performance | High thermal conductivity and efficiency | Excellent high-frequency performance | Moderate efficiency and thermal properties |

| Cost | Higher initial investment | Moderate cost, but increasing | Lower cost and widespread availability |

| Ease of Implementation | Requires specialized manufacturing | Easier integration in some applications | Well-established processes and supply chains |

| Maintenance | Low, durable under extreme conditions | Moderate, sensitive to heat | Low, but may degrade over time |

| Best Use Case | High-power, high-temperature applications | RF and power electronics | General-purpose electronics |

Gallium Nitride (GaN) is a semiconductor material that excels in high-frequency and high-efficiency applications, particularly in RF and power electronics. One of its key advantages is its ability to operate at higher voltages and temperatures compared to traditional silicon, making it ideal for compact, high-performance devices such as mobile chargers and RF amplifiers. However, GaN can be more sensitive to thermal management, requiring careful design to prevent overheating. Additionally, while its initial costs are moderate, the total cost of ownership may increase due to the need for advanced cooling solutions.

Silicon (Si) remains the most widely used semiconductor material due to its lower cost and well-established manufacturing processes. It is suitable for a variety of applications, from consumer electronics to automotive systems. However, Si does not match the thermal efficiency and performance of SiC or GaN under high-stress conditions, which limits its use in high-power applications. The maintenance costs can also be higher over time due to thermal degradation. For buyers looking for cost-effective solutions for standard applications, silicon remains a viable option.

When selecting the most appropriate material for your business needs, it is essential to consider the specific requirements of your application. For high-power, high-temperature applications, Siliziumkarbid offers unparalleled performance, albeit at a higher cost. Gallium Nitride presents a balanced option for RF and power electronics, while traditional Silicon serves well in general-purpose applications. Buyers should assess their project specifications, budget constraints, and long-term maintenance considerations to make an informed decision that aligns with their operational goals.

Understanding the critical technical properties of Siliziumkarbid (SiC) is essential for international B2B buyers in sectors like electronics, manufacturing, and renewable energy. Here are several key specifications that impact the material’s performance and applicability:

Material Grade

Material grades of SiC are categorized based on their purity and crystal structure. High-purity SiC is crucial for electronic applications, as impurities can significantly affect electrical conductivity and thermal performance. B2B buyers must consider the grade that aligns with their specific operational requirements to ensure optimal performance in their applications.

Thermal Conductivity

SiC exhibits excellent thermal conductivity, typically ranging from 120 to 200 W/m·K. This property is vital for applications involving high temperatures and power electronics, as it allows for efficient heat dissipation. Buyers in the electronics sector should prioritize SiC materials with high thermal conductivity to enhance the reliability and longevity of their devices.

Electrical Breakdown Field Strength

The electrical breakdown field strength of SiC is notably higher than that of traditional semiconductor materials like silicon, often exceeding 3 MV/cm. This property allows SiC devices to operate at higher voltages, making them ideal for high-power applications. For international B2B buyers, understanding this specification can inform decisions regarding power management systems and high-voltage applications.

Hardness and Abrasion Resistance

SiC is known for its exceptional hardness, ranking around 9.5 on the Mohs scale. This characteristic makes it suitable for use as an abrasive material and in applications where durability is essential. Buyers in manufacturing and construction should consider SiC for cutting tools and wear-resistant surfaces to reduce maintenance costs and improve efficiency.

Thermal Stability

The thermal stability of SiC allows it to maintain its structural integrity at elevated temperatures, often exceeding 1600°C. This property is particularly beneficial in high-temperature applications such as furnaces and aerospace components. B2B buyers should evaluate thermal stability to ensure their materials can withstand the operational conditions of their intended applications.

Familiarity with industry jargon is crucial for international B2B buyers to navigate the procurement process effectively. Here are several common terms that are particularly relevant:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of SiC, understanding OEM relationships can help buyers identify reliable sources for their materials and components, ensuring compatibility and performance in their applications.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for SiC materials is essential for buyers to manage inventory levels and cash flow effectively, especially for smaller businesses or startups.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific quantities of SiC materials. This process is crucial for buyers to compare options and negotiate terms, ensuring they receive competitive pricing and favorable conditions.

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping, insurance, and liability, minimizing potential disputes and ensuring smooth transactions.

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times for SiC materials is critical for buyers to plan their production schedules effectively and maintain supply chain efficiency.

By comprehensively understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance their operational effectiveness and competitiveness in the market.

The siliziumkarbid (SiC) market is witnessing robust growth driven by several global factors, including the increasing demand for energy-efficient solutions and advancements in semiconductor technologies. As industries focus on reducing carbon footprints, SiC's efficiency in high-power applications positions it as a key player in sectors such as automotive, renewable energy, and telecommunications. The transition towards electric vehicles (EVs) and the integration of renewable energy sources are particularly significant, with SiC devices enabling faster charging, higher efficiency, and enhanced thermal performance.

Emerging trends show a shift towards localized sourcing as international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to mitigate supply chain risks. This is especially relevant for buyers in Argentina and Spain, where the demand for sustainable and reliable semiconductor components is rising. Furthermore, partnerships between manufacturers and technology firms are becoming more prevalent, allowing for innovation in SiC production processes and applications.

Additionally, the increasing focus on automation and smart technologies is propelling the need for high-performance materials like SiC, which can operate efficiently under extreme conditions. International buyers should keep an eye on these trends to enhance their sourcing strategies and align with the evolving demands of the market.

Sustainability is becoming a pivotal factor in the sourcing of siliziumkarbid materials. The environmental impact of SiC production, particularly concerning energy consumption and emissions, necessitates a focus on ethical sourcing practices. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as utilizing renewable energy sources in manufacturing processes and minimizing waste.

Moreover, certifications like ISO 14001 (Environmental Management) and adherence to the REACH regulations (Registration, Evaluation, Authorisation and Restriction of Chemicals) are essential for suppliers aiming to attract international buyers. By choosing suppliers with 'green' certifications, companies can ensure that their supply chains are not only efficient but also environmentally responsible.

In regions such as Europe and the Middle East, where regulatory frameworks are becoming stricter, the importance of ethical supply chains cannot be overstated. Buyers from these areas must engage with suppliers who are committed to transparency and sustainability, thus enhancing their corporate social responsibility profiles while ensuring compliance with local laws.

The journey of siliziumkarbid as a prominent material began in the early 20th century with its discovery as a synthetic compound. Initially utilized for abrasive applications, its semiconductor properties were recognized in the 1970s. The evolution of SiC technology has accelerated with the rise of high-power and high-temperature applications in the electronics sector.

Today, advancements in SiC manufacturing techniques, such as the Acheson process and the development of epitaxial growth methods, have led to improved material quality and availability. This evolution reflects the increasing integration of SiC into critical technologies, including power electronics and renewable energy systems, highlighting its significance in the modern industrial landscape.

For international B2B buyers, understanding the historical context of siliziumkarbid can provide valuable insights into its current applications and future potential, enabling informed sourcing decisions that align with technological advancements and market demands.

How do I determine the quality of siliziumkarbid suppliers?

To assess the quality of suppliers offering siliziumkarbid, consider factors such as certifications (ISO 9001, etc.), industry reputation, and customer reviews. Request samples to evaluate the material's physical properties like hardness and thermal conductivity. Additionally, inquire about their manufacturing processes and quality assurance measures. Engaging in direct communication with the supplier can also provide insights into their reliability and customer service standards.

What is the best application for siliziumkarbid in electronic components?

Siliziumkarbid excels in applications involving high-power electronics, particularly in devices like Schottky diodes and MOSFETs. Its high thermal conductivity and ability to operate at elevated temperatures make it ideal for power inverters, electric vehicle systems, and renewable energy applications. For B2B buyers, understanding the specific needs of their projects can help in selecting the right SiC components that enhance efficiency and performance.

What are the minimum order quantities (MOQ) for siliziumkarbid?

Minimum order quantities for siliziumkarbid can vary significantly between suppliers and depend on the type of product and customization required. Typically, MOQs can range from a few kilograms for standard products to larger quantities for specialized applications. It’s crucial for buyers to communicate their needs upfront and negotiate MOQs that align with their project scales to avoid excess inventory costs.

What payment terms should I expect when sourcing siliziumkarbid internationally?

Payment terms for international purchases of siliziumkarbid can vary by supplier, but common practices include advance payment, 30-60 days net, or letter of credit arrangements. Discussing payment methods such as wire transfers, PayPal, or escrow services is essential to ensure security. Understanding the supplier's terms can help in budgeting and cash flow management for your procurement process.

How can I customize siliziumkarbid products for my specific needs?

Customization of siliziumkarbid products often involves specifying dimensions, grades, and the intended application. Many suppliers have the capability to produce tailored solutions based on client requirements, including special formulations for unique performance characteristics. Engaging in early discussions with suppliers about your specific needs can lead to better alignment in product development and lead times.

What logistics considerations should I keep in mind when importing siliziumkarbid?

When importing siliziumkarbid, consider factors such as shipping methods, customs clearance, and import duties. Choose reliable logistics partners who understand the intricacies of handling industrial materials. Additionally, ensure that the supplier provides all necessary documentation, such as certificates of origin and material safety data sheets, to facilitate smooth customs processes and compliance with local regulations.

How do I evaluate the environmental impact of siliziumkarbid sourcing?

Evaluating the environmental impact of sourcing siliziumkarbid involves assessing the supplier's sustainability practices, such as waste management and energy consumption during production. Seek suppliers who prioritize eco-friendly manufacturing processes and have certifications related to environmental standards (e.g., ISO 14001). Understanding the lifecycle impact of siliziumkarbid can also help your company meet its sustainability goals and improve its brand image.

What quality assurance measures are common in siliziumkarbid manufacturing?

Quality assurance in siliziumkarbid manufacturing typically involves rigorous testing protocols, including mechanical property assessments, thermal conductivity measurements, and chemical composition analysis. Suppliers often implement in-process inspections and final product evaluations to ensure compliance with industry standards. Requesting detailed QA documentation can provide confidence in the reliability and performance of the siliziumkarbid products you source.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

As international B2B buyers look toward the future, understanding the strategic sourcing of siliziumkarbid (SiC) is crucial. This advanced material stands out for its exceptional properties, including high thermal conductivity and resilience in harsh environments, making it invaluable in various applications such as power electronics and renewable energy systems. By investing in SiC, businesses can enhance product efficiency and sustainability, aligning with global trends toward greener technologies.

Effective strategic sourcing of SiC not only streamlines procurement processes but also fosters partnerships with suppliers who are at the forefront of SiC technology. This collaboration can lead to innovative solutions and reduced costs over time, benefiting organizations across Africa, South America, the Middle East, and Europe. As demand for SiC grows, being proactive in sourcing strategies will position companies to capitalize on market opportunities and gain a competitive edge.

Looking ahead, B2B buyers should prioritize suppliers with a strong track record in SiC production and a commitment to sustainability. Engaging with these suppliers will not only secure quality materials but also contribute to a more sustainable future. Embrace the potential of siliziumkarbid and make strategic sourcing decisions that will pave the way for innovation and efficiency in your operations. The time to act is now—ensure your business is ready to harness the benefits of this transformative material.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina