Navigating the complexities of sourcing single crystal alumina can be a daunting task for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With its critical applications in industries ranging from electronics to medical devices, understanding the nuances of this specialized material is essential. This guide offers a comprehensive look at single crystal alumina, detailing its various types, applications, and the pivotal role it plays in advanced manufacturing processes.

Buyers will gain insights into effective supplier vetting techniques, helping them identify reliable partners who can meet their specific quality and production needs. Additionally, the guide will explore cost considerations, enabling informed financial decisions that align with budget constraints and project timelines.

Armed with this information, international B2B buyers, including those from emerging markets like Brazil and South Africa, will be empowered to make confident purchasing decisions. By demystifying the sourcing process and providing actionable insights, this guide serves as a valuable resource for businesses looking to leverage the unique properties of single crystal alumina in their operations. Whether you are new to the market or seeking to optimize your supply chain, understanding these critical elements will be key to your success.

Single crystal alumina, also known as sapphire, is available in various forms tailored to specific applications. Understanding these variations is crucial for selecting the right product for your needs.

Evaluating potential suppliers involves a thorough assessment of their capabilities, certifications, and past performance. This section outlines best practices for ensuring you partner with the right suppliers.

From high-performance electronics to medical instruments, single crystal alumina has diverse applications. This section will highlight its significance across various industries.

Understanding the factors that contribute to pricing can help you budget effectively and negotiate better deals with suppliers. This guide will break down the cost components associated with single crystal alumina.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Crystal Sapphire | High optical clarity, excellent thermal stability | Semiconductor substrates, optical components | Pros: Superior performance, high reliability. Cons: Higher cost, limited availability. |

| Al2O3 with Doping | Tailored properties for specific applications | Electronics, sensors, medical devices | Pros: Customizable features, enhanced performance. Cons: Complexity in sourcing, potential quality variability. |

| Sapphire Glass | Combination of sapphire and glass properties | High-end displays, protective covers | Pros: Excellent scratch resistance, aesthetic appeal. Cons: Fragility, higher production costs. |

| Polycrystalline Alumina | Composed of multiple crystals, lower cost | General industrial applications | Pros: Cost-effective, good mechanical strength. Cons: Lower performance compared to single crystal variants. |

| Transparent Alumina | High transparency and strength | Aerospace, optical applications | Pros: Lightweight, strong, versatile. Cons: Limited suppliers, niche applications. |

Single Crystal Sapphire, primarily composed of aluminum oxide (Al2O3), is renowned for its exceptional optical clarity and thermal stability. This material is highly suitable for demanding applications in the semiconductor industry, where precision and reliability are paramount. B2B buyers should consider the higher cost associated with this material, but the long-term benefits in performance and durability often justify the investment.

Al2O3 with Doping is engineered to meet specific application requirements by incorporating various dopants, which modify its electrical, optical, or mechanical properties. This variation is particularly useful in sectors like electronics and medical devices, where tailored performance is essential. Buyers must weigh the advantages of customizability against potential challenges in sourcing and the variability in quality that may arise from different suppliers.

Sapphire Glass merges the advantageous properties of sapphire with glass, resulting in a material that boasts excellent scratch resistance and aesthetic appeal. It is commonly used in high-end displays and protective covers. For B2B buyers, while the visual and protective qualities are a significant draw, they should also be aware of the material's fragility and the higher production costs associated with it.

Polycrystalline Alumina consists of multiple crystalline structures, making it a more cost-effective option for various industrial applications. While it offers good mechanical strength and durability, it does not match the performance of single crystal variants. B2B buyers looking for budget-friendly solutions may find this type advantageous, but they must consider the trade-off in performance.

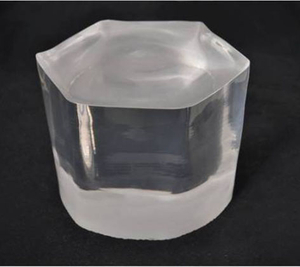

A stock image related to single crystal alumina.

Transparent Alumina is characterized by its high transparency and strength, making it suitable for specialized applications in aerospace and optical fields. Its lightweight nature combined with exceptional strength makes it appealing for high-performance needs. However, buyers should be aware of the limited supplier options and the niche nature of its applications, which can affect availability and pricing.

| Industry/Sector | Specific Application of single crystal alumina | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Semiconductor Industry | Substrates for LED and laser diodes | Enhances efficiency and performance of devices | Supplier certifications, production capabilities |

| Medical Technology | Components for surgical instruments | Increases durability and precision in medical tools | Regulatory compliance, material purity |

| Aerospace and Defense | Optical components for sensors | Provides high transparency and resistance to harsh conditions | Performance specifications, sourcing traceability |

| Electronics and Sensor Technology | Insulators in high-frequency circuits | Improves signal integrity and reduces loss | Quality assurance, compatibility with existing systems |

| Energy and Environmental Technology | Components in renewable energy systems | Enhances reliability and efficiency of energy conversion | Cost-effectiveness, availability of materials |

In the semiconductor industry, single crystal alumina serves as a substrate for LEDs and laser diodes. Its high thermal conductivity and excellent electrical insulation properties make it ideal for these applications, enhancing the efficiency and performance of devices. For international B2B buyers, especially in regions like South Africa and Brazil, it’s crucial to consider supplier certifications and production capabilities to ensure the quality of the substrates meets industry standards.

Single crystal alumina is utilized in the medical technology sector for manufacturing components of surgical instruments. Its exceptional durability and biocompatibility contribute to the precision and longevity of medical tools, making them safer for patient use. Buyers from Europe and the Middle East should prioritize suppliers who adhere to regulatory compliance and can guarantee high material purity to avoid any complications in medical applications.

In aerospace and defense, single crystal alumina is employed in optical components for sensors. Its high transparency and resistance to extreme environmental conditions make it suitable for critical applications where performance is paramount. B2B buyers in this sector need to focus on performance specifications and sourcing traceability to ensure the components can withstand rigorous testing and operational demands.

A stock image related to single crystal alumina.

Within electronics and sensor technology, single crystal alumina acts as an insulator in high-frequency circuits. Its properties enhance signal integrity and minimize loss, crucial for the performance of advanced electronic systems. Buyers should emphasize quality assurance and compatibility with existing systems when sourcing these materials, especially in competitive markets across South America and Europe.

In energy and environmental technology, single crystal alumina is utilized in components for renewable energy systems. Its reliability and efficiency in energy conversion processes are vital for advancing sustainable technologies. For international buyers, particularly those in emerging markets in Africa and South America, cost-effectiveness and material availability are key considerations when sourcing components that utilize single crystal alumina.

Related Video: What is Crystallization | Definition, Process, and Industrial Applications

The Problem:

B2B buyers often face challenges in sourcing high-quality single crystal alumina due to the limited number of suppliers and varying quality standards. This can lead to inconsistent product performance, which affects the reliability of applications, especially in sectors like electronics and aerospace. Buyers from regions such as Africa and South America may find it particularly difficult to connect with reputable manufacturers, leading to uncertainty in procurement.

The Solution:

To mitigate this sourcing challenge, buyers should conduct thorough market research to identify established suppliers with a proven track record. Look for manufacturers that provide certifications and detailed specifications regarding the purity and crystalline structure of their single crystal alumina. Engaging in direct communication with suppliers can also help clarify quality standards and production processes. Additionally, consider attending industry trade shows or exhibitions to meet potential suppliers in person and evaluate their offerings firsthand. Building long-term relationships with suppliers can lead to better pricing and priority access to high-quality materials.

The Problem:

Another common pain point for B2B buyers is dealing with inconsistent quality of single crystal alumina, which can result in manufacturing delays and increased costs. Variations in material properties can lead to defects in final products, causing disruptions in the supply chain and negatively impacting customer satisfaction. This issue is particularly pressing for companies in the Middle East and Europe, where precision engineering is critical.

The Solution:

To address quality inconsistencies, buyers should implement stringent quality control measures when receiving shipments. This includes conducting thorough inspections and testing of the material upon arrival. Additionally, establish clear quality benchmarks and communicate these requirements to suppliers upfront. Consider leveraging third-party testing services to verify the material properties before use. Furthermore, integrating a robust feedback loop with suppliers can help ensure they are aware of quality issues and can make necessary adjustments. Regular audits and quality assessments will foster a culture of excellence and help maintain consistent product quality over time.

The Problem:

B2B buyers often struggle with the technical specifications required for the effective application of single crystal alumina in their products. This complexity can lead to misunderstandings between engineering teams and suppliers, resulting in the wrong material being used for specific applications. Buyers from diverse industries, such as medical technology or semiconductor manufacturing, may find it particularly challenging to navigate these technical requirements.

The Solution:

To overcome the complexities of technical specifications, buyers should invest in training for their engineering and procurement teams to better understand the properties and potential applications of single crystal alumina. Collaborating with suppliers during the design phase can also enhance the understanding of material requirements and lead to more tailored solutions. Additionally, creating detailed documentation that outlines the specific applications, environmental conditions, and performance expectations can serve as a clear reference point for suppliers. Establishing a partnership with suppliers that includes ongoing technical support can ensure that any questions or concerns about material specifications are addressed promptly, ultimately leading to more successful application outcomes.

Single crystal alumina, commonly known as sapphire, exhibits remarkable properties that make it suitable for various high-performance applications. Key properties include:

When considering single crystal alumina for B2B applications, it's essential to weigh its pros and cons:

Thermal Conductivity: It has good thermal conductivity, which is beneficial in heat management applications.

Cons:

The choice of single crystal alumina significantly influences application performance:

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are specific considerations:

| Material | Typical Use Case for single crystal alumina | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Single Crystal Alumina | Semiconductor substrates, optical components | High durability and temperature resistance | High manufacturing cost | High |

| Polycrystalline Alumina | General ceramics, wear-resistant parts | Lower cost and easier to manufacture | Lower hardness compared to sapphire | Medium |

| Alumina Ceramics | Insulators, abrasives | Good electrical insulation | Limited temperature resistance | Low |

| Sapphire Glass | Optical windows, high-end watches | Excellent optical clarity | Brittle and prone to chipping | High |

This strategic material selection guide provides B2B buyers with essential insights into single crystal alumina, facilitating informed decision-making for various applications across different industries and regions.

The production of single crystal alumina, often referred to as sapphire, involves several critical stages, each requiring specialized techniques and equipment. Understanding these stages is vital for B2B buyers to ensure they partner with manufacturers who adhere to high-quality standards.

The manufacturing process begins with the careful selection of raw materials. High-purity aluminum oxide (Al2O3) is typically used, sourced from reliable suppliers to guarantee quality. The preparation phase also involves the precise mixing of aluminum oxide with dopants, which can enhance specific properties of the final product, such as electrical conductivity or color.

The most common methods for producing single crystal alumina include the Czochralski process and the Verneuil process:

Czochralski Process: This method involves melting high-purity aluminum oxide in a crucible. A seed crystal is dipped into the molten material and gradually pulled upwards while rotating, forming a large single crystal as it cools.

Verneuil Process: In this technique, powdered aluminum oxide is melted using an oxy-hydrogen flame. The molten droplets fall onto a rotating pedestal, solidifying into a single crystal structure.

Both methods require precise control over temperature and environment to prevent impurities and defects, critical for industries requiring high-performance materials, such as electronics and aerospace.

Once the crystal is grown, the next step is forming and cutting it into desired shapes and sizes. This is typically done using techniques like:

The finishing stage enhances the surface quality and prepares the material for its intended application. Techniques may include:

These finishing processes require strict adherence to quality standards, as imperfections can significantly impact the performance of the final product.

Quality assurance (QA) in the manufacturing of single crystal alumina is paramount. It involves adherence to international standards and rigorous testing protocols to ensure that the final product meets specific performance criteria.

B2B buyers should be aware of several international quality standards that manufacturers of single crystal alumina typically comply with:

Quality control (QC) involves several checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. It ensures that only high-purity aluminum oxide is used.

In-Process Quality Control (IPQC): During the production stages, regular inspections are conducted to monitor the growth process and ensure that parameters remain within specified limits.

Final Quality Control (FQC): After the product is completed, a thorough inspection is performed. This includes dimensional checks, surface quality assessments, and functional testing, depending on the intended application.

B2B buyers should understand the testing methods that manufacturers employ to verify the quality of single crystal alumina:

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier's quality control processes is essential. Here are several strategies to ensure compliance with quality standards:

Performing regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This includes evaluating their adherence to ISO standards and other relevant certifications.

Buyers should request detailed quality assurance reports that outline the testing methods used, results obtained, and any corrective actions taken in response to quality issues. This documentation can help assess the supplier's commitment to quality.

Utilizing third-party inspection services can provide an unbiased assessment of a supplier's quality control processes. These services can conduct thorough inspections and testing before products are shipped, ensuring compliance with international standards.

When sourcing single crystal alumina, international buyers must consider various nuances related to quality control:

Cultural and Regulatory Differences: Different regions may have varying expectations regarding quality standards. Understanding local regulations is crucial, especially in industries like medical devices or aerospace.

Supply Chain Complexity: The global nature of the supply chain can complicate quality assurance. Buyers should ensure that suppliers have robust tracking and traceability systems in place.

Communication: Clear communication regarding quality expectations and standards is essential. Buyers should establish direct lines of communication with suppliers to address any quality concerns promptly.

By understanding the manufacturing processes and quality assurance measures associated with single crystal alumina, B2B buyers can make informed decisions and ensure they are sourcing high-quality materials for their applications.

In the competitive landscape of international B2B procurement, sourcing single crystal alumina requires a strategic approach. This guide serves as a practical checklist for buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. Follow these steps to ensure a successful procurement process.

Before initiating the sourcing process, it is essential to clearly define your technical requirements. Specifications should include parameters like crystal orientation, purity levels, and desired dimensions.

- Why it matters: Precise specifications ensure that you receive products that meet your application needs, reducing the risk of costly errors or delays.

Conduct thorough research to identify potential suppliers of single crystal alumina. Utilize online directories, industry forums, and trade shows to compile a list of candidates.

- What to consider: Look for suppliers with a strong reputation and experience in your specific industry. Pay attention to their production capabilities and product range.

Verify that your shortlisted suppliers hold relevant industry certifications, such as ISO 9001 or equivalent. These certifications indicate adherence to quality management standards.

- Key details: Ensure that the certifications are current and applicable to the specific materials you intend to purchase. This step mitigates the risk of substandard products.

Request samples of single crystal alumina from your top suppliers. Testing these samples allows you to evaluate quality, consistency, and performance in your specific application.

- Why this is crucial: Samples provide tangible evidence of a supplier's capabilities and help you avoid potential issues in larger orders.

Collect pricing information and evaluate payment terms from each supplier. Look for transparency in pricing structures and any hidden costs that may arise.

- Considerations: Compare not only the base price but also shipping costs, payment terms, and potential discounts for bulk orders. Understanding these factors can lead to better budget management.

Ask suppliers for references or case studies from previous clients, especially those in similar industries or regions. This will help you assess their reliability and performance.

- Why it’s important: Real-world examples of successful projects provide insights into a supplier's capabilities and customer satisfaction levels.

Once you've selected a supplier, ensure that you finalize a contract that includes all agreed-upon terms and conditions. This should cover delivery schedules, quality expectations, and penalties for non-compliance.

- What to include: Clear communication of expectations in the contract protects both parties and helps avoid disputes later in the process.

By following these steps, B2B buyers can streamline their sourcing process for single crystal alumina, ensuring they partner with reliable suppliers who meet their specific needs.

When sourcing single crystal alumina, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The raw material cost for single crystal alumina is significant, as high-purity alumina is essential for quality. Prices can fluctuate based on market demand and availability.

Labor: Skilled labor is required for the manufacturing process, particularly for crystal growth and fabrication. Labor costs vary by region, impacting the overall price.

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads.

Tooling: Custom tooling may be necessary for specific applications, adding to the initial investment. The complexity of tooling directly correlates with the final product specifications.

Quality Control (QC): Rigorous QC processes ensure that the product meets the required standards, which can increase costs but is essential for maintaining quality.

Logistics: Transportation and warehousing costs can vary significantly, especially when sourcing from different regions. Efficient logistics management is key to minimizing these costs.

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on competition and supplier reputation.

Several factors influence the pricing of single crystal alumina that international buyers should consider:

Volume/MOQ: Purchasing in larger quantities can lead to discounts, making it vital for buyers to assess their needs carefully. Minimum order quantities (MOQs) set by suppliers can also affect overall costs.

Specifications and Customization: Custom specifications may lead to higher costs due to the need for specialized manufacturing processes. Clear communication of requirements can help manage costs.

Material Quality and Certifications: Higher quality materials and compliance with specific certifications (e.g., ISO, ASTM) often command higher prices. Buyers should evaluate whether these certifications are necessary for their applications.

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers may offer better quality but at a premium price.

Incoterms: Understanding shipping terms (Incoterms) is essential for cost calculations. Different terms can shift the responsibility for shipping costs and risks between the buyer and seller.

To secure favorable pricing, B2B buyers should consider the following strategies:

Leverage Total Cost of Ownership (TCO): Focus on the TCO rather than just the purchase price. Consider long-term costs such as maintenance, performance, and potential savings from higher quality products.

Conduct Market Research: Understand market trends and pricing benchmarks. This knowledge can empower buyers during negotiations, ensuring they do not overpay.

Build Relationships with Suppliers: Long-term relationships can lead to better pricing and terms. Suppliers may offer more favorable deals to trusted customers.

Explore Alternative Suppliers: Diversifying the supplier base can provide leverage in negotiations. This approach can help buyers find the best value without sacrificing quality.

Clarify Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce upfront costs. Terms such as extended payment periods or discounts for early payments can be beneficial.

For buyers from Africa, South America, the Middle East, and Europe, several regional considerations can impact sourcing:

Regulatory Compliance: Different regions may have varying regulations regarding material sourcing and safety standards. Understanding these regulations is crucial to avoid compliance issues.

Currency Fluctuations: Exchange rates can significantly affect pricing. Buyers should account for potential currency risks when negotiating prices.

Cultural Differences: Negotiation styles and business practices can vary across regions. Being aware of these differences can facilitate smoother transactions.

Logistics and Delivery Times: Assess logistics options and potential delays in shipping. Factors like customs clearance and transportation infrastructure can impact lead times.

Please note that prices for single crystal alumina can vary widely based on the factors outlined above. The information provided is for general guidance and should not be considered as definitive pricing. Always consult with suppliers for the most accurate and current pricing tailored to your specific needs.

When exploring materials for high-performance applications, single crystal alumina (sapphire) is often considered alongside various alternatives. Understanding the strengths and weaknesses of these options is crucial for B2B buyers, particularly those in industries like electronics, aerospace, and medical technology.

| Comparison Aspect | Single Crystal Alumina | Polycrystalline Alumina | Silicon Carbide |

|---|---|---|---|

| Performance | Excellent hardness, high thermal stability, optical clarity | Good hardness, lower thermal stability | Superior thermal conductivity, high hardness |

| Cost | High initial investment | Moderate cost | Moderate to high cost |

| Ease of Implementation | Complex fabrication process | Easier to process and manufacture | Requires specialized manufacturing |

| Maintenance | Low maintenance, durable | Moderate maintenance due to wear | Low maintenance, durable |

| Best Use Case | High-precision optics, semiconductor substrates | General industrial applications | High-temperature environments, power electronics |

Polycrystalline alumina offers a more cost-effective alternative to single crystal alumina. It is easier to manufacture, making it accessible for a broader range of applications. However, while it exhibits good hardness, it falls short in thermal stability compared to its single crystal counterpart. This makes it less suitable for high-performance environments where precision and durability are critical. B2B buyers in sectors like automotive or general manufacturing may find polycrystalline alumina adequate for less demanding applications.

Silicon carbide is a robust alternative known for its exceptional thermal conductivity and hardness. It excels in high-temperature applications, making it ideal for power electronics and components subjected to extreme conditions. However, the manufacturing process can be more complex and costly than polycrystalline alumina. Buyers in the aerospace or energy sectors might prefer silicon carbide for its performance in harsh environments, but they should be prepared for potential higher costs and longer lead times.

Selecting the right material involves assessing specific operational requirements, including performance needs, budget constraints, and implementation capabilities. Single crystal alumina is best for applications demanding precision and durability, while polycrystalline alumina serves as a more economical option for less critical uses. Silicon carbide stands out for high-temperature and high-stress applications but may require a higher investment. By carefully analyzing these factors, B2B buyers can make informed decisions that align with their strategic goals and operational demands.

Single crystal alumina, also known as sapphire, is a highly valued material in various industries, particularly in electronics, optics, and aerospace. Understanding its critical properties is essential for B2B buyers to make informed purchasing decisions.

Material grade refers to the purity and composition of the alumina. Single crystal alumina is typically available in grades such as 4N (99.99% purity) and 6N (99.9999% purity). Higher grades are crucial for applications requiring high optical transparency and thermal stability, such as in semiconductor substrates or optical components. Buyers must ensure they select the appropriate grade to meet their specific application needs.

The crystal orientation of single crystal alumina significantly affects its physical and optical properties. Common orientations include C-plane (0001) and R-plane (11-20). The choice of orientation can impact the material's strength, thermal conductivity, and light transmission properties. Understanding this parameter allows buyers to optimize performance for specific applications, such as LED substrates or high-temperature environments.

Tolerance refers to the permissible limits of variation in a physical dimension. For single crystal alumina, tight tolerances are often required to ensure precise fit and function in high-tech applications. Typical tolerances can be as tight as ±0.05 mm. B2B buyers should prioritize suppliers who can provide detailed specifications and adhere to strict tolerances to avoid costly rework or failures in their applications.

Thermal conductivity is a measure of a material's ability to conduct heat. Single crystal alumina exhibits excellent thermal conductivity (up to 30 W/mK), making it ideal for applications in electronics where heat dissipation is critical. Buyers should consider thermal conductivity when selecting materials for high-power applications or environments with fluctuating temperatures.

Single crystal alumina boasts remarkable mechanical strength, often exceeding 400 MPa. This property is essential for applications that require durability and resistance to wear and tear. Buyers in industries like aerospace and medical technology should evaluate the mechanical strength of the material to ensure it meets their rigorous operational demands.

Understanding the terminology used in the trade of single crystal alumina is crucial for effective communication and negotiation between suppliers and buyers.

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of single crystal alumina, OEMs often require specific material grades and tolerances to fit their product requirements. Buyers should clarify their needs to ensure compatibility with OEM specifications.

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers who may have varying demands. Understanding MOQ helps buyers manage inventory costs and negotiate better terms with suppliers, especially when sourcing single crystal alumina for large-scale projects.

An RFQ is a document sent to suppliers requesting a price quote for specific goods or services. B2B buyers should prepare detailed RFQs for single crystal alumina, including material grades, dimensions, and quantities. This practice ensures accurate pricing and helps streamline the procurement process.

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in global trade. For single crystal alumina, understanding terms such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight) is essential for clarifying shipping costs and responsibilities. Buyers should ensure they are familiar with these terms to avoid misunderstandings and additional costs.

Lead time refers to the time it takes from placing an order until the product is delivered. In the context of single crystal alumina, lead times can vary significantly based on material availability and manufacturing processes. Buyers should factor in lead time when planning their projects to ensure timely delivery and avoid disruptions.

By grasping the essential technical properties and trade terminology associated with single crystal alumina, B2B buyers can make more informed decisions that align with their business needs and operational goals.

The single crystal alumina market is experiencing significant growth, driven by various global factors. The increasing demand for high-performance materials in electronics, aerospace, and healthcare sectors is propelling the need for single crystal alumina, known for its exceptional hardness, thermal stability, and optical properties. Notably, advancements in semiconductor technology and the rising trend towards miniaturization are influencing sourcing strategies among international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe.

Emerging trends indicate a shift towards automation and digitalization in the sourcing process. Companies are increasingly leveraging data analytics and supply chain management tools to optimize procurement, enhance transparency, and reduce lead times. Additionally, there is a growing emphasis on local sourcing to mitigate risks associated with global supply chain disruptions, particularly highlighted during the COVID-19 pandemic. B2B buyers are encouraged to explore partnerships with local suppliers that can provide not only competitive pricing but also quick delivery times.

Furthermore, the sustainability narrative is becoming increasingly relevant, with buyers prioritizing suppliers who demonstrate a commitment to environmental stewardship and ethical practices. This shift is particularly evident in Europe, where regulations on material sourcing and waste management are becoming more stringent. As such, international buyers should remain agile and responsive to these evolving market dynamics to maximize their competitive edge.

The environmental impact of sourcing single crystal alumina cannot be overlooked, as the production processes can be resource-intensive. Therefore, ethical sourcing practices are increasingly important for B2B buyers aiming to align with sustainability goals. Companies that prioritize ethical supply chains not only contribute positively to the environment but also enhance their brand reputation, which is crucial in today's market where consumers are increasingly aware of corporate social responsibility.

Buyers should look for suppliers who hold recognized sustainability certifications, such as ISO 14001 for environmental management or those that comply with the Responsible Minerals Initiative (RMI). These certifications indicate a commitment to reducing environmental footprints and ensuring ethical practices in material extraction and processing. Moreover, utilizing "green" materials that are sourced responsibly can significantly reduce the overall lifecycle impact of products made from single crystal alumina.

As the demand for sustainable products continues to rise, B2B buyers who actively engage in ethical sourcing will not only fulfill regulatory requirements but also appeal to a broader customer base that values sustainability. This strategic approach can lead to stronger partnerships and better market positioning.

The evolution of single crystal alumina dates back to the early 20th century when its unique properties began to be recognized for industrial applications. Initially used in optical components and high-temperature applications, advancements in crystal growth technologies have expanded its use in various high-tech industries. The introduction of sapphire substrates in semiconductor manufacturing marked a pivotal moment, leading to a surge in demand.

In recent years, the focus has shifted towards enhancing production efficiency and reducing costs, with innovations in manufacturing techniques such as the Kyropoulos method and Czochralski process gaining prominence. This historical context is essential for B2B buyers, as understanding the origins and advancements in single crystal alumina can inform sourcing strategies and supplier evaluations. By choosing suppliers who are not only innovative but also rooted in responsible practices, buyers can ensure they are part of a forward-looking industry that values sustainability and quality.

How do I ensure quality when sourcing single crystal alumina?

To ensure quality when sourcing single crystal alumina, it’s essential to establish strict quality assurance protocols. Request detailed certifications from suppliers, such as ISO 9001, and ask for material test reports (MTR) that verify the product’s specifications. Additionally, consider visiting the supplier's manufacturing facility or hiring a third-party inspection service to assess quality before shipment. Engaging in small-scale trial orders can also help evaluate product performance and supplier reliability.

What are the common applications of single crystal alumina?

Single crystal alumina is widely used in various applications, including semiconductor manufacturing, optical devices, and high-performance coatings. Its exceptional hardness, thermal stability, and electrical insulation properties make it ideal for use in cutting tools, wear-resistant parts, and components in aerospace and medical devices. Understanding the specific application requirements will help buyers choose the right type of single crystal alumina for their needs.

What factors should I consider when selecting a supplier for single crystal alumina?

When selecting a supplier for single crystal alumina, consider factors such as the supplier’s reputation, production capacity, and experience in the industry. Look for suppliers who specialize in advanced ceramics and have a proven track record of meeting international quality standards. Evaluate their customer service, lead times, and ability to customize products to meet specific requirements. Request references from other international buyers to assess their reliability and service quality.

What are the minimum order quantities (MOQ) for single crystal alumina?

Minimum order quantities (MOQ) for single crystal alumina can vary significantly based on the supplier and specific product specifications. Generally, MOQs may range from a few kilograms to several hundred kilograms. It’s advisable to communicate directly with suppliers to understand their MOQs and negotiate terms based on your project needs. If your requirements are below their MOQ, consider partnering with other companies to consolidate orders.

What payment terms should I expect when purchasing single crystal alumina internationally?

Payment terms for international purchases of single crystal alumina typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers require a deposit (often 30-50%) before production, with the balance due upon shipment. It’s crucial to clarify payment terms upfront and ensure they align with your company's financial policies. Using secure payment methods can also help mitigate risks associated with international transactions.

How can I customize single crystal alumina products for my specific needs?

To customize single crystal alumina products, communicate your specific requirements clearly to your chosen supplier. This may include dimensions, purity levels, or additional coatings. Many suppliers offer engineering support to help develop tailored solutions. Be prepared to share detailed specifications and possibly engage in a prototyping phase to validate the design before full-scale production. Understanding the supplier's capabilities in customization is key to achieving your desired outcomes.

What are the logistics considerations when importing single crystal alumina?

Logistics considerations when importing single crystal alumina include shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with handling advanced ceramics to ensure safe transportation. Be aware of import duties and taxes applicable in your country, as these can impact overall costs. Planning for potential delays and ensuring proper documentation (like shipping invoices and certificates of origin) will facilitate a smoother customs clearance process.

What should I do if there are issues with the quality of single crystal alumina upon delivery?

If you encounter quality issues with single crystal alumina upon delivery, immediately document the defects with photos and written descriptions. Contact the supplier to discuss the problem and review their return or replacement policy. Many suppliers will have procedures in place for handling quality disputes, including issuing refunds or replacements. Maintaining open communication and a professional relationship with your supplier can often lead to a swift resolution of any issues.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, strategic sourcing of single crystal alumina is pivotal for international B2B buyers seeking to enhance their operations across various industries, including electronics, automotive, and medical technology. The material's superior properties, such as high thermal resistance and electrical insulation, make it a valuable asset for cutting-edge applications. Buyers should prioritize partnerships with reliable suppliers who can ensure quality and consistency, particularly those who understand the regional demands in Africa, South America, the Middle East, and Europe.

Investing in strategic sourcing not only optimizes supply chains but also drives innovation. By collaborating with suppliers who offer advanced materials and technologies, businesses can reduce costs and improve product performance. As the demand for single crystal alumina continues to rise, proactive engagement with manufacturers will be essential for securing competitive pricing and reliable delivery timelines.

Looking ahead, the market for single crystal alumina is poised for growth, driven by advancements in technology and increased industrial applications. B2B buyers are encouraged to stay informed about market trends and emerging technologies to capitalize on opportunities. Engaging in strategic partnerships and adopting a forward-thinking approach will enable companies to navigate the evolving landscape effectively. Now is the time to act—evaluate your sourcing strategies, explore new supplier relationships, and position your business for future success in the global marketplace.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina