Navigating the complexities of the global market for white fused alumina can pose significant challenges for international B2B buyers, especially when it comes to sourcing high-quality materials that meet their specific needs. As a versatile industrial mineral, white fused alumina is essential in various applications, including abrasives, ceramics, and metallurgy. This comprehensive guide is designed to provide you with valuable insights into the different types of white fused alumina, their applications, and the critical factors to consider when selecting suppliers.

From understanding the manufacturing processes to evaluating costs and quality standards, this guide empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Italy—to make informed purchasing decisions. We will also cover best practices for supplier vetting to ensure you partner with reliable manufacturers who can deliver consistent quality and performance.

By equipping you with the necessary tools and knowledge, this guide aims to streamline your procurement process, minimize risks, and enhance your competitive edge in the global marketplace. Whether you're looking to expand your product offerings or optimize your supply chain, understanding the diverse uses of white fused alumina is crucial for your success.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Abrasive Grains | High hardness, low porosity | Grinding wheels, sandpaper | Pros: Excellent durability; Cons: Higher initial cost. |

| Refractory Materials | Thermal stability, low thermal conductivity | Kiln linings, furnace applications | Pros: Long lifespan; Cons: Requires specialized handling. |

| Ceramics | Fine particle size, high purity | Advanced ceramics, cutting tools | Pros: Superior finish quality; Cons: More expensive. |

| Coatings | Smooth finish, customizable formulations | Surface treatments, protective coatings | Pros: Enhances product life; Cons: May require multiple layers. |

| Specialty Blends | Tailored compositions for specific uses | Aerospace, automotive applications | Pros: Optimized performance; Cons: Limited availability. |

Abrasive grains are one of the most common uses of white fused alumina. These grains are characterized by their high hardness and low porosity, making them ideal for applications requiring durability and resistance to wear. They are primarily used in grinding wheels and sandpaper, providing a long-lasting solution for metalworking and surface finishing. When purchasing abrasive grains, buyers should consider the specific grit size and bonding agents that align with their production needs, as these factors can significantly impact the grinding efficiency and the surface finish of the final product.

Refractory materials derived from white fused alumina are known for their thermal stability and low thermal conductivity. These materials are crucial in high-temperature environments, such as kiln linings and furnace applications. Their ability to withstand extreme heat without degrading makes them indispensable in industries like metallurgy and ceramics. Buyers should assess the thermal properties and chemical resistance of these materials to ensure they meet the operational demands of their specific applications, as improper selection can lead to costly downtime.

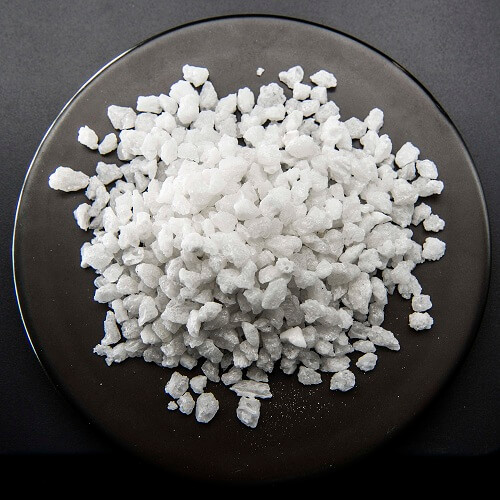

A stock image related to white fused alumina uses.

A stock image related to white fused alumina uses.

Ceramics made from white fused alumina feature fine particle sizes and high purity levels, which contribute to their exceptional performance in advanced applications. They are widely used in the production of cutting tools and other high-performance ceramic components. The key purchasing considerations for buyers include the specific material properties required for the intended application, such as hardness, wear resistance, and thermal stability. While these ceramics provide superior finish quality, they typically come at a higher price point, which buyers must weigh against the performance benefits.

Coatings that incorporate white fused alumina offer a smooth finish and can be customized to meet various performance criteria. These coatings are often applied in surface treatments and protective applications, enhancing the lifespan and durability of the underlying materials. When considering coatings, buyers should evaluate the specific environmental conditions they will face, as well as the required thickness and application method. While these coatings can significantly improve product longevity, they may also require multiple application layers, which can increase labor and material costs.

Specialty blends of white fused alumina are tailored compositions designed for specific industrial uses, particularly in sectors like aerospace and automotive. These blends optimize performance characteristics such as strength and thermal resistance, making them suitable for high-stakes applications. Buyers should focus on the specific requirements of their projects when selecting specialty blends, as these products often come with limited availability and may require minimum order quantities. While they can provide significant performance advantages, the cost and sourcing challenges should be carefully considered.

Related Video: White fused alumina, alumina oxide

| Industry/Sector | Specific Application of white fused alumina uses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives | Production of grinding wheels and abrasive tools | Enhanced durability and performance of tools | Quality of alumina, sourcing from reputable suppliers |

| Ceramics | Manufacturing of high-performance ceramics | Improved mechanical strength and thermal stability | Consistency in particle size, purity, and sourcing location |

| Refractories | Use in refractory materials for high-temperature applications | High resistance to thermal shock and corrosion | Compliance with industry standards, sourcing certifications |

| Metal Treatment | Used in metal surface treatment processes | Improved surface finish and hardness | Availability of specific grades, delivery timelines |

| Coatings and Paints | As an additive in coatings for improved durability | Increased wear resistance and longevity of coatings | Compatibility with other materials, environmental regulations |

White fused alumina (WFA) is an essential material across various industries due to its unique properties, including high purity, hardness, and thermal stability. These characteristics make it suitable for numerous applications, particularly in sectors such as abrasives, ceramics, refractories, metal treatment, and coatings.

In the abrasives sector, white fused alumina is primarily used to produce grinding wheels and other abrasive tools. Its hardness allows for efficient material removal while maintaining tool integrity. This application benefits businesses by providing tools that last longer and perform better under demanding conditions. International buyers should consider the quality and consistency of alumina sourced, ensuring that suppliers adhere to stringent manufacturing standards.

In the ceramics industry, WFA is utilized to create high-performance ceramic products. Its addition enhances mechanical strength and thermal stability, making ceramics more resilient to extreme conditions. For B2B buyers, it is crucial to ensure the alumina's particle size and purity meet specific requirements, as these factors directly influence the quality of the final ceramic product. Sourcing from reliable suppliers with a proven track record is essential.

White fused alumina is a critical component in the production of refractory materials, which are used in high-temperature applications such as furnaces and kilns. Its ability to withstand thermal shock and corrosion makes it invaluable for maintaining structural integrity in extreme environments. Buyers should verify that their suppliers comply with industry standards and possess the necessary sourcing certifications to ensure quality and reliability.

In metal treatment, white fused alumina is used in surface treatment processes to improve the finish and hardness of metal components. This application helps businesses achieve superior surface quality, which is vital for performance and longevity. Buyers should assess the availability of specific grades of WFA that meet their processing needs, as well as consider delivery timelines to avoid production delays.

As an additive in coatings and paints, white fused alumina enhances durability and wear resistance. This application is particularly beneficial for industries requiring long-lasting protective coatings. When sourcing WFA for this purpose, buyers must ensure compatibility with other materials in the formulation and stay informed about relevant environmental regulations that may impact product use.

Related Video: Production process test process of white fused aluminum oxide

The Problem:

Many B2B buyers, particularly in industries like abrasives, ceramics, and refractories, struggle with sourcing high-quality white fused alumina. This challenge often stems from inconsistent quality among suppliers, leading to performance issues in end products. For instance, in the production of grinding wheels, low-quality alumina can lead to increased wear rates and lower efficiency, ultimately affecting the bottom line and customer satisfaction.

The Solution:

To overcome this problem, buyers should establish a rigorous supplier evaluation process that includes quality certifications and product samples. Look for suppliers that provide detailed specifications and third-party testing results to ensure compliance with industry standards. Additionally, consider sourcing from manufacturers that have a proven track record in your specific application area. For instance, if you are in the refractory industry, seek out suppliers with expertise in high-temperature applications. Regular audits and open communication regarding quality expectations can also help maintain consistency in product quality.

The Problem:

Another common pain point for B2B buyers is the difficulty in understanding the technical specifications required for different applications of white fused alumina. With varying grades and particle sizes, making the right choice can be overwhelming, leading to suboptimal usage and potential project delays. Buyers may find themselves purchasing the wrong grade, resulting in inefficiencies during manufacturing processes or failure to meet product performance criteria.

The Solution:

Buyers should invest time in educating themselves on the different grades and specifications of white fused alumina. Create a checklist of key technical requirements based on your specific application, such as particle size, purity levels, and thermal stability. Collaborating with suppliers who offer technical support can also be beneficial. They can provide insights on the best grade for your needs and even assist with product trials to evaluate performance in real-world conditions. Furthermore, attending industry seminars or workshops can enhance understanding and facilitate better purchasing decisions.

The Problem:

Environmental and safety regulations are increasingly affecting how businesses operate, and the use of materials like white fused alumina is no exception. Buyers may face challenges regarding the safe handling and disposal of alumina products, particularly in regions with stringent environmental laws, such as Europe. Non-compliance with these regulations can lead to legal repercussions and damage to a company’s reputation.

The Solution:

To mitigate these risks, buyers should proactively engage with suppliers who prioritize environmental sustainability and safety compliance. Ensure that the supplier provides Material Safety Data Sheets (MSDS) and complies with local regulations regarding handling and disposal. Additionally, consider implementing training programs for employees on safe handling practices to minimize risks associated with exposure. Buyers can also explore alternative products or modifications to their processes that reduce environmental impact, such as recycling used alumina or utilizing more sustainable raw materials. By adopting a comprehensive approach to safety and compliance, businesses can protect themselves and contribute positively to their communities.

White fused alumina (WFA) is a high-purity, high-alumina material produced by melting alumina in an electric arc furnace. Its unique properties make it suitable for various applications, particularly in abrasive and refractory industries. Key properties include:

The impact of WFA on applications varies significantly based on its properties. For instance, in abrasive applications, its hardness ensures effective material removal, while in refractory applications, its temperature resistance is crucial for maintaining structural integrity under extreme conditions. Additionally, WFA's low thermal conductivity makes it suitable for insulation applications, where heat retention is essential.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several factors:

| Material | Typical Use Case for white fused alumina uses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| White Fused Alumina | Abrasives in grinding wheels | High hardness and durability | Manufacturing complexity | Medium |

| White Fused Alumina | Refractory linings in furnaces | Excellent temperature resistance | Limited availability in some regions | High |

| White Fused Alumina | Sandblasting and surface preparation | Versatile application | Initial cost may be higher | Medium |

| White Fused Alumina | Insulation materials for high-temperature applications | Low thermal conductivity | Potential sourcing challenges | Medium |

This structured approach to understanding the strategic material selection of white fused alumina provides international B2B buyers with the insights needed to make informed purchasing decisions. By considering the properties, advantages, and regional factors, buyers can optimize their sourcing strategies for enhanced operational efficiency.

The production of white fused alumina (WFA) involves several critical stages that ensure the final product meets the rigorous demands of various applications, such as abrasives, ceramics, and refractory materials. Understanding these processes can help international B2B buyers make informed decisions when sourcing WFA.

The first step in manufacturing white fused alumina is raw material preparation, which typically includes the following:

After the initial fusing process, the next stages involve forming, cooling, and finishing the white fused alumina:

Quality assurance is a vital aspect of white fused alumina production. Implementing strict quality control measures ensures that the final product meets international standards and customer specifications.

For white fused alumina, several international standards are pertinent:

Quality control checkpoints are integrated throughout the manufacturing process:

B2B buyers should be familiar with common testing methods that manufacturers use to ensure quality:

When sourcing white fused alumina, international buyers should consider several strategies to verify the quality control processes of suppliers:

International B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe must navigate various nuances when dealing with quality control:

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures associated with white fused alumina is essential for international B2B buyers. By focusing on key manufacturing stages, relevant international standards, and effective quality control practices, buyers can make informed decisions that align with their specific needs and regulatory requirements.

In today's competitive market, sourcing high-quality white fused alumina is crucial for businesses in various industries, including abrasives, ceramics, and metallurgy. This guide provides a practical checklist for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe to ensure a successful procurement process.

Understanding your specific needs is the first step in sourcing white fused alumina. Clearly define the grade, particle size, and purity levels required for your applications. This clarity will help you communicate effectively with suppliers and ensure that you receive the right product for your manufacturing process.

Conduct thorough research to identify reputable suppliers of white fused alumina. Look for companies with a proven track record in the industry and a solid reputation among their clients.

Before making any commitments, verify the certifications and compliance of potential suppliers. Ensure that they meet international quality standards, such as ISO 9001 or ASTM specifications.

Always request samples before placing a bulk order. This allows you to assess the quality of the white fused alumina directly.

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. While cost is an important factor, it should not be the only consideration.

Engage in negotiations to establish favorable terms for both parties. Clearly outline delivery timelines, payment conditions, and quality expectations in the contract.

Once the supplier is selected, establish a clear communication plan to ensure smooth collaboration. Regular updates and feedback loops can prevent misunderstandings and ensure that both parties are aligned on expectations.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for white fused alumina, ensuring they partner with the right suppliers to meet their specific needs.

When sourcing white fused alumina, understanding the cost structure is essential for international B2B buyers. The main components include:

Materials: The primary cost driver in the production of white fused alumina is the raw materials used, such as bauxite and other alumina sources. Prices can fluctuate based on market demand and supply chain conditions.

Labor: Labor costs vary significantly by region. Buyers in Africa and South America may find lower labor costs compared to Europe or the Middle East. Understanding local labor markets can aid in forecasting total costs.

Manufacturing Overhead: This encompasses utilities, equipment depreciation, and facility maintenance. Manufacturers may face different overhead rates based on their operational efficiency and location.

Tooling: The initial investment in tooling can be significant, especially for customized specifications. Buyers should inquire about the amortization of these costs over large order volumes.

Quality Control (QC): Ensuring product quality is paramount, especially for industries like aerospace and automotive. Quality assurance processes can add to the overall cost but are crucial for maintaining standards.

Logistics: Shipping costs can vary greatly depending on the origin and destination. Incoterms (International Commercial Terms) can influence pricing, as they define the responsibilities of buyers and sellers in shipping arrangements.

Margin: Suppliers will typically add a margin to cover their costs and profit. This can vary widely based on market competition and the supplier's positioning.

Several factors influence pricing in the white fused alumina market:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced prices per unit due to economies of scale. Buyers should consider negotiating MOQ to maximize cost efficiency.

Specifications and Customization: Custom specifications can increase costs due to additional processing or material requirements. Clear communication about needs can help avoid unexpected expenses.

Material Quality and Certifications: Higher quality materials and specific certifications (e.g., ISO, ASTM) can raise costs. Buyers should evaluate whether the added expense aligns with their application requirements.

Supplier Factors: The reliability, reputation, and financial stability of suppliers can also impact pricing. Engaging with established suppliers may lead to better pricing and service reliability.

Incoterms: Understanding and negotiating Incoterms is crucial for cost management. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost of goods.

For international B2B buyers, particularly from diverse regions, employing strategic sourcing practices can yield significant savings:

Negotiate Effectively: Leverage relationships and volume commitments to negotiate better pricing. Understanding market conditions can provide leverage in discussions.

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider costs associated with shipping, handling, and potential quality issues. A lower upfront cost may not always result in the best value.

Understand Pricing Nuances: Different regions may have varying pricing dynamics due to local market conditions. Buyers from the Middle East may encounter different pricing structures compared to those in Europe or South America.

Maintain Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and access to new products or innovations.

In conclusion, a comprehensive understanding of the cost components and price influencers in sourcing white fused alumina is essential for international B2B buyers. By applying strategic sourcing practices and negotiating effectively, buyers can optimize their procurement processes, ensuring both cost efficiency and quality in their supply chains. Note that prices can vary widely based on market conditions, and it is advisable to conduct thorough market research and supplier assessments before finalizing contracts.

When considering materials for abrasive applications, it's crucial to evaluate alternatives to white fused alumina (WFA). This analysis will help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed decisions based on performance, cost, and application suitability.

| Comparison Aspect | White Fused Alumina Uses | Alternative 1: Brown Fused Alumina | Alternative 2: Silicon Carbide |

|---|---|---|---|

| Performance | High hardness and durability, suitable for precision grinding | Slightly lower hardness; effective for general-purpose applications | Extremely hard and sharp, ideal for high-speed applications |

| Cost | Moderate to high | Generally lower than WFA | Higher than WFA but varies with grade |

| Ease of Implementation | Widely available, familiar to users | Readily available, similar handling | Requires specific equipment for optimal use |

| Maintenance | Low maintenance required | Low maintenance required | Moderate maintenance due to equipment wear |

| Best Use Case | Precision grinding, ceramics, and refractories | General abrasive applications, such as sandblasting | High-performance applications, including automotive and aerospace |

Brown fused alumina (BFA) is a viable alternative to white fused alumina, particularly for general-purpose abrasive applications. It offers a good balance between performance and cost, making it suitable for sandblasting and surface preparation. While BFA is slightly less hard than WFA, it can still achieve satisfactory results in many applications. However, it may not provide the same level of precision and durability for specialized tasks, potentially leading to more frequent replacements in demanding environments.

Silicon carbide (SiC) is known for its exceptional hardness and sharpness, making it ideal for high-speed applications, including cutting and grinding of hard materials. It excels in environments requiring high performance, such as in the automotive and aerospace industries. However, SiC typically comes at a higher cost than WFA and may necessitate specialized equipment to maximize its effectiveness. Its maintenance requirements can also be moderate due to the wear on tools and machinery, which could impact overall operational costs.

Choosing the right abrasive material depends on various factors, including the specific application, budget constraints, and performance requirements. For precision grinding and high durability, white fused alumina remains a top choice, while brown fused alumina offers a cost-effective solution for less demanding tasks. Silicon carbide shines in high-performance scenarios but may require a greater investment in both material and equipment.

As an international B2B buyer, understanding these alternatives will empower you to make decisions that align with your operational goals and financial considerations. Always assess your specific needs against the strengths and weaknesses of each material to ensure optimal results in your applications.

White fused alumina (WFA) is a high-purity, high-alumina material widely used in various industrial applications, such as abrasives, refractory products, and ceramics. Understanding its technical properties is crucial for B2B buyers in making informed purchasing decisions.

Material Grade

- White fused alumina is typically classified into various grades based on purity and grain size. High-purity grades (e.g., 99.5% Al₂O₃) are preferred for applications requiring superior performance. Buyers should specify the grade that aligns with their intended use to ensure optimal results.

Grain Size Distribution

- The grain size of WFA can significantly affect its performance in applications such as sandblasting or grinding. Common sizes range from 0.1 mm to 1.0 mm, with finer grains being ideal for polishing applications. Buyers should assess their specific requirements to choose the appropriate grain size, which can enhance product efficiency and finish quality.

Bulk Density

- Bulk density measures the mass of WFA per unit volume and influences its handling and transportation costs. Higher bulk density often correlates with better performance in abrasive applications. Buyers should consider this property when evaluating the cost-effectiveness of their materials.

Mohs Hardness

- WFA has a Mohs hardness of 9, making it one of the hardest materials available. This property is essential for abrasive applications, where durability and resistance to wear are critical. Buyers should prioritize hardness in their selection process, especially for demanding applications.

Thermal Stability

- WFA exhibits excellent thermal stability, maintaining its properties at high temperatures, which is crucial for refractory applications. Understanding the thermal limits of WFA is vital for buyers in industries like steel and glass manufacturing, where high-performance materials are needed.

Chemical Composition

- The chemical composition of WFA can vary, affecting its performance in different applications. Buyers should request detailed composition analyses to ensure compatibility with their production processes and end products.

Navigating the terminology associated with white fused alumina can be challenging for international B2B buyers. Familiarity with these terms can facilitate smoother transactions and better communication with suppliers.

OEM (Original Equipment Manufacturer)

- OEM refers to companies that produce products or components that are used in another company's end product. In the context of WFA, OEM buyers often seek specific formulations or grades tailored to their manufacturing processes.

MOQ (Minimum Order Quantity)

- MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ for WFA is crucial for buyers to ensure they can meet their production needs without overcommitting financially.

RFQ (Request for Quotation)

- An RFQ is a document that buyers send to suppliers to request pricing and terms for specific quantities of WFA. Crafting a detailed RFQ can help buyers receive accurate and competitive offers tailored to their specifications.

Incoterms (International Commercial Terms)

- Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms helps buyers understand the logistics involved in procuring WFA, including who bears the costs and risks at various points in the shipping process.

Lead Time

- Lead time refers to the time taken from placing an order until it is delivered. Understanding lead times for WFA can assist buyers in planning their inventory and production schedules effectively.

Certification Standards

- Many buyers require WFA to meet specific certification standards (e.g., ISO, ASTM) to ensure quality and consistency. Familiarity with these standards can help buyers ensure compliance and avoid potential quality issues.

Understanding these technical properties and trade terms will empower B2B buyers from regions such as Africa, South America, the Middle East, and Europe to make informed decisions regarding their procurement of white fused alumina.

The white fused alumina market is experiencing significant growth driven by various global factors. The increasing demand for high-performance abrasives across industries such as automotive, aerospace, and electronics is a primary driver. As manufacturing processes become more sophisticated, there is a growing need for materials that offer superior hardness and thermal stability. Additionally, the rise of emerging economies in Africa and South America is fostering new opportunities, as industries in these regions seek to enhance their production capabilities.

Emerging technologies, particularly in the digital realm, are reshaping sourcing strategies. B2B buyers are increasingly leveraging platforms that facilitate direct sourcing from manufacturers, which enhances transparency and reduces costs. Automation and AI-driven analytics tools are also becoming essential for buyers to evaluate supplier performance and optimize procurement processes. This trend is particularly evident in Europe and the Middle East, where companies are adopting smart technologies to streamline operations and improve efficiency.

Furthermore, sustainability has become a pivotal consideration in sourcing decisions. Buyers are now prioritizing suppliers who demonstrate environmentally responsible practices, such as reduced energy consumption during production and waste management strategies. This shift is not just a regulatory response; it is also driven by consumer demand for more sustainable products, influencing companies to adopt greener practices.

In the context of white fused alumina, sustainability is not merely a buzzword; it is a critical business strategy. The environmental impact of alumina production, including energy consumption and carbon emissions, is prompting buyers to seek suppliers who utilize renewable energy sources and implement energy-efficient processes.

Ethical sourcing practices are increasingly vital for B2B buyers. Establishing a supply chain that prioritizes ethical labor practices and transparent operations fosters trust and brand loyalty. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as benchmarks for identifying suppliers committed to sustainable practices. By choosing certified suppliers, companies can ensure that their sourcing aligns with global sustainability goals, appealing to environmentally-conscious consumers and stakeholders.

Moreover, there is a growing trend towards the use of recycled materials in the production of white fused alumina. Buyers should explore partnerships with suppliers who incorporate recycled alumina into their products, thereby reducing the environmental footprint while maintaining quality standards.

The history of white fused alumina dates back to the early 20th century when it was first developed as a high-purity abrasive material. Initially, its primary applications were limited to metalworking and glass industries. Over the decades, advancements in refining techniques and processing technologies have expanded its use across various sectors, including ceramics, refractories, and electronics.

In recent years, the market has evolved to meet the increasing demands for higher performance and specialized applications. The introduction of new manufacturing methods has allowed for the production of finer grades of alumina, catering to specific industry needs. As global markets continue to expand, the versatility and effectiveness of white fused alumina make it an indispensable material for a wide range of applications, solidifying its position in the B2B landscape.

By understanding these market dynamics, sourcing trends, and the historical context, international B2B buyers can make informed decisions that enhance their procurement strategies and align with global sustainability efforts.

What are the primary applications of white fused alumina in various industries?

White fused alumina is primarily used in abrasives, refractories, and coatings. In the abrasives industry, it is utilized for grinding, polishing, and blasting applications due to its high hardness and durability. In refractories, it serves as a critical material in high-temperature furnaces. Additionally, it is employed in the manufacturing of ceramic products and as a filler in coatings, enhancing the overall performance of the finished products. Understanding these applications can help you determine its suitability for your specific needs.

What is the minimum order quantity (MOQ) for white fused alumina?

The minimum order quantity for white fused alumina can vary significantly between suppliers and depends on factors such as product type and market demand. Generally, MOQs can range from 1 ton to several tons. It's essential to discuss your specific requirements with potential suppliers to negotiate terms that suit your purchasing capacity. Some suppliers may offer flexibility for smaller orders, especially for new customers or trial runs.

What payment terms are typically offered for international purchases of white fused alumina?

Payment terms for international purchases of white fused alumina usually include options such as advance payment, letters of credit, or payment upon delivery. Common practices involve a 30% deposit upon order confirmation with the balance due before shipment. It’s advisable to clarify these terms upfront to avoid misunderstandings. Additionally, consider using escrow services for large transactions to ensure secure payments.

How can I ensure the quality of white fused alumina products?

To ensure the quality of white fused alumina, request documentation that confirms the material’s specifications, such as purity, particle size distribution, and hardness. Many reputable suppliers conduct regular quality assurance tests and can provide certificates of analysis (COA). It’s also beneficial to establish a quality control protocol that includes receiving inspections and testing samples from each shipment to verify compliance with your standards.

What are the logistics considerations for importing white fused alumina?

When importing white fused alumina, logistics considerations include shipping methods, delivery timelines, and customs clearance processes. Ensure your supplier has experience with international shipping and can provide details on freight costs and insurance options. It’s crucial to understand local import regulations and potential tariffs that may apply. Working with a reliable freight forwarder can streamline the logistics process and help navigate any challenges.

Can white fused alumina be customized for specific applications?

Yes, white fused alumina can often be customized to meet specific application requirements. Suppliers may offer variations in particle size, purity levels, and packaging options. When discussing your needs with a supplier, provide detailed specifications regarding the intended application to receive tailored recommendations. Custom formulations can enhance the performance of the material in your specific processes.

What should I know about the sustainability of sourcing white fused alumina?

Sustainability in sourcing white fused alumina involves understanding the environmental practices of your suppliers. Look for manufacturers who utilize eco-friendly production methods and have initiatives in place to minimize waste and energy consumption. Additionally, inquire about the sourcing of raw materials and whether they are obtained from sustainable sources. Supporting suppliers with strong sustainability credentials can align your business with global environmental standards and enhance your corporate social responsibility profile.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of white fused alumina presents significant opportunities for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This versatile material is essential in various industries, including abrasives, ceramics, and electronics, offering superior quality and performance. By prioritizing suppliers that adhere to stringent quality standards and sustainable practices, buyers can ensure that they receive consistent, high-grade products that meet their specific requirements.

Engaging in strategic sourcing not only enhances product quality but also optimizes cost efficiency and strengthens supplier relationships. By establishing long-term partnerships with reliable manufacturers, companies can mitigate risks associated with supply chain disruptions and price volatility. It is crucial for buyers to conduct thorough market research and leverage data analytics to identify the best sourcing strategies tailored to their regional needs.

As the demand for white fused alumina continues to grow, international buyers should be proactive in exploring new sourcing avenues and partnerships. Embrace innovation and sustainability in procurement practices to stay ahead of industry trends. By taking these steps, businesses can position themselves for success in an increasingly competitive market. Now is the time to act—evaluate your sourcing strategies today to capitalize on the benefits of white fused alumina and secure your competitive edge.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina