In today's competitive landscape, sourcing high-quality piedra de carburo de silicio (silicon carbide stone) presents a significant challenge for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. As industries increasingly rely on this versatile material for applications ranging from abrasives to semiconductor manufacturing, understanding how to effectively navigate the global market becomes essential. This guide aims to provide comprehensive insights into the various types of silicon carbide products available, their applications, and the intricacies of supplier vetting.

B2B buyers will find valuable information on assessing suppliers, understanding cost structures, and identifying potential risks in the procurement process. With a focus on actionable strategies, this guide empowers businesses to make informed purchasing decisions that align with their operational needs and budget constraints. By breaking down the complexities of the silicon carbide market, we enable buyers to streamline their sourcing processes, ensuring they secure reliable and high-quality materials.

Whether you are exploring options for industrial applications or looking to enhance your product offerings, this guide serves as a crucial resource for navigating the global market landscape. With the right knowledge and tools at your disposal, you can confidently source piedra de carburo de silicio to meet your business objectives and drive growth in your respective markets.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Green Silicon Carbide (SiC) | High purity, excellent hardness, and thermal conductivity | Abrasives, semiconductor devices | Pros: High performance, cost-effective. Cons: Limited availability in some regions. |

| Black Silicon Carbide (SiC) | Lower purity, slightly less hardness than green SiC | Grinding wheels, refractory materials | Pros: Cost-effective, good for general use. Cons: Lower performance in high-end applications. |

| Alpha Silicon Carbide | Single crystal structure, high thermal stability | High-performance electronics | Pros: Superior thermal conductivity. Cons: Higher cost, specialized sourcing needed. |

| Beta Silicon Carbide | Polycrystalline form, lower thermal conductivity | Metal cutting tools, abrasives | Pros: Versatile, easier to manufacture. Cons: Less efficient in high-temperature applications. |

| Silicon Carbide Nanoparticles | Nanoscale particles, high surface area | Advanced coatings, electronics | Pros: Innovative applications, high reactivity. Cons: Requires specialized handling and processing. |

Green Silicon Carbide (SiC) is renowned for its high purity and exceptional hardness, making it ideal for a variety of B2B applications, particularly in abrasives and semiconductor devices. Its thermal conductivity also enhances its utility in high-temperature environments. Buyers should consider the availability of this type, as it may vary by region, impacting procurement strategies. The performance benefits often outweigh the potential cost implications, making it a sought-after choice for industries requiring precision materials.

Black Silicon Carbide is characterized by its lower purity compared to its green counterpart, yet it remains a popular choice for grinding wheels and refractory materials. Its slightly reduced hardness makes it less suitable for high-end applications but still effective for general industrial uses. B2B buyers can benefit from its cost-effectiveness, although they must be aware of its limitations in demanding environments. This type is readily available, which can streamline procurement processes for manufacturers.

Alpha Silicon Carbide features a single crystal structure that provides superior thermal stability and conductivity, making it an excellent choice for high-performance electronics. Although it comes at a higher cost, its unique properties justify the investment for businesses requiring advanced materials. B2B buyers should evaluate their specific needs to determine if the benefits of Alpha SiC align with their operational goals, particularly in sectors where performance is critical.

Beta Silicon Carbide is a polycrystalline form that offers versatility in manufacturing, particularly for metal cutting tools and abrasives. While it has lower thermal conductivity compared to Alpha SiC, its ease of production makes it an attractive option for various industries. Buyers should weigh the advantages of its versatility against its performance limitations in high-temperature applications. This type is often more accessible, making it a practical choice for businesses seeking reliable materials without excessive lead times.

Silicon Carbide Nanoparticles are notable for their high surface area and reactivity, which open doors for advanced coatings and electronic applications. While they represent a cutting-edge option, buyers need to consider the specialized handling and processing requirements associated with nanoparticles. The innovative potential of this material may justify the additional complexities in procurement and application, particularly for businesses focused on developing next-generation products.

Related Video: 3.2.3 (4) - 1 - Celda unidad de Carburo de Silicio, SiC

| Industry/Sector | Specific Application of piedra de carburo de silicio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Abrasives for cutting and grinding | Increases efficiency and precision in machining | Assess purity levels and grit size; consider local suppliers for cost savings. |

| Semiconductor | Wafer fabrication and polishing | Enhances performance and longevity of electronic devices | Ensure compatibility with existing processes; prioritize suppliers with advanced technology. |

| Metallurgy | Lining for furnaces and kilns | Improves thermal conductivity and wear resistance | Evaluate thermal properties and durability; seek suppliers with proven track records. |

| Automotive | Brake pads and clutches | Enhances braking performance and safety | Look for high-quality formulations; consider testing certifications for reliability. |

| Aerospace | Components in jet engines and turbines | Increases operational efficiency and reduces weight | Source from certified suppliers meeting aerospace standards; check for compliance with international regulations. |

In the manufacturing sector, 'piedra de carburo de silicio' is primarily utilized as an abrasive material for cutting, grinding, and polishing various materials. Its hardness enables it to efficiently remove material from metals, ceramics, and composites, leading to enhanced machining precision and reduced cycle times. For B2B buyers, sourcing high-purity silicon carbide is crucial to ensure optimal performance and longevity in manufacturing processes, particularly when operating in competitive markets in Africa, South America, the Middle East, and Europe.

In the semiconductor industry, 'piedra de carburo de silicio' is essential for wafer fabrication and polishing. Its unique properties facilitate the creation of ultra-smooth surfaces required for high-performance semiconductor devices. Buyers must focus on suppliers that offer advanced polishing techniques and materials that meet strict quality standards, as this directly impacts the functionality and reliability of electronic products. This is especially vital for international buyers in regions like Saudi Arabia and Europe, where technology standards are high.

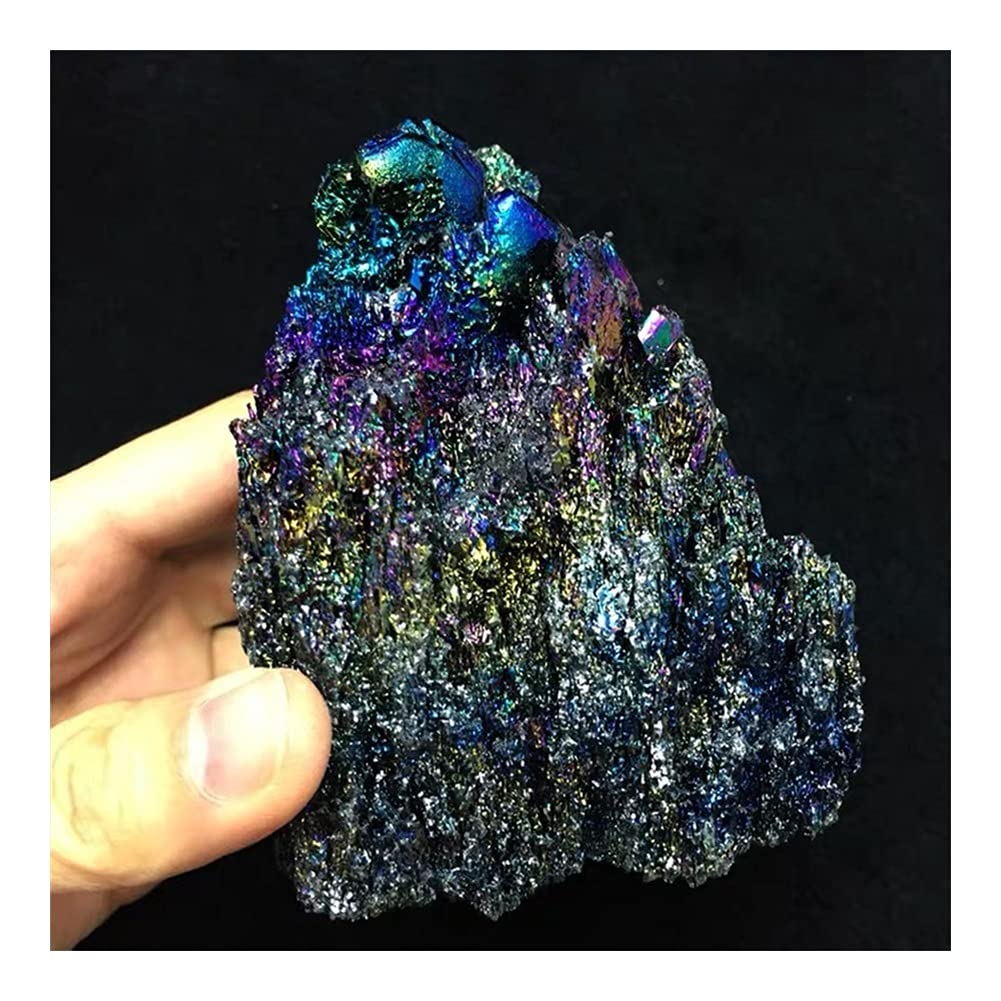

A stock image related to piedra de carburo de silicio.

In metallurgy, 'piedra de carburo de silicio' serves as a lining material for furnaces and kilns. Its ability to withstand high temperatures and corrosive environments makes it invaluable for enhancing thermal conductivity and wear resistance. Buyers in this sector should prioritize sourcing from suppliers who can demonstrate proven thermal performance and durability, as these factors are critical for maintaining operational efficiency and minimizing downtime, particularly in regions with demanding industrial operations.

Within the automotive industry, 'piedra de carburo de silicio' is commonly used in the production of brake pads and clutches. Its high friction coefficient contributes to improved braking performance and safety, which are paramount in vehicle design. B2B buyers should look for high-quality formulations that meet industry testing certifications to ensure reliability and performance. This is particularly important for buyers in emerging markets in Africa and South America, where safety standards are increasingly scrutinized.

A stock image related to piedra de carburo de silicio.

In the aerospace sector, 'piedra de carburo de silicio' is utilized in various components of jet engines and turbines. Its lightweight and heat-resistant properties significantly enhance operational efficiency, making it a preferred choice for critical applications. Buyers in this industry must source materials from certified suppliers that comply with stringent aerospace standards to ensure safety and performance. This is especially relevant for international buyers in Europe and the Middle East, where compliance with regulations is mandatory.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem:

B2B buyers often face significant challenges when it comes to the quality consistency of 'piedra de carburo de silicio' (silicon carbide stone). With suppliers scattered across various regions, including Africa and the Middle East, the risk of receiving subpar materials that do not meet specifications is high. This variability can lead to production delays, increased costs, and even reputational damage if the end products fail to perform as expected.

The Solution:

To mitigate this risk, buyers should implement a robust supplier evaluation process. Start by requesting samples from potential suppliers and conducting thorough quality tests to verify compliance with industry standards. Establish clear communication regarding specifications and performance expectations upfront. Additionally, consider partnering with suppliers who have certifications from recognized quality assurance bodies. Utilizing technology platforms that offer supplier ratings and reviews can also aid in making informed decisions. Lastly, cultivating long-term relationships with a select few high-quality suppliers can enhance reliability and consistency in your supply chain.

The Problem:

Many B2B buyers struggle with understanding the technical specifications of 'piedra de carburo de silicio', which is crucial for its application in various industries, such as electronics and automotive. Insufficient knowledge can lead to incorrect purchasing decisions, resulting in materials that do not meet the specific needs of their projects or processes.

The Solution:

Buyers should invest time in educating themselves about the properties of silicon carbide, such as its hardness, thermal conductivity, and chemical resistance. Engaging with technical experts or consultants can provide valuable insights tailored to specific applications. Creating a checklist of required properties based on intended use can also streamline the selection process. Additionally, attending industry conferences and workshops focused on material science can enhance understanding and foster connections with knowledgeable suppliers who can provide the right product specifications.

The Problem:

Importing 'piedra de carburo de silicio' can pose logistical challenges, particularly for buyers in Africa and South America, where infrastructure may not be as developed. Delays in shipping, customs clearance issues, and fluctuating transportation costs can lead to unexpected project setbacks and budget overruns.

The Solution:

To overcome these logistical hurdles, it is essential to develop a comprehensive logistics strategy. Start by identifying reliable freight forwarders who specialize in handling industrial materials and have experience with your specific regions. Establishing a clear timeline for shipping and proactively managing customs documentation can prevent delays. Additionally, consider using local suppliers where possible to reduce transportation costs and minimize risk. Engaging in strategic partnerships with logistics companies that offer tracking technology can also provide real-time updates on shipment status, allowing for better planning and resource allocation.

When selecting materials for piedra de carburo de silicio (silicon carbide stones), international B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. Below, we analyze four common materials used in conjunction with silicon carbide, focusing on their properties, advantages, disadvantages, and implications for buyers, particularly from Africa, South America, the Middle East, and Europe.

Silicon carbide itself is the primary material for piedra de carburo de silicio. It exhibits exceptional hardness and thermal conductivity, making it ideal for high-performance applications. Its temperature rating can exceed 1,600°C, and it is resistant to oxidation and corrosion.

Alumina is often used in conjunction with silicon carbide due to its good mechanical properties and thermal stability. It can withstand temperatures up to 1,200°C and is resistant to many corrosive environments.

Boron carbide is another material that can be combined with silicon carbide to enhance hardness and wear resistance. It is known for its ability to withstand high temperatures and is often used in abrasive applications.

Zirconia is used in some specialized applications due to its excellent toughness and thermal stability. It can withstand high temperatures and is resistant to chemical attack.

| Material | Typical Use Case for piedra de carburo de silicio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | High-performance abrasive applications | Exceptional hardness and thermal conductivity | High manufacturing complexity and cost | High |

| Alumina (Al₂O₃) | Moderate temperature applications | Cost-effective with good wear resistance | Lower thermal conductivity | Medium |

| Boron Carbide (B₄C) | Abrasive tools and components | Extremely hard and lightweight | Brittle, prone to cracking | High |

| Zirconia (ZrO₂) | High toughness applications | Excellent thermal stability and toughness | Higher cost and complex manufacturing | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers of piedra de carburo de silicio, ensuring informed decision-making based on material properties, application suitability, and compliance considerations.

The production of piedra de carburo de silicio (silicon carbide) involves several critical stages that ensure the final product meets the required specifications for various industrial applications. Understanding these manufacturing processes is essential for B2B buyers looking to source high-quality materials.

The first step in the manufacturing process is the preparation of raw materials. Silicon carbide is typically produced from silica (SiO₂) and carbon (C). These raw materials are sourced from reputable suppliers to ensure quality.

The forming stage is where the prepared material is shaped into its final form. This is crucial for achieving the desired physical characteristics of the piedra de carburo de silicio.

After forming, finishing processes are applied to ensure that the silicon carbide meets the necessary specifications.

Quality assurance (QA) is a fundamental aspect of manufacturing piedra de carburo de silicio. It ensures that the products meet international standards and customer expectations.

B2B buyers need to ensure that their suppliers adhere to relevant international standards. Some key certifications include:

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that the product meets the required specifications:

To ensure that suppliers maintain high-quality standards, B2B buyers should take proactive steps to verify their quality control processes.

Engaging third-party inspection services can provide an unbiased assessment of a supplier's quality control processes. These organizations can perform inspections at various stages of production and provide detailed reports that highlight any issues.

International buyers must be aware of specific nuances that can affect quality assurance in different regions:

Understanding the manufacturing processes and quality assurance measures for piedra de carburo de silicio is essential for B2B buyers. By focusing on raw material preparation, forming techniques, finishing processes, and stringent quality control measures, buyers can ensure they are sourcing high-quality products that meet their needs. Engaging in thorough supplier audits and leveraging third-party inspections further enhances the reliability of the procurement process, especially in the diverse markets of Africa, South America, the Middle East, and Europe.

Sourcing 'piedra de carburo de silicio' (silicon carbide stone) can be a complex process, especially for international B2B buyers from diverse regions like Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to streamline your procurement process, ensuring you find reliable suppliers and high-quality materials.

Clearly outlining your technical requirements is the first step in sourcing silicon carbide stone. This includes understanding the desired grain size, purity levels, and specific applications (e.g., abrasives or refractory materials).

Conduct thorough research to identify potential suppliers who specialize in silicon carbide stone. Utilize industry directories, trade shows, and online platforms to compile a list of candidates.

Before proceeding, verify that your potential suppliers hold relevant certifications, such as ISO 9001 for quality management systems.

Once you have shortlisted suppliers, request samples of their silicon carbide stone for quality testing.

Engage in discussions with your selected suppliers to negotiate pricing, payment terms, and delivery schedules.

Set up a consistent communication channel with your chosen supplier to facilitate ongoing collaboration.

Once all terms have been agreed upon, finalize the contract and place your order for silicon carbide stone.

By following these steps, international B2B buyers can ensure a more efficient and effective sourcing process for silicon carbide stone, tailored to their specific needs and regional considerations.

When sourcing piedra de carburo de silicio (silicon carbide stone), understanding the cost structure is crucial for B2B buyers. The primary cost components typically include:

Several factors influence the pricing of piedra de carburo de silicio, making it essential for international buyers to conduct thorough market research:

B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can leverage several strategies to secure favorable pricing on piedra de carburo de silicio:

When sourcing piedra de carburo de silicio, buyers should be aware that prices can vary widely based on the factors discussed above. It’s essential to conduct comprehensive research and consider the total cost of ownership. Prices mentioned in discussions or advertisements should be treated as indicative, as they can fluctuate based on market conditions and specific buyer needs. Always request formal quotes and verify all costs before making purchasing decisions.

When considering industrial materials, particularly for abrasive applications, it is essential to evaluate various alternatives to ensure optimal performance and cost-effectiveness. This section compares piedra de carburo de silicio (silicon carbide) with other viable alternatives, helping B2B buyers make informed decisions.

| Comparison Aspect | Piedra De Carburo De Silicio | Alternative 1: Aluminium Oxide | Alternative 2: Cubic Boron Nitride |

|---|---|---|---|

| Performance | High hardness, excellent thermal conductivity, and wear resistance | Good hardness, less effective at high temperatures | Extremely hard, excellent for hard materials |

| Cost | Moderate to high | Generally lower | High due to manufacturing complexity |

| Ease of Implementation | Requires specialized machinery for processing | Widely available and easy to process | Requires specialized tools for application |

| Maintenance | Low maintenance, stable under high temperatures | Moderate, may require replacement | Low, but can be costly to replace |

| Best Use Case | Precision grinding, high-performance applications | General-purpose grinding and polishing | Machining of hard metals and ceramics |

Aluminium oxide is a common abrasive used in a variety of applications due to its lower cost and availability. It is effective for general-purpose grinding and polishing tasks. However, while it provides decent performance, it does not match the hardness or thermal resistance of piedra de carburo de silicio. This makes it less suitable for high-stress applications or environments with elevated temperatures. Its ease of processing and lower initial investment can be appealing for businesses looking to balance performance with budget constraints.

Cubic boron nitride (CBN) is known for its exceptional hardness, second only to diamond. It excels in machining hard materials, making it ideal for applications like grinding hardened steels. However, its high cost and the need for specialized equipment can be significant drawbacks for many businesses. CBN is less versatile than piedra de carburo de silicio, which can be used in a wider range of applications. While CBN offers superior performance for specific tasks, the investment may not be justified for all users.

When evaluating which abrasive material to use, B2B buyers should consider their specific application requirements, budget, and the operational environment. Piedra de carburo de silicio stands out for high-performance applications requiring durability and thermal resistance. In contrast, aluminium oxide may be a better fit for businesses focused on cost-effectiveness and less demanding tasks. Cubic boron nitride, while offering unmatched hardness, should be reserved for high-value machining operations where performance justifies the expense.

Ultimately, the right choice depends on a careful analysis of operational needs, material characteristics, and cost implications. By weighing these factors, international B2B buyers from regions like Africa, South America, the Middle East, and Europe can make informed decisions that align with their business objectives.

Understanding the technical specifications of piedra de carburo de silicio (silicon carbide stone) is crucial for international B2B buyers, particularly in industries such as manufacturing, construction, and electronics. Here are some essential properties to consider:

The material grade of silicon carbide indicates its purity and crystalline structure. Higher-grade materials, such as 98% or above, are used in high-performance applications, including semiconductor manufacturing. Buyers must assess the grade to ensure it meets the specific requirements of their applications.

Silicon carbide is renowned for its exceptional hardness, typically rated between 9 and 9.5 on the Mohs scale. This property makes it an ideal choice for abrasive materials and cutting tools. For B2B buyers, understanding hardness levels can influence their selection based on the intended use, such as machining or grinding.

With a thermal conductivity of about 120-200 W/mK, silicon carbide efficiently dissipates heat, which is vital in high-temperature applications. This property is particularly significant for buyers in the electronics sector, where managing heat is critical for device longevity and performance.

Silicon carbide exhibits excellent resistance to chemical corrosion, making it suitable for harsh environments, such as chemical processing plants. Buyers should consider this property when sourcing materials for applications exposed to corrosive substances.

Tolerance levels define the allowable deviation in dimensions during manufacturing. For silicon carbide products, tight tolerances are essential for precision applications, such as in aerospace and automotive sectors. Buyers should verify tolerance specifications to ensure compatibility with their production processes.

Navigating the world of silicon carbide trade requires familiarity with specific jargon. Here are some common terms that B2B buyers should know:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For silicon carbide, understanding OEM relationships can aid buyers in sourcing components that are compatible with their machinery or systems.

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers who must manage inventory and production schedules effectively. Knowing the MOQ can help in budgeting and planning purchases.

An RFQ is a document sent to suppliers requesting pricing and other relevant details for a specific quantity of goods. For buyers of silicon carbide, issuing an RFQ ensures that they receive competitive quotes, allowing for better negotiation and cost management.

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers determine shipping costs, insurance, and liability, ensuring a smooth procurement process.

Lead time refers to the time taken from placing an order to receiving the goods. In industries reliant on silicon carbide, knowing lead times is essential for project scheduling and inventory management, particularly when sourcing from international suppliers.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing piedra de carburo de silicio, ultimately enhancing their operational efficiency and product quality.

The global market for piedra de carburo de silicio (silicon carbide) is witnessing significant growth driven by increasing demand in industries such as automotive, electronics, and renewable energy. Key trends influencing this market include the rise of electric vehicles (EVs), which require high-performance materials for power electronics, and the expanding use of silicon carbide in semiconductor applications. Buyers from regions such as Africa, South America, the Middle East, and Europe are particularly interested in these developments, as they seek advanced materials to enhance their manufacturing capabilities.

Emerging technologies, including the adoption of Industry 4.0, are reshaping sourcing strategies. B2B buyers are leveraging data analytics and artificial intelligence to streamline procurement processes, improve supplier selection, and optimize inventory management. International buyers should focus on establishing partnerships with suppliers who have a strong track record in innovation and can provide materials that meet stringent quality standards. Moreover, the growing trend towards local sourcing can mitigate risks associated with supply chain disruptions, which have become more prevalent due to geopolitical tensions and the COVID-19 pandemic.

Sustainability is becoming a critical consideration for B2B buyers in the piedra de carburo de silicio sector. The environmental impact of sourcing and manufacturing processes is under scrutiny, leading to a demand for ethical supply chains. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as reducing carbon footprints, minimizing waste, and utilizing renewable energy sources in production.

Moreover, certifications for 'green' materials are gaining traction. Buyers should look for suppliers that offer eco-friendly certifications, which not only assure compliance with environmental regulations but also enhance corporate social responsibility (CSR) profiles. This trend is particularly relevant for international buyers from Africa and South America, where sustainable development initiatives are increasingly prioritized. Emphasizing sustainability in procurement processes not only helps in meeting regulatory requirements but also appeals to environmentally-conscious customers, thereby driving sales.

The evolution of the piedra de carburo de silicio sector dates back to its discovery in the late 19th century, but its commercial significance surged in the 21st century with advancements in materials science. Initially used primarily in abrasives and cutting tools, silicon carbide has expanded its applications to include high-performance semiconductors, LED technology, and power electronics. This diversification has been fueled by technological advancements and the growing demand for efficient energy solutions.

As international B2B buyers look to source piedra de carburo de silicio, understanding its historical context can provide insights into current market dynamics and future trends. The transition from traditional uses to cutting-edge applications underscores the importance of sourcing from suppliers who are not only knowledgeable but also innovative in their approach to product development. This knowledge can empower buyers to make informed decisions that align with both their operational needs and sustainability goals.

How do I choose the right supplier for piedra de carburo de silicio?

Choosing the right supplier for piedra de carburo de silicio involves several key steps. Start by researching potential suppliers' reputations through online reviews and industry forums. Request samples to assess product quality and consistency. Verify certifications and compliance with international standards, such as ISO 9001. Additionally, consider suppliers' production capacity, lead times, and logistics capabilities to ensure they can meet your demand effectively.

What is the best grade of piedra de carburo de silicio for industrial applications?

The best grade of piedra de carburo de silicio for industrial applications typically depends on the specific use case. For abrasive applications, a black silicon carbide grade is preferred due to its hardness and durability. For high-temperature applications, green silicon carbide is often recommended due to its thermal stability and superior performance. Always consult with technical experts to determine the most suitable grade for your specific requirements.

What are the minimum order quantities (MOQ) for piedra de carburo de silicio?

Minimum order quantities (MOQ) for piedra de carburo de silicio can vary significantly between suppliers. Generally, MOQs range from 500 kg to several tons, depending on the product grade and supplier policies. It's essential to discuss your purchasing needs with potential suppliers to negotiate favorable terms, especially if you are a smaller buyer or just starting out in the market.

What payment terms should I expect when sourcing piedra de carburo de silicio?

Payment terms for sourcing piedra de carburo de silicio can differ by supplier and region. Common terms include advance payment, 30% deposit with the balance before shipping, or net 30/60 days after delivery. It's advisable to establish clear payment conditions upfront and consider using letters of credit for large transactions to mitigate risk. Always review terms carefully to ensure they align with your cash flow needs.

How can I ensure quality assurance when purchasing piedra de carburo de silicio?

To ensure quality assurance when purchasing piedra de carburo de silicio, request detailed product specifications and certifications from your supplier. Implement a quality control process that includes inspecting samples before bulk orders and conducting random checks during production. Collaborating with third-party inspection agencies can also provide additional verification of product quality and compliance with required standards.

What logistics considerations should I keep in mind when importing piedra de carburo de silicio?

When importing piedra de carburo de silicio, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Determine whether air freight or sea freight is more cost-effective based on your urgency and budget. Familiarize yourself with import duties and taxes specific to your country to avoid unexpected costs. Partnering with a reliable freight forwarder can streamline the process and ensure timely delivery.

How do trade regulations impact the import of piedra de carburo de silicio?

Trade regulations can significantly impact the import of piedra de carburo de silicio, depending on your country and the supplier's location. Be aware of tariffs, import quotas, and any specific regulations regarding hazardous materials. Staying updated on trade agreements between countries can also provide advantages, such as reduced tariffs. Consulting with a customs broker can help navigate these complexities and ensure compliance.

Can I customize the specifications of piedra de carburo de silicio for my needs?

Yes, many suppliers offer customization options for the specifications of piedra de carburo de silicio. You can request specific particle sizes, purity levels, and packaging formats tailored to your application. It's crucial to communicate your requirements clearly and work closely with the supplier's technical team to ensure that the customized product meets your performance expectations and industry standards.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the competitive landscape of international trade, strategic sourcing of piedra de carburo de silicio presents numerous opportunities for B2B buyers, especially in Africa, South America, the Middle East, and Europe. Engaging with reputable suppliers ensures access to high-quality materials, which is crucial for applications ranging from abrasives to semiconductor production. By leveraging regional supply chains and understanding local market dynamics, buyers can optimize costs while enhancing product quality.

Adopting a strategic sourcing approach not only mitigates risks associated with supply disruptions but also fosters long-term partnerships with suppliers. This is particularly important in regions experiencing rapid industrial growth, where reliable access to raw materials can significantly impact production timelines and overall business performance. Buyers should prioritize collaboration and transparency in their sourcing strategies to build resilience and adaptability in their operations.

Looking ahead, international B2B buyers must remain agile and informed about market trends and technological advancements in the piedra de carburo de silicio sector. By investing in strategic sourcing initiatives, businesses can position themselves for sustainable growth and innovation. Take the initiative to explore new partnerships and refine your sourcing strategies today—your competitive edge depends on it.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina