In the ever-evolving landscape of international trade, sourcing the right SIC chemical formula can present a formidable challenge for B2B buyers. With the growing demand for specialized chemicals across various industries, including construction, electronics, and automotive, understanding the nuances of sourcing and procurement becomes crucial. This comprehensive guide delves into the multifaceted world of SIC chemical formulas, providing insights into different types, their applications, and best practices for supplier vetting and cost management.

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, making informed purchasing decisions is essential to remain competitive. This guide equips you with actionable insights, enabling you to navigate the complexities of the global market effectively. From identifying reliable suppliers to understanding pricing dynamics, each section is designed to empower you to optimize your sourcing strategy.

Whether you're looking to enhance your production processes or seeking innovative solutions to meet specific industry needs, this guide serves as a valuable resource. By leveraging the information presented, buyers can mitigate risks, ensure compliance with regulations, and ultimately drive business growth. Join us as we explore the intricacies of SIC chemical formulas and unlock the potential for successful international procurement.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicon Carbide (SiC) | High thermal conductivity, high hardness, chemical stability | Electronics, automotive, aerospace | Pros: Excellent thermal performance; Cons: Higher cost compared to alternatives. |

| Silicon Nitride (Si3N4) | High strength, low thermal expansion, excellent wear resistance | Bearings, cutting tools, aerospace | Pros: Superior toughness; Cons: Difficult to machine. |

| Silicon Dioxide (SiO2) | Abundant, chemically inert, good insulation properties | Electronics, optics, construction | Pros: Versatile and cost-effective; Cons: Limited mechanical strength. |

| Silicon Carbide Ceramics | Combines SiC with ceramic properties for enhanced toughness | Military, industrial applications | Pros: High strength and durability; Cons: Fragility under extreme conditions. |

| Silicon Phosphide (SiP) | Combines silicon with phosphorus for unique electrical properties | Photonics, semiconductor applications | Pros: Enhances electronic performance; Cons: Limited availability and higher costs. |

Silicon Carbide (SiC) is characterized by its exceptional thermal conductivity and hardness, making it ideal for high-temperature applications. This material is widely used in the electronics sector, particularly in power devices and high-frequency applications. For B2B buyers, SiC provides significant advantages in efficiency and performance, but its higher cost can be a consideration, especially for budget-sensitive projects.

Silicon Nitride (Si3N4) is known for its high strength and low thermal expansion, which makes it suitable for applications requiring durability and resistance to thermal shock. It is commonly used in bearings, cutting tools, and aerospace components. B2B buyers should consider Si3N4 for applications that demand high-performance materials; however, its machining difficulty may increase processing costs.

Silicon Dioxide (SiO2) is abundant and chemically inert, offering excellent insulation properties. Its versatility makes it applicable in electronics, optics, and construction. For international B2B buyers, SiO2 represents a cost-effective solution; however, its limited mechanical strength may not meet the needs of all high-stress applications.

Silicon Carbide Ceramics combine the properties of SiC with ceramic materials, resulting in enhanced toughness and durability. These materials are often utilized in military and industrial applications where high strength is critical. Buyers should weigh the benefits of durability against potential fragility under extreme conditions when considering these materials.

Silicon Phosphide (SiP) is notable for its unique electrical properties, making it valuable in photonics and semiconductor applications. While it can enhance electronic performance, its limited availability and higher costs may deter some B2B buyers. Those looking to innovate in the semiconductor space should assess SiP's potential benefits against supply chain considerations.

Related Video: Chemical Equations | Environmental Chemistry | Chemistry | FuseSchool

| Industry/Sector | Specific Application of sic chemical formula | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Use in manufacturing high-performance brake systems | Enhanced safety and performance in vehicles | Look for suppliers with certifications for quality and safety. |

| Electronics | Application in semiconductor devices and circuits | Improved efficiency and reliability of electronic components | Ensure compliance with international standards for electronic parts. |

| Construction and Building | Utilization in advanced concrete formulations | Increased durability and strength of construction materials | Source from manufacturers with proven track records in construction. |

| Aerospace | Employed in lightweight composite materials | Reduced weight and improved fuel efficiency in aircraft | Verify material specifications and certifications for aerospace applications. |

| Renewable Energy | Integration in solar panel production | Enhanced energy conversion efficiency | Consider suppliers with sustainable practices and certifications. |

In the automotive sector, the sic chemical formula is crucial for developing high-performance brake systems. The use of silicon carbide (SiC) enhances the durability and heat resistance of brake components, which ultimately leads to improved safety and performance in vehicles. International buyers, particularly from regions like Africa and South America, should prioritize sourcing from suppliers who adhere to stringent quality certifications to ensure compliance with automotive safety standards.

The electronics industry leverages the sic chemical formula primarily in the production of semiconductor devices and circuits. Silicon carbide's superior thermal conductivity and electrical performance make it an ideal material for high-efficiency electronic components. B2B buyers in Europe and the Middle East should focus on sourcing from manufacturers that comply with international electronic standards, ensuring reliability and performance in their products.

In construction, the sic chemical formula is utilized in advanced concrete formulations that enhance the material's strength and durability. By integrating silicon carbide into concrete mixes, businesses can significantly improve the lifespan and load-bearing capacity of structures. Buyers in the construction sector, especially from developing regions, should consider sourcing from manufacturers with a proven history of quality in construction materials to avoid performance issues.

The aerospace industry employs the sic chemical formula in the creation of lightweight composite materials, which are essential for reducing the overall weight of aircraft. This reduction in weight leads to improved fuel efficiency and performance. International buyers, particularly from Europe, should ensure that their suppliers meet the rigorous specifications and certifications required for aerospace materials to guarantee safety and compliance.

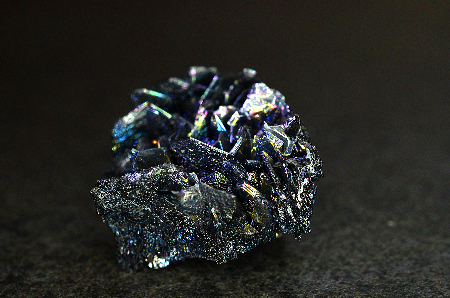

A stock image related to sic chemical formula.

In the renewable energy sector, the sic chemical formula is integrated into the production of solar panels, where it enhances energy conversion efficiency. Silicon carbide's properties allow for better performance in photovoltaic applications, making it a valuable component for solar energy solutions. Buyers from South America and Africa should prioritize sourcing from suppliers who not only provide high-quality materials but also practice sustainability in their production processes.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem: B2B buyers often face challenges in sourcing high-quality sic chemical formulas that meet strict industry standards. For companies in sectors like construction and electronics, the quality of materials directly impacts product performance and safety. Buyers from Africa and South America may struggle with limited local suppliers, leading to reliance on international sources, which can introduce variability in quality. Additionally, inconsistent product specifications can lead to production delays and increased costs.

The Solution: To overcome sourcing challenges, B2B buyers should establish robust relationships with reputable suppliers who specialize in sic chemical formulas. Conduct thorough due diligence by checking certifications, customer reviews, and previous project case studies to verify the supplier's reliability. It's also beneficial to request samples and conduct independent testing before placing bulk orders. Consider diversifying your supplier base across different regions to mitigate risks associated with supply chain disruptions. Leveraging platforms that aggregate supplier information can streamline this process, making it easier to compare options and ensure compliance with local regulations.

The Problem: Many international B2B buyers encounter difficulties in understanding the technical specifications of sic chemical formulas, which can lead to incorrect applications and product failures. This is particularly true for companies in the Middle East and Europe, where specific regulations dictate the performance standards of chemical materials. Buyers often receive technical datasheets filled with jargon, making it hard to discern the right product for their needs.

The Solution: To navigate complex specifications, buyers should invest in training for their procurement and technical teams. This can include workshops led by industry experts who can break down the chemistry behind sic chemical formulas and clarify how various properties impact performance. Additionally, collaborating closely with suppliers can yield valuable insights; they can provide tailored recommendations based on your application needs. Establishing a clear line of communication to discuss your requirements can lead to better product matching and reduce the risk of misapplication.

The Problem: Compliance with local and international regulations is a significant pain point for B2B buyers dealing with sic chemical formulas. Companies in regions like Africa and South America may struggle to keep up with evolving regulations, which can vary widely from one country to another. This can result in costly fines, project delays, and reputational damage if non-compliance is discovered.

The Solution: B2B buyers should implement a proactive compliance management system that includes regular updates on relevant regulations and standards. This can be achieved by subscribing to industry newsletters, joining professional associations, or engaging legal consultants who specialize in chemical regulations. Furthermore, maintaining a comprehensive documentation process for all chemical purchases and applications can help ensure that all products meet compliance standards. Establishing a compliance team that works closely with suppliers can also facilitate better understanding and adherence to regulations, reducing the likelihood of non-compliance issues arising.

A stock image related to sic chemical formula.

When selecting materials for the sic chemical formula, it is crucial to consider various factors that influence product performance and application suitability. Here, we analyze four common materials used in conjunction with sic chemical formulations, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Silicon carbide (SiC) is a widely used material in the production of sic chemical formulas due to its exceptional thermal and mechanical properties. It boasts a high temperature rating, often exceeding 1600°C, and excellent thermal conductivity. Additionally, SiC exhibits remarkable corrosion resistance, making it suitable for harsh chemical environments. This material is particularly effective in applications requiring high wear resistance, such as in semiconductor manufacturing and abrasive materials.

Pros: SiC is highly durable and can withstand extreme conditions, making it ideal for long-term applications. Its thermal stability also enhances performance in high-temperature processes.

Cons: The primary drawback of SiC is its high cost compared to other materials. Manufacturing complexity can also be a concern, as the production process for SiC components often requires specialized equipment and techniques.

Impact on Application: SiC's compatibility with various media, including corrosive chemicals and high temperatures, makes it a preferred choice for industries such as aerospace and automotive.

Alumina, or aluminum oxide, is another popular material used in sic chemical formulas. It is known for its excellent hardness and wear resistance, with a temperature rating of up to 1700°C. Alumina also has good electrical insulation properties, making it suitable for electronic applications.

Pros: The main advantage of alumina is its cost-effectiveness and relative ease of manufacturing. It is also widely available, which can streamline supply chains for international buyers.

Cons: While alumina is durable, it is more brittle than SiC, which can lead to failure under impact or stress. Its corrosion resistance is also lower than that of SiC, limiting its use in highly aggressive environments.

Impact on Application: Alumina's compatibility with a range of chemicals makes it suitable for applications in the chemical processing and electronics industries.

Zirconia, or zirconium dioxide, is recognized for its exceptional toughness and thermal stability, with a temperature rating of around 2400°C. It also exhibits excellent chemical resistance, making it suitable for use in aggressive environments.

Pros: Zirconia's high toughness and resistance to thermal shock make it ideal for applications requiring durability under extreme conditions. It also has good aesthetic properties, which can be advantageous in consumer-facing products.

Cons: The main limitation of zirconia is its relatively high cost and complexity in manufacturing, which can affect overall project budgets. Additionally, its brittleness can be a concern in certain applications.

Impact on Application: Zirconia's compatibility with a variety of aggressive media positions it well for applications in the chemical and pharmaceutical sectors.

Graphite is often used in conjunction with sic chemical formulas, particularly in applications requiring lubrication and thermal conductivity. It performs well at high temperatures, with a rating of up to 3000°C.

Pros: Graphite is relatively inexpensive and easy to manufacture, making it an attractive option for many applications. Its excellent lubricating properties can reduce wear and extend the life of components.

Cons: However, graphite is not as chemically resistant as SiC or zirconia, which can limit its use in corrosive environments. It is also more prone to oxidation at elevated temperatures.

Impact on Application: Graphite is often used in applications where lubrication is critical, such as in bearings and seals, but care must be taken in environments with aggressive chemicals.

| Material | Typical Use Case for sic chemical formula | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | Semiconductor manufacturing, abrasives | High durability and thermal stability | High cost, complex manufacturing | High |

| Alumina (Al2O3) | Chemical processing, electronics | Cost-effective and widely available | Brittle, lower corrosion resistance | Medium |

| Zirconia (ZrO2) | Chemical and pharmaceutical applications | High toughness and chemical resistance | High cost, brittle | High |

| Graphite | Bearings, seals | Inexpensive, excellent lubrication | Lower chemical resistance, oxidation | Low |

This guide aims to equip international B2B buyers with the knowledge necessary to make informed material selections for sic chemical formulas, considering performance, cost, and application suitability.

The manufacturing of silicon carbide (SiC), often referred to as Sic, involves several critical stages that ensure the final product meets the high standards required for various industrial applications. These stages typically include material preparation, forming, assembly, and finishing.

The initial stage involves sourcing high-purity raw materials such as silicon and carbon. These materials are often obtained from specialized suppliers who adhere to stringent quality standards. The selection of raw materials is crucial, as impurities can significantly affect the performance of the final Sic products.

The raw materials are then subjected to processes such as crushing, grinding, and sieving to achieve the desired particle size and distribution. This step is essential for ensuring uniformity in the subsequent stages of production.

Once the materials are prepared, the next step is forming. This can be achieved through various techniques, including:

Sintering: This involves heating the material below its melting point to allow particles to bond together. Sintering is critical for producing dense and strong Sic components, which are often used in high-temperature applications.

Chemical Vapor Deposition (CVD): This technique is particularly useful for creating thin films of Sic. It involves the deposition of gaseous precursors onto a substrate, resulting in the formation of a solid material. CVD is widely used in semiconductor applications.

Extrusion: For certain applications, Sic can be extruded into specific shapes. This process allows for continuous production of components with complex geometries, which are essential in various industrial applications.

In cases where Sic components are part of larger assemblies, the assembly process comes into play. This may involve:

Joining Techniques: Various methods such as brazing, welding, or adhesive bonding are employed to assemble Sic components with other materials. The choice of joining technique depends on the specific application and the materials involved.

Quality Checks: During the assembly process, quality checks are essential to ensure that the components fit together properly and meet the required specifications. This may involve dimensional checks and visual inspections.

Finishing processes are crucial for enhancing the surface properties of Sic products. Common techniques include:

Grinding and Polishing: These processes improve the surface finish and dimensional accuracy of Sic components. A smooth surface is often necessary for applications that involve friction or wear.

Coating: Applying protective coatings can enhance the performance of Sic products in harsh environments. Coatings can provide additional benefits such as corrosion resistance and improved thermal properties.

Quality assurance (QA) is a critical component of the manufacturing process for Sic products. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer requirements and enhance satisfaction.

B2B buyers should also be aware of industry-specific standards that may apply to Sic products, including:

CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

API Standards: In industries such as oil and gas, adherence to American Petroleum Institute (API) standards is crucial. These standards ensure that materials used in critical applications meet stringent performance criteria.

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established at various stages:

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified quality standards.

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor parameters such as temperature, pressure, and material consistency. This helps identify any deviations from the desired process conditions.

Final Quality Control (FQC): After the completion of manufacturing, final inspections are carried out to ensure that the finished products meet the specified requirements. This may involve dimensional checks, visual inspections, and functional testing.

B2B buyers should be familiar with the common testing methods employed in the quality assurance of Sic products:

Mechanical Testing: This includes tests for hardness, tensile strength, and impact resistance. These tests are essential for determining the material's performance under different conditions.

Thermal Testing: Given the high-temperature applications of Sic, thermal conductivity and thermal shock resistance tests are critical.

Chemical Analysis: Techniques such as X-ray fluorescence (XRF) and scanning electron microscopy (SEM) are used to analyze the composition and microstructure of Sic materials.

B2B buyers can take several steps to verify the quality control practices of their suppliers:

Conduct Audits: Regular audits of suppliers can help buyers assess compliance with quality standards and identify areas for improvement. This can include reviewing production processes, quality control measures, and documentation practices.

Request Quality Reports: Suppliers should provide detailed quality reports that outline testing results, certifications, and compliance with relevant standards. These reports can offer valuable insights into the supplier's commitment to quality.

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier's quality control processes. These inspectors can conduct thorough evaluations and provide recommendations for improvement.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control:

Regulatory Differences: Different countries may have varying regulations regarding quality standards. Buyers should familiarize themselves with local regulations and ensure that their suppliers comply.

Cultural Considerations: Understanding cultural differences in business practices can enhance communication and collaboration with suppliers. This is particularly important when discussing quality expectations and standards.

Supply Chain Risks: International buyers should consider the potential risks associated with global supply chains, including geopolitical factors, transportation challenges, and changes in regulations. Developing a robust risk management strategy can mitigate these challenges.

By understanding the manufacturing processes and quality assurance measures associated with the Sic chemical formula, B2B buyers can make informed decisions, ensuring that they procure high-quality products that meet their specific industrial needs.

To successfully procure SIC chemical formulas, international B2B buyers must follow a structured approach that ensures quality, compliance, and value for money. This practical sourcing guide provides a step-by-step checklist to streamline your procurement process.

Understanding your specific needs is critical before approaching suppliers. Clearly outline the chemical properties, purity levels, and application requirements of the SIC chemical formula you need.

- Considerations:

- What are the intended applications?

- Are there specific regulatory standards that must be met in your region?

Conduct thorough research to identify reputable suppliers who specialize in SIC chemical formulas. Utilize industry-specific platforms and trade shows to gather a list of potential vendors.

- Resources:

- Online directories and trade associations.

- Networking with industry peers for recommendations.

Before initiating negotiations, verify that suppliers possess the necessary certifications. This includes ISO certifications, compliance with local regulations, and adherence to international safety standards.

- Why This Matters:

- Certifications serve as a quality assurance mechanism and can mitigate risks related to product quality and legal compliance.

Once you have shortlisted potential suppliers, request samples of the SIC chemical formula. Testing these samples in your own facilities will help determine if they meet your specifications.

- Key Actions:

- Analyze the samples for purity and performance.

- Assess the supplier's responsiveness and willingness to accommodate your testing requirements.

Engage in discussions with suppliers to negotiate pricing, delivery schedules, and payment terms. A clear understanding of these elements is crucial for a successful partnership.

- Considerations:

- What are the minimum order quantities?

- Are there discounts for bulk purchases?

Implement a quality assurance process to monitor the performance of the SIC chemical formula post-purchase. This includes setting up inspection protocols and feedback mechanisms with your suppliers.

- Importance:

- Regular quality checks can prevent issues down the line and ensure consistent product performance.

Once you have successfully sourced your SIC chemical formula, focus on building a long-term relationship with your suppliers. Regular communication and collaboration can lead to better pricing, priority service, and potential product innovations.

- Strategies:

- Schedule regular meetings to discuss performance and needs.

- Share insights on market trends and future requirements.

By following this checklist, B2B buyers from Africa, South America, the Middle East, and Europe can ensure a thorough and effective sourcing process for SIC chemical formulas, ultimately leading to better procurement outcomes and partnerships.

When sourcing sic chemical formulas, understanding the cost structure is essential for effective budgeting and negotiation. The primary components that contribute to the overall cost include:

Materials: The raw materials used in the production of sic chemicals can significantly influence pricing. Fluctuations in the global market for silicon carbide or other essential ingredients can lead to variances in costs. Buyers should stay informed about market trends to anticipate changes.

Labor: Labor costs encompass the wages of the workforce involved in manufacturing, packaging, and quality control. Regions with higher labor costs may impact the final price of the product, particularly in Europe compared to Africa or South America.

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, thus lowering the overall price.

Tooling: The cost of molds and other tooling necessary for production is a fixed cost that must be amortized over the production volume. Higher tooling costs may be justifiable for custom formulations but can inflate the price for standard offerings.

Quality Control (QC): Ensuring the product meets specific standards requires investment in quality control measures. Certifications (like ISO) and testing can add to the cost but are essential for maintaining product integrity, especially in regulated industries.

Logistics: Shipping and handling costs vary widely depending on the destination, mode of transportation, and Incoterms. Understanding these factors is crucial for budgeting and can significantly affect the total cost.

Margin: Suppliers will typically add a margin to cover their costs and profit. This margin can vary based on competition, demand, and the supplier’s position in the market.

Several factors can influence the pricing of sic chemical formulas:

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing discounts. Buyers should assess their needs to determine the best order size that balances cost and inventory management.

Specifications and Customization: Custom formulations or specific quality grades will generally incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can affect pricing. Higher quality materials or certifications can lead to increased costs but may provide better performance and reliability.

Supplier Factors: Established suppliers may offer more competitive pricing due to economies of scale, while new entrants might charge higher prices until they build their market presence.

Incoterms: The terms of sale can significantly impact logistics costs. Understanding the implications of different Incoterms (like FOB, CIF, etc.) is essential for accurate cost analysis.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may be willing to adjust their prices based on long-term partnerships or larger order commitments.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost over the product’s lifecycle, including maintenance, disposal, and potential downtime due to quality issues.

Assess Pricing Nuances: Be aware of regional pricing strategies. For example, suppliers in Europe may have different pricing structures than those in Africa or South America due to varying cost bases and market dynamics.

Stay Informed: Regularly monitor market trends and supplier performance. Being informed allows buyers to make better purchasing decisions and leverage market conditions to their advantage.

Request Quotations from Multiple Suppliers: Gathering multiple quotes can provide leverage in negotiations and help buyers identify the best value.

Prices for sic chemical formulas can vary widely based on the aforementioned factors, and the information provided should be considered as indicative rather than definitive. Buyers are encouraged to conduct thorough market research and engage in direct negotiations with suppliers to obtain accurate pricing tailored to their specific needs.

In the rapidly evolving landscape of industrial chemistry, B2B buyers must consider various solutions that can fulfill their operational needs. While the Sic chemical formula has established itself as a reliable option, it is essential to explore alternative methods or technologies that may offer different advantages. This analysis will compare the Sic chemical formula with two viable alternatives, providing insights to help international buyers make informed decisions.

| Comparison Aspect | Sic Chemical Formula | Alternative 1: Silicon Carbide (SiC) | Alternative 2: Gallium Nitride (GaN) |

|---|---|---|---|

| Performance | High thermal stability | Excellent thermal and electrical performance | Superior efficiency in high-frequency applications |

| Cost | Moderate production cost | Higher initial investment | Higher cost but decreasing with advancements |

| Ease of Implementation | Established processes | Requires specialized manufacturing techniques | Needs advanced fabrication technology |

| Maintenance | Low maintenance requirements | Moderate maintenance needs | Relatively low maintenance |

| Best Use Case | General industrial applications | Power electronics, high-temperature applications | RF and microwave devices |

Silicon Carbide (SiC) is a semiconductor material known for its robustness and high thermal conductivity. One of its primary advantages is its ability to operate at high temperatures and voltages, making it ideal for power electronics and high-frequency applications. However, the initial investment can be significantly higher than that of the Sic chemical formula. Additionally, the manufacturing processes for SiC are more complex, which may require specialized equipment and expertise, thus increasing the implementation time.

Gallium Nitride (GaN) is another semiconductor that has gained traction in various applications, particularly in RF and microwave devices. Its superior efficiency in high-frequency scenarios allows for smaller, lighter devices, which is a significant advantage in telecommunications and aerospace industries. Despite its benefits, GaN can be expensive, and the technology for its fabrication is still developing, which can lead to higher costs and longer lead times for international buyers.

When evaluating the Sic chemical formula against alternatives like Silicon Carbide and Gallium Nitride, B2B buyers should weigh the specific performance requirements, budget constraints, and ease of implementation relevant to their operations. The choice will depend on the application context—whether it’s for general industrial use or specialized high-frequency applications. By thoroughly assessing these factors, international buyers from regions such as Africa, South America, the Middle East, and Europe can make strategic decisions that align with their business objectives and operational capabilities.

When considering the purchase of materials or products involving the silicon carbide (SiC) chemical formula, it's essential to understand several critical technical properties. These specifications not only inform product quality but also impact operational efficiency and cost-effectiveness for B2B buyers.

Material grade indicates the purity and composition of silicon carbide. High-grade SiC is typically used in applications requiring superior thermal conductivity and mechanical strength, such as in semiconductor devices. For B2B buyers, selecting the appropriate grade is crucial as it directly affects product performance and lifecycle.

Tolerance levels refer to the permissible limits of variation in a physical dimension. In the context of SiC components, tighter tolerances ensure better fit and function, which is particularly important in precision applications like aerospace or medical devices. Understanding tolerance specifications allows buyers to avoid costly reworks and ensure compatibility with existing systems.

Thermal conductivity measures a material's ability to conduct heat. SiC is renowned for its high thermal conductivity, making it suitable for applications in high-temperature environments. Buyers should prioritize this property to ensure reliability and efficiency in their processes, particularly when dealing with power electronics or high-performance ceramics.

The hardness of SiC is a critical property that determines its wear resistance. It is often measured on the Mohs scale, where SiC ranks high due to its exceptional hardness. For B2B applications, selecting hard materials can lead to lower maintenance costs and extended product lifespans, making this a vital consideration in procurement.

Electrical conductivity indicates how well a material can conduct electricity. SiC is a semiconductor, which means it has unique electrical properties that can be leveraged in various electronic applications. Buyers looking to integrate SiC into their products should evaluate its conductivity based on the intended application to optimize performance and efficiency.

Understanding industry terminology is essential for effective communication and negotiation in the procurement process. Here are some common terms that B2B buyers should be familiar with:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with an OEM can provide access to high-quality components that meet specific requirements, often with customization options.

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for buyers, as it affects inventory levels and cash flow. Negotiating a favorable MOQ can lead to cost savings and better inventory management.

An RFQ is a document that buyers send to suppliers requesting pricing information for specific quantities of goods or services. For international B2B buyers, issuing RFQs helps in comparing costs and ensuring competitive pricing, which is vital in securing the best deals.

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, ultimately aiding in smoother cross-border trade.

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for B2B buyers as it impacts project timelines and inventory management. Buyers should communicate their needs clearly to ensure timely deliveries.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing silicon carbide products, ultimately leading to improved operational efficiency and cost-effectiveness.

The SIC chemical formula sector is experiencing significant transformation driven by globalization, technological advancements, and shifting consumer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are witnessing an increase in demand for high-performance materials. This demand is fueled by industries such as automotive, construction, and electronics, where the need for innovative solutions is paramount.

Emerging trends include the integration of digital technologies into supply chains, enhancing transparency and efficiency. The adoption of data analytics and AI tools allows businesses to optimize sourcing strategies and reduce costs. Moreover, the growing importance of real-time data access enables international buyers to make informed decisions swiftly, thus enhancing their competitive edge.

Another notable trend is the rise of regional sourcing partnerships. Buyers are increasingly looking for suppliers that can provide localized support, which not only reduces lead times but also mitigates risks associated with global supply chain disruptions. The geopolitical landscape and fluctuating trade policies further necessitate this shift towards regionalism, making it essential for international buyers to adapt their sourcing strategies accordingly.

The environmental impact of chemical production is a critical consideration for today's B2B buyers. As sustainability becomes a central focus, the demand for ethically sourced materials has surged. Buyers from Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of green certifications and eco-friendly materials in the production of SIC chemicals.

Ethical sourcing not only helps in reducing the carbon footprint but also enhances brand reputation. B2B buyers can leverage sustainability as a differentiator in competitive markets. Companies that adopt responsible sourcing policies and invest in sustainable innovations are better positioned to meet the regulatory requirements and consumer expectations of today.

Furthermore, the circular economy is gaining traction, encouraging businesses to rethink waste management and resource utilization. Buyers are encouraged to collaborate with suppliers who have robust recycling and waste reduction programs in place, thereby fostering a sustainable supply chain.

The SIC chemical formula sector has evolved significantly over the past decades. Initially, the focus was primarily on traditional manufacturing processes that prioritized efficiency over sustainability. However, as environmental concerns gained prominence, the industry began to pivot towards more sustainable practices.

In recent years, technological advancements have accelerated this evolution, enabling the development of innovative materials with enhanced performance characteristics. The rise of digital tools has transformed sourcing strategies, allowing for greater transparency and efficiency. As a result, the SIC chemical formula sector is not only adapting to market demands but also leading the way in sustainable manufacturing practices, positioning itself as a crucial player in the global marketplace.

In summary, international B2B buyers must navigate these evolving dynamics and trends in the SIC chemical formula sector to optimize their sourcing strategies effectively. By focusing on sustainability and leveraging technology, they can enhance their competitive advantage and contribute to a more responsible supply chain.

How can I ensure the quality of sic chemical formula products from suppliers?

To ensure the quality of sic chemical formula products, start by vetting suppliers through industry certifications such as ISO 9001 or equivalent. Request samples and conduct laboratory testing to validate product specifications. Additionally, establish clear quality assurance protocols, including regular audits and performance evaluations. Engaging with local industry associations can also provide insights into supplier reputations and reliability.

What are the minimum order quantities (MOQ) for sic chemical formula?

Minimum order quantities for sic chemical formula can vary significantly between suppliers. Typically, you might encounter MOQs ranging from 100 kg to several tons depending on the manufacturer’s capabilities and production runs. It’s advisable to negotiate terms based on your specific requirements, as some suppliers may accommodate smaller orders for new customers or ongoing projects.

What payment terms should I expect when sourcing sic chemical formula internationally?

Payment terms when sourcing sic chemical formula can differ widely among suppliers. Common terms include advance payment, 30% deposit with the balance upon shipment, or net 30-60 days after delivery. It is crucial to clarify these terms upfront and consider using secure payment methods such as letters of credit or escrow services to mitigate risks, especially for larger transactions.

How do I find reliable suppliers of sic chemical formula in Africa and South America?

To find reliable suppliers of sic chemical formula in Africa and South America, leverage online B2B marketplaces, industry trade shows, and local business directories. Networking through industry associations can also yield valuable contacts. Verify supplier credentials by checking references, customer reviews, and certifications. Attending trade fairs in these regions can provide firsthand insights into supplier operations and product quality.

What logistics considerations should I keep in mind when importing sic chemical formula?

When importing sic chemical formula, consider factors such as shipping methods, customs regulations, and lead times. Ensure that your suppliers provide accurate documentation, including invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, evaluate shipping costs and potential tariffs, and choose logistics partners with experience in handling chemical products to ensure compliance with safety regulations.

Can I customize the sic chemical formula to meet specific application needs?

Yes, many suppliers offer customization options for sic chemical formulas to meet specific application requirements. Communicate your needs clearly, including desired specifications, packaging, and delivery schedules. Collaborating closely with the supplier during the formulation process can lead to better product performance in your applications, whether in manufacturing, construction, or other sectors.

What are the common applications of sic chemical formula in various industries?

Sic chemical formula is commonly used in industries such as ceramics, electronics, and metallurgy. In ceramics, it serves as a key component in producing high-strength materials. In electronics, it is utilized in semiconductor manufacturing. Understanding these applications can help buyers identify the best suppliers who specialize in the specific use cases relevant to their industry needs.

How can I assess the sustainability practices of sic chemical formula suppliers?

To assess the sustainability practices of sic chemical formula suppliers, request information on their environmental management systems and certifications, such as ISO 14001. Inquire about their waste management practices, energy consumption, and sourcing of raw materials. Engaging in dialogue about their corporate social responsibility (CSR) initiatives can also provide insights into their commitment to sustainable practices and ethical sourcing.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, effective strategic sourcing of the silicon carbide (SiC) chemical formula presents a multitude of opportunities for international B2B buyers, particularly from emerging markets in Africa, South America, the Middle East, and established economies in Europe. By prioritizing supplier relationships, understanding regional market dynamics, and leveraging technological advancements, buyers can not only enhance their supply chain resilience but also achieve significant cost savings.

Investing time in robust sourcing strategies allows companies to tap into innovative solutions and superior product quality, ultimately leading to improved operational efficiency. As the demand for SiC continues to rise due to its applications in various industries, including electronics and automotive, positioning oneself as a forward-thinking buyer will be crucial.

Looking ahead, it is essential for B2B buyers to stay informed about market trends and regulatory changes affecting the SiC sector. By actively participating in industry forums and establishing connections with reliable suppliers, you can position your organization for long-term success. Embrace the potential of strategic sourcing today to unlock growth and ensure your place in the competitive landscape of tomorrow.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina