Navigating the complexities of sourcing siliziumkarbidpulver can be a daunting challenge for international B2B buyers, particularly those in emerging markets like Africa, South America, the Middle East, and Europe. As industries increasingly rely on this versatile material for applications ranging from semiconductor manufacturing to abrasives, understanding how to effectively procure high-quality silicon carbide powder becomes essential. This comprehensive guide aims to demystify the global market by exploring various types of siliziumkarbidpulver, their applications, and the critical factors to consider when vetting suppliers.

In the following sections, we will delve into essential topics such as the different grades and specifications of silicon carbide powder, its role in various industrial applications, and practical strategies for supplier selection. Additionally, we will provide insights into pricing dynamics and cost considerations that affect procurement decisions. By equipping B2B buyers with the knowledge needed to make informed purchasing choices, this guide empowers businesses to navigate the global market with confidence.

Whether you are based in Argentina, Egypt, or elsewhere, understanding the nuances of sourcing siliziumkarbidpulver will enhance your procurement strategy and ensure you secure the best materials for your operational needs. Let’s embark on this journey to unlock the potential of silicon carbide powder in your supply chain.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Black Silicon Carbide | High hardness, low thermal conductivity | Abrasives, cutting tools | Pros: Cost-effective, versatile. Cons: Brittle, less effective in wet applications. |

| Green Silicon Carbide | Higher purity, better thermal conductivity | Electronics, semiconductor manufacturing | Pros: Excellent thermal stability, high purity. Cons: Higher cost compared to black variant. |

| Micro Silica Carbide | Very fine particle size, high surface area | Advanced ceramics, composites | Pros: Enhances material strength. Cons: Requires careful handling due to fine dust. |

| Silicon Carbide Nanoparticles | Nanoscale, unique optical and electronic properties | Nanotechnology applications, coatings | Pros: Innovative applications, high performance. Cons: Limited availability, can be expensive. |

| Silicon Carbide Grit | Coarse particle size, used in abrasive processes | Sandblasting, polishing | Pros: Durable and effective for heavy-duty applications. Cons: Less suitable for precision tasks. |

Black Silicon Carbide (SiC) is known for its high hardness and low thermal conductivity. This type is commonly used in abrasives and cutting tools due to its excellent wear resistance. B2B buyers in sectors like metalworking and construction often prefer black SiC for its cost-effectiveness. However, it's important to note that while it performs well in dry applications, its brittleness can be a drawback in wet environments.

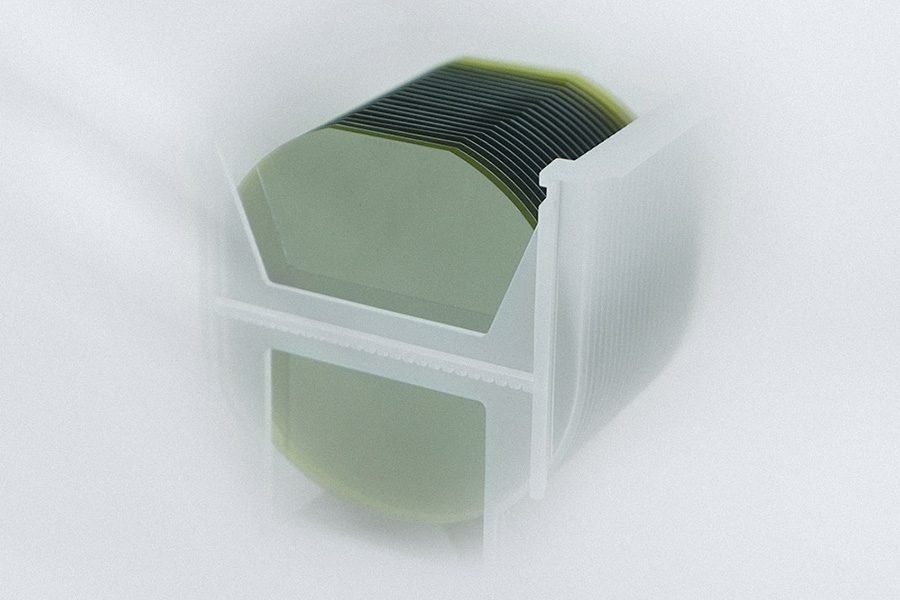

A stock image related to siliziumkarbidpulver.

Green Silicon Carbide features higher purity levels and better thermal conductivity compared to its black counterpart. It is predominantly utilized in electronics and semiconductor manufacturing, where high performance and reliability are critical. B2B buyers should weigh the benefits of its excellent thermal stability against the higher costs associated with its production. This type is suitable for applications requiring precision and high-quality materials.

Micro Silica Carbide is characterized by its very fine particle size and high surface area, making it ideal for advanced ceramics and composite materials. This type enhances the strength and durability of products, making it appealing for manufacturers looking to improve material properties. However, its fine dust can pose handling challenges, so buyers should consider appropriate safety measures during procurement and use.

Silicon Carbide Nanoparticles are notable for their unique optical and electronic properties at the nanoscale. They find applications in nanotechnology, advanced coatings, and high-performance materials. For B2B buyers, the innovative potential of these nanoparticles can lead to cutting-edge products. However, limited availability and higher costs may restrict their use, necessitating careful consideration of budget and application requirements.

Silicon Carbide Grit is typically available in coarse particle sizes, making it suitable for abrasive processes such as sandblasting and polishing. Its durability ensures effective performance in heavy-duty applications, appealing to industries like manufacturing and automotive. However, this grit may not be ideal for precision tasks, so buyers should evaluate their specific application needs before selection.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of siliziumkarbidpulver | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of high-performance ceramic matrix composites (CMCs) | Enhances thermal resistance and reduces weight, improving fuel efficiency | Quality certifications, supplier reliability, and compliance with aerospace standards |

| Automotive | Production of brake pads and clutches | Increases durability and performance under high-stress conditions | Consistency in particle size, purity levels, and delivery schedules |

| Electronics | Semiconductor manufacturing | Facilitates high thermal conductivity and electrical performance | Material purity, sourcing from reputable suppliers, and compliance with industry standards |

| Metalworking | Abrasive tools and grinding applications | Provides superior cutting efficiency and tool longevity | Specification of grit size, bonding agents, and supplier experience |

| Renewable Energy | Solar cell production | Improves efficiency and durability of photovoltaic cells | Material sourcing transparency, cost-effectiveness, and technical support availability |

In the aerospace sector, siliziumkarbidpulver is essential for creating ceramic matrix composites (CMCs). These materials are used in engine components that require high thermal resistance and lightweight properties. By incorporating silicon carbide powder, manufacturers can significantly enhance fuel efficiency and operational performance. For international B2B buyers, especially in regions like Africa and Europe, it is crucial to ensure that suppliers meet stringent aerospace quality certifications and standards.

In automotive applications, siliziumkarbidpulver is widely utilized in the production of brake pads and clutches. The material enhances the durability and performance of these components under extreme conditions, such as high temperatures and mechanical stress. This leads to improved vehicle safety and reliability. Buyers from South America and the Middle East should focus on sourcing silicon carbide powder that offers consistent particle size and purity to ensure optimal performance.

For the electronics industry, siliziumkarbidpulver is a critical material in semiconductor manufacturing. Its high thermal conductivity and excellent electrical performance make it ideal for use in high-power devices. This contributes to improved efficiency and longevity of electronic components. B2B buyers in Europe and Africa must prioritize sourcing from reputable suppliers who can guarantee material purity and compliance with industry-specific regulations.

In metalworking, siliziumkarbidpulver is primarily used in the production of abrasive tools and grinding applications. Its unique properties allow for superior cutting efficiency and extended tool life, which are vital for maintaining productivity in manufacturing processes. Buyers should consider the specifications related to grit size and bonding agents when sourcing silicon carbide powder, ensuring that suppliers have a proven track record in the industry.

Siliziumkarbidpulver is increasingly being integrated into solar cell production, enhancing the efficiency and durability of photovoltaic cells. This application is particularly important as the demand for renewable energy solutions grows globally. For international buyers, especially in regions like South America and Africa, it is essential to evaluate suppliers based on material transparency, cost-effectiveness, and the availability of technical support to ensure successful integration into solar technologies.

Related Video: Commonly Used Injection // Common Injections and Their Uses

The Problem:

B2B buyers often face challenges in sourcing siliziumkarbidpulver (silicon carbide powder) due to the variability in quality and specifications across different suppliers. This inconsistency can lead to significant issues in production processes, especially in industries such as electronics or manufacturing where high-performance materials are critical. Buyers may find themselves receiving subpar materials that do not meet their required standards, resulting in increased costs, wasted resources, and potential delays in project timelines.

The Solution:

To mitigate quality variability, buyers should implement a robust vendor evaluation process before engaging with suppliers. Start by requesting samples of siliziumkarbidpulver from multiple sources and conducting rigorous testing to evaluate properties such as particle size distribution, purity, and hardness. Establishing clear specifications based on your application requirements can help filter out unsuitable suppliers. Additionally, consider leveraging third-party testing laboratories for independent quality verification. Building long-term relationships with reputable suppliers can also provide consistency; seek out companies with a proven track record in the industry, and don’t hesitate to ask for customer references or case studies to gauge their reliability.

The Problem:

B2B buyers often struggle with understanding the specific requirements for siliziumkarbidpulver in their applications, which can vary significantly across industries. For instance, the semiconductor industry may require ultra-fine powders for precise applications, whereas the automotive sector might need coarser grades for abrasive materials. Misalignment between the product specifications and application needs can lead to performance issues, product failures, and costly rework.

The Solution:

To address this challenge, buyers should invest time in understanding the unique requirements of their specific application. Collaborate closely with engineering teams to identify the desired characteristics of the siliziumkarbidpulver, such as grain size, morphology, and thermal stability. Engaging with suppliers who specialize in application-specific solutions can also be beneficial. They can provide expert insights and recommendations tailored to your needs. Furthermore, consider participating in industry forums or workshops where you can share experiences and gather knowledge about the best practices in using siliziumkarbidpulver in your specific field.

The Problem:

International B2B buyers, particularly from regions like Africa and South America, often experience supply chain disruptions that affect the timely delivery of siliziumkarbidpulver. Factors such as geopolitical issues, transportation delays, and fluctuating demand can result in longer lead times, making it difficult for companies to maintain production schedules and meet customer demands.

The Solution:

To effectively manage supply chain risks, buyers should diversify their supplier base by establishing relationships with multiple vendors across different geographical locations. This strategy helps mitigate the impact of regional disruptions. Implementing a just-in-time inventory system can also be advantageous, as it allows for more flexible response times to demand changes. Additionally, maintaining open lines of communication with suppliers regarding their capabilities and potential challenges can lead to better forecasting and planning. Utilizing technology such as supply chain management software can provide visibility into inventory levels and lead times, enabling proactive decision-making to avoid production halts.

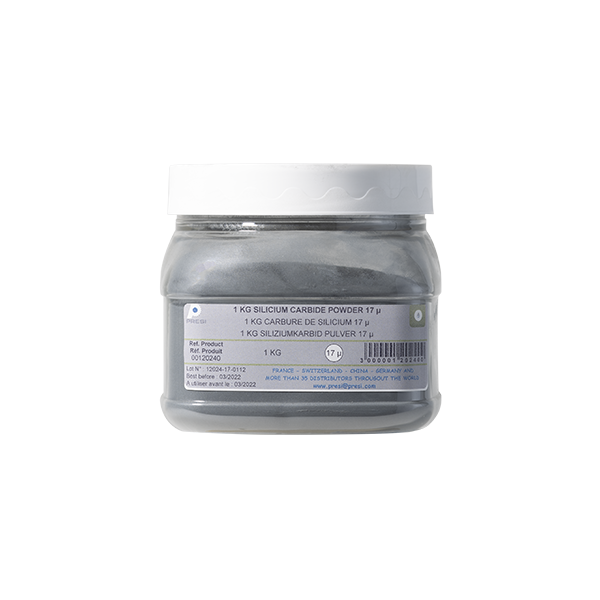

A stock image related to siliziumkarbidpulver.

Siliziumkarbidpulver, or silicon carbide powder, is a versatile material used in various applications, particularly in abrasive and semiconductor industries. Understanding the materials that can be utilized in its production is crucial for international B2B buyers. Here, we analyze several common materials relevant to siliziumkarbidpulver, focusing on their properties, advantages, disadvantages, and implications for buyers from regions such as Africa, South America, the Middle East, and Europe.

Key Properties: Silicon carbide exhibits exceptional thermal conductivity, high-temperature resistance (up to 1600°C), and excellent wear resistance. It is also chemically inert, making it suitable for various corrosive environments.

Pros & Cons: The durability of SiC is a significant advantage, providing long-lasting performance in abrasive applications. However, the cost of high-purity SiC can be high, and its manufacturing process is complex, often requiring specialized equipment.

Impact on Application: SiC is compatible with a wide range of media, including oils, gases, and corrosive chemicals, making it ideal for use in harsh environments. Its high hardness makes it suitable for cutting, grinding, and polishing applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should ensure that suppliers can provide documentation for the material's purity and performance characteristics.

Key Properties: Alumina is known for its high melting point (around 2050°C) and excellent hardness. It also offers good electrical insulation properties and resistance to wear and corrosion.

Pros & Cons: The main advantage of alumina is its cost-effectiveness compared to SiC. However, it is less durable under high-temperature conditions and may not perform as well in highly corrosive environments.

Impact on Application: Alumina is commonly used in applications requiring electrical insulation and moderate wear resistance. It is suitable for environments where temperatures do not exceed its limits.

Considerations for International Buyers: Buyers should be aware of the specific grades of alumina available and their compatibility with local regulations. Certifications that meet regional standards can enhance trust in the material's quality.

Key Properties: Boron carbide is one of the hardest materials known, with a high melting point (around 2450°C). It has excellent neutron absorption properties, making it unique for specific applications.

Pros & Cons: The extreme hardness of boron carbide makes it suitable for abrasive applications and armor materials. However, its high cost and the complexity of its manufacturing process can be limiting factors.

Impact on Application: Due to its hardness, boron carbide is often used in cutting tools and protective gear. Its neutron absorption capability makes it valuable in nuclear applications.

Considerations for International Buyers: Buyers in regions with stringent safety and environmental regulations, such as Europe, should verify compliance with local standards. Documentation regarding the sourcing and processing of boron carbide is essential for transparency.

Key Properties: Zirconia offers high thermal stability and mechanical strength, with a melting point of about 2700°C. It is also known for its resistance to corrosion and wear.

Pros & Cons: The key advantage of zirconia is its exceptional toughness and thermal resistance, making it suitable for high-performance applications. However, it can be more expensive than other materials, and its processing requires specialized techniques.

Impact on Application: Zirconia is often used in applications such as dental ceramics and high-performance cutting tools, where both strength and aesthetic qualities are necessary.

Considerations for International Buyers: Buyers should consider the availability of zirconia in their region and the associated costs. Compliance with international standards for quality assurance is also vital.

| Material | Typical Use Case for siliziumkarbidpulver | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Abrasives, semiconductors | High durability and thermal resistance | High cost, complex manufacturing | High |

| Alumina | Electrical insulation, moderate abrasives | Cost-effective, good insulation properties | Less durable at high temperatures | Medium |

| Boron Carbide | Cutting tools, armor materials | Extreme hardness | High cost, complex manufacturing | High |

| Zirconia | Dental ceramics, high-performance tools | Exceptional toughness and thermal stability | Higher processing costs | High |

This guide aims to equip international B2B buyers with actionable insights into the strategic selection of materials for siliziumkarbidpulver, ensuring informed decision-making that aligns with regional standards and application requirements.

The manufacturing of siliziumkarbidpulver (silicon carbide powder) involves several critical stages, each designed to ensure the final product meets the required specifications for various industrial applications.

Material Preparation: The initial stage involves sourcing high-purity raw materials, primarily silica sand and petroleum coke. These materials must undergo rigorous screening and purification processes to eliminate impurities that can affect the quality of the final product. For international buyers, ensuring the supplier has reliable sourcing channels and quality materials is crucial.

Forming: Once the raw materials are prepared, they are mixed in specific proportions and subjected to high-temperature processes such as carbothermal reduction. This stage is vital, as the chemical reactions taking place will determine the structural integrity and properties of the silicon carbide produced. Techniques like fluidized bed reactors may be used for better control over the reaction conditions.

Grinding and Milling: After the initial formation, the silicon carbide is cooled and then ground into fine powder using ball mills or jet mills. This step is essential for achieving the desired particle size distribution, which is critical for applications in abrasives, ceramics, and electronics.

Finishing: The final stage includes additional processing steps like classification, where the powder is separated based on particle size. This may also involve surface treatments to enhance the powder's properties, such as improving its wettability or flowability.

Quality assurance in the manufacturing of siliziumkarbidpulver is paramount, especially for international B2B transactions. Buyers must be aware of relevant standards and checkpoints throughout the production process.

International Standards: Compliance with international standards such as ISO 9001 ensures that manufacturers follow a quality management system that consistently meets customer and regulatory requirements. Additionally, certifications like CE mark and industry-specific standards (e.g., API for the petroleum industry) further validate the quality of the product.

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for purity and quality before they enter the production process.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages ensures that any deviations from specified parameters are corrected immediately.

- Final Quality Control (FQC): The finished product undergoes comprehensive testing to confirm that it meets all specified criteria before shipment.

Common Testing Methods: Various testing methods are employed to assess the properties of siliziumkarbidpulver, including:

- Particle Size Analysis: Techniques like laser diffraction or sieve analysis help determine the distribution of particle sizes.

- Chemical Composition Testing: X-ray fluorescence (XRF) or scanning electron microscopy (SEM) can be utilized to analyze the chemical makeup of the powder.

- Thermal Analysis: Differential thermal analysis (DTA) can evaluate the thermal stability of the product.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to ensure the reliability and performance of siliziumkarbidpulver.

Supplier Audits: Conducting on-site audits allows buyers to review the manufacturing processes, quality control systems, and compliance with international standards. This direct engagement provides insights into the operational capabilities of the supplier.

Quality Reports: Requesting detailed quality reports that outline the results of IQC, IPQC, and FQC can help buyers assess the consistency and reliability of the supplier's products. These reports should include data on testing methods used and any corrective actions taken in case of quality issues.

Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier's manufacturing processes and final products. This is particularly important for buyers who may not have the resources to conduct their own audits.

Understanding the nuances of quality control and certification is crucial for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe.

Regional Standards Variability: Different regions may have varying standards for siliziumkarbidpulver. For example, European buyers often prioritize CE marking, while buyers in the Middle East may look for compliance with local regulatory frameworks. Familiarizing oneself with these regional standards can streamline the procurement process.

Documentation and Compliance: Buyers should ensure that suppliers provide complete documentation, including material safety data sheets (MSDS), certificates of analysis (CoA), and compliance certificates. This documentation is essential for regulatory compliance and for ensuring the safety and quality of the product.

Long-term Relationships: Establishing long-term relationships with suppliers can enhance the reliability of quality control. Continuous engagement and feedback loops can help in aligning quality expectations and improving processes over time.

Cultural Considerations: Understanding cultural differences in business practices can also play a role in negotiations and supplier relationships. Building trust and effective communication is vital for ensuring quality standards are met.

By paying close attention to the manufacturing processes and quality assurance measures outlined above, international B2B buyers can make informed decisions when sourcing siliziumkarbidpulver, ultimately ensuring the success of their operations across various industries.

To effectively procure siliziumkarbidpulver (silicon carbide powder), international B2B buyers should follow a structured approach to ensure they select the right suppliers and products that meet their specific requirements. This checklist serves as a practical guide for sourcing silicon carbide powder, particularly useful for buyers from Africa, South America, the Middle East, and Europe.

Clearly outline the specific characteristics and quality requirements for the silicon carbide powder you need. This includes particle size, purity levels, and any relevant certifications.

- Why it Matters: Precise specifications help in filtering suppliers who can meet your needs and avoid potential quality issues.

- What to Look For: Industry standards that apply to your application, such as ASTM or ISO certifications, should be referenced.

Investigate the current market landscape for silicon carbide powder. This involves identifying key suppliers, pricing trends, and product availability.

- Why it Matters: Understanding the market helps in making informed decisions about pricing and supplier selection.

- What to Look For: Reports on industry trends, competitor sourcing strategies, and reviews of popular suppliers.

Before making a commitment, it is crucial to thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Why it Matters: A comprehensive evaluation reduces the risk of partnering with unreliable suppliers.

- What to Look For: Check for years of experience in the industry, customer testimonials, and any awards or recognitions they have received.

Always ask for product samples to assess quality before placing a bulk order. Testing samples in your application can reveal compatibility and performance.

- Why it Matters: Evaluating samples ensures that the product meets your technical specifications and quality standards.

- What to Look For: Consistency in particle size, absence of contaminants, and overall performance in your specific application.

Ensure that your potential suppliers have the necessary certifications and adhere to quality management systems such as ISO 9001.

- Why it Matters: Certifications demonstrate a commitment to quality and regulatory compliance, which is crucial for maintaining industry standards.

- What to Look For: Copies of certifications, recent audit results, and any quality assurance processes in place.

Evaluate the supplier’s ability to meet your delivery timelines and manage logistics effectively.

- Why it Matters: Reliable supply chain capabilities are essential for maintaining consistent production schedules.

- What to Look For: Their track record in shipping times, logistics partnerships, and flexibility in order quantities.

Once you've selected a supplier, discuss and negotiate pricing, payment terms, and delivery schedules.

- Why it Matters: Clear terms prevent misunderstandings and ensure both parties are aligned on expectations.

- What to Look For: Detailed contracts outlining responsibilities, penalties for non-compliance, and dispute resolution mechanisms.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing silicon carbide powder effectively, ensuring they select the best suppliers for their needs.

Understanding the cost structure of siliziumkarbidpulver (silicon carbide powder) is crucial for international B2B buyers. The main cost components can be categorized as follows:

Materials: The primary raw material for siliziumkarbidpulver is silicon carbide itself. Prices can fluctuate based on global supply and demand, as well as the purity and quality of the silicon carbide sourced. Buyers should also consider the sourcing location, as local tariffs and import duties may apply.

Labor: Labor costs will vary significantly depending on the region where manufacturing occurs. In countries with lower wage rates, such as those in parts of Africa and South America, buyers may find more competitive pricing. However, it’s essential to assess the skill level and training of the labor force to ensure quality production.

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and indirect labor. Overhead can be a substantial part of the total cost, particularly in regions with higher energy costs or stringent environmental regulations.

Tooling: Initial tooling costs for production can be high, especially for custom specifications. Buyers should discuss tooling costs upfront, as these can be amortized over large orders, reducing the per-unit cost.

Quality Control (QC): Implementing quality assurance processes is vital to ensure the product meets industry standards. The cost of QC can vary based on the complexity of testing required and the certifications needed for different markets.

Logistics: Shipping costs can greatly affect the total price. Factors such as distance, shipping method, and local infrastructure play significant roles. Additionally, understanding Incoterms is essential to determine who bears the shipping costs and risks.

Margin: Suppliers will include their profit margin in the final pricing. Margins can vary widely based on the supplier’s market position and the competitive landscape.

Several factors can influence the pricing of siliziumkarbidpulver:

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield better pricing due to economies of scale. Buyers should negotiate MOQs to find a balance between sufficient supply and cost efficiency.

Specifications and Customization: Customized products often come at a premium. Buyers should clearly define specifications to avoid unexpected costs and delays.

Quality and Certifications: Higher quality products and certifications (e.g., ISO, RoHS) can increase costs but may be necessary for certain applications. Buyers should weigh the benefits of certification against the additional cost.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

Incoterms: Understanding the implications of Incoterms can help buyers manage their logistics costs effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate responsibilities and can affect the total landed cost.

International B2B buyers can adopt several strategies to optimize their sourcing of siliziumkarbidpulver:

Negotiation: Leverage volume and long-term contracts to negotiate better pricing. Building a relationship with suppliers can also lead to more favorable terms.

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess the TCO, which includes shipping, handling, and any potential costs associated with product failure or quality issues.

Market Research: Stay informed about market trends and pricing fluctuations. Understanding the global market dynamics can empower buyers during negotiations.

Supplier Diversification: Avoid dependence on a single supplier. Having multiple sources can enhance bargaining power and mitigate risks related to supply chain disruptions.

Regional Considerations: Buyers from Africa, South America, the Middle East, and Europe should consider local regulations and economic conditions, as these can significantly affect sourcing strategies and costs.

While the pricing landscape for siliziumkarbidpulver can be complex, understanding the cost components, price influencers, and strategic procurement tips can empower international B2B buyers to make informed decisions. It is essential to remain flexible and adaptable to market conditions, ensuring that sourcing strategies align with overall business goals. Note that prices can vary widely based on these factors, and the information provided here is indicative.

When evaluating options for industrial applications, it's essential to consider the strengths and weaknesses of various materials. Siliziumkarbidpulver (silicon carbide powder) is a popular choice due to its unique properties, but several alternatives may also fit specific needs for B2B buyers in regions such as Africa, South America, the Middle East, and Europe. Understanding these alternatives can help companies make informed decisions that align with their operational goals.

| Comparison Aspect | Siliziumkarbidpulver | Alternative 1: Aluminum Oxide | Alternative 2: Boron Carbide |

|---|---|---|---|

| Performance | High thermal conductivity, excellent hardness | Good hardness, lower thermal conductivity | Extremely high hardness, resistant to wear |

| Cost | Moderate to high | Lower than silicon carbide | High due to rarity and processing |

| Ease of Implementation | Requires specialized handling | Generally easier to handle and apply | Requires careful handling and mixing |

| Maintenance | Low, but requires protective measures | Low, standard precautions needed | Moderate, can be brittle under stress |

| Best Use Case | High-temperature applications, abrasive products | General-purpose abrasives, cutting tools | Defense applications, specialized abrasives |

Aluminum oxide is a prevalent alternative to siliziumkarbidpulver, especially in the abrasive industry. Its lower cost makes it an attractive option for businesses looking to minimize expenses while still achieving satisfactory performance. However, it does not match the thermal conductivity or hardness of silicon carbide, which could limit its effectiveness in high-temperature applications. This makes aluminum oxide best suited for general-purpose use, such as in grinding and cutting tools.

Boron carbide is known for its extreme hardness and resistance to wear, making it one of the hardest materials available. This quality makes it ideal for specialized applications, such as in defense and armor-piercing projectiles. However, its high cost and the brittle nature can pose challenges in handling and application. Boron carbide is best utilized where extreme durability is required, but it may not be the most cost-effective option for all businesses.

When selecting between siliziumkarbidpulver and its alternatives, B2B buyers should assess their specific application requirements, including performance expectations, budget constraints, and ease of implementation. Each material offers unique advantages and disadvantages, so understanding these factors will help businesses make informed decisions. For companies operating in diverse markets like Africa, South America, the Middle East, and Europe, aligning the material choice with operational demands and local market conditions is crucial to achieving optimal results.

When sourcing siliziumkarbidpulver (silicon carbide powder), international B2B buyers should be aware of several critical technical properties that can affect performance and compatibility with various applications. Here are some essential specifications to consider:

Material Grade

- Definition: This refers to the purity and composition of the silicon carbide powder, typically categorized into grades like green silicon carbide (SiC) and black silicon carbide.

- Importance: Higher-grade materials offer superior hardness and thermal conductivity, making them suitable for demanding applications such as abrasives, electronics, and ceramics. Selecting the right grade ensures product effectiveness and longevity.

Particle Size Distribution

- Definition: This measures the range of particle sizes within the silicon carbide powder, often specified in micrometers (µm).

- Importance: A well-defined particle size affects the material's flowability and packing density, which are crucial for applications in grinding and polishing. Buyers must ensure the particle size aligns with their production needs to optimize performance.

Tolerances

- Definition: Tolerances refer to the allowable deviations from specified dimensions or properties in the silicon carbide powder.

- Importance: Strict tolerances ensure consistency in manufacturing processes, which is vital for high-precision applications. Understanding tolerances helps buyers mitigate risks associated with product variations.

Density

- Definition: The density of silicon carbide powder is typically measured in grams per cubic centimeter (g/cm³).

- Importance: Density influences the material's mechanical strength and thermal properties. Buyers should consider density when evaluating the suitability of the powder for specific applications, particularly in high-temperature environments.

Chemical Composition

- Definition: This indicates the elemental makeup of the silicon carbide powder, including impurities and additives.

- Importance: Different applications may require specific chemical compositions to achieve desired characteristics. Buyers need to assess chemical composition to avoid issues related to compatibility and performance in their end products.

Understanding industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms related to siliziumkarbidpulver:

OEM (Original Equipment Manufacturer)

- Definition: An OEM is a company that produces components that are used in another company's end products.

- Importance: Buyers should identify if their suppliers are OEMs to ensure they are sourcing high-quality materials that meet specific performance standards required for their applications.

MOQ (Minimum Order Quantity)

- Definition: This term refers to the minimum amount of product a supplier is willing to sell.

- Importance: Understanding MOQ is crucial for budget planning and inventory management. Buyers should negotiate MOQs that align with their production needs to avoid excess inventory costs.

RFQ (Request for Quotation)

- Definition: An RFQ is a document sent to suppliers to request pricing and other information for specific products.

- Importance: Issuing an RFQ helps buyers compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. A well-crafted RFQ can lead to better pricing and terms.

Incoterms (International Commercial Terms)

- Definition: Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions.

- Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs, allowing for smoother logistics and clearer communication with suppliers.

Lead Time

- Definition: This refers to the amount of time from placing an order to receiving the product.

- Importance: Knowing the lead time is essential for production planning and inventory management. Buyers should consider lead times when placing orders to ensure timely delivery and avoid production delays.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing siliziumkarbidpulver, ultimately leading to improved product quality and operational efficiency.

The global market for siliziumkarbidpulver (silicon carbide powder) is experiencing robust growth, driven by increased demand in sectors such as electronics, automotive, and aerospace. The rise of electric vehicles (EVs) and the push for renewable energy solutions are significant factors propelling this trend. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to capitalize on these opportunities, understanding the nuances of market dynamics becomes crucial.

Emerging technologies in the production of silicon carbide powder are reshaping sourcing strategies. Automation and advanced manufacturing techniques are enabling suppliers to produce higher-quality materials with reduced costs. Additionally, the digitalization of supply chains is facilitating better transparency and efficiency, allowing buyers to track sourcing from production to delivery. Buyers should focus on suppliers who leverage these technologies for competitive pricing and quality assurance.

Moreover, fluctuating raw material prices and geopolitical factors are influencing sourcing strategies. B2B buyers must stay informed about market forecasts and engage in strategic partnerships to mitigate risks associated with supply chain disruptions. The rise of regional suppliers in Africa and South America presents new opportunities for buyers looking for localized sourcing options, potentially reducing lead times and costs.

Sustainability is becoming a critical consideration in the procurement process for siliziumkarbidpulver. The environmental impact of silicon carbide production, particularly in terms of energy consumption and emissions, is prompting buyers to seek out suppliers committed to sustainable practices. These practices can include the use of renewable energy sources, waste reduction initiatives, and more efficient manufacturing processes.

Ethical sourcing is equally vital, as B2B buyers increasingly prefer suppliers who uphold strong labor standards and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers aiming to attract conscientious buyers. By partnering with certified suppliers, companies can enhance their brand reputation and appeal to a growing market segment that prioritizes sustainability.

Furthermore, the demand for 'green' materials is on the rise. Buyers should explore options for silicon carbide that are produced with less environmental impact, including recycled materials or those sourced from sustainable practices. This not only meets regulatory demands but also aligns with consumer preferences for eco-friendly products.

The siliziumkarbidpulver sector has evolved significantly over the last few decades. Initially, its primary applications were limited to abrasives and cutting tools. However, advancements in material science and technology have expanded its use into high-performance applications, including semiconductors and power electronics.

The shift towards electric vehicles and renewable energy systems has further accelerated the demand for silicon carbide due to its superior thermal conductivity and efficiency in high-voltage applications. This evolution reflects a broader trend in the materials industry, where traditional materials are being re-evaluated for new applications, driving innovation and competitive sourcing strategies.

As international B2B buyers navigate this dynamic landscape, understanding these historical shifts can provide context for current sourcing decisions and future market trends.

How do I select the right siliziumkarbidpulver supplier for my business needs?

To select the ideal supplier for siliziumkarbidpulver, start by evaluating their industry experience and reputation. Look for suppliers with proven track records in your specific application area, whether it be abrasives, ceramics, or electronics. Request samples to assess product quality and consistency. Additionally, check their certifications and compliance with international standards, especially if you're sourcing from regions with varying regulatory environments. Finally, consider their logistical capabilities to ensure timely delivery to your location in Africa, South America, the Middle East, or Europe.

What are the typical minimum order quantities (MOQs) for siliziumkarbidpulver?

Minimum order quantities for siliziumkarbidpulver can vary significantly based on the supplier and your specific requirements. Generally, MOQs range from 100 kg to several tons, depending on the grade and application of the material. For international buyers, it’s crucial to negotiate MOQs that align with your production needs while ensuring that they are economically viable. Some suppliers may offer flexibility on MOQs for first-time orders or long-term contracts, so it’s advisable to discuss your circumstances openly.

What payment terms should I expect when sourcing siliziumkarbidpulver internationally?

Payment terms can differ widely among suppliers, but typical practices include options such as advance payment, letters of credit, or payment upon delivery. For international transactions, it’s common to negotiate a 30% deposit with the balance due upon shipment. Ensure that the payment terms are clear and documented in the contract to avoid any misunderstandings. Using secure payment methods can also provide an additional layer of protection against fraud, particularly when dealing with new suppliers.

How can I ensure the quality of siliziumkarbidpulver before purchasing?

To ensure quality, request a Certificate of Analysis (CoA) from the supplier, which details the chemical composition and physical properties of the siliziumkarbidpulver. Conduct thorough supplier audits if possible, focusing on their manufacturing processes and quality control measures. Additionally, consider third-party testing of samples before making a bulk order. Establishing a robust quality assurance process can mitigate risks associated with subpar materials, especially for critical applications in your production line.

What factors should I consider regarding logistics and shipping for siliziumkarbidpulver?

When planning logistics for siliziumkarbidpulver, consider the weight and bulk of the material, as it can influence shipping costs. Evaluate the shipping methods available, such as air freight for urgent needs or sea freight for cost-effective bulk orders. Ensure that the supplier has reliable logistics partnerships to avoid delays. Additionally, factor in customs clearance processes and potential tariffs that may apply based on your country’s trade agreements with the supplier’s country.

Can siliziumkarbidpulver be customized for specific applications?

Yes, many suppliers offer customization options for siliziumkarbidpulver to meet specific application needs, such as varying particle sizes or chemical compositions. When discussing customization, provide detailed specifications regarding your intended use, whether for abrasive materials, semiconductor applications, or other industrial uses. Be prepared to collaborate with the supplier on formulations or processing techniques to achieve the desired properties, ensuring that the customized product aligns with your production requirements.

What are the common applications of siliziumkarbidpulver in different industries?

Siliziumkarbidpulver is widely used across several industries due to its hardness and thermal conductivity. Common applications include abrasives for grinding and cutting tools, components in ceramics and refractory materials, and as a semiconductor material in electronics. Additionally, it plays a role in manufacturing automotive parts, solar cells, and various industrial coatings. Understanding these applications can help you identify the right grade of siliziumkarbidpulver for your business needs.

How do I navigate international trade regulations when sourcing siliziumkarbidpulver?

Navigating international trade regulations requires thorough research into both your country's import regulations and those of the supplier’s country. Ensure compliance with safety standards and environmental regulations, which may differ significantly across regions. Engaging a customs broker can help streamline the import process and provide guidance on tariffs and documentation. Additionally, stay informed about trade agreements that could benefit your sourcing strategy, particularly if you are purchasing from suppliers in regions like Europe or the Middle East.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of siliziumkarbidpulver is crucial for international B2B buyers aiming to enhance their supply chain efficiency and product quality. By prioritizing partnerships with reliable suppliers, companies can secure favorable pricing, ensure consistent quality, and mitigate risks associated with market volatility. Buyers from Africa, South America, the Middle East, and Europe, such as those in Argentina and Egypt, should focus on developing strong relationships with manufacturers that offer transparency and adaptability to meet their specific needs.

Moreover, leveraging technology and data analytics in the sourcing process can lead to smarter purchasing decisions, enabling businesses to forecast demand and optimize inventory management effectively. As the global market for siliziumkarbidpulver continues to evolve, staying informed about industry trends and innovations will empower buyers to capitalize on new opportunities.

Now is the time to reassess your sourcing strategies and engage with suppliers who align with your business goals. By doing so, you can drive growth, enhance operational efficiency, and secure a competitive edge in the market. Embrace the future of sourcing and take proactive steps toward building a resilient supply chain that meets your needs and exceeds your expectations.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina