In today's competitive global market, sourcing reliable suppliers for white fused alumina and understanding the associated Material Safety Data Sheets (MSDS) can be a daunting task for international B2B buyers. As industries in regions such as Africa, South America, the Middle East, and Europe expand, the demand for high-quality abrasives like white fused alumina grows, necessitating a thorough understanding of their properties and safe handling practices. This guide aims to demystify the complexities surrounding white fused alumina MSDS, equipping buyers with essential knowledge on various types, applications, and the critical elements of supplier vetting.

Throughout this comprehensive resource, you will find detailed insights into the applications of white fused alumina across different sectors, including manufacturing and construction, along with guidance on evaluating suppliers based on quality, reliability, and compliance with safety standards. Additionally, we will cover cost considerations and procurement strategies that can lead to more informed purchasing decisions.

By leveraging this guide, B2B buyers from diverse regions, including Italy and Kenya, can confidently navigate the market landscape, ensuring they select the most suitable products that meet their operational needs while adhering to safety regulations. Empowering buyers with knowledge not only fosters better supplier relationships but also enhances overall procurement efficiency in an increasingly interconnected global economy.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard White Fused Alumina | High purity, low iron content, excellent hardness | Abrasives, refractory materials, ceramic products | Pros: Cost-effective, widely available. Cons: Limited performance in extreme conditions. |

| Calcined White Fused Alumina | Higher temperature stability, fine particle size | High-performance ceramics, advanced refractories | Pros: Enhanced durability, improved thermal properties. Cons: Higher cost compared to standard types. |

| White Fused Alumina for Blasting | Uniform grain size, sharp edges for effective blasting | Surface preparation, metal finishing | Pros: Efficient for surface treatment. Cons: May generate more dust during use. |

| White Fused Alumina for Grinding | Specific grain shapes for precision grinding applications | Precision grinding, polishing | Pros: High precision, excellent surface finish. Cons: Requires specialized equipment. |

| White Fused Alumina for Coatings | Fine particle size for smooth coatings | Paints, coatings, and sealants | Pros: Smooth finish, enhances coating durability. Cons: May require additional processing. |

Standard White Fused Alumina is characterized by its high purity and low iron content, making it suitable for various industrial applications. It is commonly used in the production of abrasives, refractory materials, and ceramic products. B2B buyers should consider its cost-effectiveness and wide availability, but they should also be aware that its performance may be limited in extreme conditions, potentially impacting the longevity of the products made from it.

Calcined White Fused Alumina is known for its enhanced temperature stability and finer particle size compared to standard variants. This type is particularly suitable for high-performance ceramics and advanced refractories, making it ideal for industries that require materials to withstand extreme heat. While it offers improved durability and thermal properties, buyers should note that it comes at a higher cost, which may affect budget considerations.

The White Fused Alumina for Blasting variant is distinguished by its uniform grain size and sharp edges, making it particularly effective for surface preparation and metal finishing. This type is favored in industries that require efficient surface treatment. While it provides an efficient blasting solution, buyers must consider the potential for increased dust generation during use, which may necessitate additional safety measures.

White Fused Alumina for Grinding is designed with specific grain shapes that facilitate precision grinding applications. This type is ideal for tasks that require high precision and excellent surface finishes, such as in the manufacturing of tools and components. However, it may require specialized equipment, which can increase initial investment costs for buyers looking to implement this type into their operations.

White Fused Alumina for Coatings features fine particle sizes that contribute to a smooth finish in paints, coatings, and sealants. Its ability to enhance the durability of coatings makes it a valuable addition in various industries. While it provides significant benefits, buyers should be aware that additional processing may be required to achieve the desired results, which could impact production timelines.

Related Video: White fused alumina, alumina oxide

| Industry/Sector | Specific Application of white fused alumina msds | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives Manufacturing | Production of grinding wheels and abrasive tools | High durability and performance in grinding | Quality of alumina, sourcing certifications, and pricing |

| Refractories | Manufacturing of refractory bricks and linings | Enhanced thermal stability and resistance to wear | Purity levels, consistency of supply, and shipping logistics |

| Ceramics | Production of ceramic tiles and sanitary ware | Improved surface finish and durability | Particle size distribution, compatibility with other materials |

| Metal Casting | Used as a blasting media for metal surfaces | Effective surface preparation for coatings | Grain size, availability, and environmental regulations |

| Electronics | Component in insulating materials for electronics | High thermal conductivity and insulation properties | Compliance with safety standards and material certifications |

In the abrasives manufacturing sector, white fused alumina is primarily used to produce high-performance grinding wheels and abrasive tools. Its exceptional hardness and durability enable manufacturers to create products that withstand heavy use while providing superior cutting efficiency. For international buyers, especially those in regions like Africa and South America, ensuring the quality and consistency of the alumina sourced is crucial, as it directly impacts the performance of the abrasives produced.

In the refractory industry, white fused alumina is a vital component in the production of refractory bricks and linings used in high-temperature applications. Its ability to maintain structural integrity under extreme heat makes it essential for industries such as steel and glass manufacturing. Buyers should prioritize sourcing alumina with high purity levels and consistent supply to ensure the longevity and effectiveness of their refractory products.

The ceramics industry utilizes white fused alumina in the production of tiles and sanitary ware, where it contributes to improved surface finishes and durability. Its fine particle size allows for smooth textures and high aesthetic appeal in finished products. Buyers in Europe, such as those in Italy, should consider the particle size distribution and compatibility with other raw materials to optimize their production processes.

In metal casting, white fused alumina serves as an effective blasting media for preparing metal surfaces before coating. This application ensures a clean and roughened surface, promoting better adhesion of paints and coatings. Buyers should focus on grain size and environmental regulations regarding the use of blasting materials, particularly in the Middle East, where compliance with safety standards is paramount.

In the electronics sector, white fused alumina is used in insulating materials due to its high thermal conductivity and insulation properties. This application is critical for enhancing the performance and reliability of electronic components. International B2B buyers must ensure that their sourcing complies with relevant safety standards and material certifications to mitigate risks associated with product performance and regulatory compliance.

Related Video: Technology | Fused Aluminum Oxide Process | Imerys

The Problem:

B2B buyers in industries such as manufacturing, construction, or abrasives often face challenges in understanding the compliance requirements associated with white fused alumina. Different countries, particularly in Africa, South America, the Middle East, and Europe, have varying regulations regarding material safety data sheets (MSDS). For instance, a buyer in Kenya might struggle to align their sourcing practices with the European Union's REACH regulations, leading to potential legal repercussions and supply chain disruptions.

The Solution:

To navigate these compliance requirements effectively, it is crucial for buyers to establish a robust system for tracking and understanding local regulations. Start by consulting with local regulatory bodies or industry associations that can provide specific guidelines on the necessary MSDS documentation for white fused alumina. Additionally, leverage technology by utilizing compliance management software that can automate updates on regulations affecting your operations. This proactive approach will not only ensure compliance but also build trust with your stakeholders by demonstrating a commitment to safety and regulatory adherence.

The Problem:

Quality inconsistency is a major concern for B2B buyers sourcing white fused alumina from different suppliers. This issue is particularly prevalent in regions with less stringent quality control standards. For instance, a buyer from Brazil might receive a shipment that does not meet the expected specifications, leading to production delays and financial losses. The lack of standardized testing and certification processes can leave buyers vulnerable to subpar products.

The Solution:

To mitigate the risk of quality inconsistency, buyers should implement a rigorous supplier evaluation process. This includes requiring potential suppliers to provide detailed quality certifications, such as ISO 9001, and conducting regular audits of their manufacturing processes. Additionally, buyers can request samples before placing large orders to conduct independent testing. Establishing long-term relationships with reliable suppliers who have a proven track record of quality can also enhance product consistency. Furthermore, consider joining industry groups or forums where suppliers are vetted, ensuring that your sourcing aligns with high-quality standards.

The Problem:

Many B2B buyers lack a comprehensive understanding of the technical specifications and applications of white fused alumina, which can lead to improper usage in their operations. For example, a buyer from Italy may not be aware of the differences between various grades of white fused alumina and how each grade affects their specific application in abrasive products. This knowledge gap can result in inefficient processes and suboptimal product performance.

The Solution:

To bridge the knowledge gap, buyers should invest in training and educational resources focused on the technical aspects of white fused alumina. Engage with suppliers who offer technical support and can provide insights into the best practices for selecting the right grade for specific applications. Additionally, attending industry seminars, webinars, or workshops can enhance understanding of the material's properties and its suitability for various applications. Lastly, consider developing a standardized internal protocol for evaluating and documenting the performance of different grades in your processes, enabling more informed decision-making in the future.

White fused alumina (WFA) is a high-purity, synthetic abrasive material that is produced by melting alumina in an electric arc furnace. Its key properties include high hardness, excellent thermal stability, and resistance to chemical corrosion. These characteristics make WFA suitable for various applications, including abrasive blasting, grinding wheels, and refractory materials. The temperature rating of WFA can reach up to 2000°C, making it ideal for high-temperature applications.

When considering white fused alumina, it is essential to weigh its advantages and disadvantages.

Pros:

- Durability: WFA is highly durable and maintains its properties even under extreme conditions. This makes it a preferred choice for heavy-duty applications.

- Cost-Effectiveness: While the initial cost may be higher than some alternatives, its longevity and performance can lead to lower overall costs in the long run.

- Versatility: It can be used across various industries, including automotive, aerospace, and construction, due to its compatibility with multiple media.

Cons:

- Manufacturing Complexity: The production process of WFA is energy-intensive and requires specialized equipment, which can limit availability in some regions.

- Limited Availability: In certain markets, particularly in Africa and South America, sourcing high-quality WFA can be challenging, impacting supply chain reliability.

The impact of white fused alumina on applications is significant. For instance, in abrasive applications, its hardness and sharpness enhance cutting efficiency and surface finish. In refractory applications, its thermal stability ensures structural integrity under high temperatures, making it suitable for kilns and furnaces. Buyers should consider the specific media compatibility and performance requirements of their applications to ensure optimal results.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of several critical factors when sourcing white fused alumina:

| Material | Typical Use Case for white fused alumina msds | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| White Fused Alumina | Abrasive blasting, grinding wheels, refractory materials | High durability and thermal stability | Manufacturing complexity and limited availability | Medium |

| Brown Fused Alumina | Metalworking, foundry applications | Cost-effective for general applications | Lower hardness compared to WFA | Low |

| Silicon Carbide | High-performance grinding and cutting tools | Exceptional hardness and thermal conductivity | More expensive and brittle | High |

| Zirconia Alumina | Advanced ceramic applications | Excellent wear resistance and toughness | Higher production costs and limited supply | High |

This guide provides essential insights for international B2B buyers looking to make informed decisions regarding the selection of materials for white fused alumina applications. Understanding the properties, advantages, and regional considerations can significantly enhance procurement strategies and application outcomes.

The manufacturing process of white fused alumina involves several critical stages, each contributing to the final product's quality and characteristics. The main stages include:

Material Preparation: This initial stage involves sourcing high-purity raw materials, primarily alumina. The alumina is then crushed and milled to achieve a specific granulation and particle size distribution, which is crucial for the subsequent processing steps.

Forming: The prepared alumina is subjected to high-temperature fusion in an electric arc furnace. This process not only melts the alumina but also forms it into a crystalline structure. The temperature and duration of this step are critical as they directly affect the purity and hardness of the final product.

Cooling and Crystallization: Once the alumina has been fused, it is allowed to cool slowly. This cooling process is essential as it influences the microstructure and, consequently, the performance characteristics of the white fused alumina.

Finishing: After cooling, the solidified alumina is crushed and graded according to specific particle sizes. This step often includes additional processes such as magnetic separation to remove impurities and ensure product purity.

Quality Control: Before packaging, the finished product undergoes rigorous quality checks to ensure it meets the required specifications. This includes testing for hardness, grain size, and chemical composition.

Quality assurance (QA) in the manufacturing of white fused alumina is paramount, especially for international B2B buyers who rely on consistent quality for their applications. Here’s how QA is typically structured:

The production process adheres to several international standards that ensure quality and safety. Key standards include:

Quality control checkpoints play a vital role in maintaining product standards throughout the manufacturing process. Common checkpoints include:

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential. Here are some actionable steps:

Conduct Supplier Audits: Regular on-site audits allow buyers to assess the manufacturing processes and quality control measures firsthand. Audits can help identify any gaps in compliance with international standards.

Request Quality Assurance Reports: Suppliers should provide detailed QA reports that outline their quality control processes, testing methods, and results. These reports can help buyers gauge the reliability of the supplier.

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of product quality. These inspectors can verify that the supplier meets the necessary standards and specifications.

Examine Certifications and Compliance Documentation: Buyers should request copies of certifications (e.g., ISO, CE) and compliance documents to ensure that suppliers adhere to industry standards.

Testing methods for white fused alumina are critical for confirming its quality and suitability for various applications. Common testing methods include:

When dealing with international suppliers, B2B buyers must be aware of specific nuances in quality control:

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing white fused alumina, ensuring they receive high-quality products that meet their specific needs.

To effectively source white fused alumina and obtain the necessary Material Safety Data Sheets (MSDS), B2B buyers should follow a structured approach. This checklist will guide you through the essential steps to ensure that you select a reliable supplier and acquire the right product for your needs.

Before initiating the sourcing process, clearly outline your technical requirements for white fused alumina. This includes understanding the desired grain size, purity levels, and any specific performance characteristics relevant to your applications. Defining these specifications upfront helps streamline the sourcing process and ensures that potential suppliers can meet your exact needs.

Conduct thorough research to identify potential suppliers of white fused alumina. Look for companies with a strong reputation in the industry and positive reviews from past clients. Utilize online platforms, trade directories, and industry associations to compile a list of suppliers that specialize in abrasive materials.

It is crucial to ensure that your selected suppliers hold relevant certifications that validate their quality management systems, such as ISO 9001. These certifications indicate that the supplier adheres to international quality standards, which can significantly affect the reliability of the product you receive. Additionally, confirm that they comply with local regulations concerning hazardous materials.

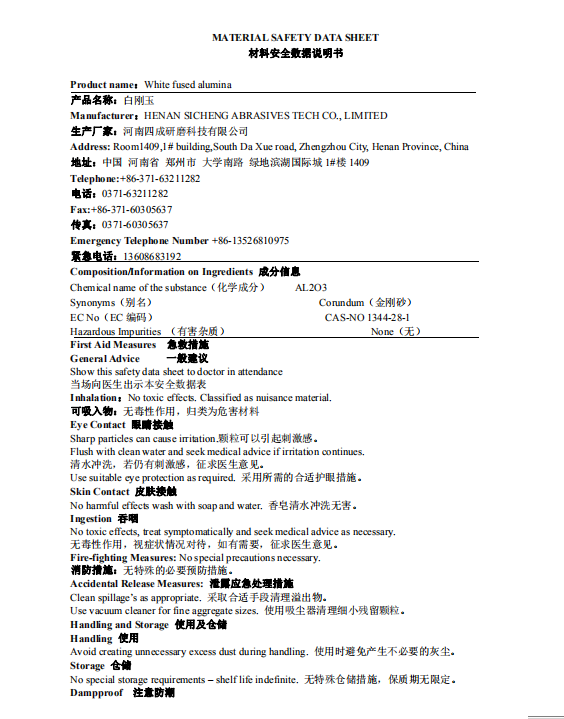

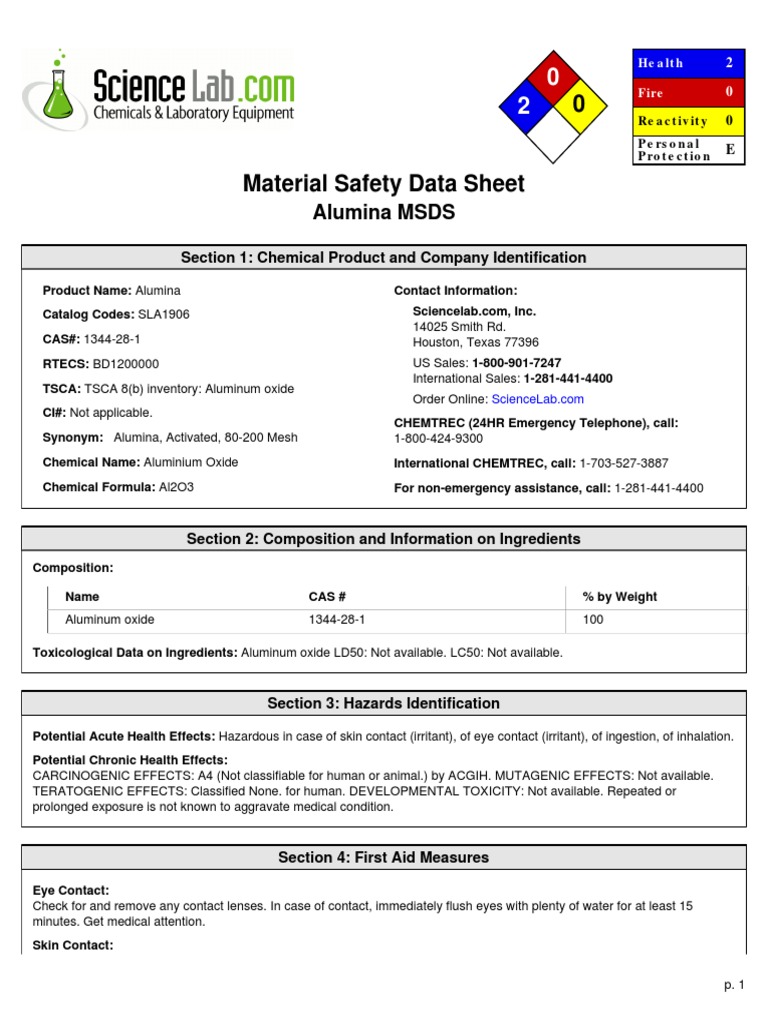

Once you have shortlisted potential suppliers, request their MSDS for the white fused alumina they offer. The MSDS provides vital information regarding the chemical composition, handling precautions, and potential hazards associated with the material. Understanding this information is essential for compliance with safety regulations in your region.

Before making a large order, request samples of the white fused alumina to assess its quality. Conduct tests to verify that the samples meet your specified requirements, such as hardness and chemical stability. This step is critical to ensure that the product will perform as needed in your applications.

Engage in discussions with your selected suppliers about pricing and payment terms. Ensure that you understand the total cost, including shipping and any customs fees if importing from abroad. Negotiating favorable terms can lead to cost savings and better overall value for your procurement.

After selecting a supplier, establish clear communication channels to facilitate ongoing interactions. This includes setting expectations for response times and regular updates on order statuses. A strong communication plan helps prevent misunderstandings and ensures a smooth procurement process.

By following this checklist, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can successfully navigate the sourcing process for white fused alumina and ensure compliance with safety standards.

When sourcing white fused alumina, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The raw material for white fused alumina is bauxite, which can fluctuate significantly in price based on global demand and local availability. Buyers should monitor market trends and consider sourcing from multiple suppliers to mitigate risks associated with price volatility.

Labor: Labor costs vary by region and can impact the overall pricing. In regions like Africa and South America, labor may be less expensive compared to Europe. However, ensure that the supplier complies with local labor laws and standards to avoid potential liabilities.

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Efficient production processes can lower these costs, so inquire about the supplier’s operational efficiencies.

Tooling: If custom tooling is required for specific applications, this can add to the initial costs. Discuss tooling requirements upfront to ensure they fit within your budget.

Quality Control (QC): Investing in QC processes is essential to maintain product consistency and reliability. Ensure that suppliers have robust QC measures in place, as the costs associated with rework or returns can be significant.

Logistics: Transportation costs can vary widely based on distance, mode of transport, and shipping terms (Incoterms). Consider the total logistics costs, including customs duties and insurance, when evaluating supplier quotes.

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding the typical margins in the industry can help you gauge whether a quote is competitive.

Several factors can influence the pricing of white fused alumina, which international buyers should consider:

Volume/MOQ (Minimum Order Quantity): Larger orders often come with discounts. Establishing a long-term relationship with suppliers may also lead to better pricing terms.

Specifications and Customization: Customized products generally incur higher costs. Clearly define your specifications to avoid unexpected charges.

Materials and Quality Certifications: Higher quality materials or specific certifications (e.g., ISO) can lead to increased prices. Evaluate whether these certifications are necessary for your application.

Supplier Factors: Supplier reputation, reliability, and their geographic location can impact pricing. A supplier with a strong track record may charge a premium, but the assurance of quality and service can justify the cost.

Incoterms: The terms of shipment (e.g., FOB, CIF) can affect the total landed cost. Understanding these terms is vital for budgeting accurately.

To optimize costs when sourcing white fused alumina, international buyers should consider the following strategies:

Effective Negotiation: Always negotiate pricing and terms. Having multiple quotes can strengthen your bargaining position.

Focus on Cost-Efficiency: Evaluate suppliers based on total cost of ownership (TCO), not just the initial purchase price. This includes considering quality, delivery times, and service levels.

Understand Pricing Nuances: Pricing can vary significantly across regions. For example, buyers in Europe may face higher logistics costs compared to those in Africa. Be aware of these nuances when comparing quotes.

Establish Long-Term Relationships: Building long-term partnerships with suppliers can lead to better pricing and priority service, which is especially beneficial in times of supply chain disruptions.

Stay Informed: Keep abreast of market trends and economic conditions that may affect pricing. This knowledge can empower you during negotiations and help you make informed sourcing decisions.

The prices for white fused alumina can vary widely based on the factors mentioned above. Always request updated quotes and consider market conditions to ensure you are making the most informed purchasing decisions.

In the realm of industrial abrasives and refractories, white fused alumina (WFA) is a well-regarded material. However, it's essential for B2B buyers to consider alternative solutions that can meet similar performance standards while potentially offering distinct advantages. This section delves into a comparative analysis of white fused alumina MSDS against alternative materials and technologies, helping international buyers from Africa, South America, the Middle East, and Europe make informed decisions.

| Comparison Aspect | White Fused Alumina MSDS | Alternative 1: Brown Fused Alumina | Alternative 2: Silicon Carbide |

|---|---|---|---|

| Performance | High purity, excellent hardness, good thermal stability | Good hardness but lower purity; suitable for specific applications | Superior hardness and thermal conductivity; effective for high-performance applications |

| Cost | Moderate cost; premium pricing for high-quality grades | Generally lower cost, making it more accessible | Higher cost due to manufacturing complexity |

| Ease of Implementation | Widely available; easy to integrate into existing processes | Simple to use; compatible with various applications | Requires specialized handling and equipment for optimal use |

| Maintenance | Low maintenance; durable under typical conditions | Low maintenance; performs well in many environments | Moderate maintenance; can wear out faster in certain applications |

| Best Use Case | Ideal for precision grinding, polishing, and refractory applications | Suitable for blasting and grinding applications | Best for high-temperature applications and where extreme hardness is required |

Brown fused alumina (BFA) is derived from bauxite and is commonly used in abrasives, refractories, and sandblasting applications. While it offers good hardness and a lower cost compared to white fused alumina, it does not match the same level of purity. This makes BFA suitable for applications where extreme precision is not critical but still provides reliable performance. BFA can be a cost-effective option for businesses looking to balance performance with budget constraints.

Silicon carbide (SiC) is known for its exceptional hardness and thermal conductivity, making it an excellent choice for high-performance applications, including cutting tools and grinding wheels. Although SiC tends to have a higher initial cost, its durability and efficiency can lead to lower long-term costs in certain applications. However, it requires careful handling and specialized equipment for effective use, which may pose challenges for some companies. SiC is particularly favored in industries that demand high precision and thermal resistance.

When selecting between white fused alumina MSDS and its alternatives, B2B buyers should assess their specific operational requirements, budget constraints, and the intended application of the material. While white fused alumina offers high purity and performance, alternatives like brown fused alumina and silicon carbide present viable options that can optimize cost and meet varying performance standards. By carefully evaluating the characteristics and benefits of each material, international buyers can make strategic decisions that align with their business objectives and enhance their operational efficiency.

1. Material Grade

White fused alumina is categorized into various grades based on its purity and application. The most common grades include A, B, and C, with A being the highest purity level (99% Al2O3). Understanding material grades is crucial for B2B buyers as it directly impacts the performance and cost-effectiveness of the final product.

2. Particle Size Distribution

The particle size of white fused alumina is typically specified in mesh sizes (e.g., 80 mesh, 120 mesh). This specification affects the abrasive quality and how the material can be used in applications like sandblasting or grinding. Buyers need to match the particle size with their specific industrial applications to ensure optimal results.

3. Hardness

White fused alumina has a Mohs hardness of about 9, making it one of the hardest abrasive materials available. This property is vital for buyers in sectors such as metal fabrication and automotive manufacturing, where durability and performance are paramount. The hardness ensures that the material can withstand rigorous applications without significant wear.

4. Tolerance Levels

Tolerance refers to the acceptable variation in size and weight of the product. For white fused alumina, a typical tolerance might be ±5%. Understanding tolerance levels is critical for manufacturers who require precise specifications to maintain product quality and compatibility with their processes.

5. Bulk Density

The bulk density of white fused alumina typically ranges from 1.5 to 1.9 g/cm³. This property affects the material's flowability and packaging. B2B buyers should consider bulk density when determining shipping costs and storage requirements, as it influences how much product can be transported and stored.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of white fused alumina, an OEM might use the material in their abrasive products. Understanding OEM relationships can help buyers identify reliable suppliers who meet their specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For white fused alumina, MOQs can vary significantly between suppliers. Buyers should be aware of MOQs as they can affect initial purchasing decisions and inventory management strategies.

3. RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. When dealing with white fused alumina, submitting an RFQ allows buyers to compare prices and specifications from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) are crucial for B2B transactions involving white fused alumina. Familiarity with Incoterms helps buyers understand shipping responsibilities and costs, minimizing risks during transportation.

5. Certification Standards

Certification standards, such as ISO 9001, indicate that a supplier adheres to quality management principles. For international buyers of white fused alumina, certifications ensure that the products meet specific quality and safety requirements, which is essential for maintaining industry standards.

By understanding these technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing white fused alumina more effectively, ensuring they select the right products for their operational needs.

The white fused alumina market has witnessed significant transformations driven by global industrial demands and technological advancements. Key trends shaping the market include the increasing utilization of white fused alumina in various applications such as abrasives, ceramics, and refractories. As industries in Africa, South America, the Middle East, and Europe (notably Italy and Kenya) continue to expand, the demand for high-quality white fused alumina is expected to rise.

A stock image related to white fused alumina msds.

International B2B buyers should be aware of emerging technologies in sourcing, such as digital procurement platforms that enhance transparency and efficiency in the supply chain. These platforms allow buyers to access real-time data, enabling informed decision-making regarding supplier selection and material quality. Additionally, sustainability has become a crucial factor; buyers are increasingly seeking suppliers who prioritize environmentally friendly practices, which can influence sourcing decisions significantly.

Furthermore, market dynamics are also affected by geopolitical factors and trade regulations. Buyers should keep abreast of the evolving trade agreements and tariffs that could impact pricing and availability. Engaging local suppliers can mitigate risks associated with international shipping delays and ensure compliance with regional regulations.

Sustainability in the white fused alumina sector is not just a trend but a necessity for B2B buyers focused on long-term viability. The environmental impact of alumina production, including energy consumption and waste generation, necessitates a shift towards more sustainable practices. Buyers should look for suppliers who utilize renewable energy sources and implement waste reduction strategies in their production processes.

Ethical sourcing is equally important, as it encompasses fair labor practices and responsible mining operations. Buyers can enhance their corporate social responsibility (CSR) profiles by partnering with suppliers that adhere to ethical standards and possess certifications like ISO 14001 for environmental management. Additionally, obtaining 'green' certifications for materials used in production can provide a competitive edge in markets increasingly prioritizing eco-friendly products.

Engaging with suppliers who are committed to sustainability not only helps in reducing the overall carbon footprint but also aligns with the growing consumer demand for environmentally responsible products. This alignment can enhance brand reputation and customer loyalty, particularly in regions where sustainability is becoming a purchasing criterion.

The evolution of the white fused alumina sector can be traced back to its inception in the early 20th century when it was first produced as a synthetic abrasive material. Over the decades, advancements in production technologies and growing industrial applications have driven its development. Initially used primarily in abrasives, the versatility of white fused alumina has led to its adoption in various sectors, including ceramics, foundries, and even as a feedstock for aluminum production.

A stock image related to white fused alumina msds.

Today, the market is characterized by a shift towards higher purity grades and specialized applications, reflecting the increasing quality standards demanded by industries. This evolution has been accompanied by a greater emphasis on sustainable production practices, as suppliers and buyers alike recognize the importance of minimizing environmental impacts while meeting market needs.

International buyers must consider this historical context as they navigate the current market landscape, understanding how past trends influence present dynamics and future opportunities in the white fused alumina MSDS sector.

How do I ensure the quality of white fused alumina products?

To ensure the quality of white fused alumina, request a copy of the Material Safety Data Sheet (MSDS) from suppliers. The MSDS provides crucial information regarding the chemical properties, handling instructions, and safety measures. Additionally, consider conducting third-party testing for quality assurance. Look for suppliers who have certifications like ISO 9001, which indicates a commitment to quality management practices. Regular audits and inspections of the supplier's production process can also help maintain quality standards.

What is the significance of the Material Safety Data Sheet (MSDS) for white fused alumina?

The Material Safety Data Sheet (MSDS) is essential for understanding the hazards associated with white fused alumina. It provides detailed information on the product's properties, safe handling, storage guidelines, and emergency measures in case of accidents. For international buyers, the MSDS ensures compliance with local regulations regarding hazardous materials, thereby reducing liability and ensuring worker safety. Always verify that the MSDS is up-to-date and complies with regulations in your country.

What are the common applications of white fused alumina in various industries?

White fused alumina is widely used in industries such as abrasives, ceramics, and refractories. In the abrasive industry, it serves as a key component in grinding wheels, sandpaper, and blasting media. In ceramics, it is utilized for producing high-strength materials. Additionally, it is used in the manufacture of refractory products due to its high melting point and stability under heat. Understanding these applications can help buyers determine the right specifications for their needs.

How can I verify the reliability of a white fused alumina supplier?

To verify a supplier's reliability, conduct thorough due diligence. Check their business history, customer reviews, and industry reputation. Request references from previous clients and inquire about their experiences. Additionally, assess their certifications and compliance with international standards. Engaging in direct communication can also provide insights into their responsiveness and professionalism. Consider visiting their facilities if possible to observe their production processes firsthand.

What are the typical minimum order quantities (MOQs) for white fused alumina?

Minimum order quantities (MOQs) for white fused alumina can vary significantly depending on the supplier and the specific grade required. Generally, MOQs can range from a few hundred kilograms to several tons. It is essential to discuss your requirements with potential suppliers to determine their MOQs and whether they can accommodate smaller orders, especially for new buyers. This flexibility can be particularly advantageous for businesses just starting or testing new products.

What payment terms should I expect when purchasing white fused alumina internationally?

Payment terms for international purchases of white fused alumina typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers prefer a partial upfront payment followed by the balance upon delivery or after inspection. Ensure that you clarify the payment terms before finalizing the order. It’s advisable to use secure payment methods to protect your transaction, and consider negotiating terms that align with your cash flow capabilities.

How can I customize white fused alumina products to meet specific requirements?

Customization of white fused alumina products often involves specifying the desired grain size, purity level, and packaging options. Discuss your specific application needs with the supplier to determine available customization options. Many suppliers have the capability to produce tailored products that meet particular industry standards. Be sure to establish clear communication regarding your requirements and any potential impacts on pricing and lead times.

What logistics considerations should I be aware of when importing white fused alumina?

When importing white fused alumina, consider factors such as shipping methods, customs regulations, and delivery timelines. Work with suppliers who have experience in international shipping to navigate customs documentation and duties effectively. Evaluate shipping options like air freight for speed or sea freight for cost savings based on your needs. Additionally, ensure that you have a reliable logistics partner to handle transportation and storage upon arrival to minimize disruptions in your supply chain.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, strategic sourcing of white fused alumina is essential for international B2B buyers seeking to optimize their supply chains and enhance product quality. By understanding the material's properties, compliance requirements, and sourcing best practices, buyers can make informed decisions that lead to cost savings and improved operational efficiency.

The value of strategic sourcing extends beyond mere procurement; it fosters long-term partnerships with suppliers who can provide consistent quality and innovation. For buyers in Africa, South America, the Middle East, and Europe, particularly in regions like Italy and Kenya, aligning sourcing strategies with local market conditions and regulations is crucial. This localized approach not only mitigates risks but also enhances responsiveness to market demands.

As you move forward, consider implementing a rigorous supplier evaluation process and staying updated on the latest industry trends to ensure your sourcing strategies remain competitive. Engage with suppliers that offer transparency regarding their Material Safety Data Sheets (MSDS) and sustainability practices. By prioritizing these aspects, you can secure a reliable supply of white fused alumina that meets both your operational needs and corporate social responsibility goals.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina